Landfill leachate graphene integrated purification system and process

A landfill leachate and purification system technology, applied in the field of landfill leachate graphene integrated purification system, can solve the problems of long time consumption, low efficiency, and difficulty in popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

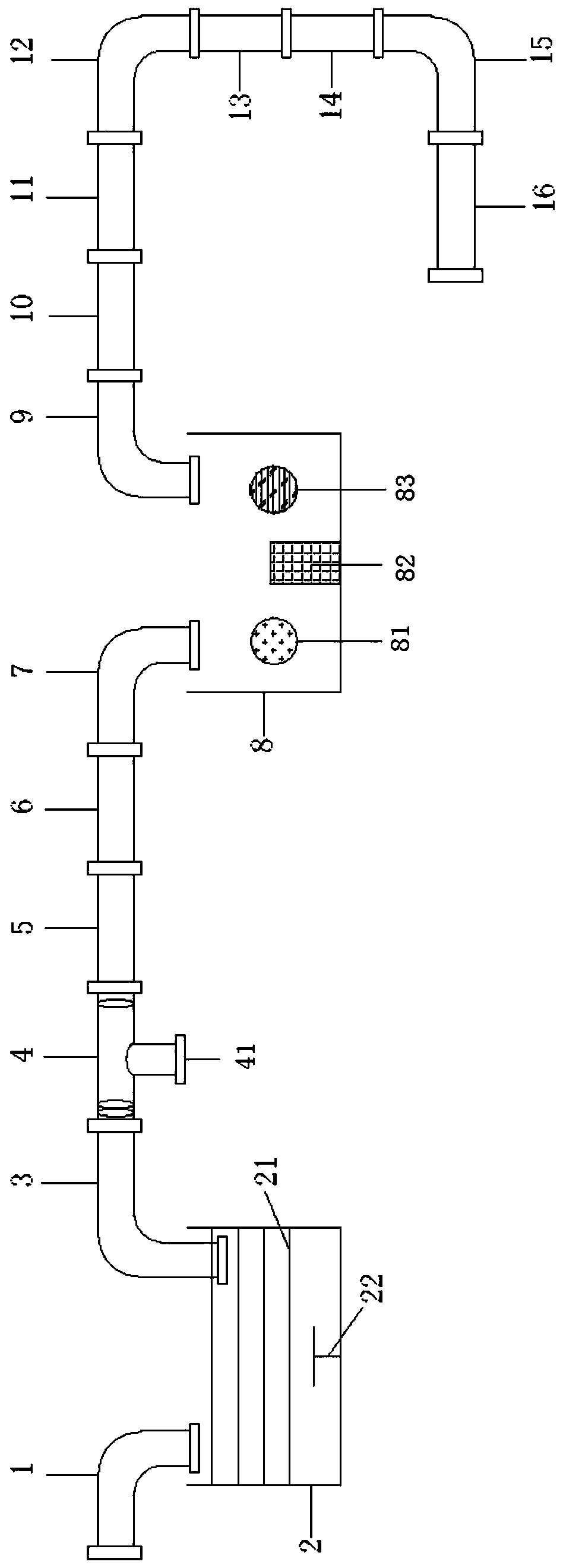

[0051] Such as figure 1 As shown, the leachate from domestic waste landfills, domestic waste dumps and other places is collected by the leachate collection valve and then transported into the anaerobic tank 2 (including the aeration port) by the permeate delivery pipe 1. The anaerobic tank 2 A multi-layer porous support 21 is built in, with a diameter of 2 mm, and is located above the stirring device 22. A pre-cultured autotrophic ammonia oxidation biofilm is placed on the support 21 in advance. The pH in the anaerobic tank 2 is controlled at 7.5, the temperature is 30℃, and the anaerobic environment is adjusted in time ( 2 And other harmless gases.

[0052] The leachate, which has been pre-removed of ammonia nitrogen and other pollutants through the anaerobic tank 2, is transported to the multi-stage filter device 4 by the delivery pipe 3 (pre-filtering screen is set at the bottom, and the screen has 16 meshes to remove most of the suspended solids). It is further filtered to r...

Embodiment 2

[0072] The difference between this embodiment and embodiment 1 is:

[0073] 1. The pore size of the multilayer porous support 21 built into the anaerobic tank 2 is 3 mm, the pH in the anaerobic tank 2 is controlled at 7.6, and the temperature is 28°C.

[0074] 2. The mesh number of the pre-filter screen located between the anaerobic tank 2 and the multi-stage filter device 4 is 12, the mesh number of the first-stage graphene enhanced filter is 12, and the mesh of the second-stage graphene enhanced filter is The number is 20, the mesh of the third-level graphene-enhanced filter is 40, the material of the first, second, and third-level graphene-enhanced filters is polypropylene, and the amount of graphene added is 2.0%.

[0075] 3. The graphene reinforced diatom ceramic material is wrapped with 20 mesh glass fiber cloth.

[0076] 4. The material of the graphene photocatalytic degradation device 6 is transparent ceramic.

[0077] 5. The size of the multiple purification tank 8 is length, ...

Embodiment 3

[0087] The difference between this embodiment and embodiment 1 is:

[0088] 1.The pore size of the multi-layer porous scaffold built into the anaerobic tank 2 is 5mm.

[0089] 2. The mesh number of the pre-filter screen located between the anaerobic tank 2 and the multi-stage filter device 4 is 8, the mesh number of the first-stage graphene enhanced filter is 14, and the mesh of the second-stage graphene enhanced filter The number is 18, the mesh of the third-level graphene-enhanced filter is 40, the material of the first, second, and third-level graphene-enhanced filters are all polyether ether ketone, and the amount of graphene added is 1.5%.

[0090] 3. The graphene reinforced diatom ceramic material is wrapped with 30 mesh glass fiber cloth.

[0091] 4. The material of the graphene photocatalytic degradation device 6 is transparent ceramics, and the graphene photocatalytic degradation agent is phosphotungstic acid / graphene oxide.

[0092] 5. The size of multiple purification tank 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com