Flare gas safe recovery and discharge system

A discharge system and flare gas technology, applied in combustion methods, lighting and heating equipment, combustion types, etc., can solve problems such as poor stability, achieve stable gas supply, system safety, and environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

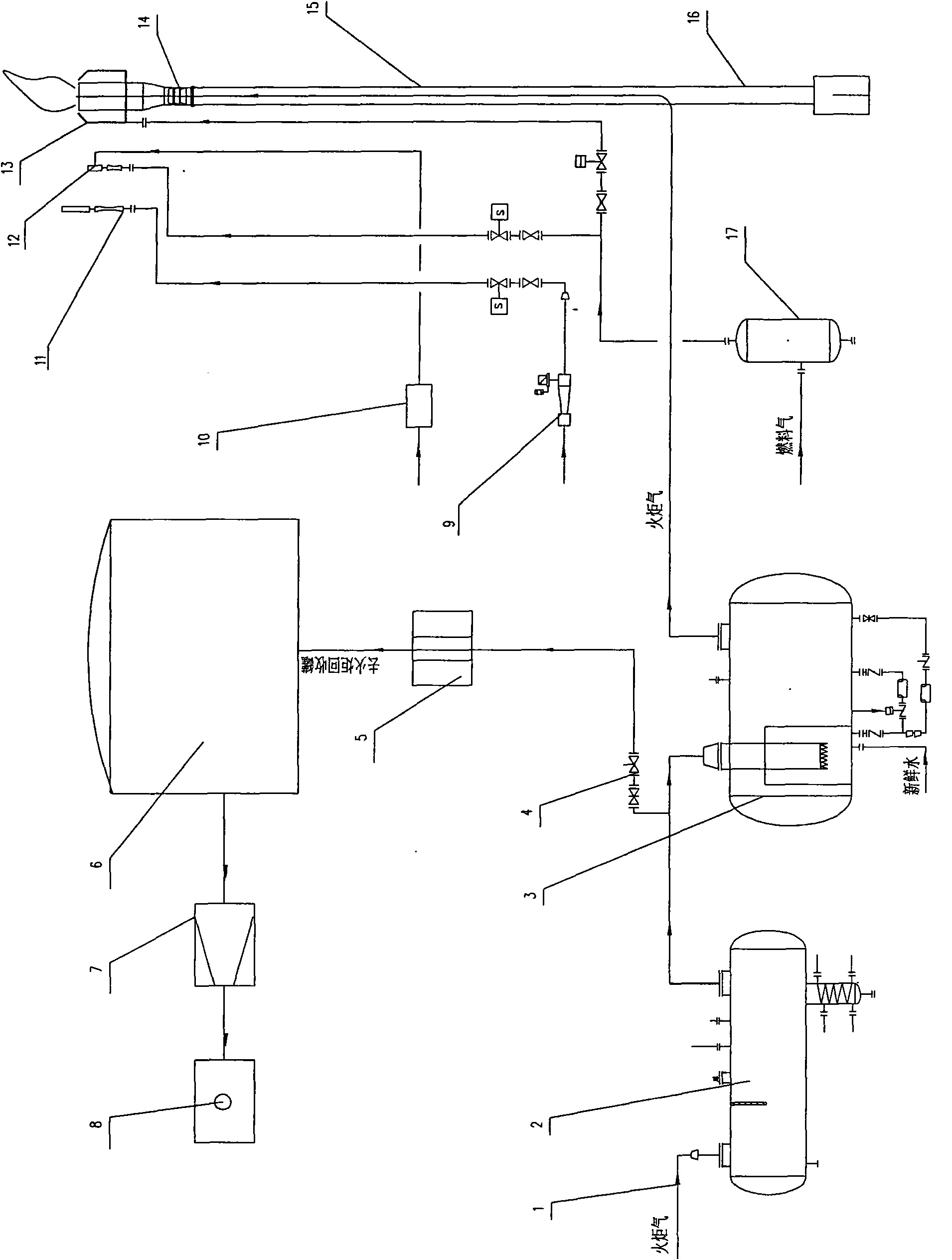

[0020] The present invention will be further described below with reference to the accompanying drawings and embodiments.

[0021] like figure 1 shown.

[0022] A flare gas safe recovery and discharge system, including flare gas liquid separation tank 2, automatic control water seal valve 3 (which can be realized by the applicant's authorized Chinese patent ZL200420079150.8, detailed as follows), gas cabinet 6 and a flare Head 13 (low calorific value acid gas torch head can be used), the inlet end of the torch gas liquid separation tank 2 is connected with the gas source through the torch gas main pipe 1, and the output end of the torch gas liquid separation tank 2 is connected to the gas torch 6 all the way. Connected to each other, the other way is connected to the torch head 13 through the automatic control water seal valve 3, and an automatic control valve 4 is also installed on the pipeline connecting the torch gas liquid separation tank 2 and the gas cabinet 6 (which ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com