Construction method for carrying out high dehydration on dredging slurry by using swirling flow, condensation, and plate-and-frame

A construction method and mud technology, applied in the field of resources and environment, can solve the problems of storage yard and storage yard tail water pollution environment, low-concentration dredging mud occupation, etc., and achieve the effect of reducing dehydration time, less pollution and improving dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] The present invention will be further described below in conjunction with specific embodiment according to above-mentioned accompanying drawing again:

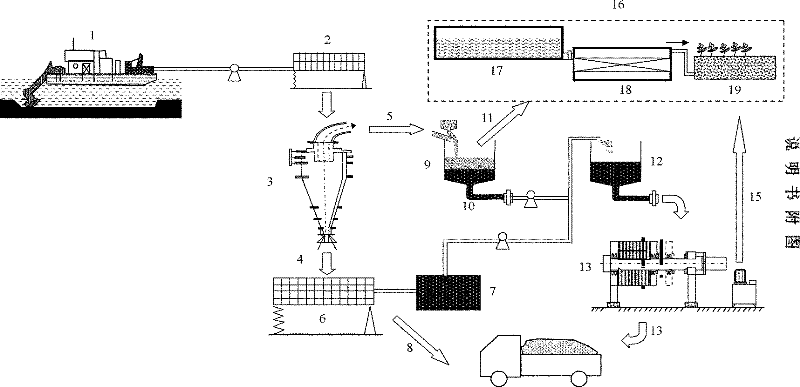

[0026] figure 1 For process flow diagram of the present invention, refer to figure 1 As shown, a construction method utilizing cyclone-concentration-plate frame to carry out highly dewatered dredging mud comprises the following steps:

[0027] (1) Use the dredging equipment on the dredging vessel 1 to dredge the sediment of a lake in Jiangsu. The concentration of the dredging slurry is between 15-20%.

[0028] (2) On the dredging ship, the dredging mud is sent to the coarse vibrating screen 2 of 5-20 mm through the conveying device, and the coarse vibrating screen 2 removes large particles and impurities in the mud;

[0029] (3) Pump the coarsely screened mud into the large-scale cyclone separator 3 with a pressure pump, and separate the downward mud with a particle size greater than 30 μm from the cyclone separator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com