Swirling inlet type electrostatic spraying wet flue gas desulphurization dedusting apparatus

A technology of wet flue gas desulfurization and electrostatic spraying, applied in the direction of electrostatic effect separation, separation methods, chemical instruments and methods, etc., can solve the problems of uneven water consumption concentration, enhance droplet absorption, etc., to increase the effective time of action, The effect of saving water resources and protecting the natural environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

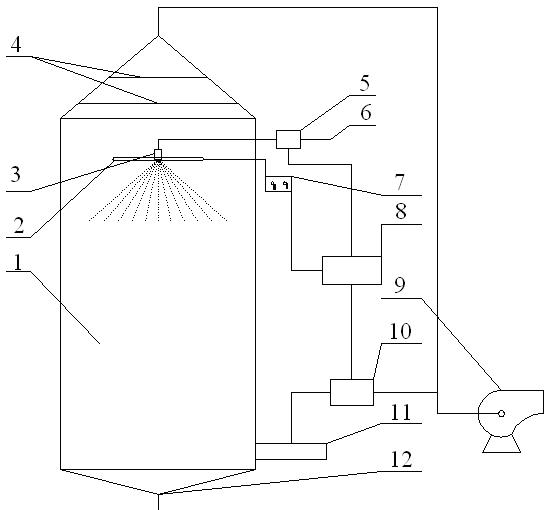

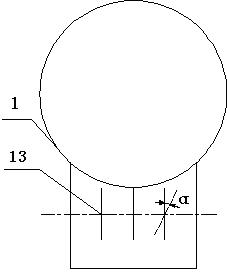

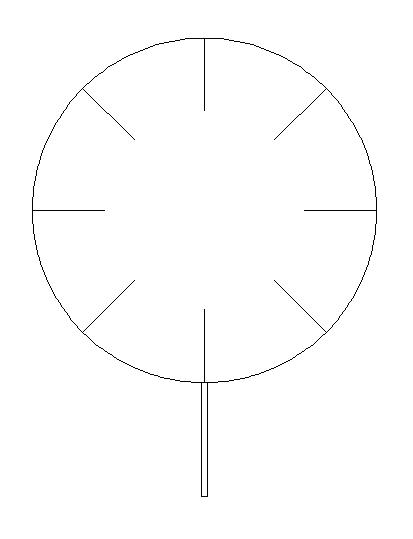

[0014] When the patent of the present invention is in use, the exhaust gas (flue gas and dust) produced by coal combustion passes through the exhaust gas inlet 11, passes through the swirl baffle 13, and the swirl baffle can be adjusted according to the angle, rotates and flows into the spray reaction tower 1, and passes through the swirl baffle 13. The slurry inlet 6 flows through the flow control valve 5, and is sprayed out from the nozzle 3, and the mist droplets charged by the ring-shaped and needle-shaped charging electrode 2 are used to remove SO 2 Effect with dust. After the droplets are sprayed through the pressure nozzle, they will generate secondary atomization under the action of the charged electrode to form finer droplets, which will chemically react with the droplets under the action of a high-voltage electrostatic field to remove SO 2 , and remove the dust in the exhaust gas. When the ring and needle electrodes are used for charging, the charging effect of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com