Polishing method for extreme ultraviolet optical elements and elements produced using the method

a technology of ultraviolet light and ultraviolet light, applied in the field of polishing silicatitania glass elements, can solve the problems of high surface roughness, material with differential stress, and material uniformity affecting the effect of material removal during polishing, and achieve the effect of high flow ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

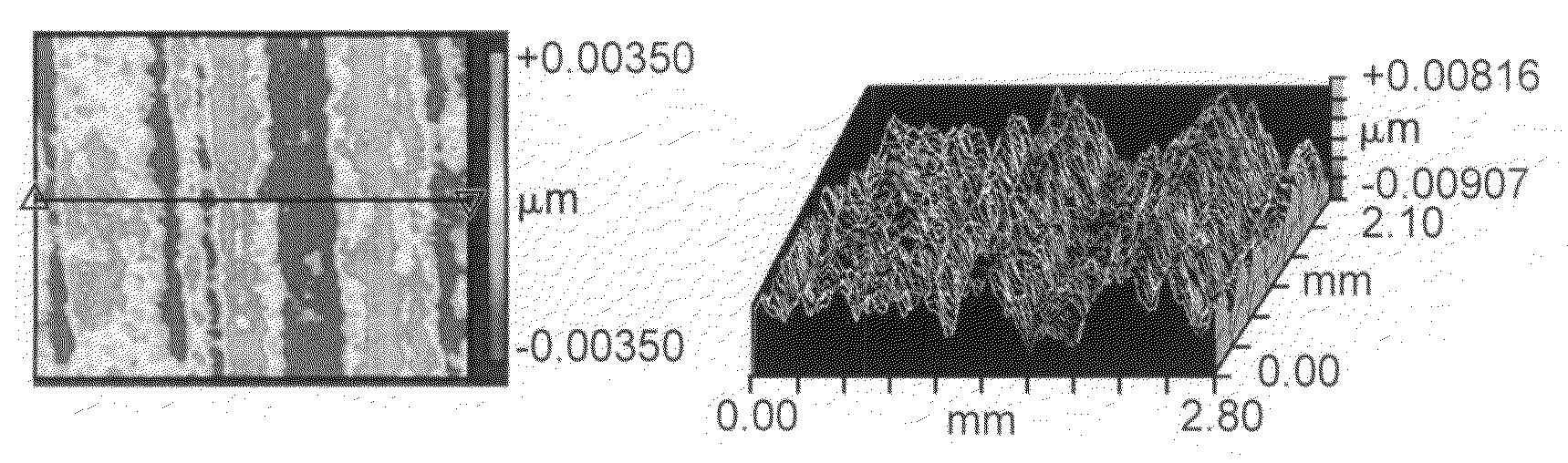

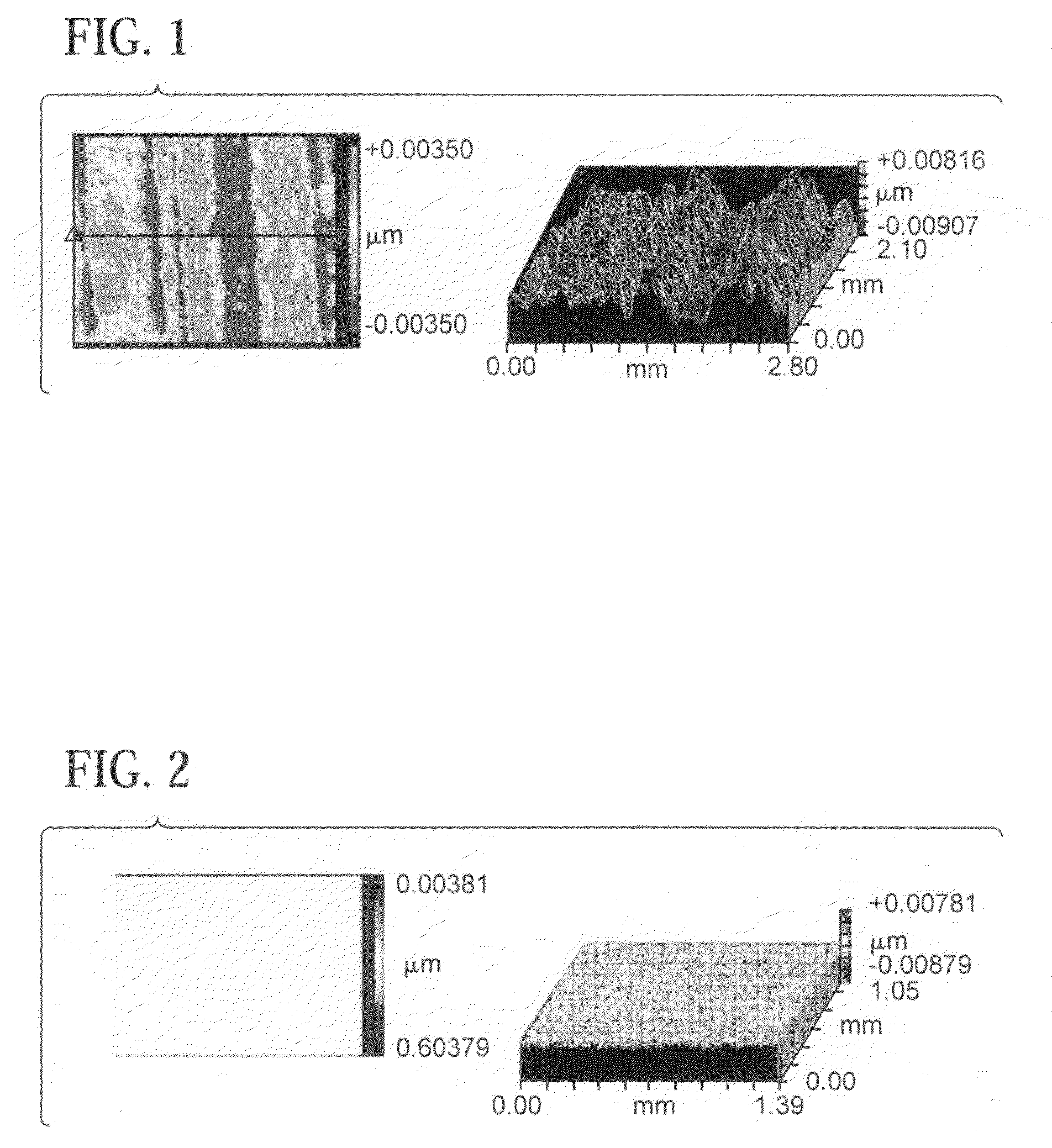

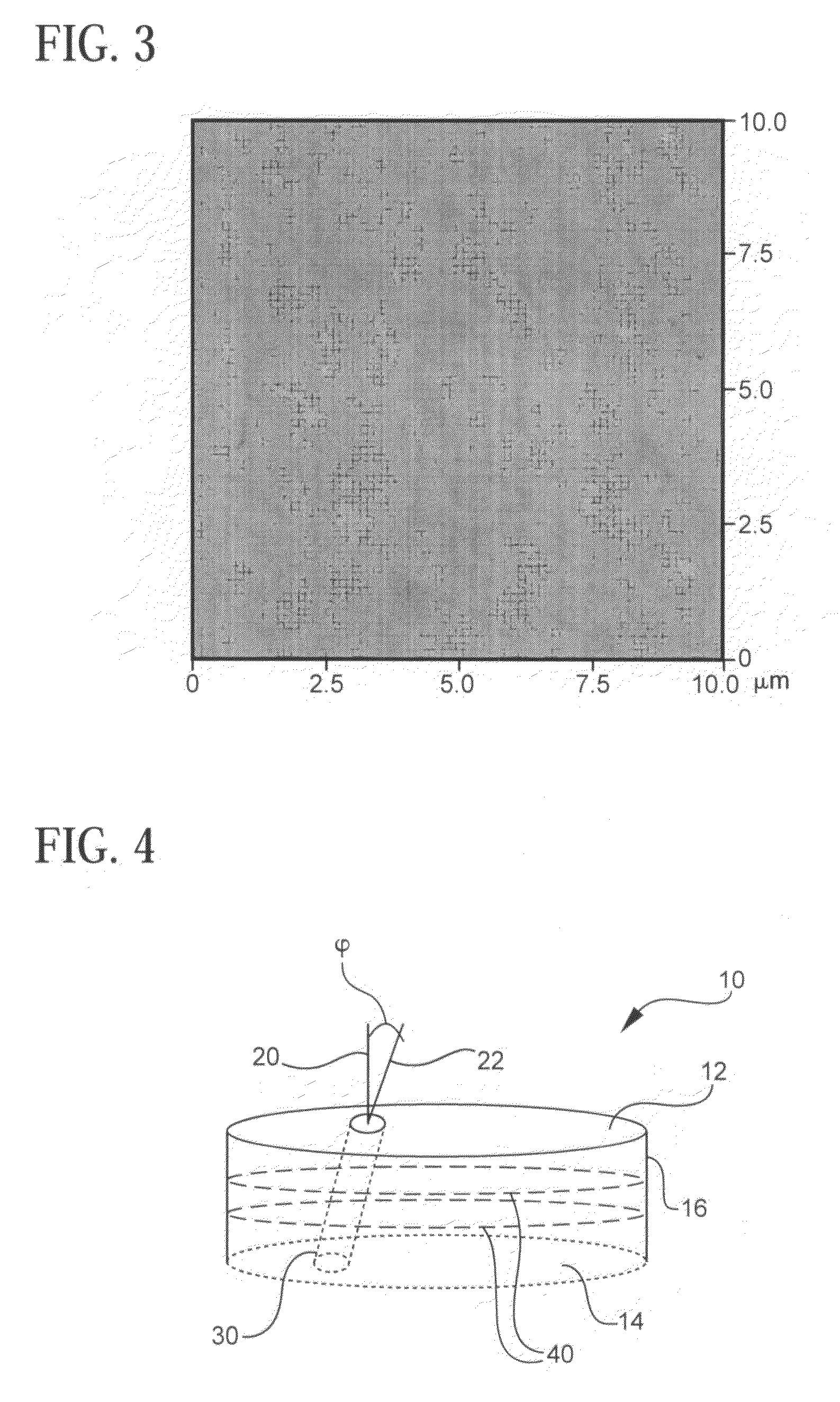

[0020]As has been mentioned above, the standard methods of polishing ultra-low expansion glass surfaces, and in particular silica-titania glass surfaces, using “low” slurry flow rates can produce surfaces that have sufficient roughness such that they are unsuitable for EUVL applications. Ultra-low expansion glasses are those having a CTE of less than 0±30×10−9 / ° C. (0±30 ppb / ° C.) as exemplified by ULE® glass from Corning Incorporated. As used herein the term “ULE” without the trademark symbol is used to signify “ultra-low expansion glass” generally, and in particular silica-titania glass and glass surfaces, that can be polished using the invention to produce optical elements with finished surfaces having extremely low mid-spatial frequency (“MSF”) and extremely low high-spatial frequency (“HSF”) roughness values. Striae in ULE is well recognized as a limiting factor in attainment of surfaces planar in the MSF range due to preferential material removal at locations of high stress be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com