Preparation method of refractory high-entropy alloy skeleton-copper spontaneous perspiration composite structure

A high-entropy alloy and composite structure technology, applied in the direction of additive processing, can solve the problems of reducing the cooling effect of spontaneous sweating, the mechanical properties of elemental tungsten are not high, and it is difficult to meet the load-bearing requirements, and achieve high practical value, improvement effect, resistance Good thermal shock performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

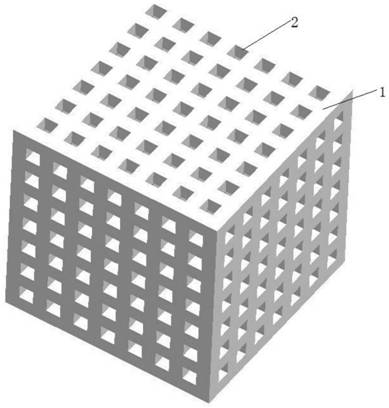

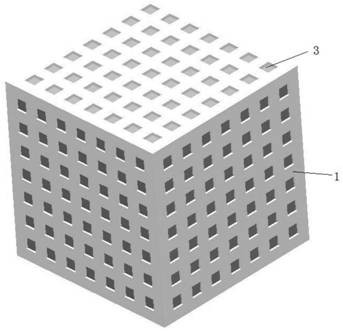

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

[0022] A method for preparing a refractory high-entropy alloy skeleton-copper spontaneous sweating composite structure of the present invention comprises the following steps:

[0023] (1) Put the refractory high-entropy alloy raw materials Ti, V, Nb, Mo, Ta and W into the melting furnace. The melting process is carried out under the protection of high-purity argon. Uniform, finally smelted to obtain a cylindrical alloy ingot, the alloy ingot is prepared by plasma rotating electrode atomization method to prepare refractory high-entropy alloy powder;

[0024] The atomization parameters of the plasma rotating electrode are: under the protection of inert gas, the current is 1500A, the electrode speed is 20000r / min, and the finally obtained refractory high-entropy alloy powder is TiVNbMoTaW refractory high-entropy alloy powder. The content is: Ti 7.34%, V 7.8%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com