Plasma rotary kiln gasification system and pyrolysis gasification method thereof

The technology of plasma and gasification system is applied in the field of gasification of carbon-containing solid raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

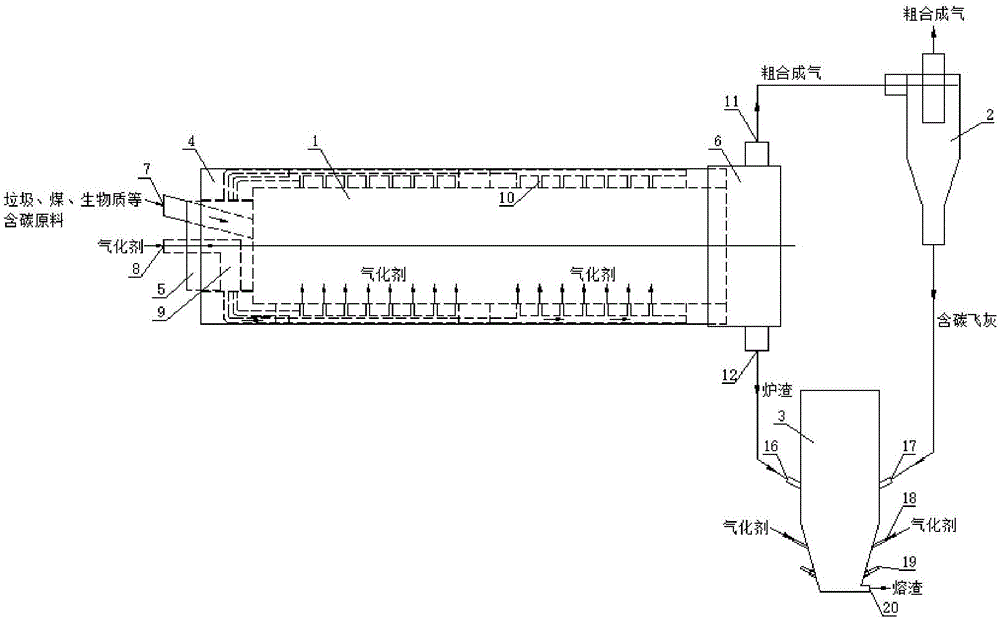

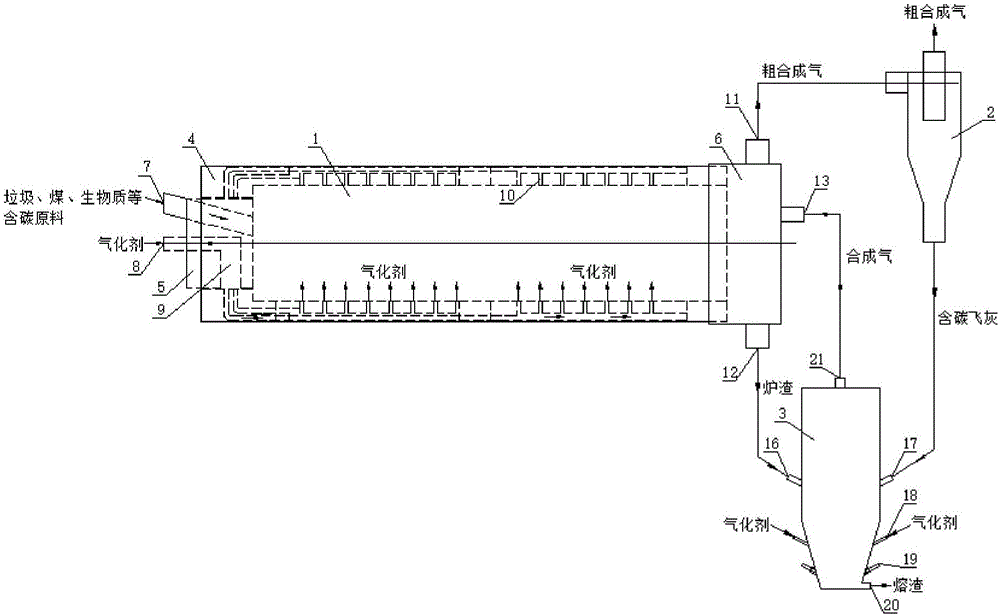

[0037] like figure 1 As shown, the plasma rotary kiln gasification system according to an embodiment of the present invention includes a rotary kiln gasifier 1, a cyclone separator 2 and a plasma-assisted gasification slag furnace 3, which are connected through several pipelines.

[0038] Plasma-assisted gasification slag furnace 3 is used for slag gasification of carbon-containing slag discharged from rotary kiln gasifier 1 and carbon-containing fly ash captured by cyclone separator 2, using plasma-assisted gasification technology , undergo combustion gasification treatment, and melt into a harmless glass body, thereby reducing the emission of pollutants such as dioxins.

[0039] The rotary kiln gasifier 1 includes a rotating cylinder 4, a kiln head 5, and a kiln tail 6. The cylinder 4 can rotate to push the carbon-containing solid raw material to move from the kiln head 5 to the kiln tail 6 of the rotary kiln gasifier 1 .

[0040] The cylinder body 4 is lined with refracto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com