A high density plasma reactor

A plasma, plasma source technology, applied in the direction of plasma, semiconductor/solid-state device manufacturing, discharge tube, etc., can solve problems such as the reduction of electron energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

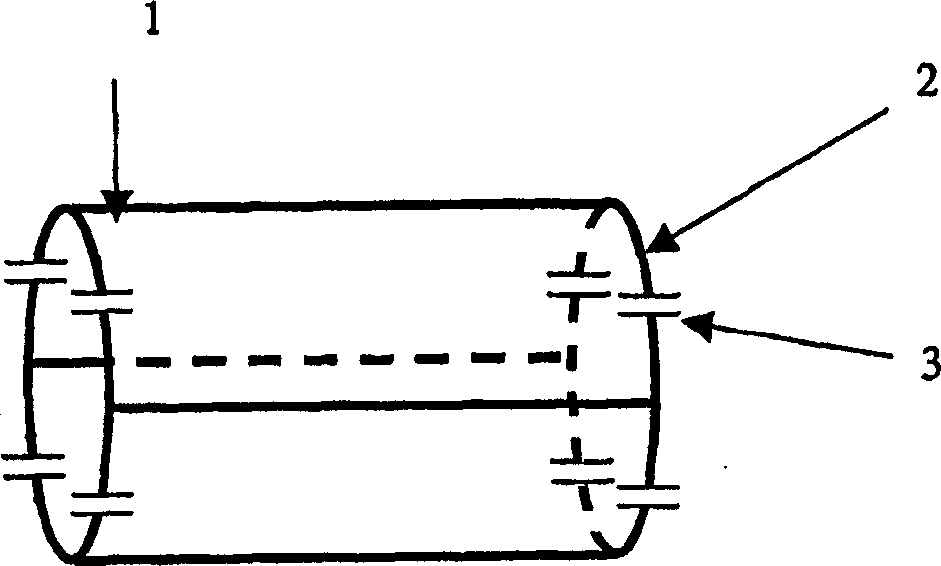

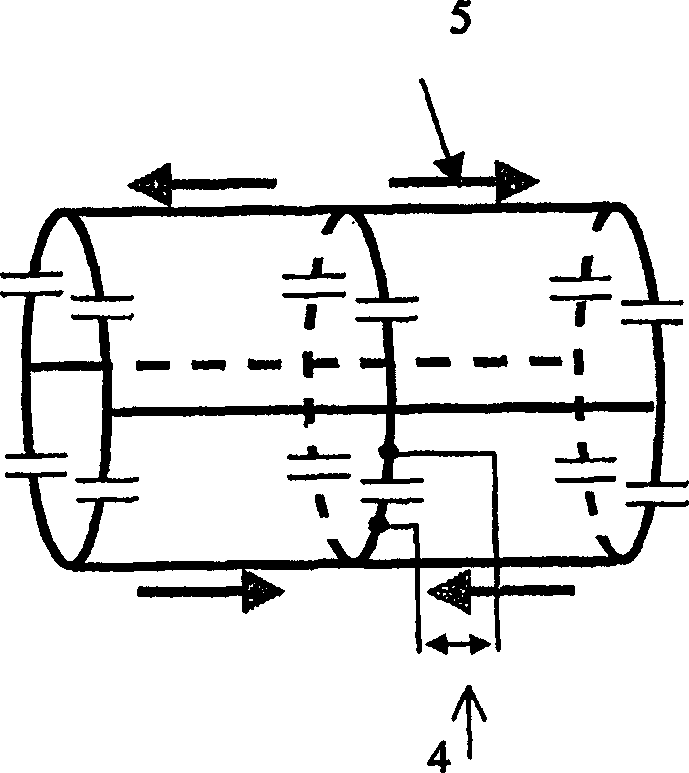

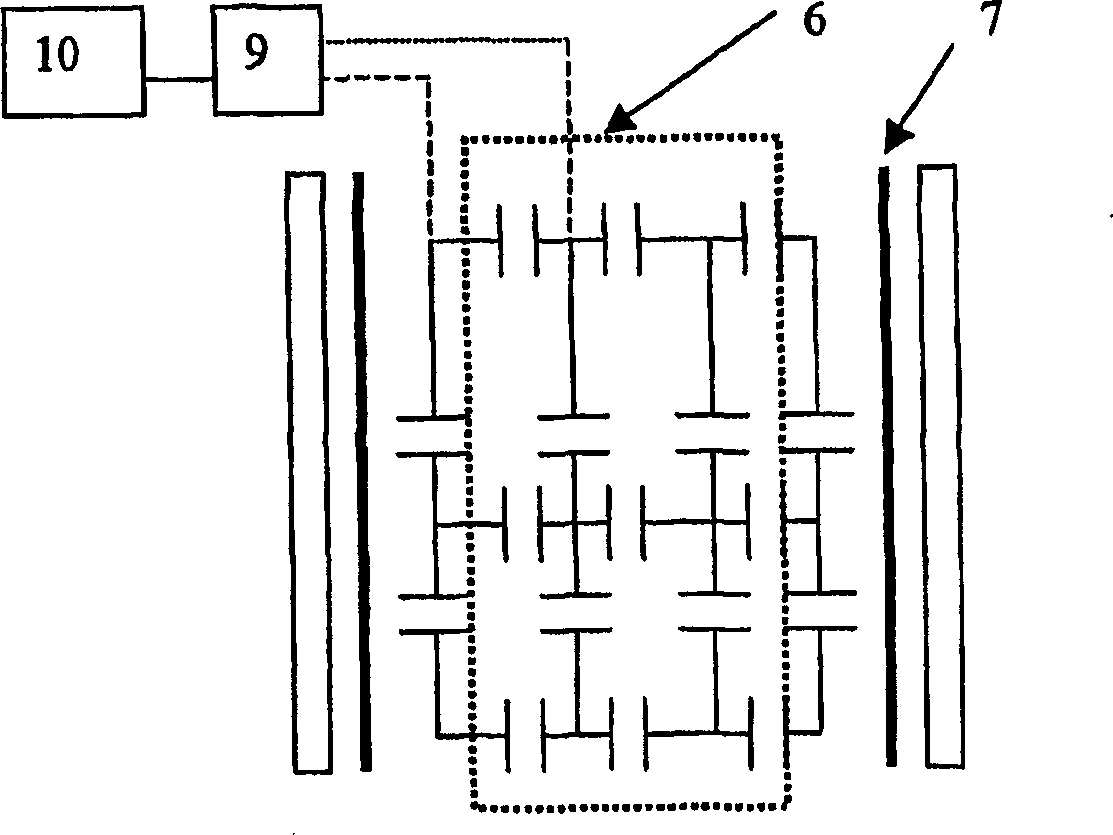

[0029] from figure 1 , 2, 4, 6 and 7, it can be seen that the first main structure of the present invention is the antenna setting:

[0030] The radio frequency current flows through at least one pair of conductive rings (of any layout) 2 and the axial conductive element 1 . In this way the current flows according to the 5 figure 2 setting. An RF voltage is supplied from an RF power supply 4 .

[0031] One characteristic of coils is related to excitation. Single excitation point excitation of the RF coil results in a linearly polarized magnetic field B. Using one of the possible settings (see figure 1) achieves 90-degree phase-shifted excitation in a direct manner. 90 degree phase shift excitation can be accomplished by exciting the coils at two input capacitors 3 placed at right angles to each other along the circumference of a conductive ring element 2 . In addition, to achieve the desired circular polarization, the radio frequency sources used to excite the coil at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com