Volute device of variable geometry pulse gas inlet turbine

A turbine and volute technology, applied in the field of internal combustion engines, can solve the problems of unrealizable fixed-section turbochargers, poor reliability, and good matching, and achieve the effects of easy control, good inheritance, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

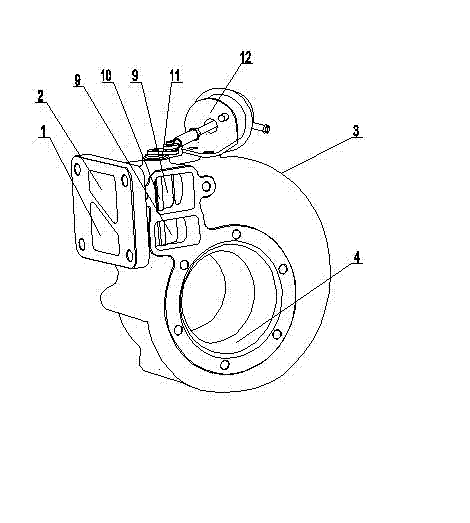

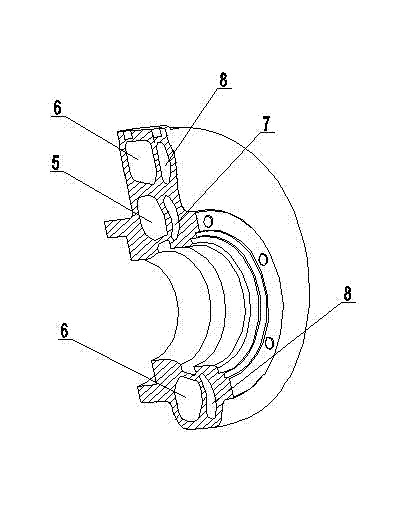

[0046] Example 1, such as figure 1 , figure 2 As shown, a volute device of a variable geometry pulse intake turbine includes a volute 3, the volute 3 is provided with an air intake channel, one end of the air intake channel is provided with an air inlet, and the other end is provided with an air inlet. A volute air outlet 4 is arranged.

[0047] The inlet runner includes two groups of working runners, one of which is an inner runner, and the other is an outer runner, and the outer runner is located on one side of the inner runner.

[0048] The inner flow channel includes a first inner flow channel 5 and a second inner flow channel 6 , and the outer flow channel includes a first outer flow channel 7 and a second outer flow channel 8 .

[0049] The air inlet includes a first volute inlet 1 and a second volute inlet 2;

[0050] The first inner flow channel 5 and the first outer flow channel 7 communicate with the first volute inlet 1 and realize half-circle air intake of 0-18...

Embodiment 2

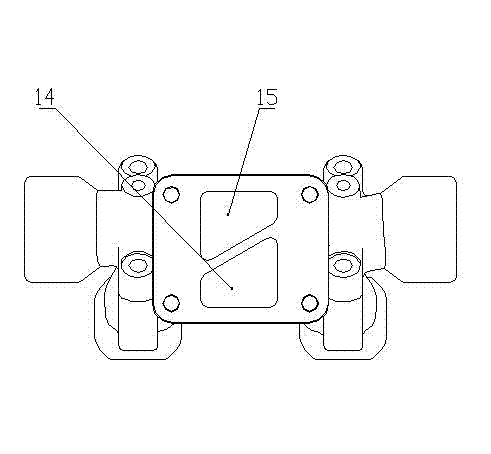

[0063] Example 2, such as Figure 6 , Figure 7 As shown, in Embodiment 1, the first volute inlet 1 and the second volute inlet 2 can also be a rectangular structure arranged side by side and communicate with the exhaust manifold respectively.

[0064] The first outer flow channel 7 , the first inner flow channel 5 , the second inner flow channel 6 and the second outer flow channel 8 are arranged side by side in the volute.

[0065] Such as Figure 8 As shown, the exhaust manifold includes a first exhaust pipe outlet 14 and a second exhaust pipe outlet 15 with a rectangular section, and the first inner runner 5 and the first outer runner 7 correspond to each other through the first volute inlet 1 It communicates with the first exhaust pipe outlet 14 , and the second inner flow channel 6 and the second outer flow channel 8 correspond to the second exhaust pipe outlet 15 through the second volute inlet 2 .

Embodiment 3

[0066] Example 3, such as Figure 9 As shown, in the above-mentioned embodiment 2, the air intake regulating devices of the two outer runners can also be located on both sides of the volute 3 respectively, and the air intake regulating devices realize the distribution of the intake air flow according to the actual working conditions of the engine.

[0067] The present invention aims at the demand of the engine for the variable section turbocharger, and completes the development of the variable flow partial intake turbine device, which effectively utilizes the energy of the exhaust gas and takes into account the supercharging requirements of the engine under low-speed and medium-high-speed working conditions . This type of variable flow partial intake turbine device can be completed by using the existing common supercharger casting and processing technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com