Rotor clutch type motor-driven power generation turbocharger and auxiliary control circuit and control method thereof

An auxiliary control circuit and turbocharger technology, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of high fuel consumption of engines, high consumption of exhaust gas energy, and low overall efficiency of turbochargers, etc., to improve Exhaust gas energy utilization rate, efficient distribution and utilization, and the effect of improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

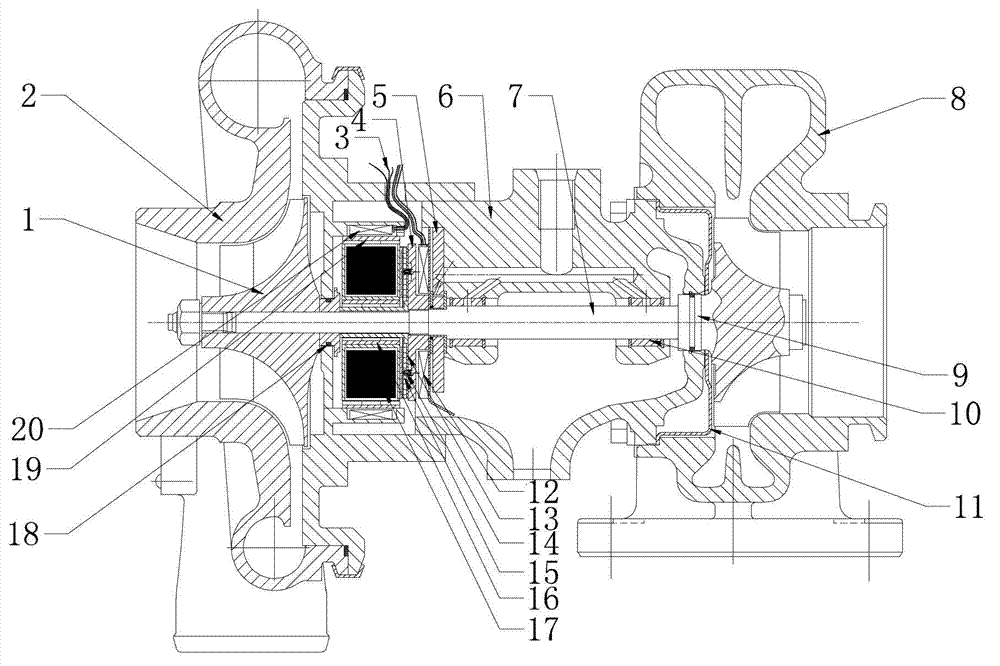

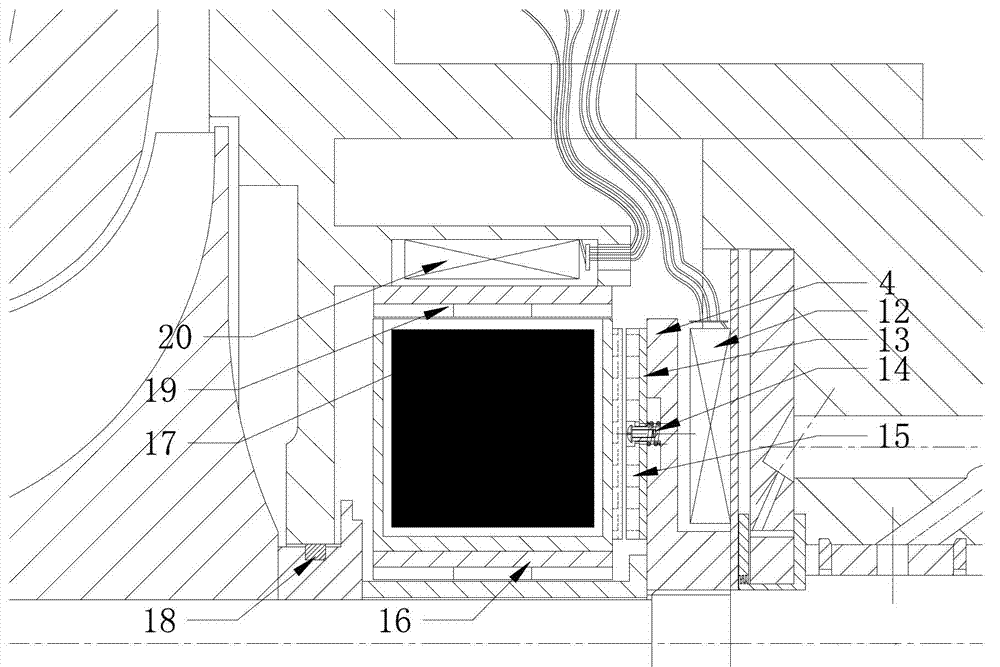

[0032] Such as figure 1 , figure 2 As shown, the electric generator turbocharger with the rotor clutch device of the present invention includes a compressor impeller 1, a compressor casing 2, an intermediate body 6, a turbine rotor 7, a turbine casing 8, a compressor back plate, a sealing sleeve, heat insulation sleeve 11, bearing, sealing ring, motor generator, electromagnetic clutch device and auxiliary control circuit, the rotor shaft and the turbine impeller fixed at one end of the rotor shaft constitute the turbine rotor 7, and the turbine impeller is located in the turbine shell 8, the compressor impeller 1 is assembled on the other end of the turbine rotor 7 and is located in the space formed by the compressor casing 2 and the compressor back plate, the compressor back plate cooperates with the turbine rotor 7 through a sealing sleeve, and the compressor A second sealing ring 18 is provided between the back plate and the sealing sleeve. The two ends of the intermediat...

Embodiment 2

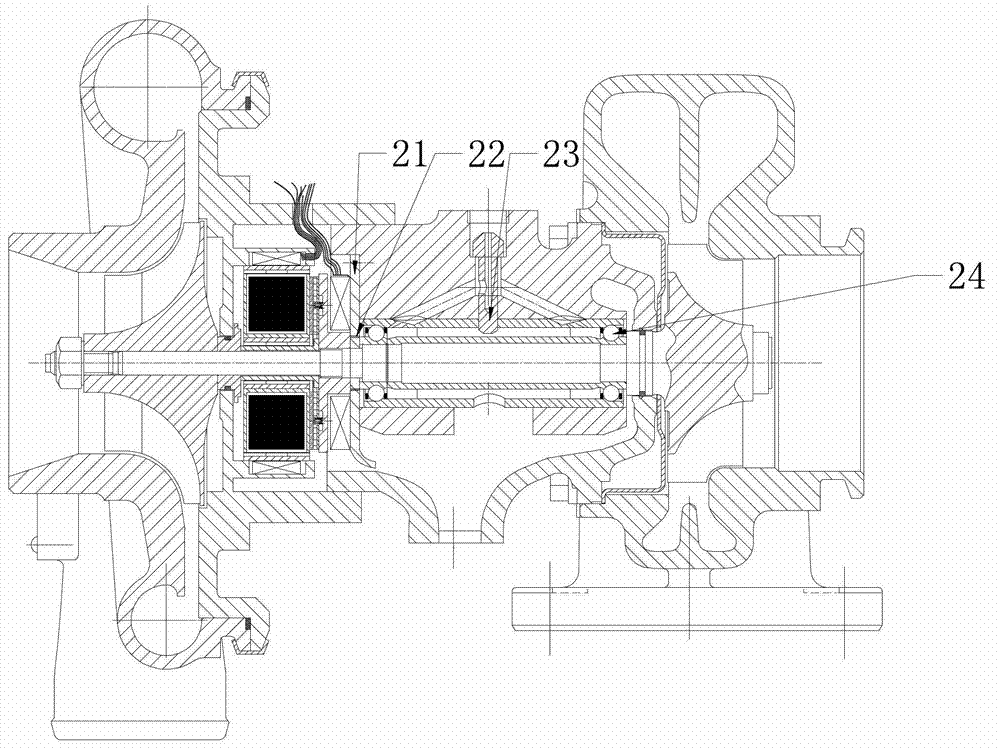

[0043] Such as image 3 , Figure 4 As shown, the main difference between this embodiment and Embodiment 1 is that the supporting bearing of the turbine rotor 7 is changed to an angular contact ball bearing 24, that is, the intermediate body 6 cooperates with the turbine rotor 7 through the angular contact ball bearing 24, and the outer angular contact ball bearing 24 The positioning mode of circle adopts positioning pin 23 to fix. Since the angular contact ball bearing 24 can withstand a certain radial load, the thrust bearing 5 on the side of the intermediate body 6 is omitted. One side of the motor generator is provided with an oil baffle 21, and a sealing device, such as a labyrinth oil seal, is installed at the junction of the oil baffle 21 and the shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com