High-pressure tumble air intake testing device for engine

A high-pressure air intake and test device technology, applied in the direction of internal combustion engine testing, etc., can solve problems such as the difficulty of measuring the intake tumble flow of gasoline engines, and achieve the effects of simple structure, increased intake pressure, and convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

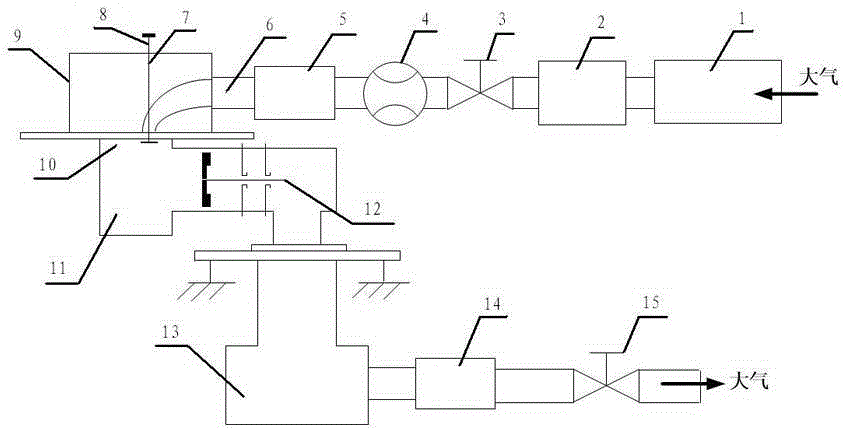

[0015] combined with figure 1 The specific embodiment of the present invention is described in detail:

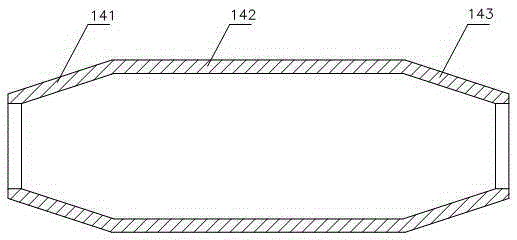

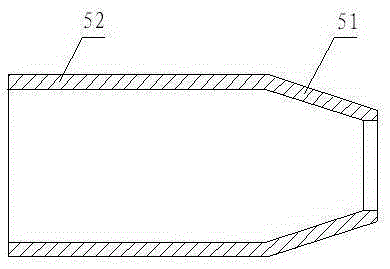

[0016] A high-pressure intake tumble test device for an engine, including a compressor 1, a first surge tank 2, an inlet pressure regulating valve 3, a flow meter 4, a second surge tank 5, an airway pressure sensor 6, and a lift sensor 7 , valve lift adjustment mechanism 8, cylinder head to be tested 9, cylinder pressure sensor 10, simulated cylinder 11, vane anemometer 12, the third voltage stabilizing box 13, the fourth stabilizing box 14, outlet pressure regulating valve 15, its It is characterized in that: the cylinder head 9 to be tested is installed on the simulated cylinder 11, the valve lift adjustment mechanism 8 is installed on the cylinder head 9 to be tested, and there is a pipeline connecting the second surge tank 5 before the intake direction of the cylinder head 9 to be tested , an airway pressure sensor 6 is installed on the pipeline between the cylinder he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com