Energy-saving supercharging device of automobile air compressor

A pressurization device and air compressor technology, applied in mechanical equipment, vehicle parts, transportation and packaging, etc., can solve the problems of fuel consumption, low efficiency of cylinder and piston pressurization, complex device structure and other problems of operating costs, and achieve shortening The effect of load operation time, reduction of fuel consumption, and improvement of air intake efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

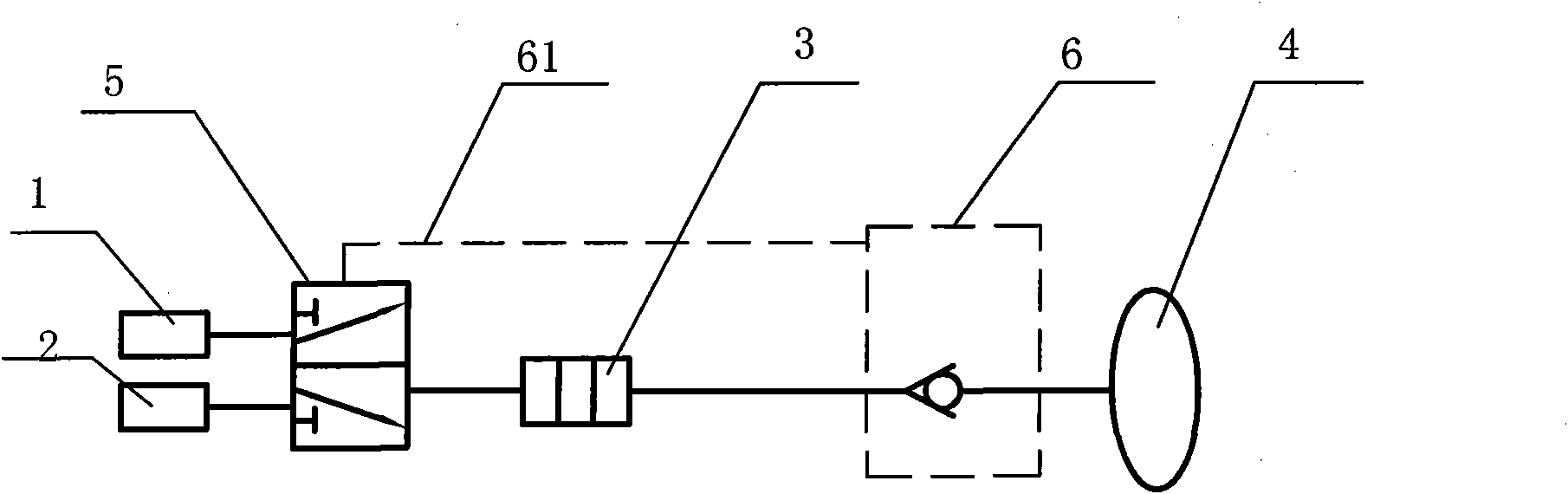

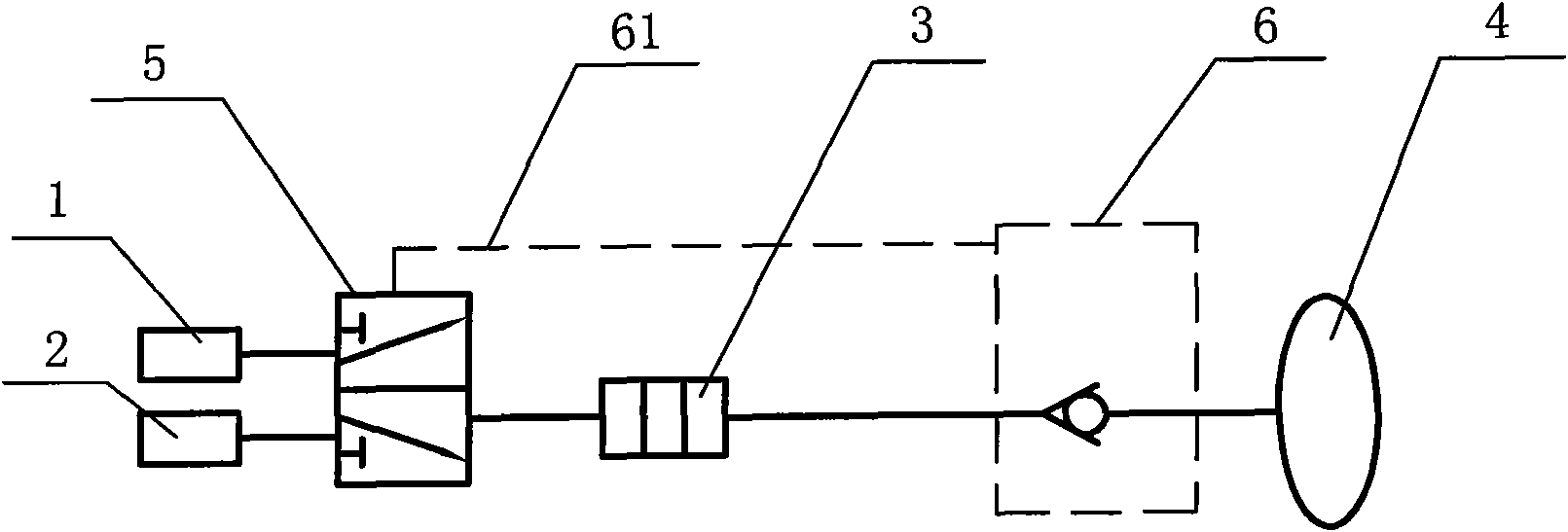

[0016] Such as figure 1 As shown, it is a structural schematic diagram of an energy-saving supercharging device for an automobile air compressor of the present invention, including an air filter 1, a turbocharger 2, an air compressor 3, and an air storage tank 4, and the air compressor 3 passes through the air inlet It communicates with the engine intake cavity, and communicates with the air storage tank 4 through the exhaust port. The air inlet of the air compressor 3 is provided with an energy-saving reversing valve 5, and the energy-saving reversing valve 5 is respectively connected to the air filter 1, The turbocharger 2 is connected, and an unloading valve 6 with a pressure feedback signal is arranged between the exhaust port of the air compressor 3 and the air storage tank 4, and the unloading valve 6 with a pressure feedback signal is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com