Coking-removing die box of drawing machine

A wire-drawing machine and wire-drawing die technology, applied in wire-drawing dies and other directions, can solve the problems of unstable and uncertain product quality, affecting the lubrication effect, etc., and achieve the effects of stable size, reliable lubrication effect and uniform wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

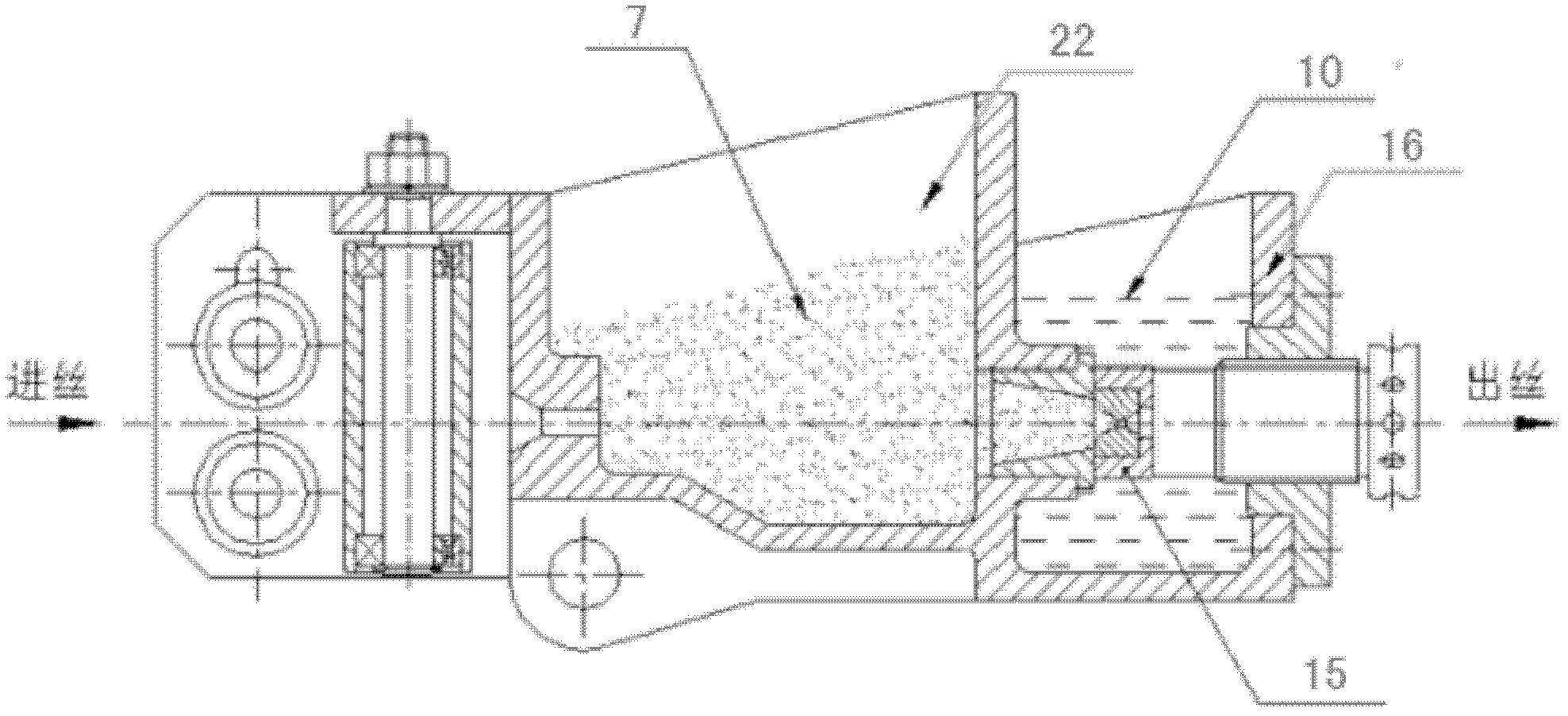

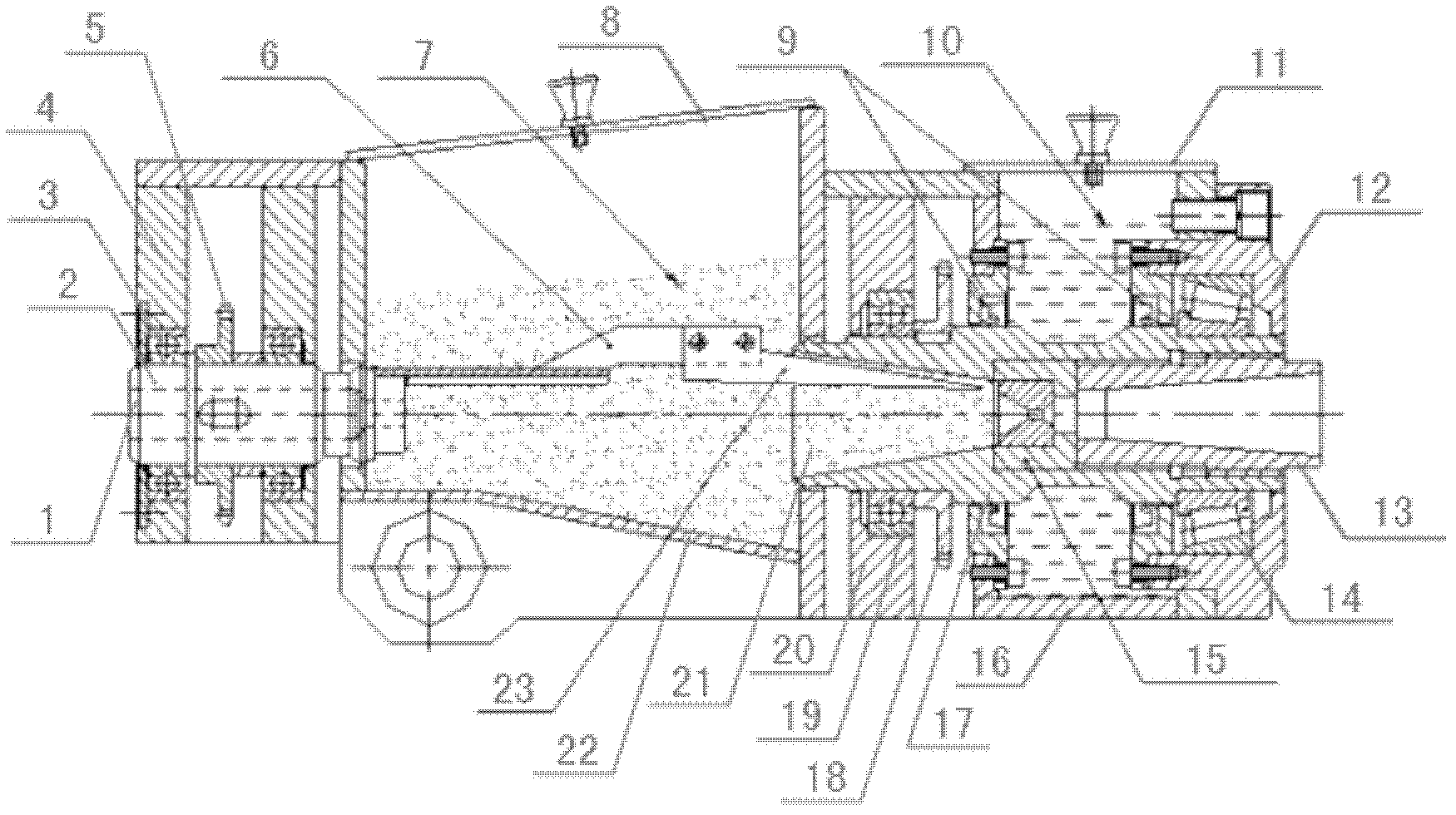

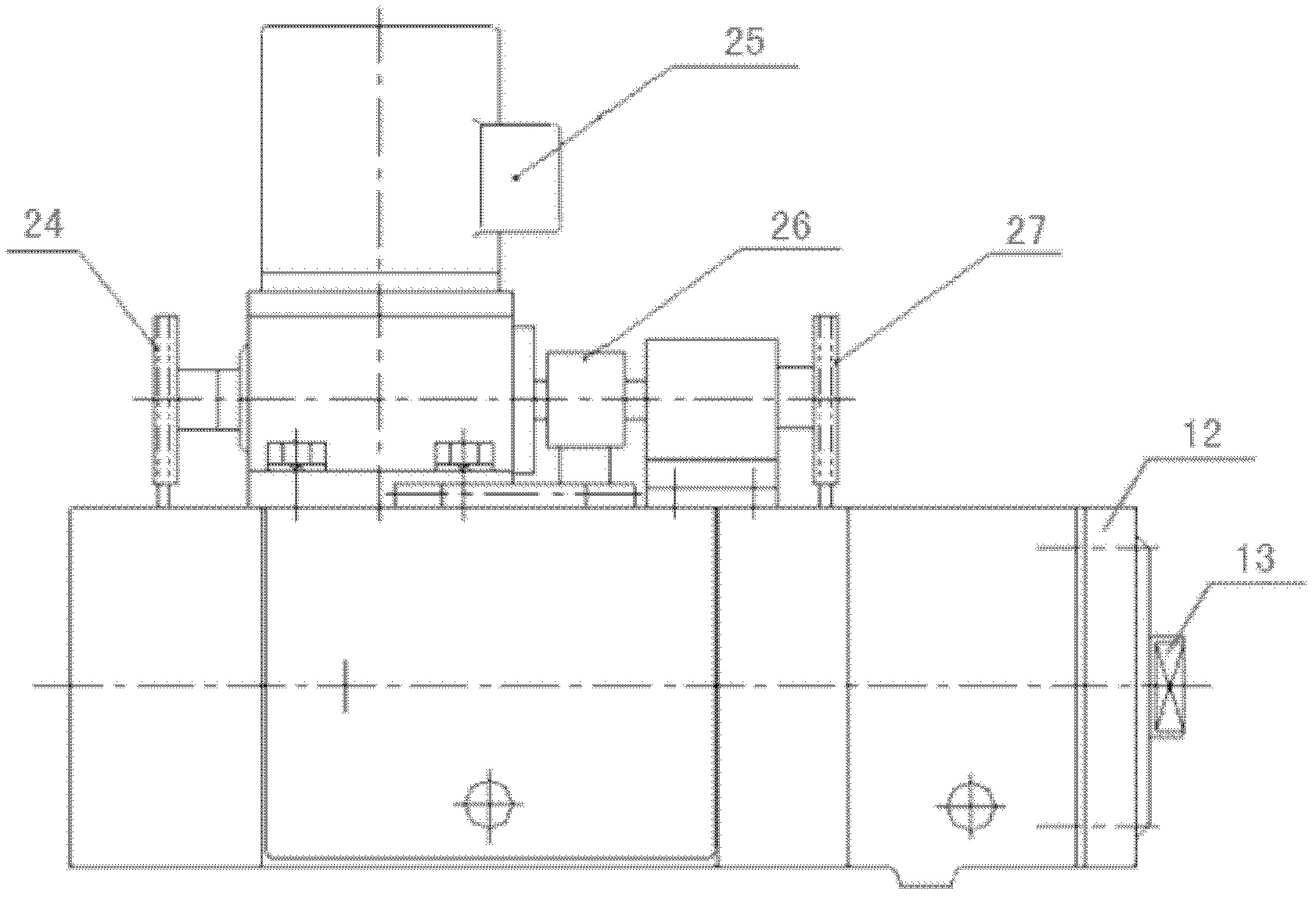

[0016] Figure 1~Figure 3 Among them, it includes wire inlet 1, stirring shaft 2, first bearing 3, first bearing seat 4, first sprocket 5, stirring rod 6, lubricating powder 7, lubricating box top cover 8, sealing ring 9, cooling water 10. Mold box body top cover 11, second bearing seat 12, top wire 13, second bearing 14, wire drawing die 15, mold box body 16, hollow shaft 17, second sprocket 18, third bearing 19, third Bearing block 20, lubricating taper hole 21, lubricating box body 22, blade 23, the 3rd sprocket 24, reduction motor 25, clutch 26, the 4th sprocket 27 etc.

[0017] Such as figure 2 , image 3 As shown, the present invention is a decoking mold box for a wire drawing machine, including a lubricating box body 22 and a mold box body 16 . Lubricating box body 22 is the container of a top opening, and lubricating powder 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com