Pressure lubrication die box for wire drawing machine

A wire drawing machine and lubrication box technology, applied in the direction of wire drawing dies, etc., can solve problems such as shortened service life of wire drawing dies, unstable product quality, and uncertainty, and achieve the effects of reduced wire breakage, simple structure, and extended life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

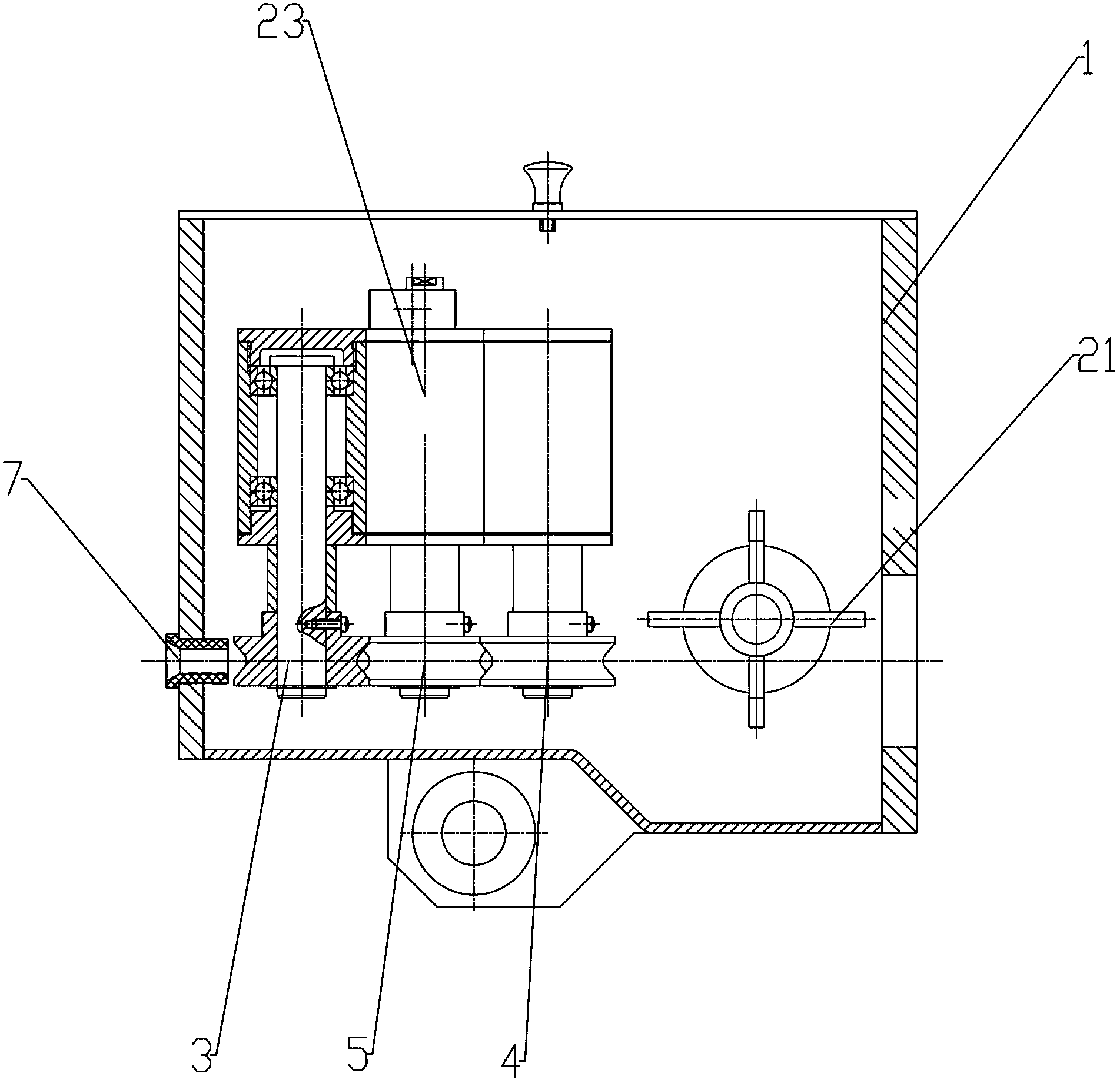

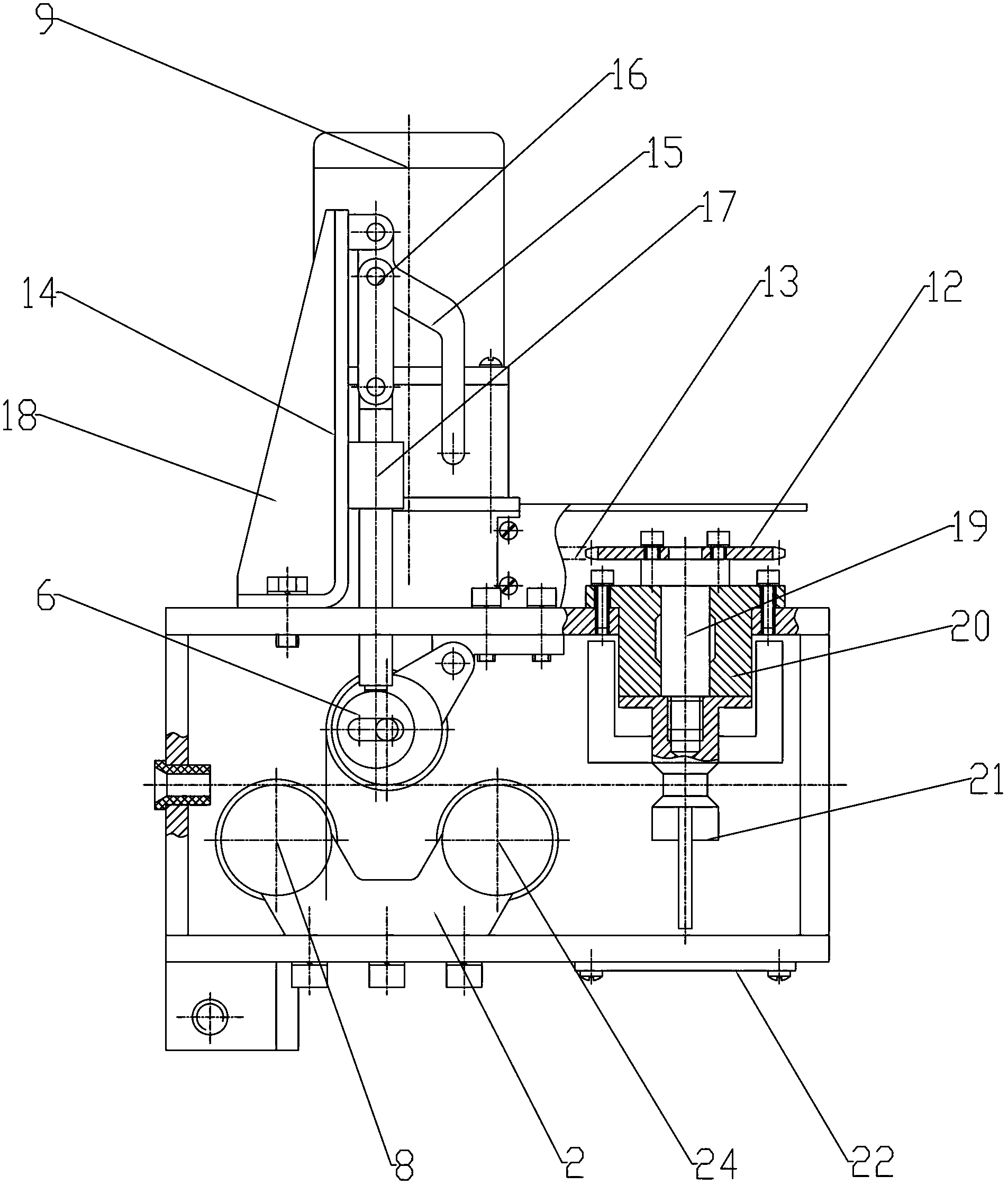

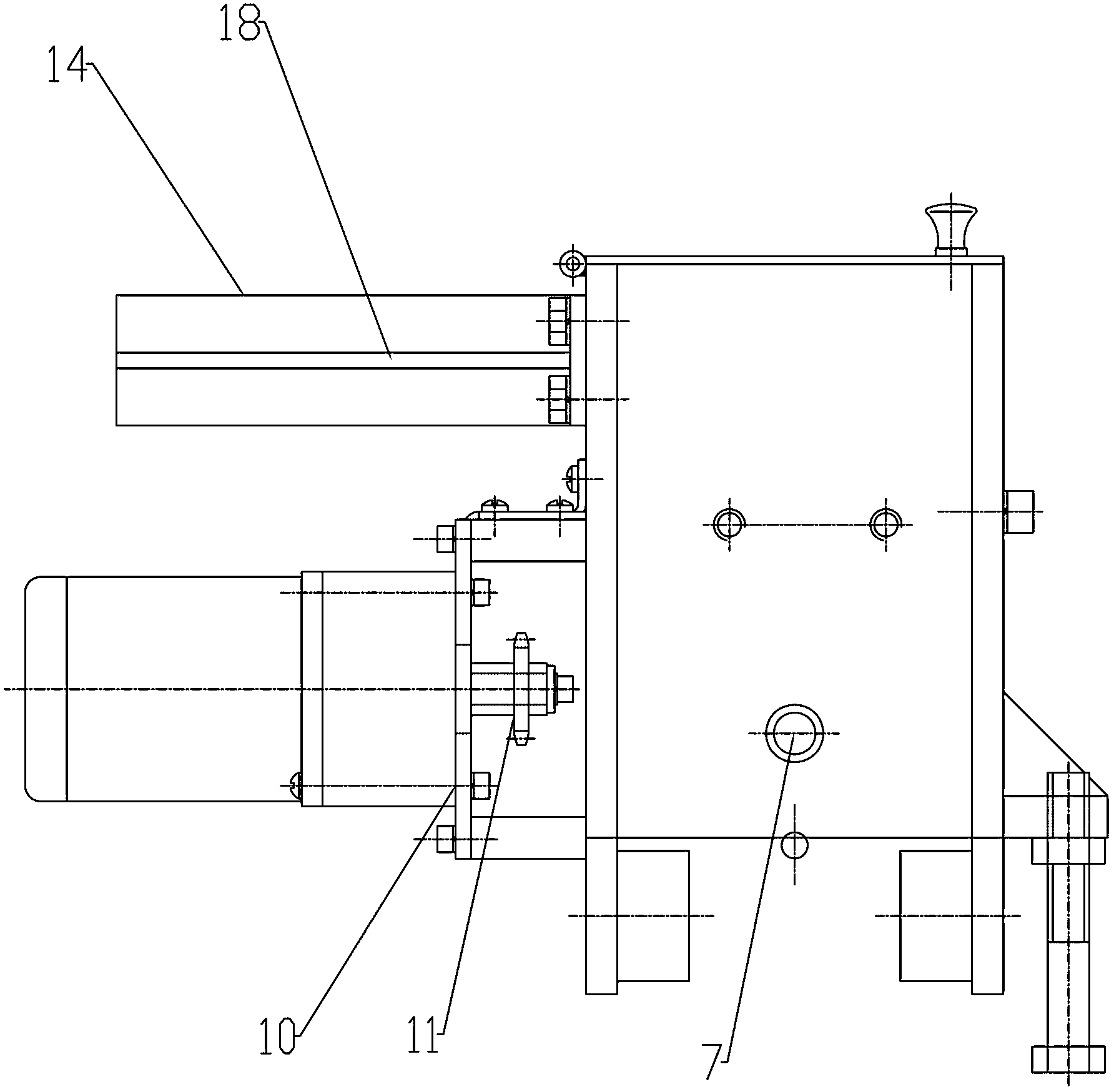

[0018] Such as Figure 1~3 As shown, the present invention mainly includes a lubricating box body 1, a roller seat 2, a slider 6, a first roller shaft 8, a reduction motor 9, a motor bracket 10, a first sprocket 11, a second sprocket 13, and a connecting rod bracket 14. Crank 15, connecting rod 16, slide rod 17, mandrel 19, bushing 20, stirring wheel 21, middle roller 23 and second roller 24.

[0019] The roller seat 2 is installed in the lubricating box body 1, and the first roller shaft 8 and the second roller shaft 24 are installed in the roller seat 2 through bearings. The lower end of the first roller shaft 8 is connected with the first roller 3 , and the lower end of the second roller shaft 24 is connected with the second roller 4 . An intermediate roller shaft 23 is arranged in the middle of the first roller shaft 8 and the second roller shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com