Method for processing soft copper foil

A processing method and technology of copper foil, applied in the petroleum industry, base material, metal rolling, etc., can solve the problems of uneven hardness, oil stain on the surface, and reduce the yield of finished products, and achieve uniform hardness, good rolling performance, Evaporative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

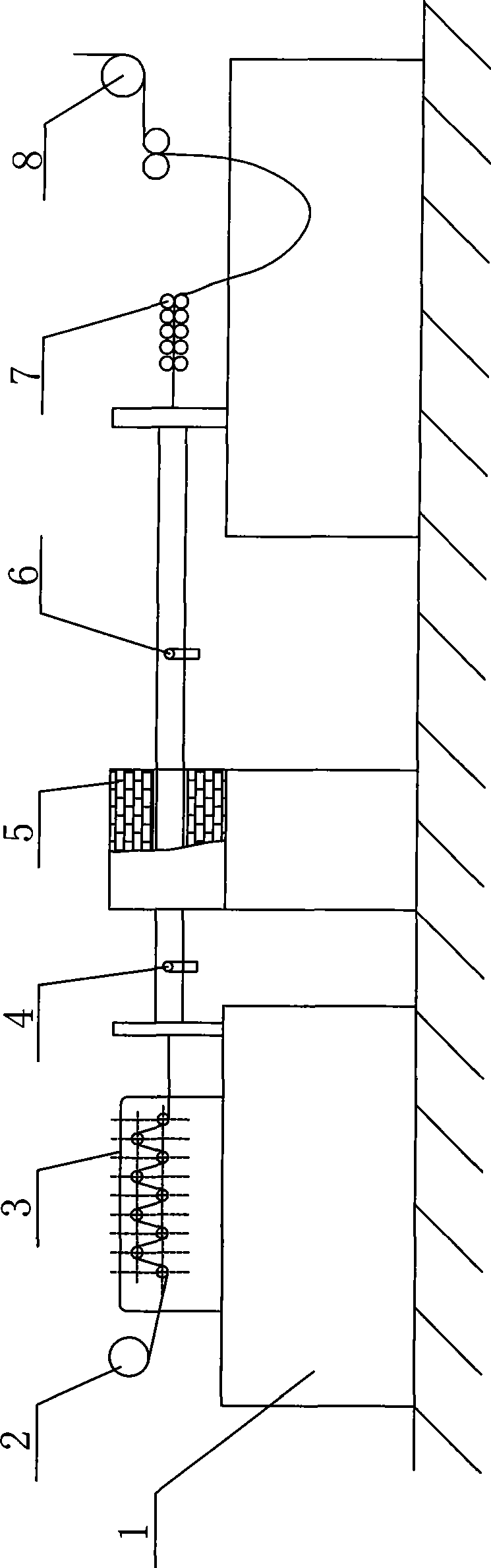

[0009] See figure 1 , the electrolytic copper of the present invention is poured into ingots after smelting, then face milling, and then enters a heating furnace for homogenization treatment. After the treatment is completed, it is immediately hot-rolled. Drying, then annealing, after annealing, enter the cold rolling process, the cold rolling process adopts four-roll cold rolling, the four-roll cold rolling equipment is an existing product in the market, and the cold rolling liquid used in cold rolling is a mixture of kerosene, gasoline, and vegetable oil. It is formulated; the ratio of each component is: 80% to 85% of kerosene, 15% to 17% of gasoline, 5% to 8% of rapeseed oil, the best ratio is 82.5% of kerosene, 16% of gasoline, 6.5% of rapeseed oil, cold Semi-automatic continuous annealing is carried out directly after rolling. During annealing, the single-layer metal foil is evenly heated in the heating body 5. 8 single-layer uncoiling, the middle is heated by the furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com