Rotary engine with homocentric arc trapezoid swivel plugs

A technology of rotating engines and concentric arcs, which is applied in the direction of internal combustion piston engines, combustion engines, machines/engines, etc., can solve the problems of unresolved vertical main axis component force, high degree of mechanical damage, and mismatched power transmission, etc., to achieve Simple structure, low cost, good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

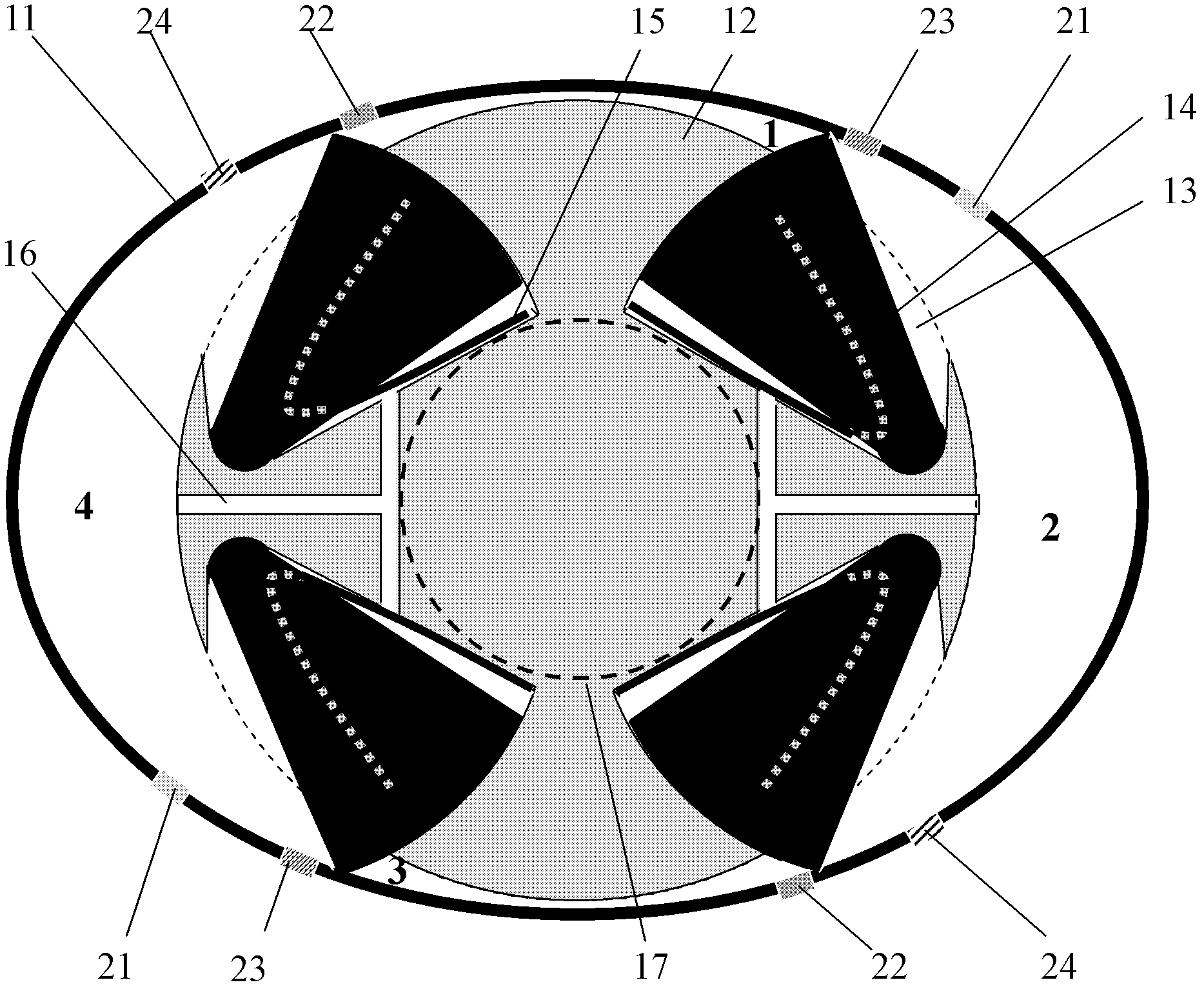

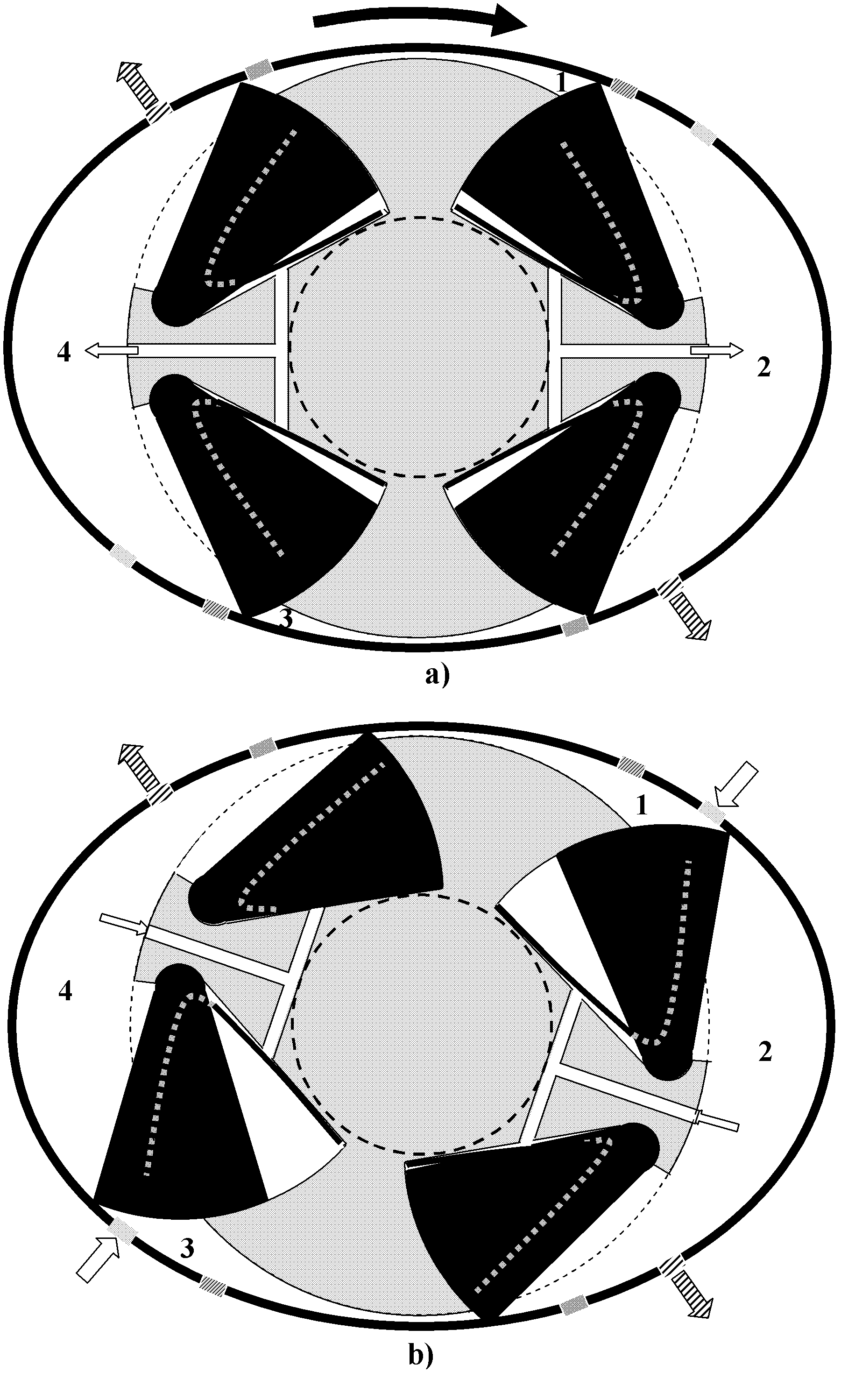

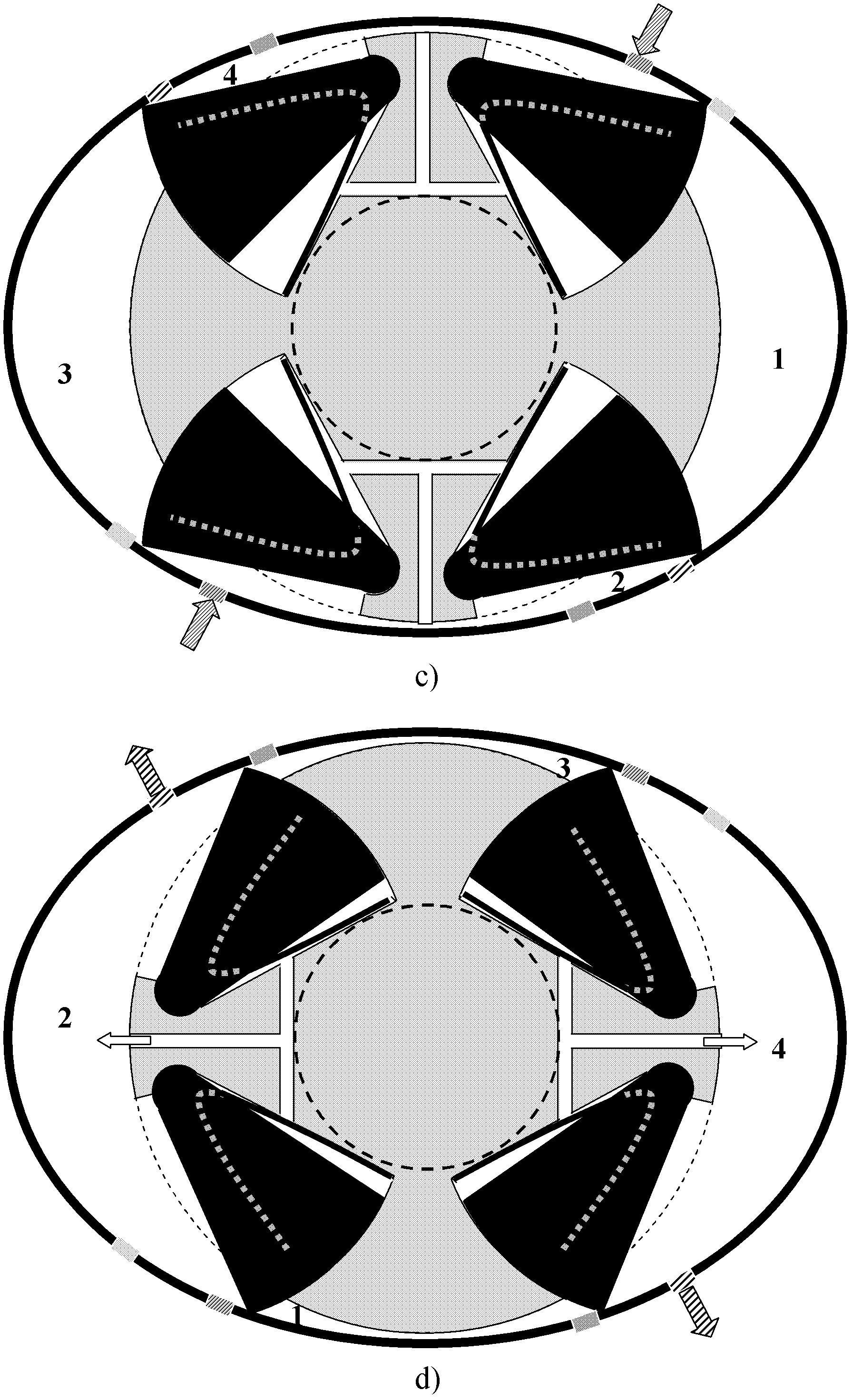

[0018] The present invention will be further described below with embodiment.

[0019] In an embodiment, the ratio of the long and short axes of the ellipse is 1.36:1, the length of the long axis is 16.3 cm, the short axis is 12 cm, the diameter of the rotor is 11.7 cm, and the length of the cylinder cavity of the ellipse is 12.5 cm. The diameter of the small arc in the concentric arc trapezoidal plug is 1 cm, the diameter of the large arc is 9.4 cm, and the chord length of the large arc is 4.1 cm. The engine compression ratio is 10.9, the four-cylinder displacement is 1.6 liters, the maximum power is 80 kW, the speed at maximum power is 3000 rpm, and the maximum torque is 940 Nm, which is nearly 7 times that of ordinary reciprocating piston engines. Such a large The torque has the potential to directly drive a small car without a gearbox.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com