Sealing leakage test device for oil-immersed transformer

An oil-immersed transformer and leak testing technology, which is applied in the field of transformer manufacturing, can solve the problems of difficult operation, long pipeline, large occupied area, etc., and achieve the effect of simple pipeline connection, flexible operation and clean ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

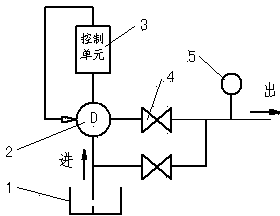

[0015] Such as figure 1 As shown, the oil-immersed transformer seal leak test device includes an oil tank 1, an oil pump 2, a control unit 3 and a pressure gauge 5; the oil tank 1 is connected to the oil pump 2 through a pipeline; the control unit 3 is arranged on the oil pump 2; the oil pump 2 and the oil tank 1 Valves 4 are installed at the outlets of the valves; pressure gauges 5 are installed on the pipeline; the control unit 3 is a pressure controller with two outlets, one is connected to the power supply, and the other is connected to the motor of the oil pump 2. The pressure controller is based on the product leak test pressure standard value Or the pressure of the pressure release valve controls the working state of the oil pump 2, and the remote control switch is installed at the power input end to ensure that the power is cut off imme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com