Aluminum alloy closed hydraulic nut for circular disc shear

A hydraulic nut and aluminum alloy technology, applied in the field of hydraulic locking, can solve the problems of easy damage to the installation shaft thread, potential safety hazards, oil leakage and wrestling, etc., to achieve convenient and quick installation and disassembly, suitable for environmental temperature changes, and meet the locking force required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

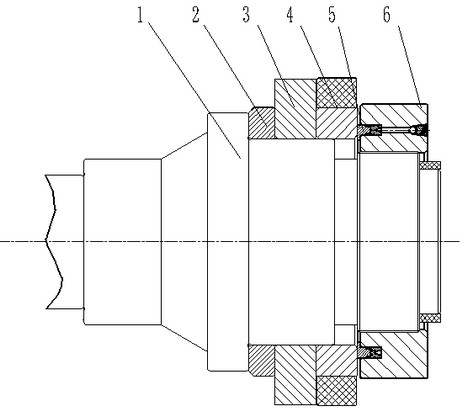

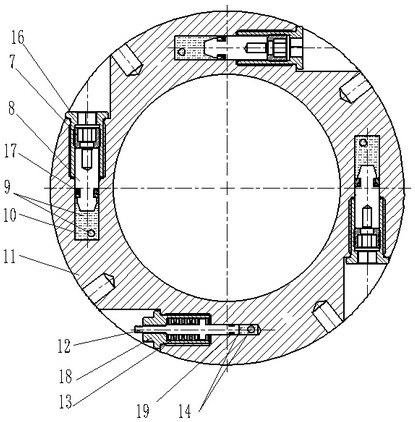

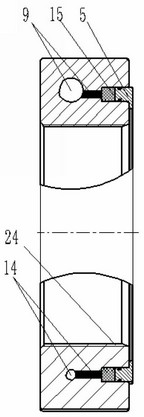

[0025] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the nut body 11 of the present invention is made of aluminum alloy material, and three plunger assemblies and one indicator rod assembly are distributed tangentially in the nut body 11, installed on the nut body 11, and connected with the oil hole 26 of the annular groove The oil nozzle 22 communicates with the plunger oil hole 9 of the plunger assembly and the indicator rod oil hole 14, and the three plunger oil holes 9 communicate with each other. The connection between the plunger oil hole 9, the indicator rod oil hole 14 and the nut body 11 A closed hydraulic nut structure is formed between them. The plunger oil hole 9 and the indicator rod oil hole 14 are connected with the straight hole of the annular groove of the nut body 1, which can change the processing technology of the original inclined hole and reduce the difficulty of processing. The oil nozzle 22 can ensure that the alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com