Processing method of automatic-feeding laser cutting

A laser cutting and automatic feeding technology, which is applied in metal processing, laser welding equipment, metal processing equipment, etc., can solve the problems of easy oil pollution, processing equipment and production impact, high installation and maintenance costs, and eliminate production safety and personnel safety. The effect of reducing risk, reducing equipment operation and maintenance costs, and improving production efficiency and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

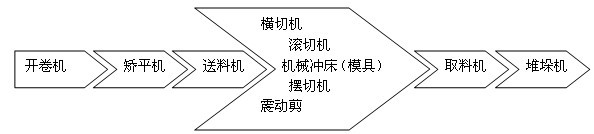

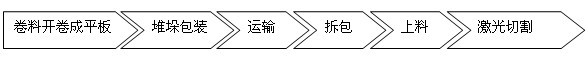

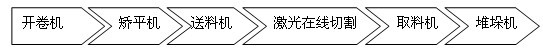

[0023] Such as figure 1 Shown: a processing method for automatic feeding laser cutting, comprising the following steps:

[0024] Step 1, push the coil material into the laser cutting work area through the automatic feeder, set the cutting and tailoring program, that is, the cutting and tailoring program set according to the size processing requirements of single or multiple workpieces, after setting the cutting and tailoring program , using single or multiple laser beams for cutting and processing to obtain single or multiple workpieces that meet the processing size requirements;

[0025] Step 2, command the feeder to automatically send the blank of the next processing step to the laser cutting work area through the linkage software, and repeat steps 1 to 2 until the entire coil is completely processed. This is a fully automatic processing process.

[0026] It should be noted that, in the present invention, before the operation of step 1, the coiled material can be uncoiled i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com