Modified polyvinylalcohol (PVA) base film, preparation method thereof and polarizer

A technology of polyvinyl alcohol base film and polyvinyl alcohol, which is applied in optics, optical elements, polarizing elements, etc., can solve the problems of poor compatibility between silica and PVA base film, limiting the elongation ratio of PVA base film, and the toughness of PVA base film Increase and other problems, to achieve the effect of improving heat and humidity resistance and mechanical strength, preventing discomfort, improving heat and humidity resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the examples, and the examples are intended to explain rather than limit the technical solution of the present invention.

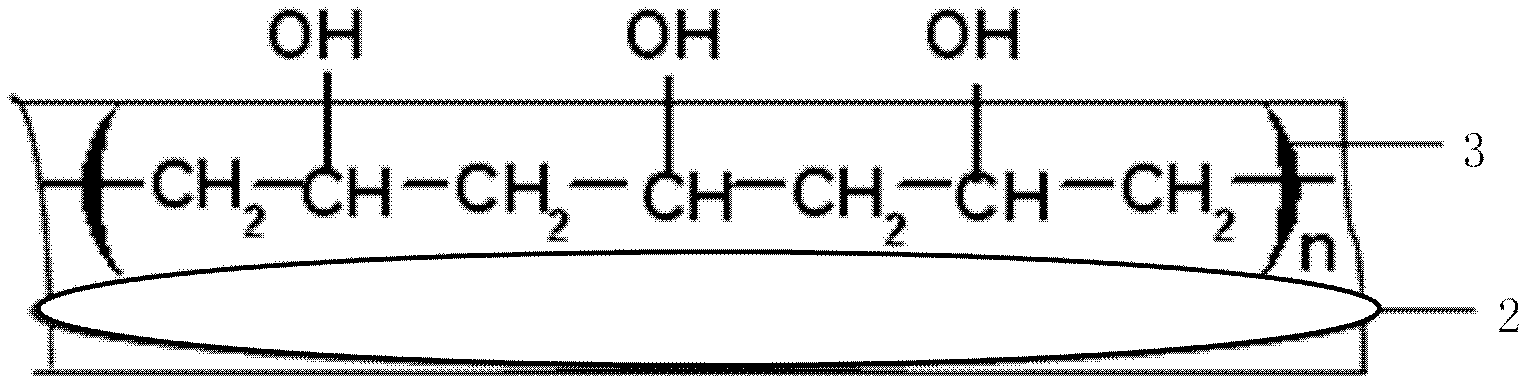

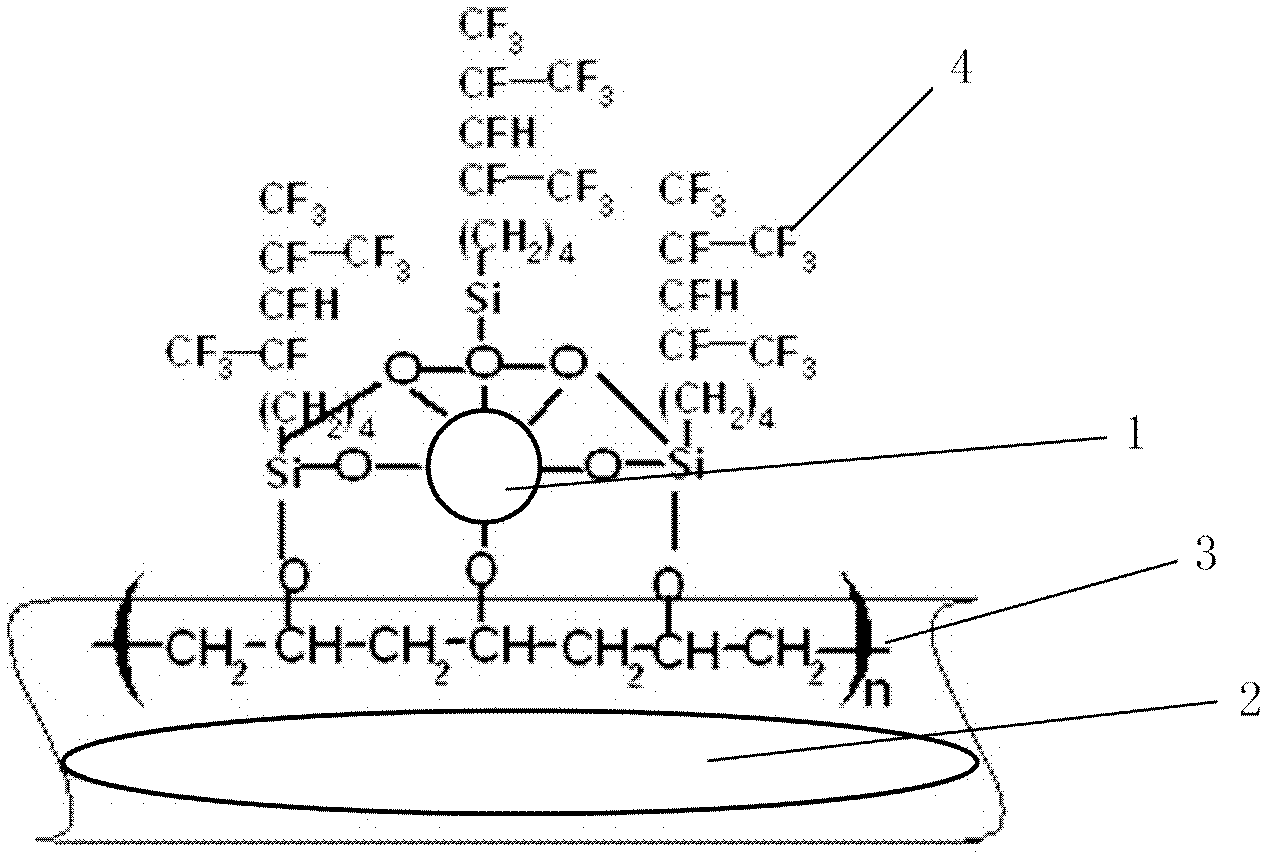

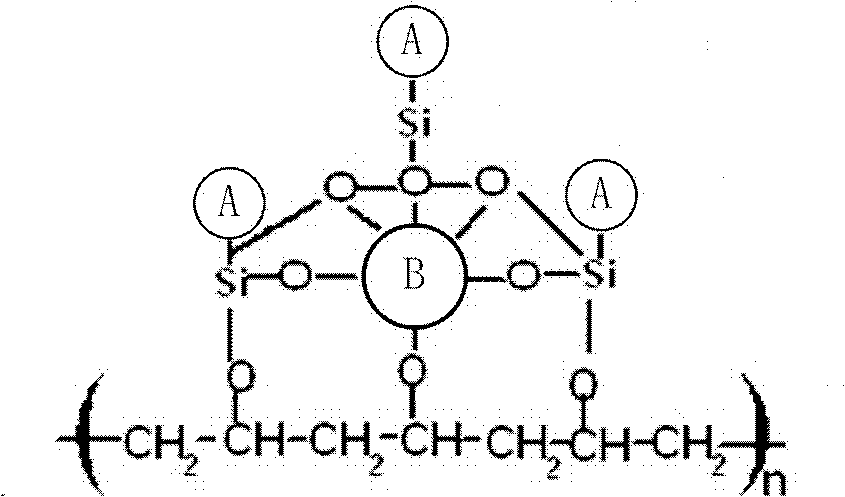

[0050] According to a preferred embodiment of the present invention, the present invention provides a kind of modified polyvinyl alcohol (PVA) base film and preparation method thereof, and its specific preparation steps comprise:

[0051] (1) Surface graft modification of nano-silica with fluorosilane: Add about 6g of dried nano-silica particles, 120mL of absolute ethanol, 6.5g of deionized water, and 3.4g of mass fraction in a round-bottomed flask 25% ammonia water and 2.0~2.4g dodecafluoroheptylpropyltrimethoxysilane; ultrasonically disperse for 1h, stir at 40°C for 5h at high speed; then filter the precipitate, wash it repeatedly with absolute ethanol, and pump it with toluene Extract for 16 hours to remove unreacted dodecafluoroheptylpropyltrimethoxysilane; vacuum dry t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com