Automatic feeding, detecting and positioning system of batteries

An automatic feeding and positioning system technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of high processing and production costs, achieve saving of processing and production costs, improve processing efficiency, and overcome the problems of high processing and production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

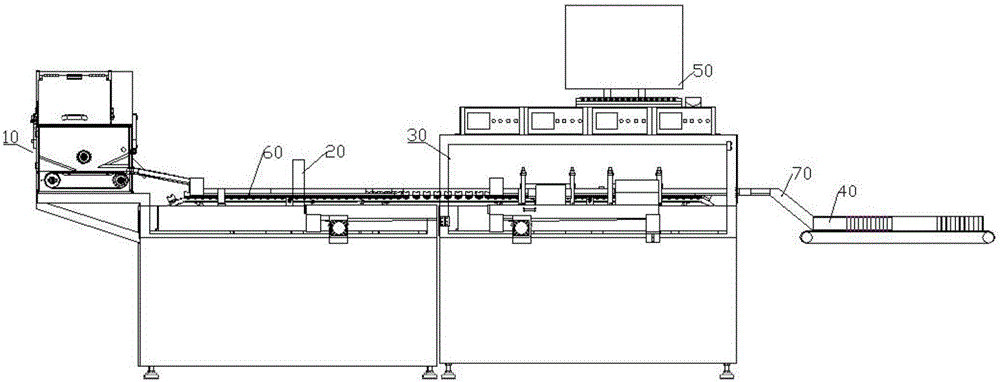

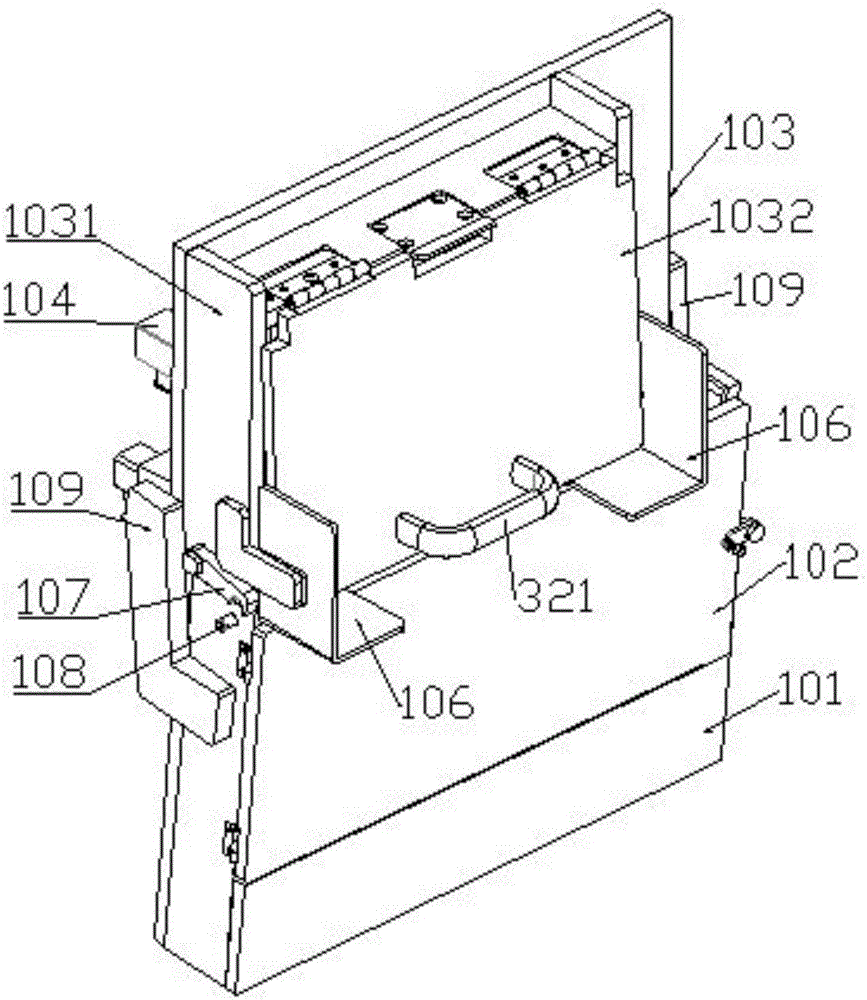

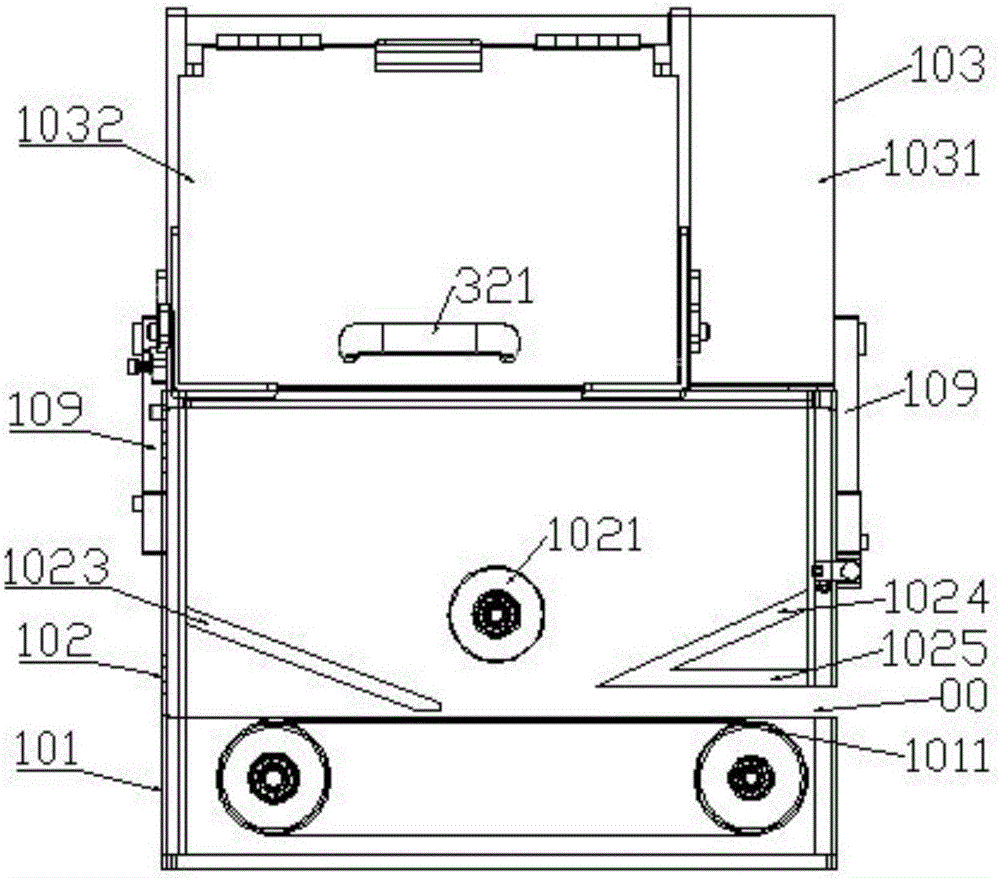

[0027] figure 1 It is a schematic structural diagram of the battery automatic feeding detection and positioning system provided in Embodiment 1 of the present invention; figure 2 It is a schematic structural diagram of the battery feeding mechanism in the battery automatic feeding detection and positioning system provided in Embodiment 1 of the present invention; image 3 It is a front view of the battery feeding mechanism in the battery automatic feeding detection and positioning system provided in Embodiment 1 of the present invention; Figure 4 It is the rear view of the battery feeding mechanism in the battery automatic feeding detection and positioning system provided in Embodiment 1 of the present invention; as shown in the figure, the battery automatic feeding detection and positioning system provided in Embodiment 1 of the present invention includes: The battery feeding mechanism 10 for the battery, the code scanning visual head 20 for identifying the battery code, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com