Illuminating device, backlight module with the illuminating device, lamp box module or digital electronic device and manufacturing method thereof

A light-emitting device and manufacturing method technology, applied in the direction of light guides, optics, optical components, etc., can solve the problems of high cost, unfavorable RBG color mixing, increase the structural depth of light-emitting devices, etc., achieve overall thickness reduction, reduce dark bands, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

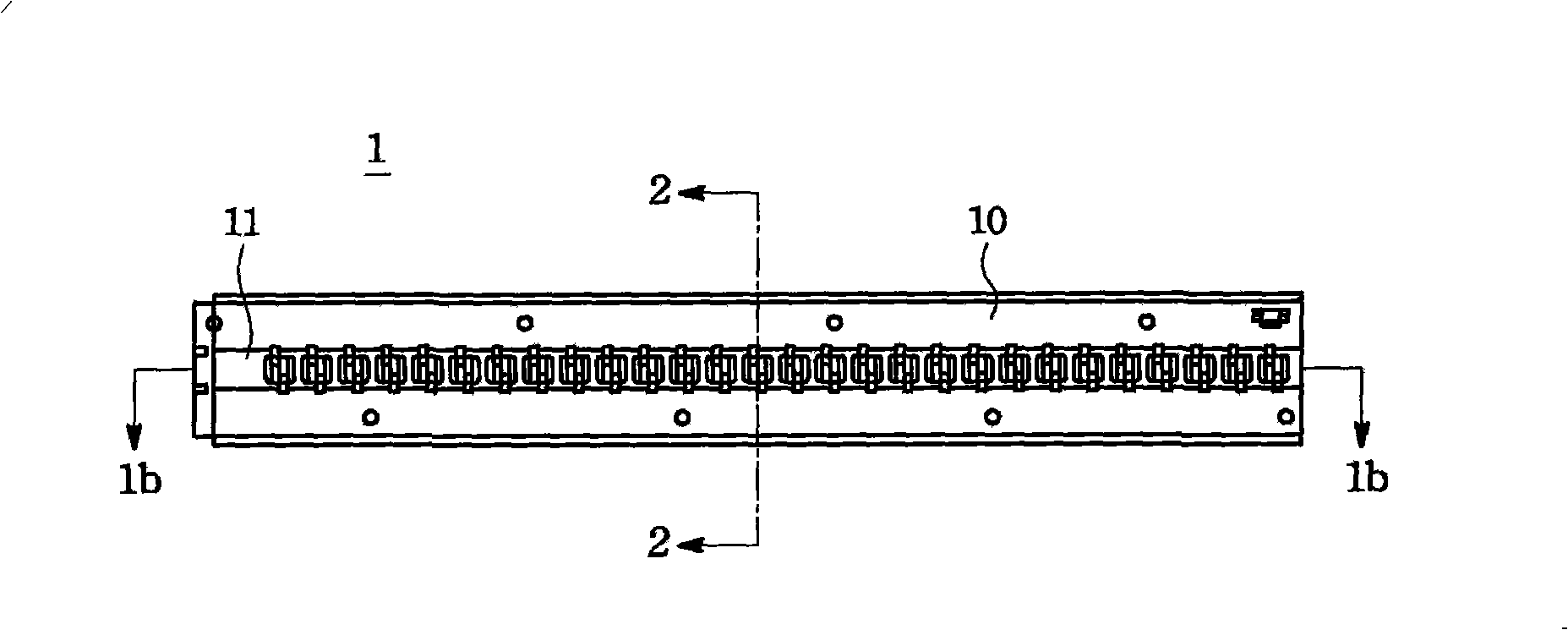

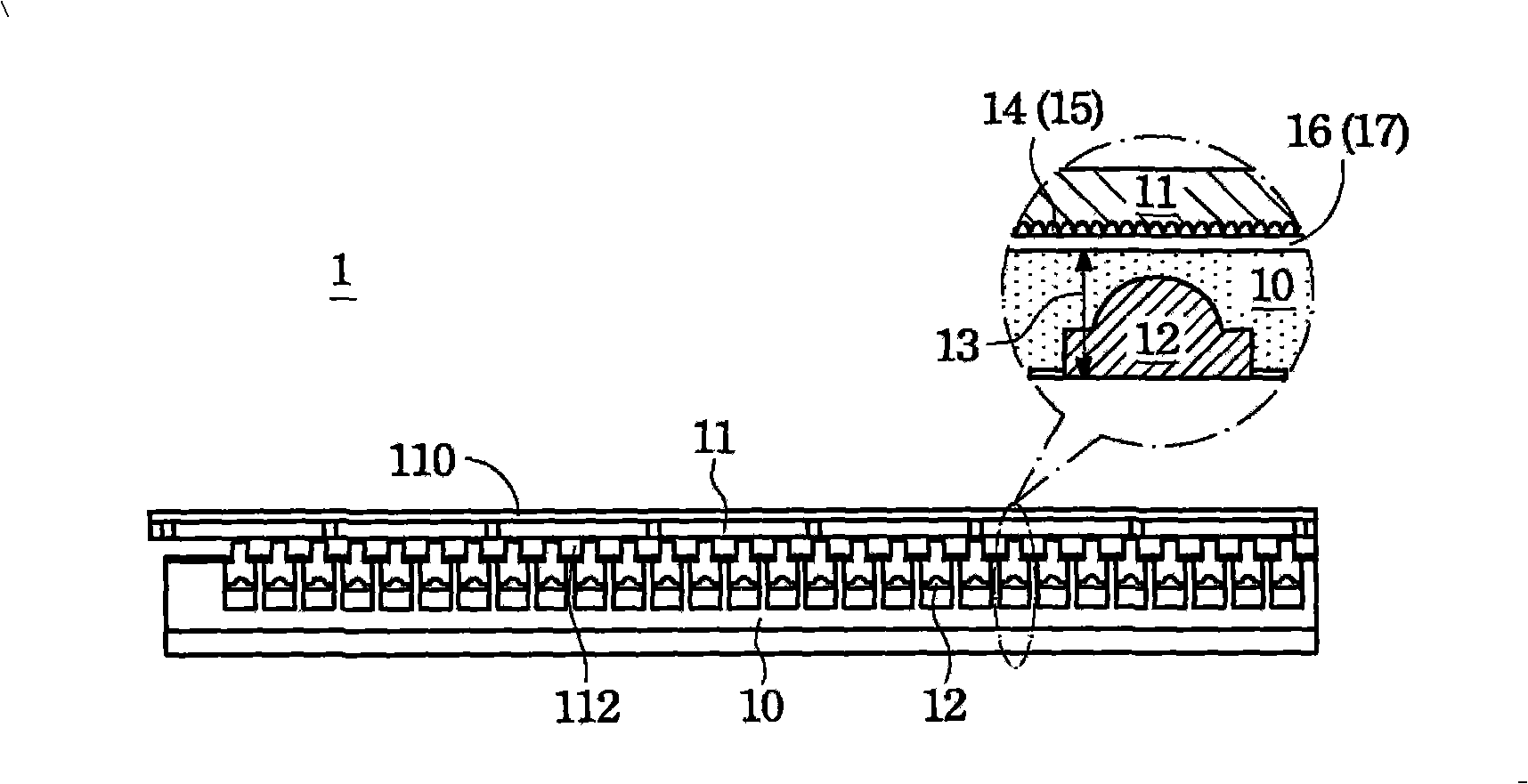

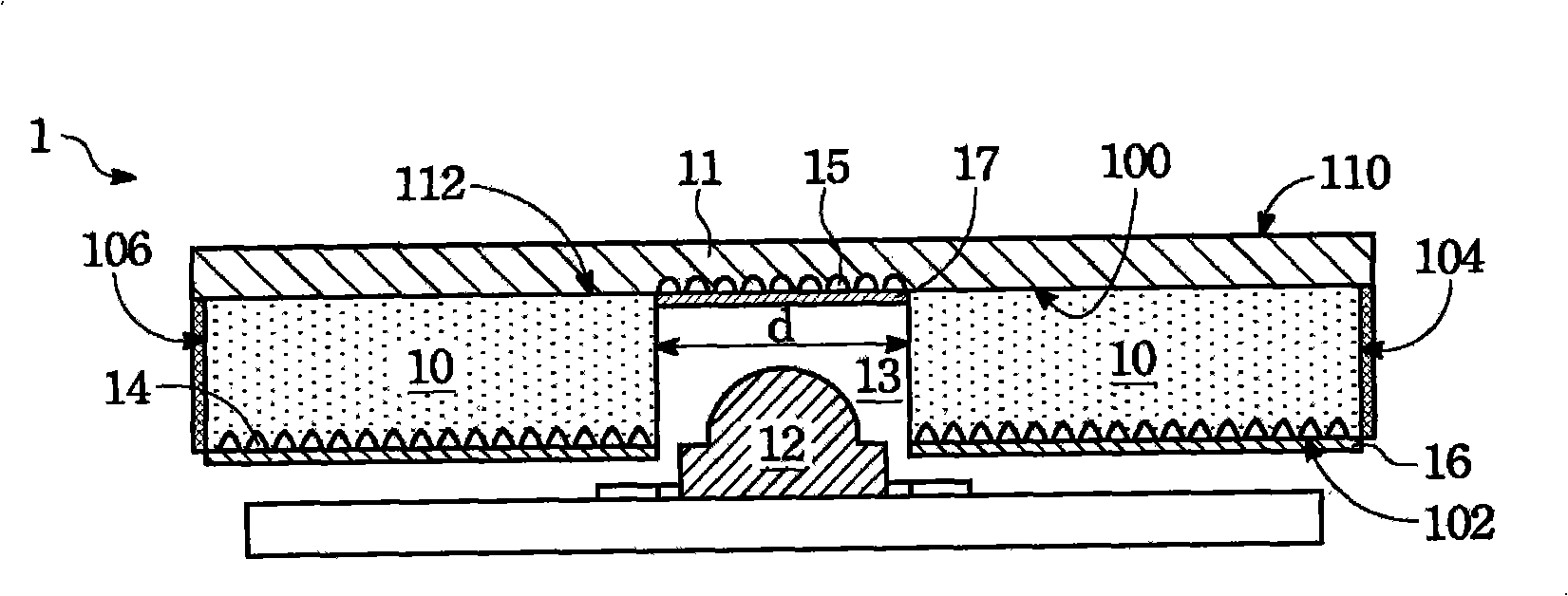

[0103] Figure 1A , Figure 1B Respectively represent the overall top view of the lighting device (Lighting device) according to the first embodiment of the present invention and the schematic cross-sectional view of the section line 1b-1b, figure 2 It means that the light-emitting device of the first embodiment of the present invention is Figure 1A In, 2-2 section schematic diagram of section line. As shown in the figure, the light emitting device 1 includes a plurality of elongated first light guide structures 10, a second light guide structure 11 and a light source 12, and the second light guide structure 11 is spliced adjacent to two first light guide structures 10. , to accommodate the light source 12 into the space 13 formed by two adjacent first light guide structures 10 and the second light guide structure 11, wherein the bottom surface of the first light guide structure 10 on the same side as the light source 12 and the second light guide structure On the second ...

no. 2 example

[0112] For the light source lighting device of the second embodiment of the present invention, please refer to Figure 7 , Figure 8 and Figure 9 A schematic cross-sectional view of the light-emitting device shown. Let me explain here that the components and structures of this embodiment are roughly the same as those of the first embodiment, and the names and numbers of the components are also used in the first embodiment. The repetitions between this embodiment and the previous embodiment will not be described in detail. This only discloses the characteristics of this embodiment different from the previous embodiments, so as to further illustrate other implementations of the present invention. Such as Figure 7 As shown, the light source lighting device 2 of the second embodiment of the present invention includes a plurality of elongated first light guide structures 20, a second light guide structure 21 and at least one light source 22, and the thickness of the second lig...

no. 3 example

[0119] Figure 10 It is a schematic overall plan view of a Matrix / Array light emitting device according to the third embodiment of the present invention. The light-emitting device of this embodiment is a light-emitting device that uses a combination of a light guide plate, a reflective layer, and a light-emitting diode (Light Emitting Diodes, LED) light source to be used as a backlight source for a color liquid crystal display. Among them, the main structure of this embodiment is the same as that of the previous embodiments, and the components and structures of each part of the light-emitting device are substantially the same as those of the first embodiment, and the names of the components are also used above. Only the third embodiment is disclosed here that is different from the previous embodiments. characteristics, to further illustrate other embodiments of the present invention. Such as Figure 10 As shown, the array light-emitting device 3 of this embodiment includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com