Thin film transistor and manufacturing method thereof, array substrate and display device

A technology for thin film transistors and substrates, applied in transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve problems such as damage, deterioration of TFT performance, and complication of TFT manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

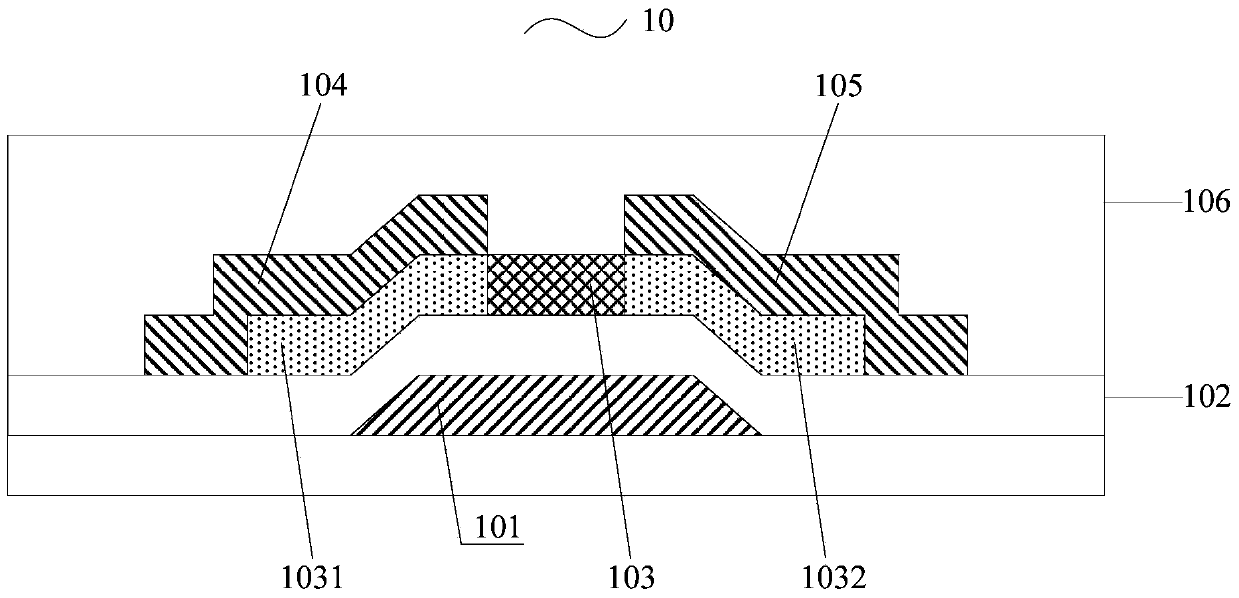

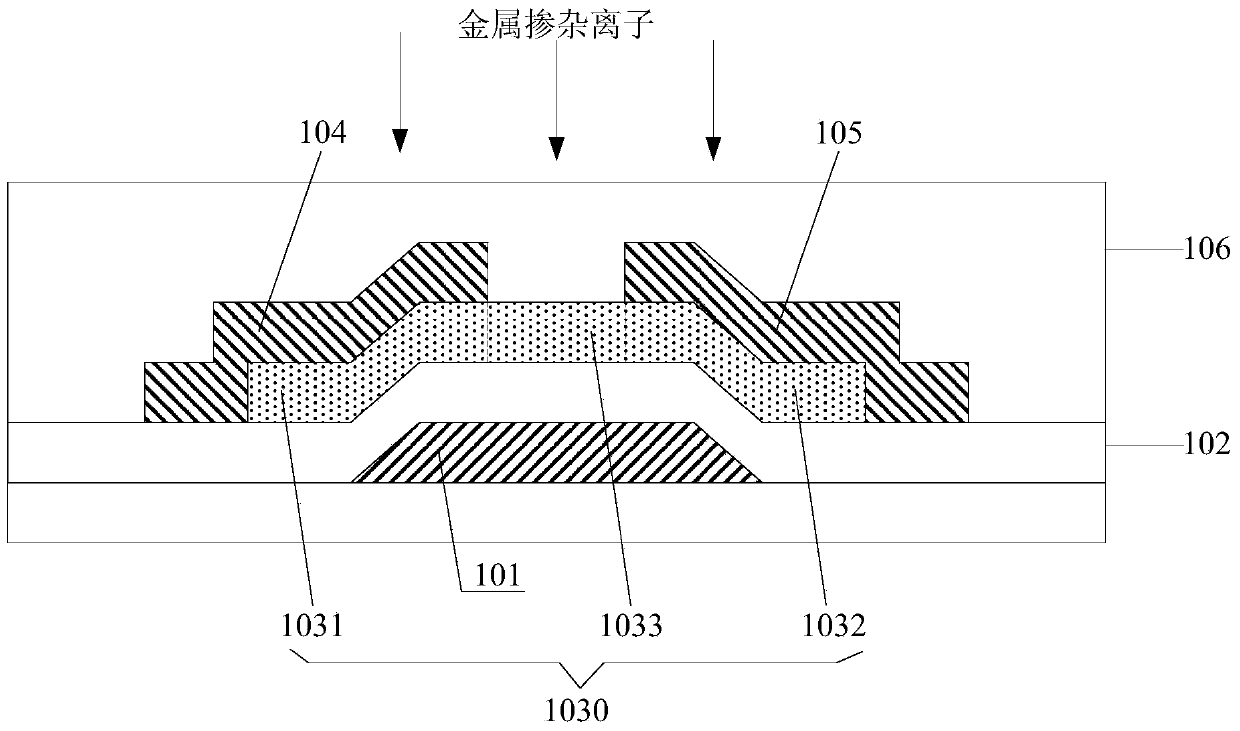

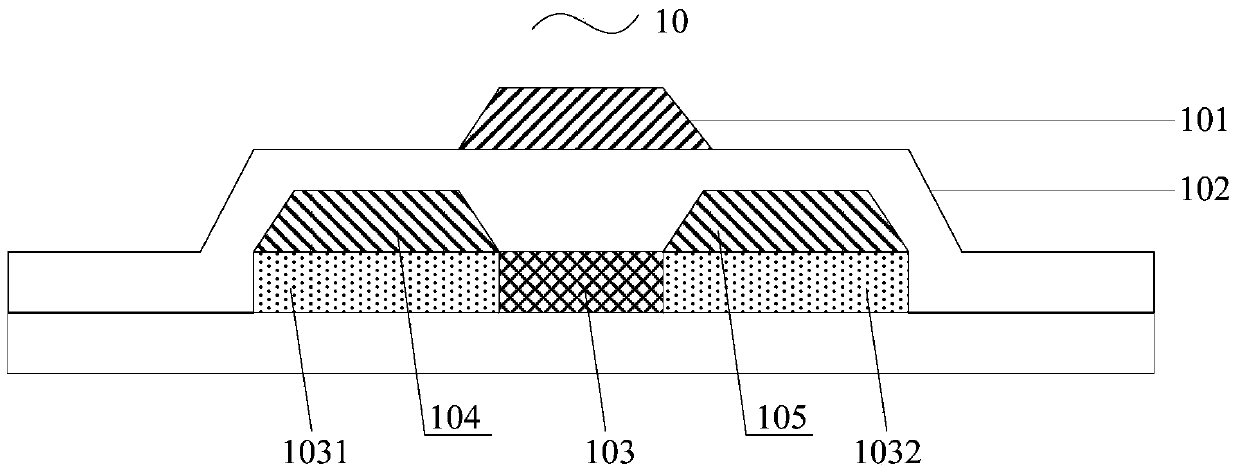

[0042] An embodiment of the present invention provides a method for manufacturing a thin film transistor 10 , which includes forming a gate 101 , a gate insulating layer 102 , a metal oxide semiconductor active layer 103 , a source 104 and a drain 105 on a substrate. The forming the metal oxide semiconductor active layer 103 on the substrate may include: forming an indium oxide-based binary metal oxide pattern layer 1030 on the substrate, the pattern layer including a first pattern 1031 corresponding to the source electrode 104 , the second pattern 1032 corresponding to the drain 105, and the third pattern 1033 corresponding to the gap between the source 104 and the drain 105, and the indium oxide-based binary metal oxide pattern Layer 1030 is in direct contact with the source electrode 104 and the drain electrode 105; the insulating layer formed above the source electrode 104 and the drain electrode 105 is used as a barrier layer, and the indium oxide based The elemental meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com