Full-inorganic perovskite solar energy cell and preparation method thereof

A solar cell and inorganic calcium technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as poor contact and charge obstruction, and achieve the effects of reducing requirements, reducing charge recombination, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

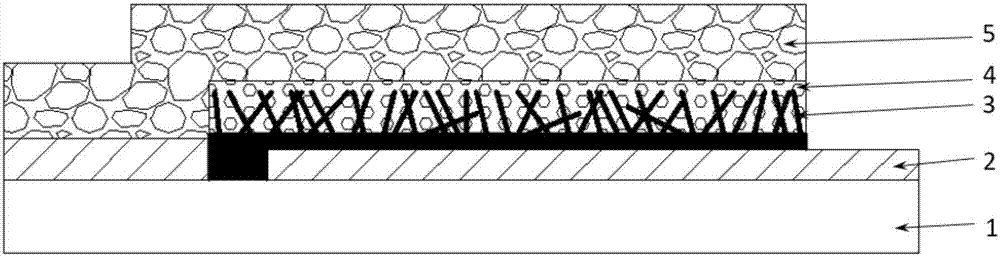

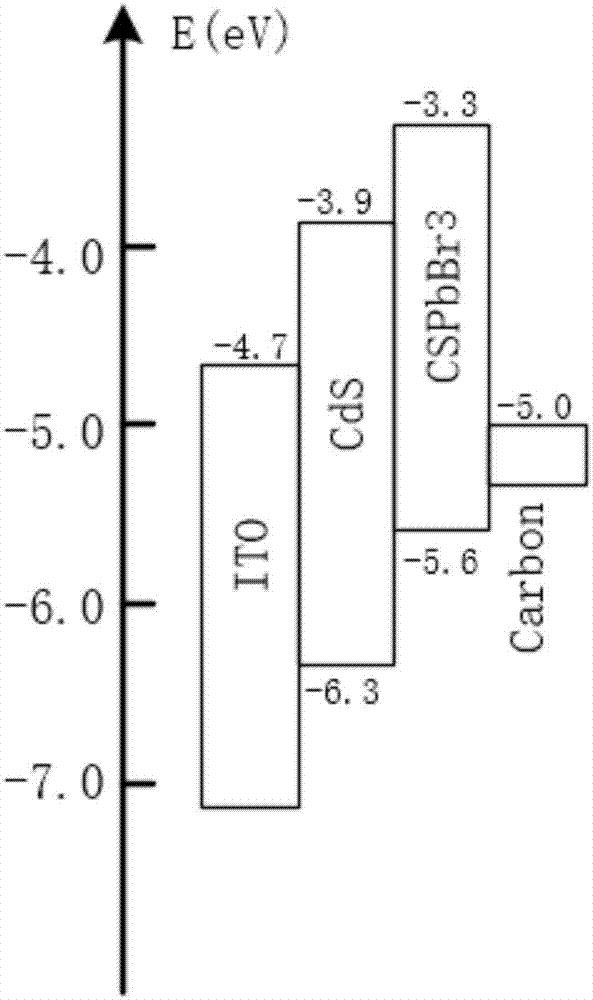

[0034] Referring to the accompanying drawings, an all-inorganic perovskite solar cell comprises a substrate glass 1, an ITO conductive layer 2 and a photoanode 3, a light absorbing layer 4 and a carbon counter electrode layer 5, wherein,

[0035]The ITO conductive layer 2 is arranged on the upper surface of the substrate glass 1;

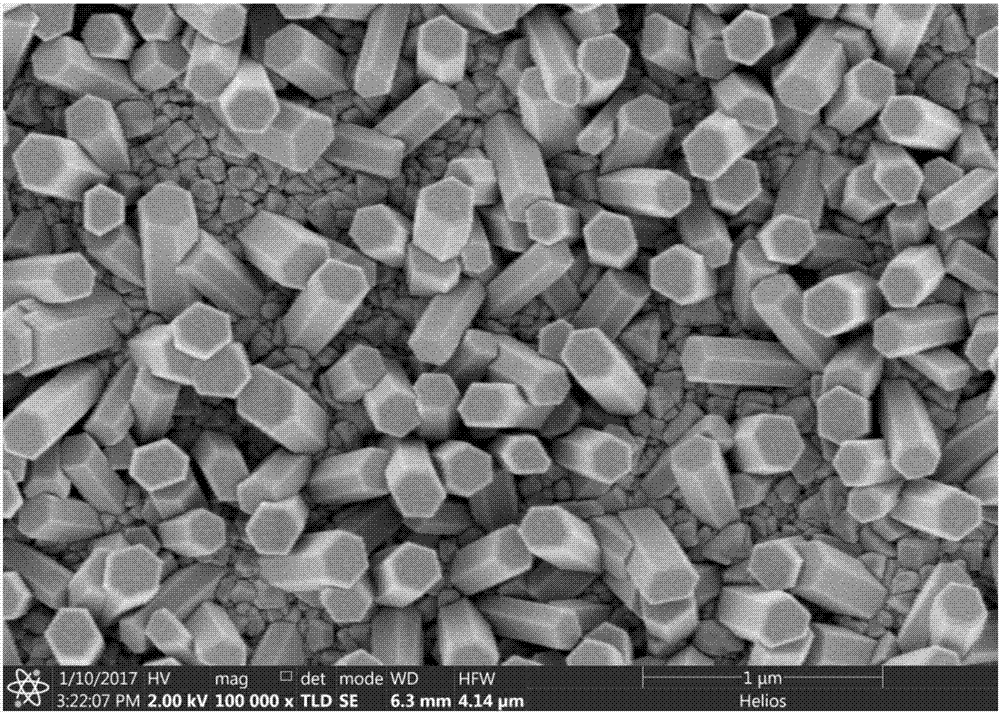

[0036] The photoanode 3 is a CdS nanorod array structure, which is arranged on the upper surface of the ITO conductive layer 2 and has a pore structure;

[0037] The light absorbing layer 4 is CsPbBr 3 an inorganic perovskite layer embedded within the pore structure of the photoanode 3 to form intimate contact with the photoanode 3;

[0038] The carbon counter electrode layer 5 is spread on the upper surface of the ITO conductive layer 2 and the upper surface of the light absorbing layer 4 , which is formed by screen printing.

[0039] Further, the CdS nanorods of the CdS nanorod array are prepared by a hydrothermal method, and each of the CdS nan...

Embodiment 2

[0048] Referring to the accompanying drawings, an all-inorganic perovskite solar cell comprises a substrate glass 1, an ITO conductive layer 2 and a photoanode 3, a light absorbing layer 4 and a carbon counter electrode layer 5, wherein,

[0049] The ITO conductive layer 2 is arranged on the upper surface of the substrate glass 1;

[0050] The photoanode 3 is a CdS nanorod array structure, which is arranged on the upper surface of the ITO conductive layer 2 and has a pore structure;

[0051] The light absorbing layer 4 is CsPbBr 3 an inorganic perovskite layer embedded within the pore structure of the photoanode 3 to form intimate contact with the photoanode 3;

[0052] The carbon counter electrode layer 5 is spread on the upper surface of the ITO conductive layer 2 and the upper surface of the light absorbing layer 4 , which is formed by screen printing.

[0053] Further, the CdS nanorods of the CdS nanorod array are prepared by a hydrothermal method. The diameter of each C...

Embodiment 3

[0062] Referring to the accompanying drawings, an all-inorganic perovskite solar cell comprises a substrate glass 1, an ITO conductive layer 2 and a photoanode 3, a light absorbing layer 4 and a carbon counter electrode layer 5, wherein,

[0063] The ITO conductive layer 2 is arranged on the upper surface of the substrate glass 1;

[0064] The photoanode 3 is a CdS nanorod array structure, which is arranged on the upper surface of the ITO conductive layer 2 and has a pore structure;

[0065] The light absorbing layer 4 is CsPbBr 3 an inorganic perovskite layer embedded within the pore structure of the photoanode 3 to form intimate contact with the photoanode 3;

[0066] The carbon counter electrode layer 5 is spread on the upper surface of the ITO conductive layer 2 and the upper surface of the light absorbing layer 4 , which is formed by screen printing.

[0067] Further, the CdS nanorods of the CdS nanorod array are prepared by a hydrothermal method, each of the CdS nanoro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com