Planetary no-superconducting joint multi-bread coil winding machine

A technology of superconducting joints and multi-cake coils, used in superconducting magnets/coils, coil manufacturing, magnetic objects, etc., can solve the problems of magnet quenching, affecting magnet stability, and consuming magnet electromagnetic energy, so as to reduce energy loss. , the effect of avoiding magnet quench and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

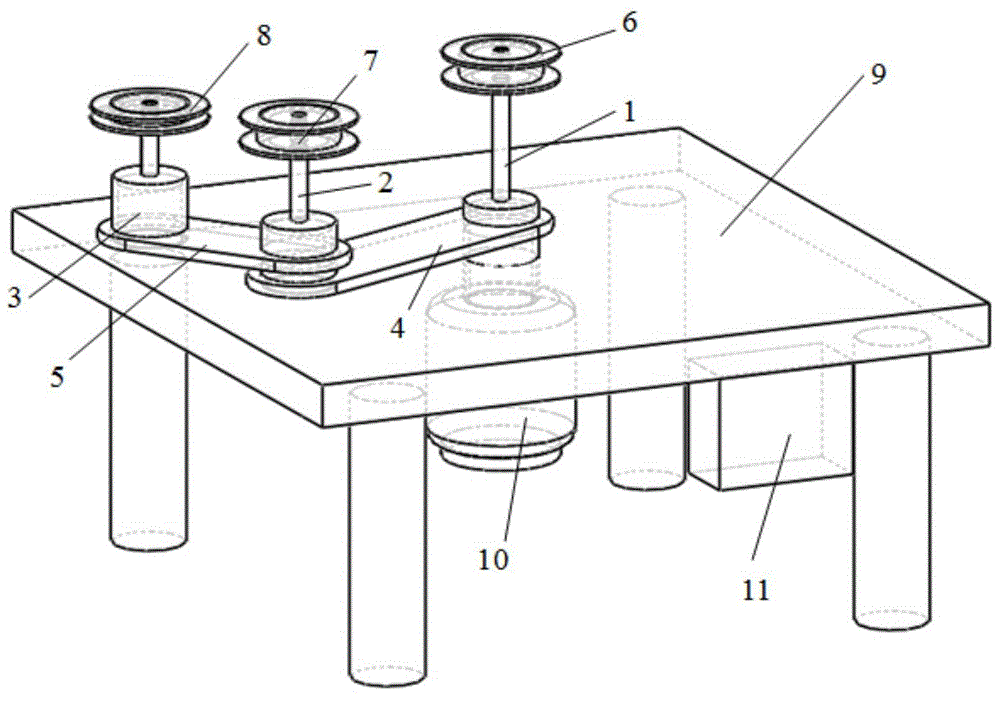

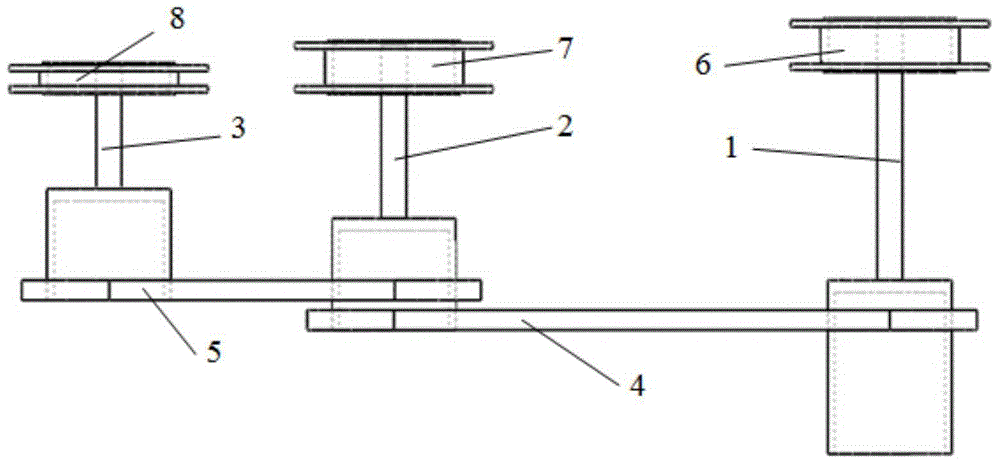

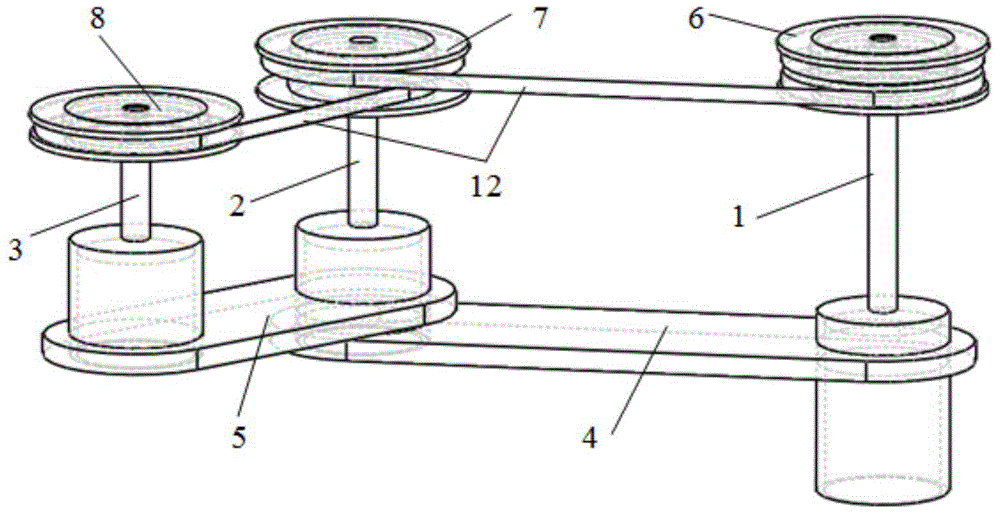

[0022] The invention is a winding machine for winding high-temperature superconducting multi-cake coils without superconducting joints, including a star winding shaft 1, a planet winding shaft 2, a satellite winding shaft 3, a planetary drive 4, a satellite drive 5, and a star winding shaft Skeleton 6 , planet winding skeleton 7 , satellite winding skeleton 8 , fixed stand 9 , speed regulating motor 10 , and controller 11 . The star winding shaft 1 is located on the fixed stand 9 . One end of the planetary transmission 4 is fixed on the lower end of the planetary winding shaft 1 , connected to and driven by the speed regulating motor 10 ; the planetary winding shaft 2 is located at the other end of the planetary transmission 4 . One end of the satellite drive 5 is located at the lower end of the planetary winding shaft 2, driven by a motor on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com