Manufacturing method of laying forming glass reinforced plastics construction

A manufacturing method and FRP technology, applied in the field of FRP materials, can solve the problems of long production cycle, large number of molds, high FRP manufacturing cost, etc., and achieve the effects of simple manufacturing process, simplified production process and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

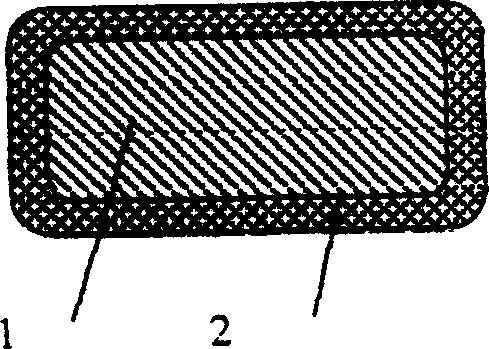

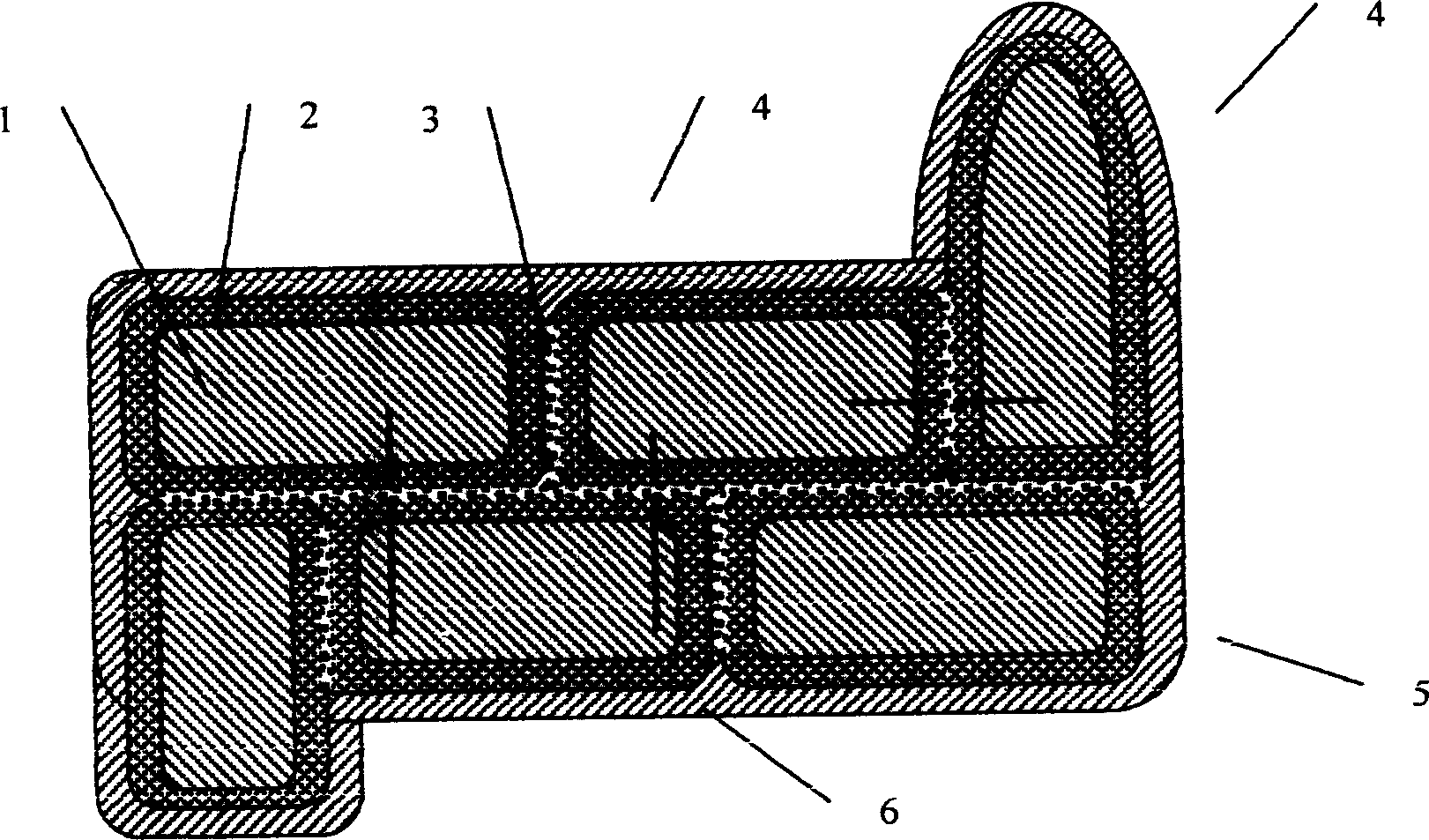

[0025] In this embodiment, the foam material is cut into the required foam core material 1 according to the drawing, and the glass fiber cloth 2 is wound on the foam core material 1; FRP resin3. At room temperature, 70% by weight of epoxy resin, 2% by weight of ethylenediamine, 10% by weight of talcum powder, and 8% by weight of quartz sand are uniformly blended into FRP resin 3 with fillers. Use positioning nails, jigs, and templates for positioning. According to the shape and structure requirements of FRP products, a FRP blank 4 is built; after the naturally dried FRP component blank is polished and modified, it is assembled into a whole blank 5 by multiple pieces; the surface of the whole blank 5 is then pasted with FRP resin and glass cloth. 6. After drying and polishing, the required FRP hull parts will be finished. The technology of the invention can be widely used in the manufacture of glass-steel structure boats, glass-steel models, sculptures, brackets and glass-ste...

Embodiment 2

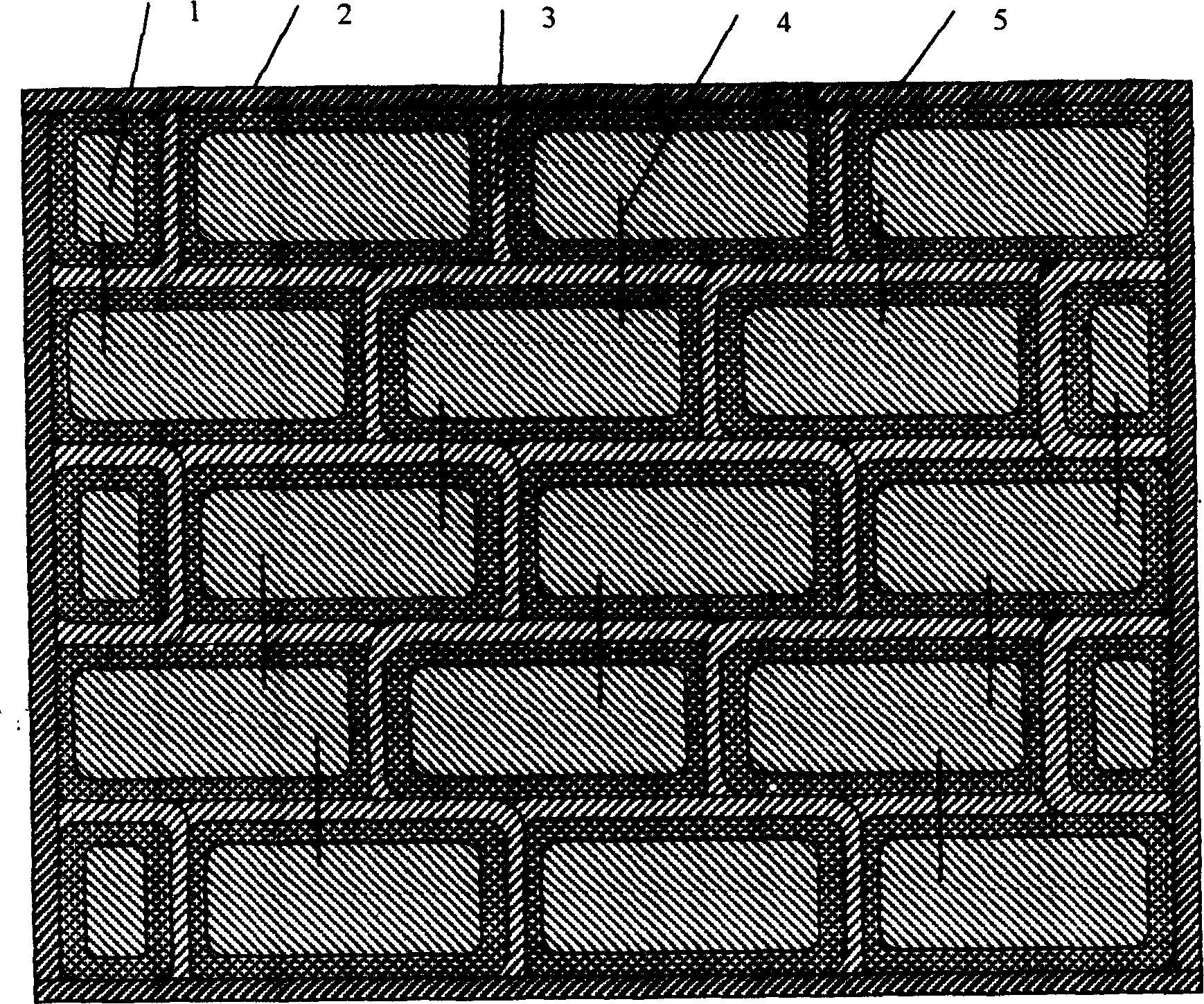

[0028] The present invention takes the foam material and cuts it into the required foam core material 1 according to the drawings. Epoxy resin 3 with fillers was uniformly blended with 72% by weight of epoxy resin, 18% by weight of ethylenediamine, and 10% by weight of quartz sand. A glass mat 2 is wound on a foam core material 1, and then epoxy resin 3 with a filler is coated on the bonding surfaces of the foam core materials wound around a plurality of glass fiber mats. Use positioning nails 4, fixtures, and pattern positioning to build a glass fiber reinforced plastic wall blank; the surface of the naturally dry wall blank is then pasted with glass fiber reinforced plastic resin, and glass cloth 5 is pasted. After drying, it is polished and modified to form the required glass fiber reinforced plastic wall. finished product. The technology of the invention can be widely used in the manufacture of glass-steel structure boats, glass-steel models, sculptures, brackets and glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com