Rotary indexing press

A press and indexing technology, which is applied in the direction of presses, material forming presses, household components, etc., can solve problems such as unsuitable for pressing tasks and damage to the support system of the indexing plate, so as to optimize the return on investment period and broaden the application Effect of range, high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

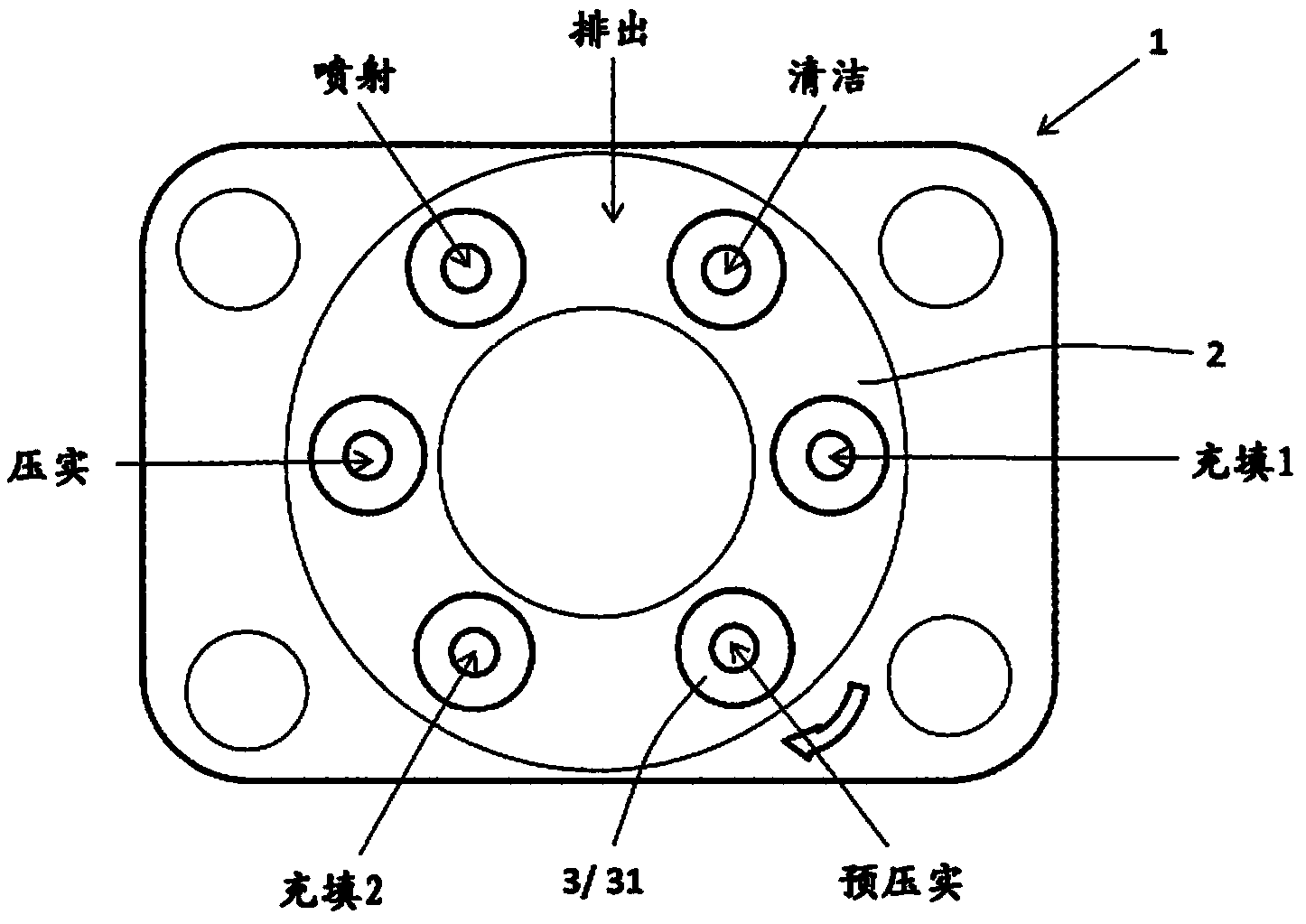

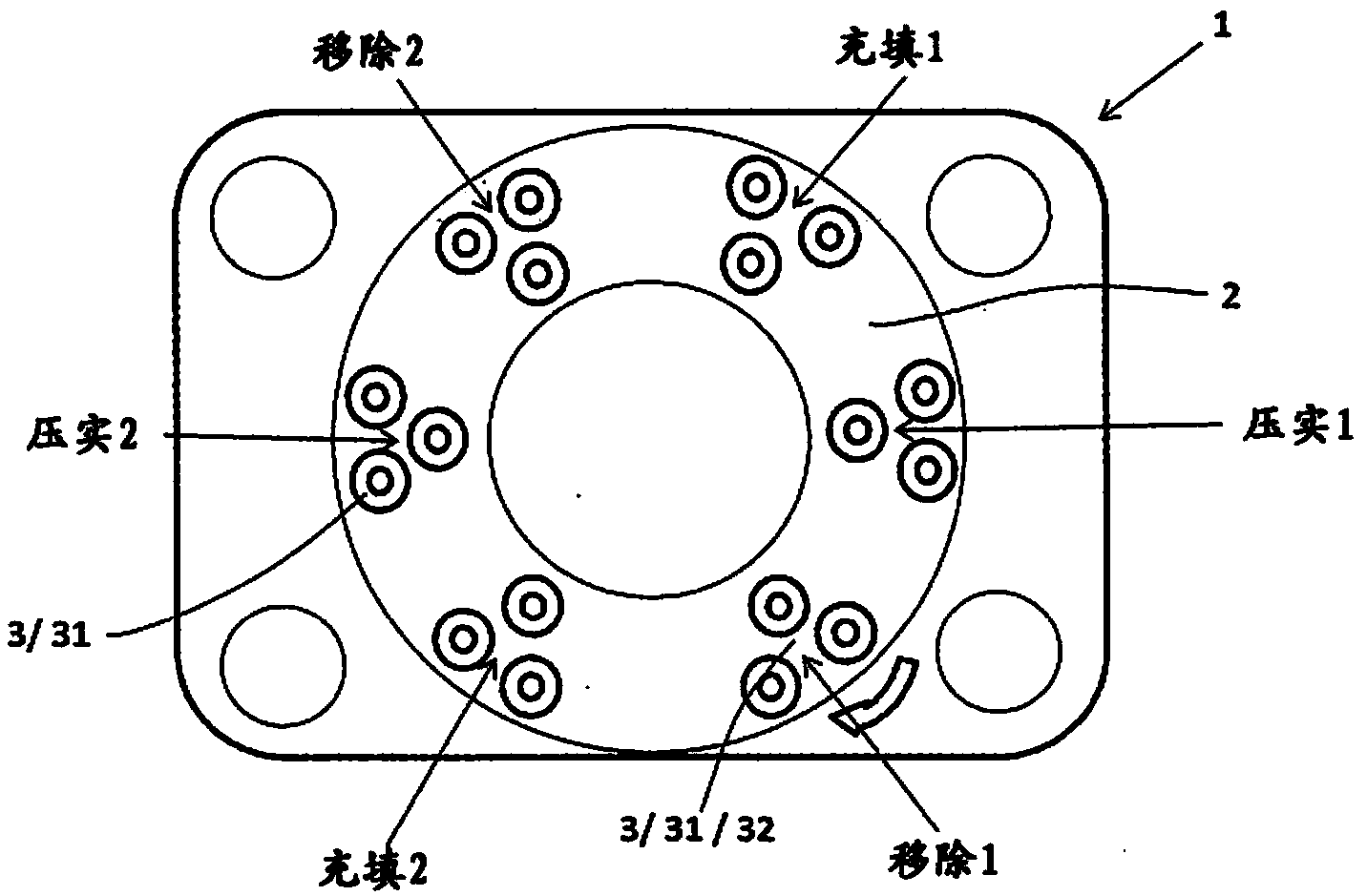

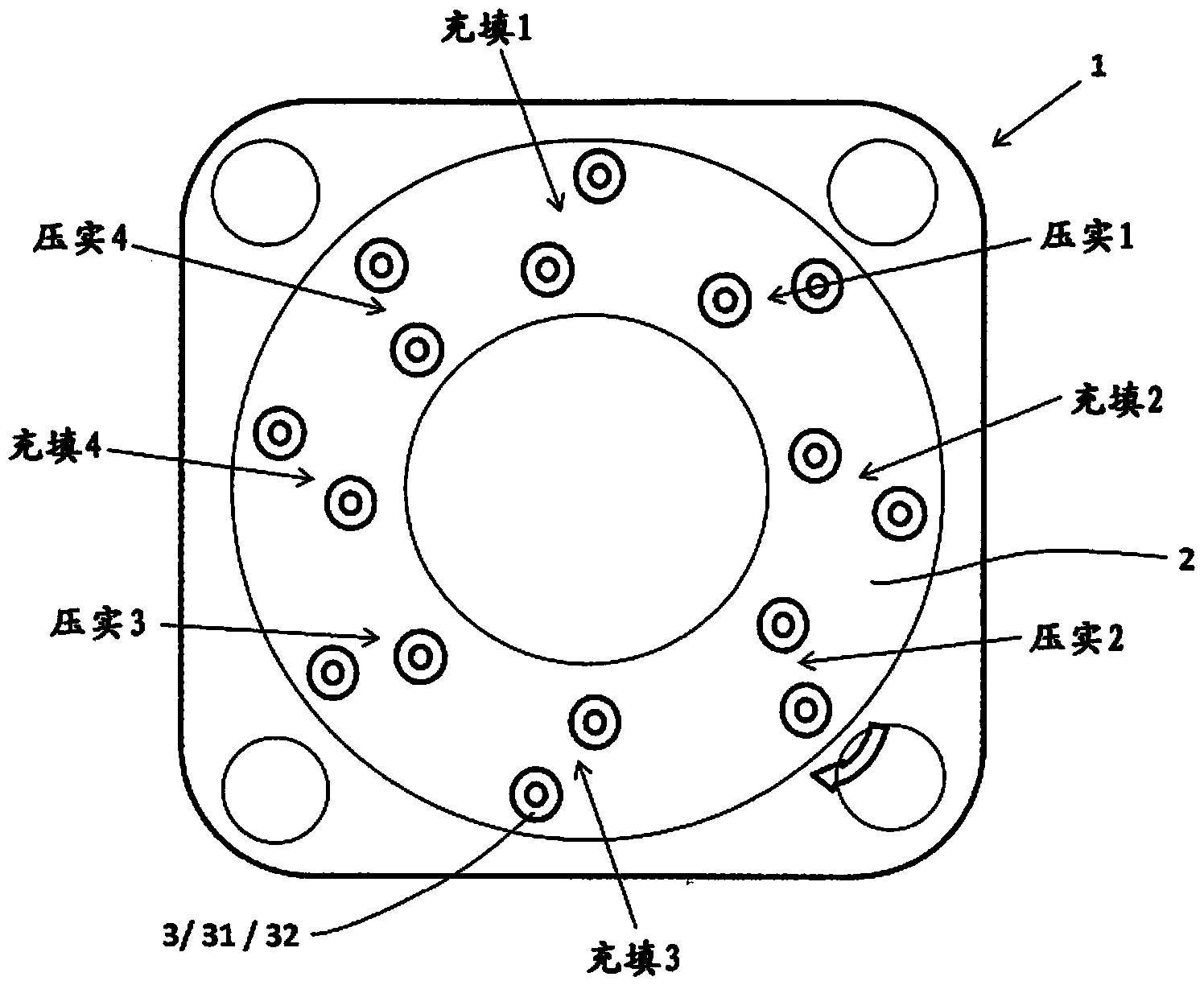

[0034] exist Figure 1-5 , it can be seen that the rotary indexing press 1 is provided with an indexing plate 2, said plate is provided with a plurality of processing stations 3, and a die and tool punching machine 31, of which only one element is identified with a reference number for the sake of clarity . In the diagram shown, the indexing plate 2 of the rotary indexing press 1 always moves clockwise. Figure 2-5 A number of tool cavities 32 are also shown.

[0035] exist figure 1 In , a two-stage filling with a single tool cavity and a two-stage compaction process are shown. Multiple fillings allow the use of different materials, which is especially advantageous given the nature of the workpiece. Following the final compaction step, the workpiece is ejected and ejected. Subsequently, the processing station 3 and the die and tool punch 31 are cleaned. With each indexing cycle of the indexing disk 2 a green compact is produced.

[0036] exist figure 2 , a single-stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com