Large-diameter high-purity oxygen-free copper cast blank horizontal continuous casting process and connected furnace

A horizontal continuous casting, oxygen-free copper technology, applied in the field of oxygen-free copper casting, can solve the problems of difficult control of oxygen content, low production efficiency, high production cost, etc., and achieve high yield, low cost, strong deoxidation and dehydrogenation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

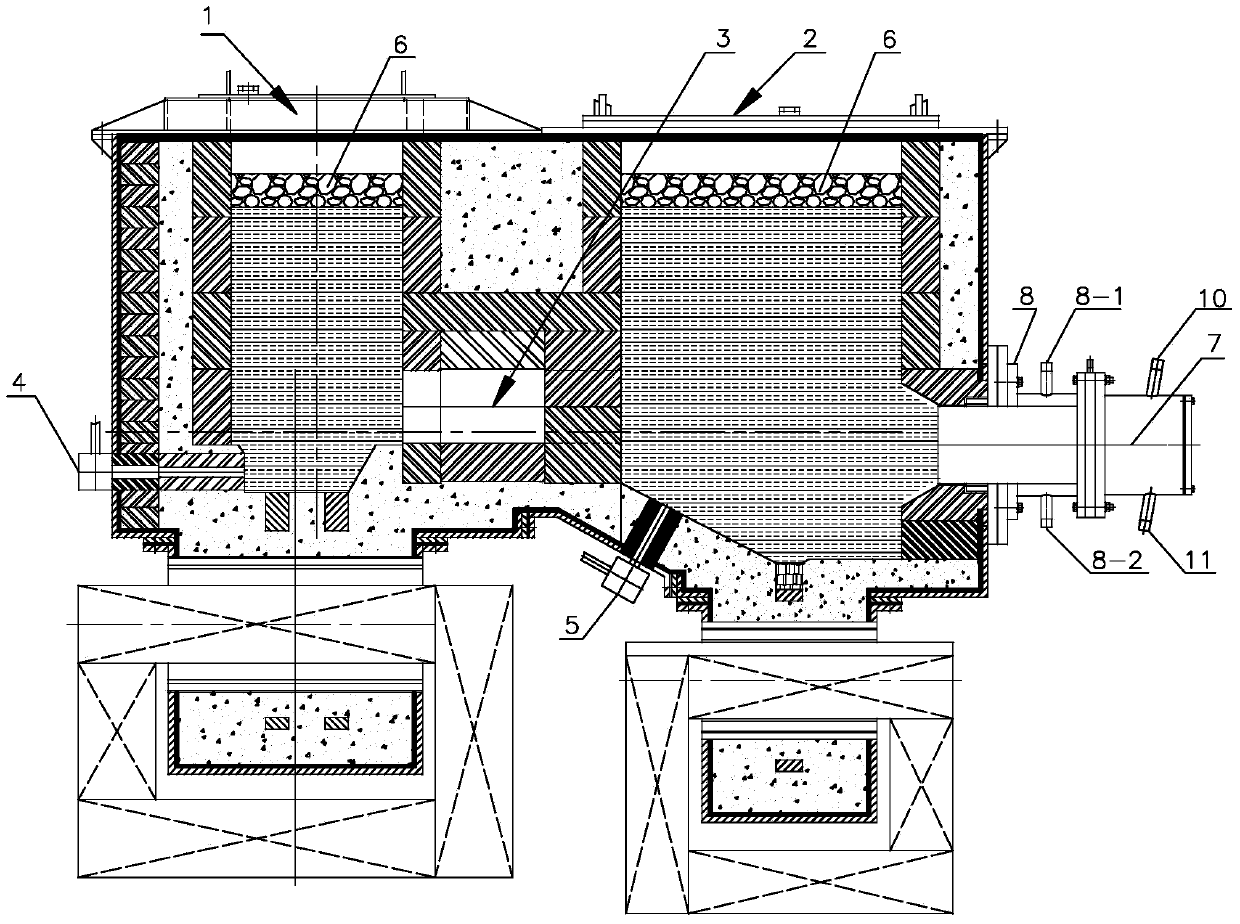

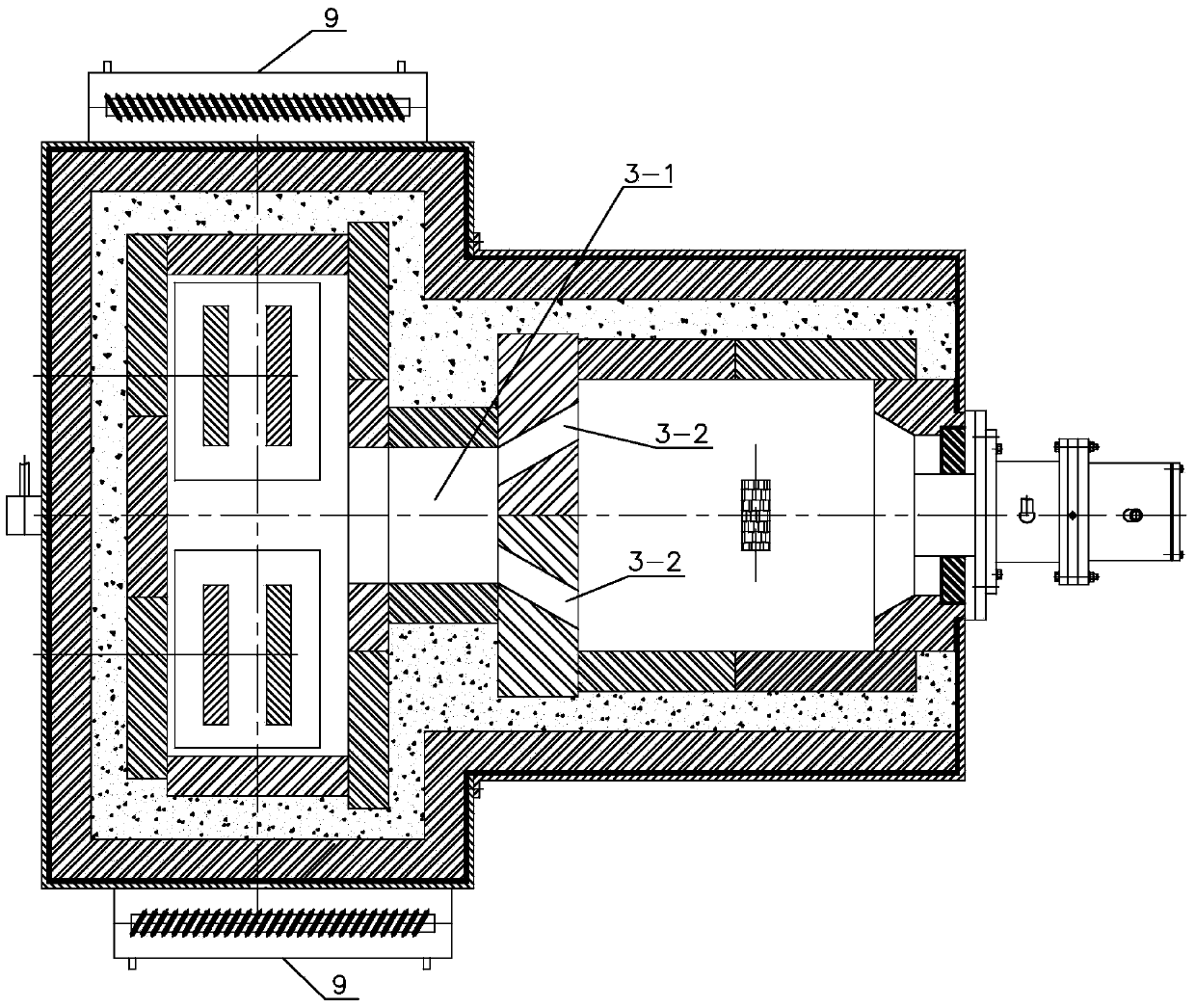

[0039] refer to figure 2 image 3 The conjoined furnace used in this embodiment includes a melting furnace 1, a holding furnace 2 and a crystallizer 7. The bottom of the melting furnace 1 is connected to the bottom of the holding furnace 2 through a pipeline, and the pipeline communicating between the melting furnace 1 and the holding furnace 2 includes The main channel 3-1 and the branch channel 3-2, one end of the main channel 3-1 communicates with the smelting furnace 1, and the other end flows into the holding furnace 2 through two branch channels 3-2.

[0040] like figure 2 , the smelting furnace 1 and the holding furnace 2 are provided with a bamboo charcoal layer 6, the molten liquid outlet of the holding furnace 2 is connected to the graphite crystallizer 7, the graphite crystallizer 7 is equipped with a spiral water jacket 8, and the spiral water jacket 8 has a cooling water outlet 8-1 and cooling water inlet 8-2.

[0041] The melting channel in the holding furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com