Regeneration method of titanium-silicon molecular sieve catalyst

A titanium-silicon molecular sieve and catalyst technology, which is applied in the field of titanium-silicon molecular sieve catalyst regeneration, can solve the problems of low catalyst activity recovery rate and long operation time, and achieve the effects of improving the activity recovery rate, reducing material consumption and improving regeneration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

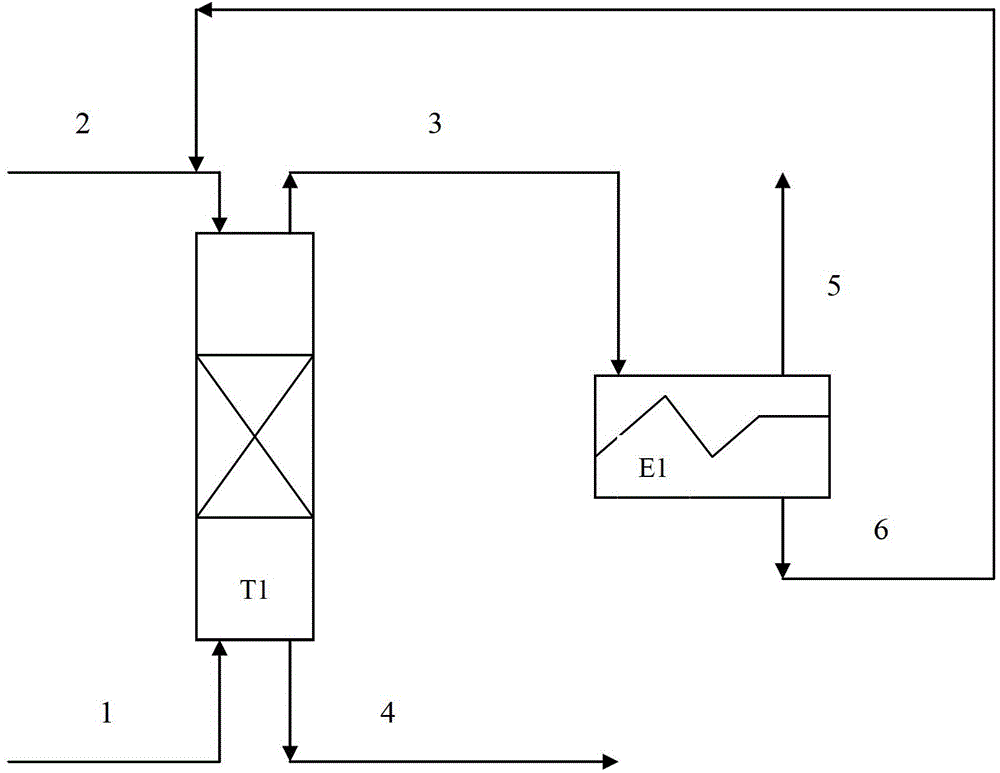

Method used

Image

Examples

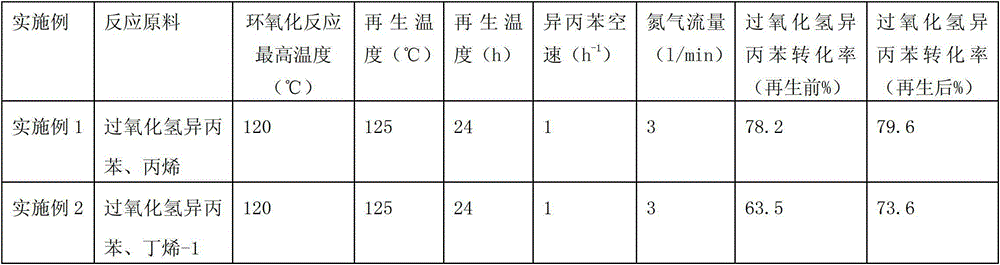

Embodiment 1

[0022] The formed titanium-silicon molecular sieve catalyst is loaded into a fixed-bed reactor. The raw materials for the reaction are cumene hydroperoxide and liquid polymer grade propylene. The weight space velocity of cumene hydroperoxide is 1.0h -1 , the reaction pressure is 4.0Mpa, and the initial reaction temperature is 70°C. At regular intervals, sample analysis is carried out from the sampling port, and sodium thiosulfate is used for titration analysis to calculate the conversion rate of cumene hydroperoxide. After the epoxidation reaction was carried out for 2000 hours, when the reaction temperature rose to 120° C., the epoxidation reaction test was stopped, and the cumene hydroperoxide raw material was stopped first, and then the propylene raw material was stopped. At this time, the catalyst solvent regeneration test was carried out again. In the fixed-bed reactor, the cumene solvent is passed, and the cumene is injected at a weight space velocity of 1h -1 It flo...

Embodiment 2

[0024] In the epoxidation reaction, the reaction raw materials are cumene hydroperoxide and butene-1, and the reaction generates butylene oxide. Other oxidation reactions and regeneration conditions are the same as in Example 1. The reaction results are shown in Table 1.

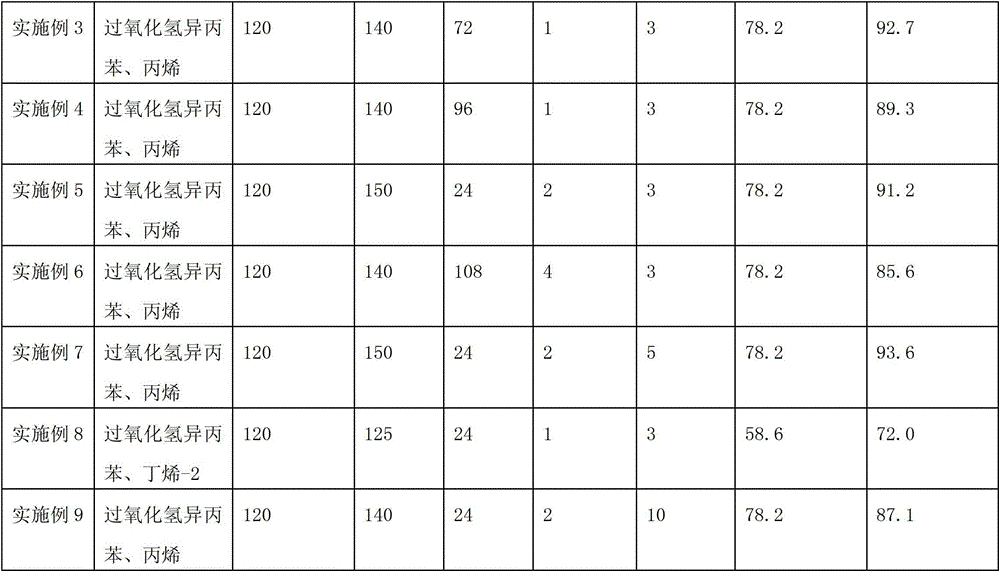

Embodiment 3

[0026] The epoxidation reaction conditions were the same as in Example 1. During the catalyst solvent regeneration test, the temperature of the catalyst bed was controlled to 140°C, and the cumene was -1 Flow through the catalyst layer from the top, nitrogen enters the catalyst layer from the bottom with a flow rate of 3 l / min, and the outlet nitrogen tail gas enters the condensing system to cool the cumene solvent obtained and can return to the fixed-bed reactor. After passing through the cumene solvent for regeneration for 72 hours, the materials were switched, and the epoxidation reaction was carried out again through cumene hydrogen oxide and propylene raw materials. The reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com