Feeding packing auger type submersible mud pump

A mud pump and submersible pump technology, which is applied in the field of feeding auger type submersible mud pump, can solve the problems of low sediment extraction efficiency, low working efficiency, poor sludge cleaning effect, etc., so as to improve the extraction and discharge effect and the extraction efficiency. , the effect of improving the emission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

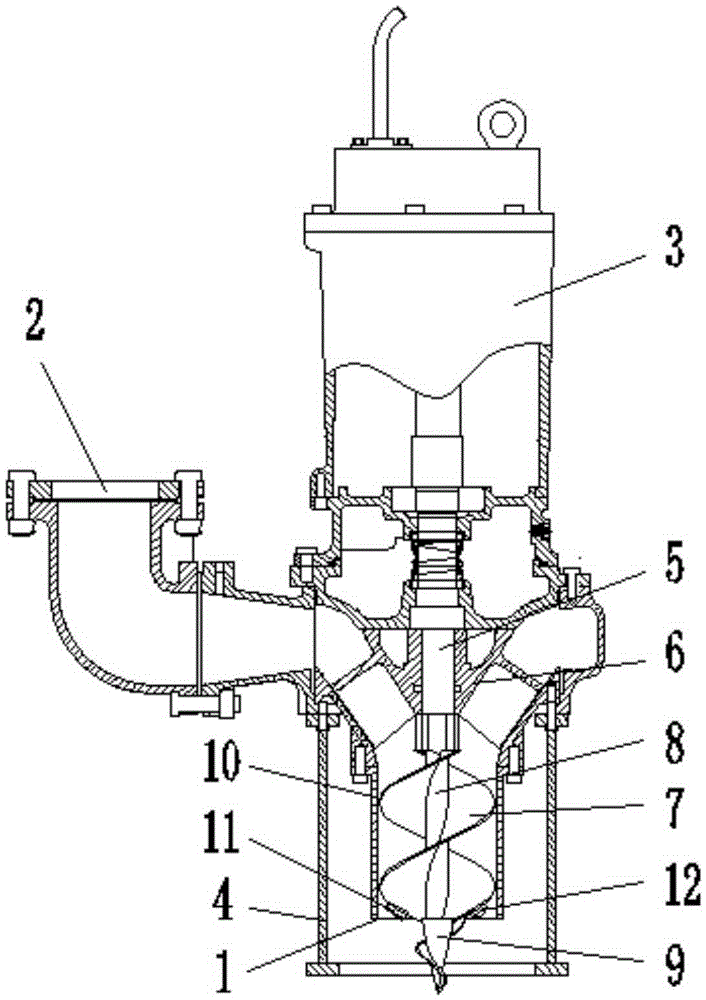

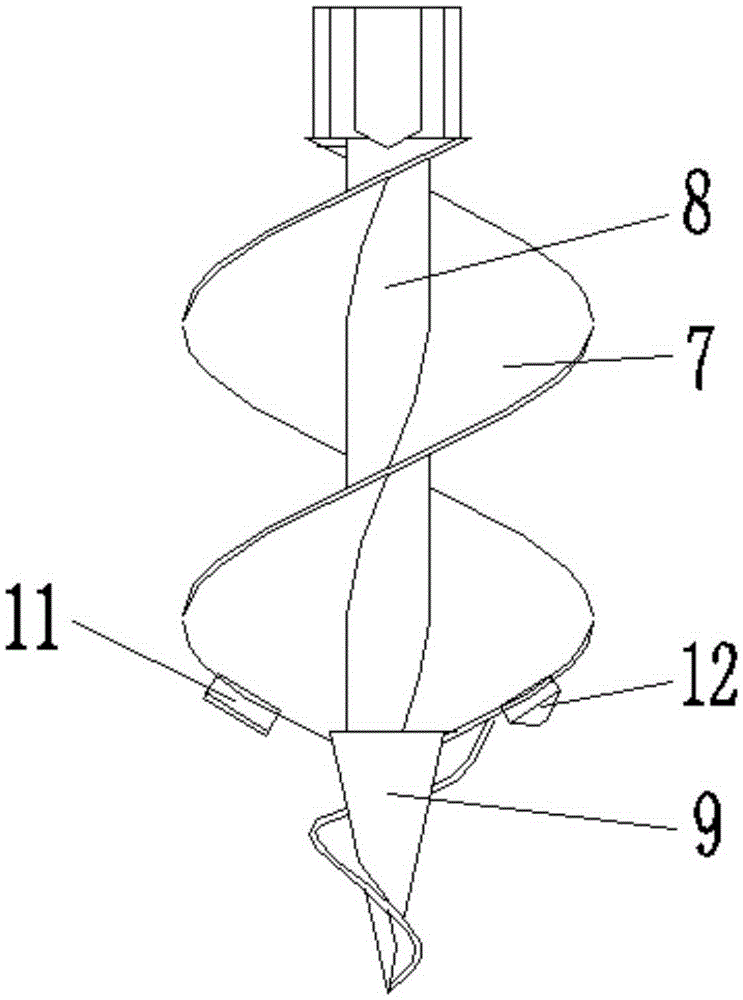

[0017] The invention relates to a feeding auger type submersible mud pump. The submersible pump includes a pump body 3 with a water inlet and a discharge port 2. The pump body 3 is provided with a vertical auger assembly driven by a motor. The vertical auger The dragon assembly includes an impeller shaft 5 and an impeller 6. The impeller 6 rotates to throw the mud to the drain 2. The end of the impeller shaft 5 is connected to a reamer shaft 8 with a helical blade 7. The end of the reamer shaft 8 is provided with a drill bit 9. The periphery of the blade 7 is provided with a guide pipe 10 , the port 1 of the guide pipe 10 serves as the water inlet of the submersible pump, and the drill bit 9 exposes the port 1 of the guide pipe 10 .

[0018] Specific examples, such as figure 1 with figure 2 As shown, in the specific implementation of the operation, the upper end of the mud pump is provided with lifting lugs, which are tied into the place where sewage needs to be discharged t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com