Plastic mixed-processing equipment

A processing equipment and compounding technology, applied in the field of plastic compounding and processing equipment, can solve the problems of troublesome operation, inability to large-scale continuous production, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

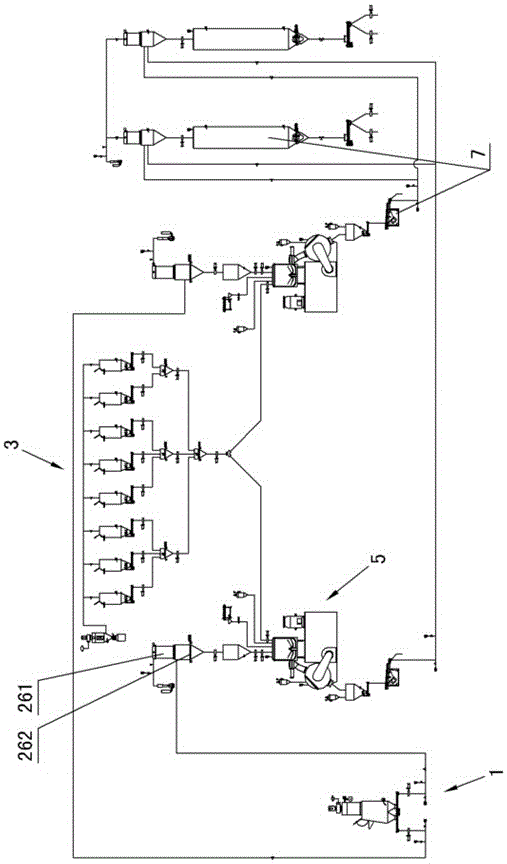

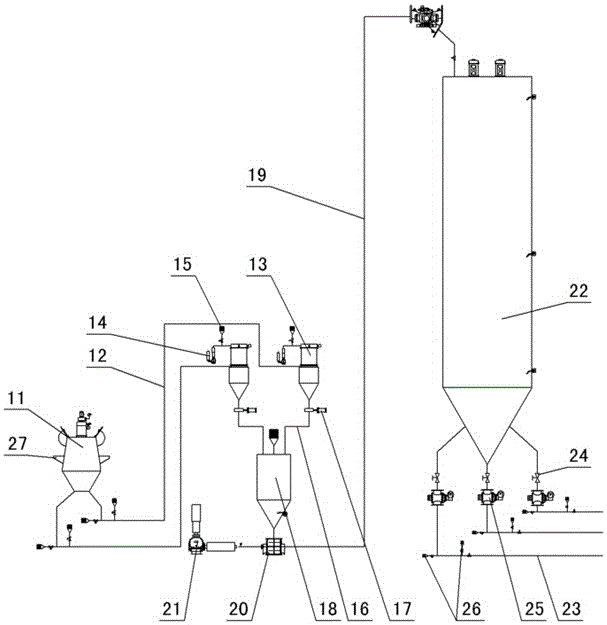

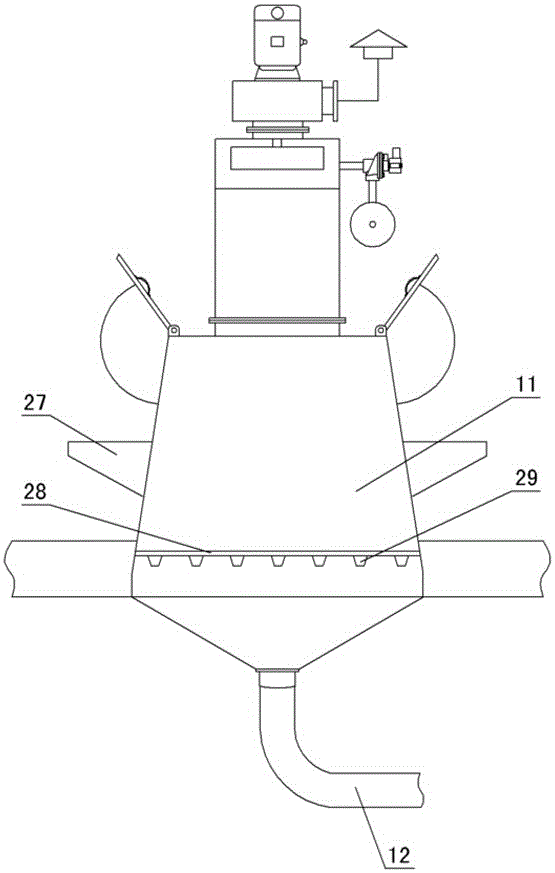

[0015] The present invention relates to a plastic compounding processing equipment, such as figure 1 — Figure 8As shown, it is characterized in that it includes a main material conveying mechanism 1, an auxiliary material conveying mechanism 3, a mixing and stirring mechanism 5 and a finished material sieve material conveying mechanism 7, and the main material conveying mechanism 1 includes a main material feeding bin 11, and the main material The main material suction pipe 12 is connected under the feeding bin, and the other end of the main material suction pipe is connected to the main material vacuum feeder 13. The main material vacuum pump 14 and the main material automatic air supply device 15 are installed on the main material vacuum feeder. The main material feeding pipe 16 is connected under the feeding machine, the gravity flap valve 17 is arranged on the main material feeding pipe, the main material transfer warehouse 18 is connected under the feeding pipe, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com