Special fabric ammonia-containing exhaust gas circulating purification and recovery technology

A waste gas circulation and special technology, applied in the direction of air quality improvement, chemical instruments and methods, and separation of dispersed particles, can solve the problems of increased energy consumption, low ammonia concentration, large water consumption, etc., and achieve the effect of improving the stripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

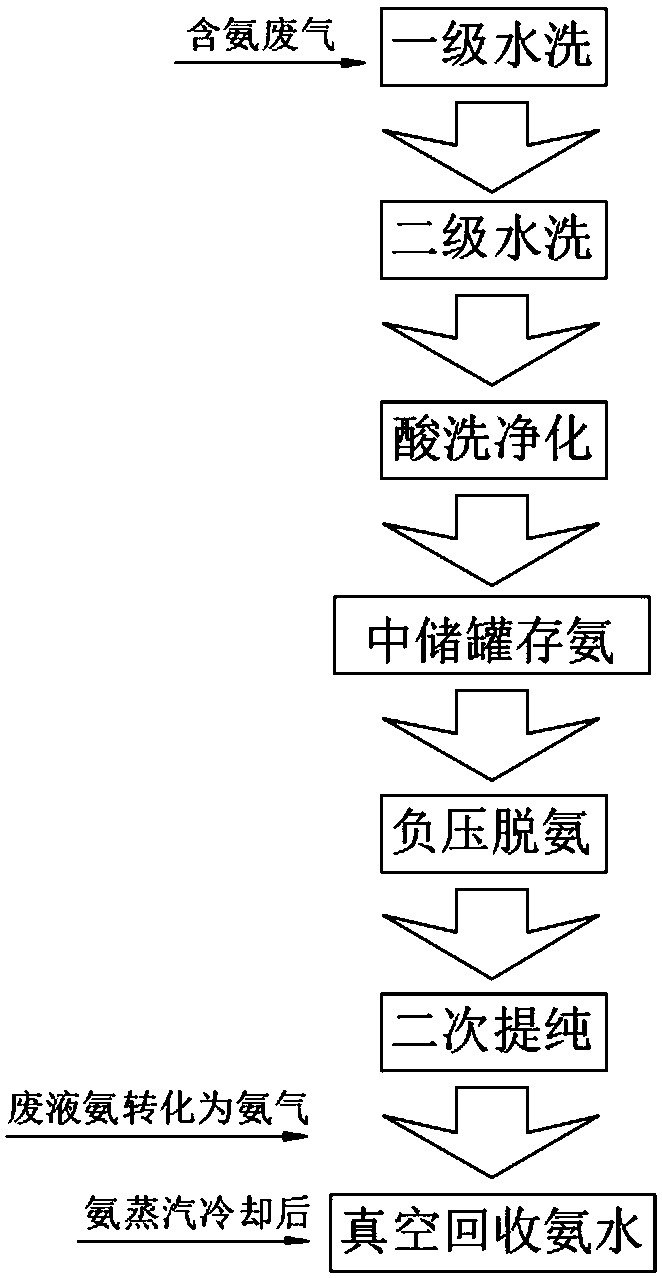

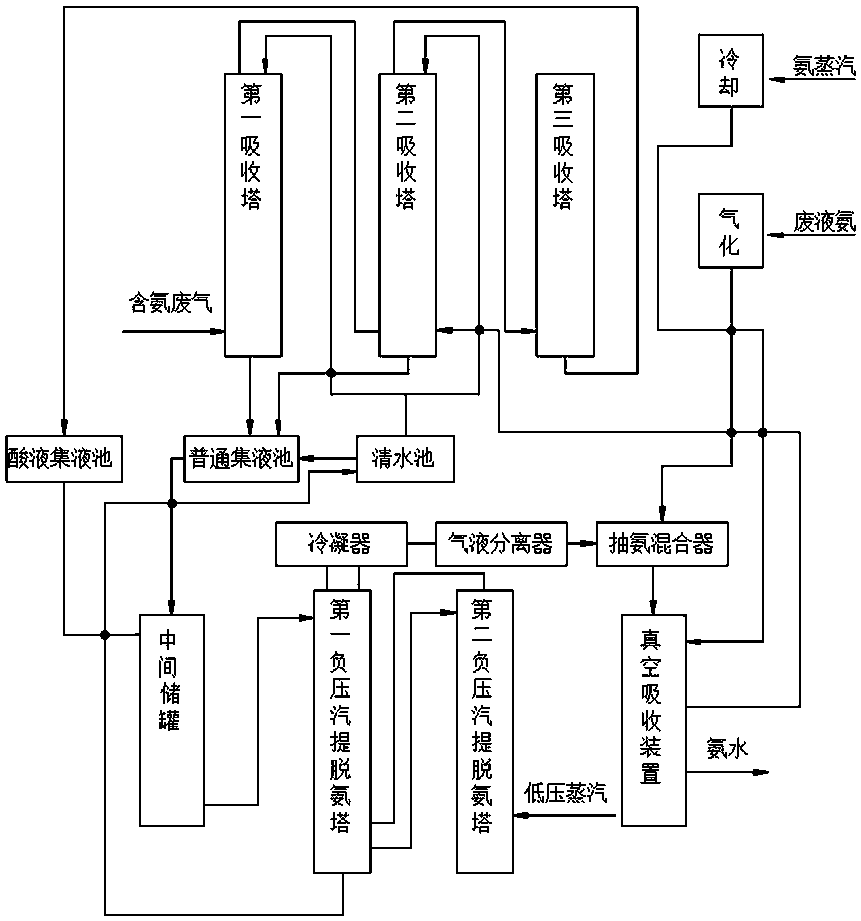

[0047] see Figure 1-2 , special fabric ammonia waste gas circulation purification recovery process, including the following steps:

[0048] 1. First-level water washing, the ammonia-containing exhaust gas source passes through the gas cooler and precision filter in sequence between compression, the gas cooler reduces the temperature of the ammonia-containing exhaust gas source from 40-90°C to 10-20°C, and the precision filter adopts Micron-level gas precision filter, the compressor pressurizes the ammonia-containing waste gas source to a pressure range of 1.0MPa-2.0MPa, and the ammonia-containing waste gas source in the special fabric production process passes through the compressor and passes through the bottom side of the first absorption tower. At the same time, the clean water in the clean water tank enters from the upper part of the first absorption tower through the water delivery pipe, and the first physical absorption of ammonia-containing waste gas is carried out thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com