Impurity removing process for rear earth feed liquid

A rare earth material liquid and process technology, which is applied in the field of rare earth material liquid impurity removal process, can solve the problems of solid waste, low grade, and rare earth loss due to ineffective use of sodium sulfide method, and achieve continuous, improved processing speed, and impurity removal The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

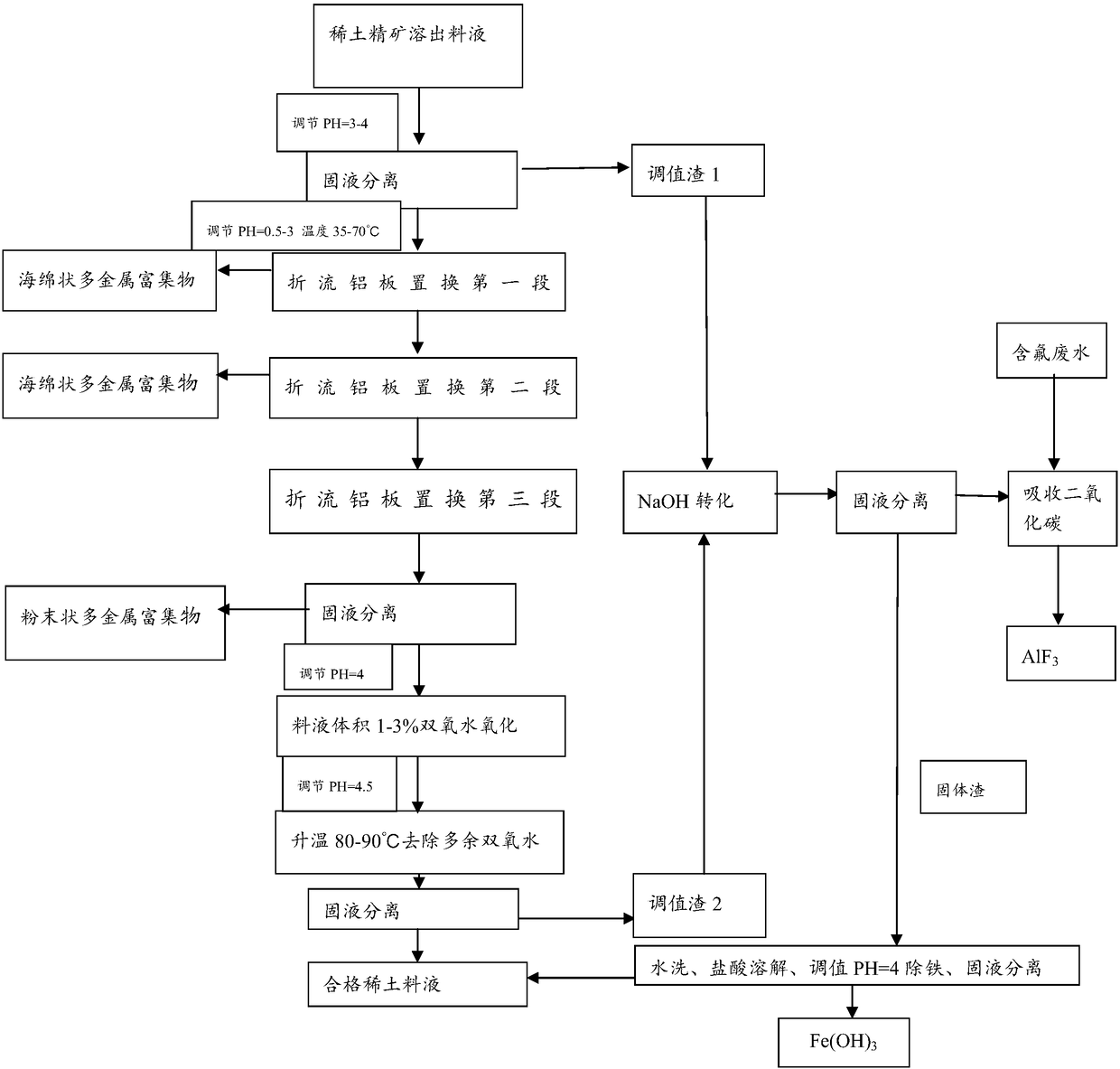

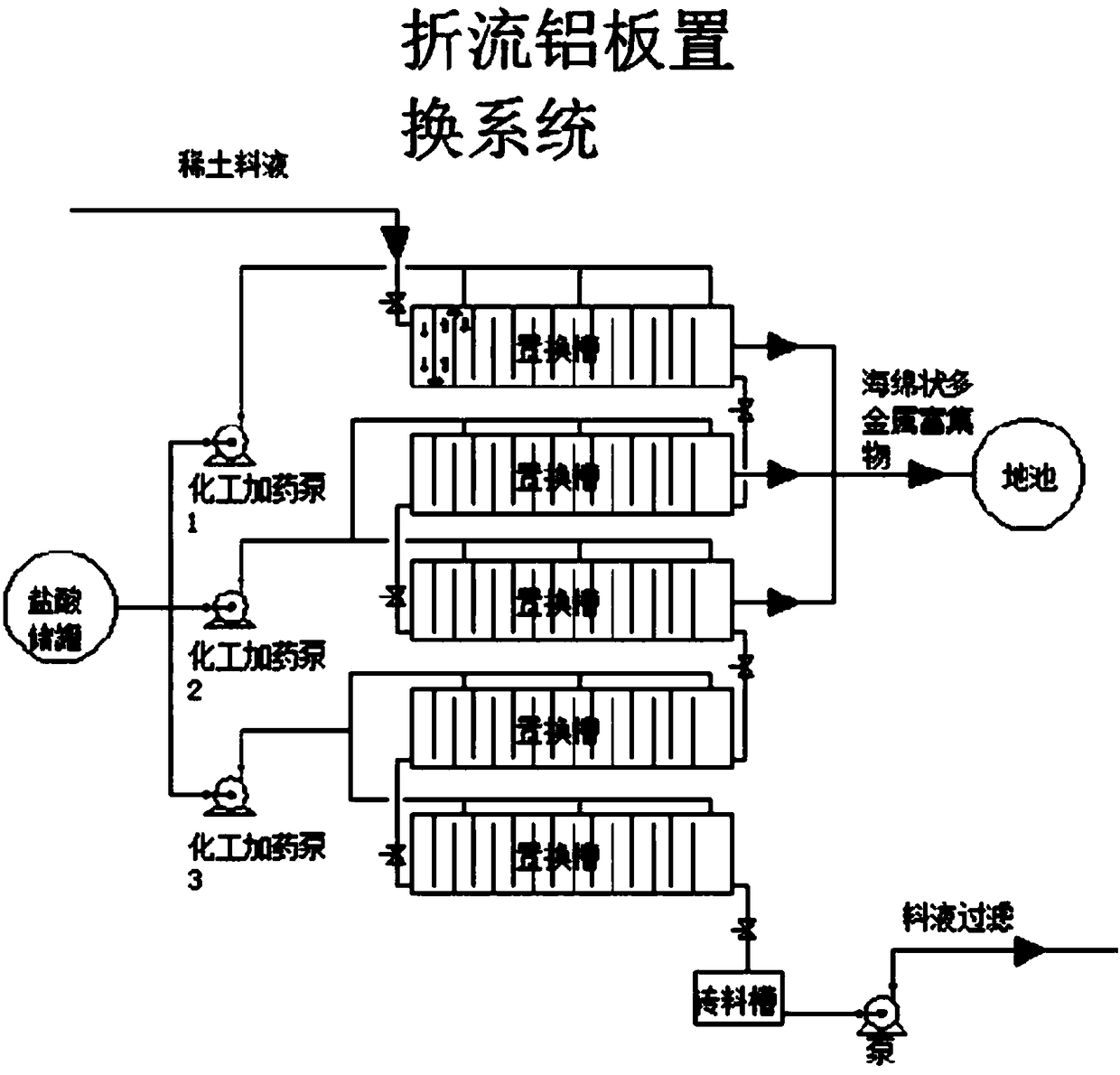

Method used

Image

Examples

Embodiment 1

[0048] Get 2L rare earth feed liquid, detect the content of each component in this rare earth feed liquid as follows: H + 12g / L, REO120g / L, FeO1.5g / L, PbO1.1g / / L, Al 2 o 3 0.4g / L, CuO0.003gL, put in a 3000ml beaker, use ammonia water to adjust PH=3.5, separate the solid and liquid to obtain adjusted slag Z and feed liquid, then return the feed liquid to the beaker, use hydrochloric acid to adjust the feed liquid PH=2, Heat up to 45°C, add hydrochloric acid to make H + The concentration is 2g / L, add 4 pieces of 100*50*3mm aluminum flakes and react for 20 minutes, collect the spongy polymetallic enrichment on the surface of the feed liquid, take out the aluminum flakes and clean the attachments on the surface of the aluminum flakes; use hydrochloric acid to adjust the feed liquid H + = 1.5g / L, put 4 pieces of aluminum flakes back into the feed solution and add another piece of aluminum flake, react for 30 minutes, collect the spongy polymetallic enrichment on the surface of th...

Embodiment 2

[0050] Get 20L rare earth feed liquid, detect the content of each component in this rare earth feed liquid as follows: H + 12g / L, REO120g / L, FeO1.5g / L, PbO1.1g / / L, Al 2 o 3 0.4g / L, CuO0.003gL, placed in a 25L plexiglass tank, using ammonia water to adjust PH=4, after solid-liquid separation, the feed liquid is returned to the plexiglass tank, and the solid-liquid separation obtains the adjustment slag H and the feed liquid, and then Return the feed liquid to the plexiglass tank, adjust the pH of the feed liquid to 1 with hydrochloric acid, raise the temperature to 50°C, add hydrochloric acid to make the H + The concentration is 3.5g / L, add 5 pieces of 250*250*3mm aluminum flakes and react for 20 minutes, collect the spongy polymetallic enrichment on the surface of the feed liquid, take out the aluminum flakes and clean the attachments on the surface of the aluminum flakes; use hydrochloric acid to adjust the feed liquid H + =2g / L, put 5 pieces of aluminum flakes back into th...

Embodiment 3

[0052] Detect the content of each component in this rare earth feed liquid as follows: H + 12g / L, REO120g / L, FeO1.5g / L, PbO1.1g / / L, Al 2 o 3 0.4g / L, CuO0.003gL, add to the reaction tank, use ammonia water in the reaction tank to adjust PH=4.5, flocculation, clarification, plate and frame filter, the feed liquid enters another reaction tank, use hydrochloric acid to adjust the feed liquid PH=3 , heated to 55°C, the 2m 3 The effective volume of feed liquid introduction is 2.5m 3 Replacement tank made of PP material. Add 20 sheets of 1000*1000*5mm aluminum plates into the reaction tank, and add hydrochloric acid during the reaction of the aluminum plates for 20 minutes to ensure that the H + =2.5g / L, collect the spongy polymetallic enrichment on the surface of the feed liquid, take out the aluminum flakes and clean up the attachments on the surface of the aluminum flakes, and use hydrochloric acid to adjust the feed liquid H + =1.5g / L, put the aluminum plate back into the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com