A kind of contact wire and its preparation method and application

A contact line and horizontal line technology, applied in overhead lines, cable/conductor manufacturing, used to reduce the size of conductors/cables, etc., can solve problems such as time-consuming, poor contact line surface quality, and no longer satisfying production efficiency , to achieve the effect of reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

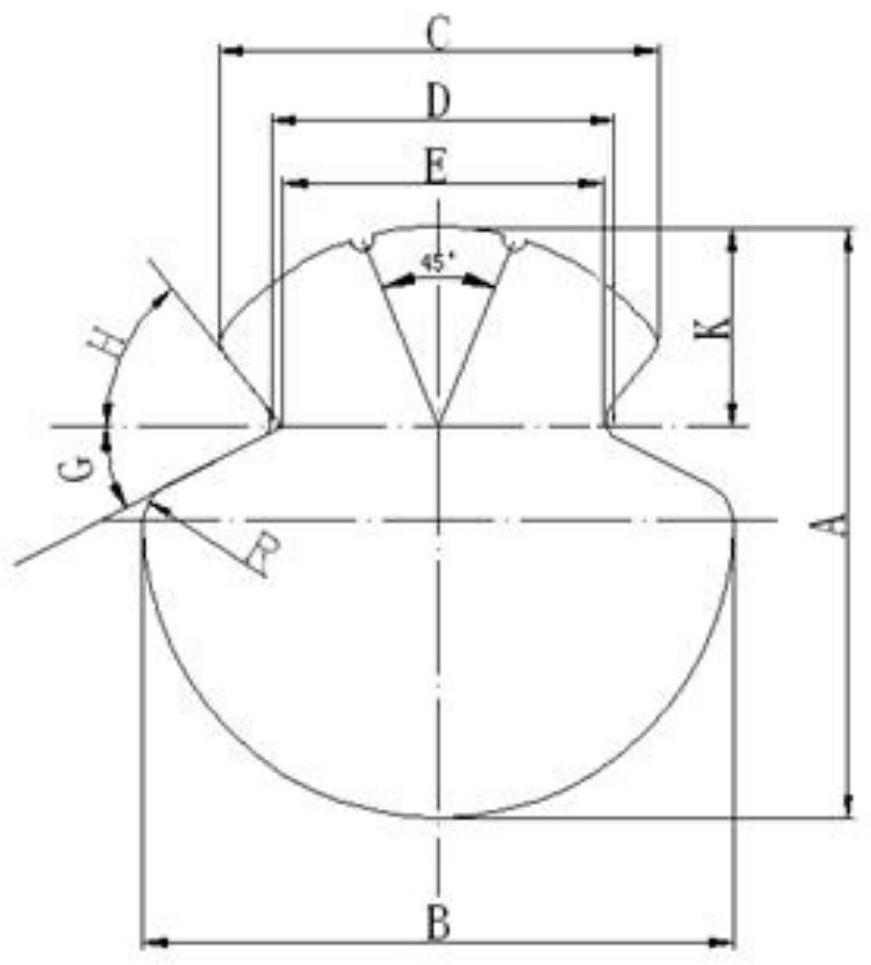

[0040] This embodiment provides a 120mm 2 The preparation method of copper-silver contact wire (CTA120) specifically comprises the steps:

[0041] Four-pass special-shaped molds (the dimensions of the special-shaped molds are shown in Table 1 below) are used for drawing, and the molds are loaded into the four-mode giant drawing machine in order from large to small, and then the copper-silver alloy extrusion rods are sequentially passed through from large to small. A small special-shaped mold is obtained by drawing.

[0042] Table 1:

[0043]

[0044] The deformation of each pass mold is 20%-25%, 27%-33%, 27%-32% and 23%-27%.

[0045] Specifically:

[0046] use Copper-silver alloy extruded rods, after the first After the mold is drawn, it becomes special-shaped pull rod, and then through the second After the mold is drawn, it becomes pull rod, then pass through the third After the mold is drawn, it becomes The pull rod, and finally through the finished produ...

Embodiment 2

[0048] This embodiment provides a 150mm 2 The preparation method of copper-silver contact wire (CTA150), specifically comprises the steps:

[0049] Four-pass special-shaped molds (the dimensions of the special-shaped molds are shown in Table 2 below) are used for drawing, and the molds are loaded into the four-mode giant drawing machine in order from large to small, and then the copper-silver alloy extrusion rods are passed through in order from large to small. A small special-shaped mold is obtained by drawing.

[0050] Table 2:

[0051]

[0052] The deformation of each pass mold is 20%-25%, 27%-33%, 27%-32% and 23%-27%.

[0053] Specifically:

[0054] use Copper-silver alloy extruded rods, after the first After the mold is drawn, it becomes special-shaped pull rod, and then through the second After the mold is drawn, it becomes pull rod, then pass through the third After the mold is drawn, it becomes The pull rod, and finally through the finished product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com