A kind of beryllium material electroless nickel plating pretreatment method

A technology for electroless nickel and beryllium plating, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve problems such as difficulty in obtaining a film layer, and achieve the advantages of short galvanizing time, pollution reduction and remarkable effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

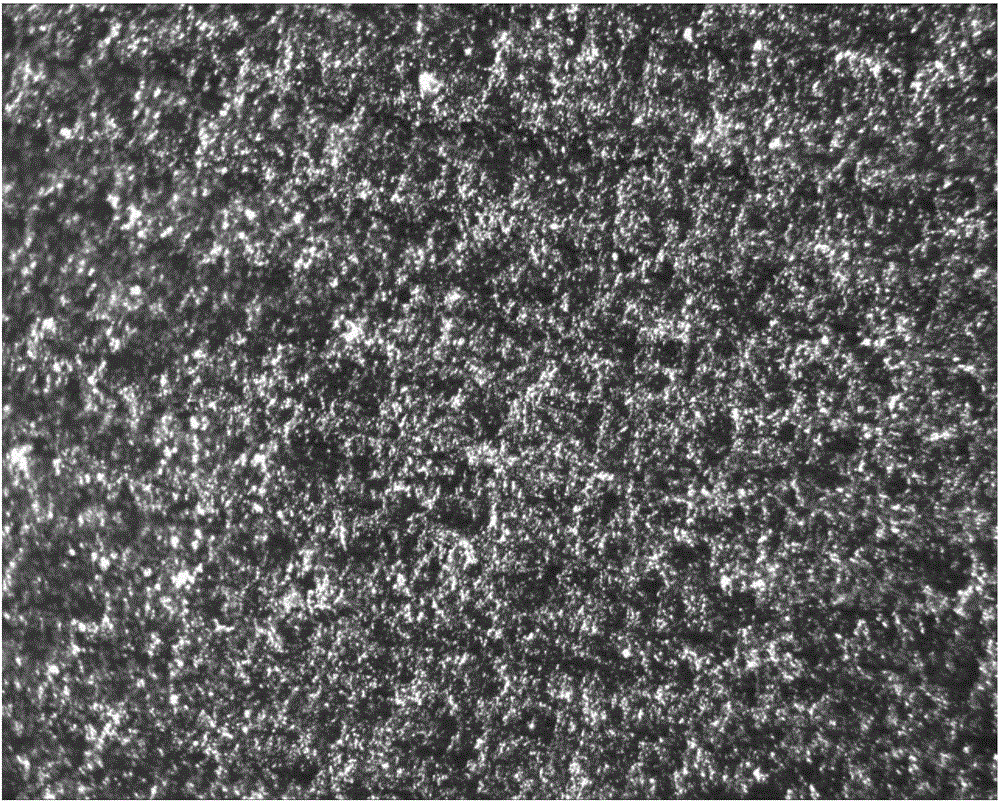

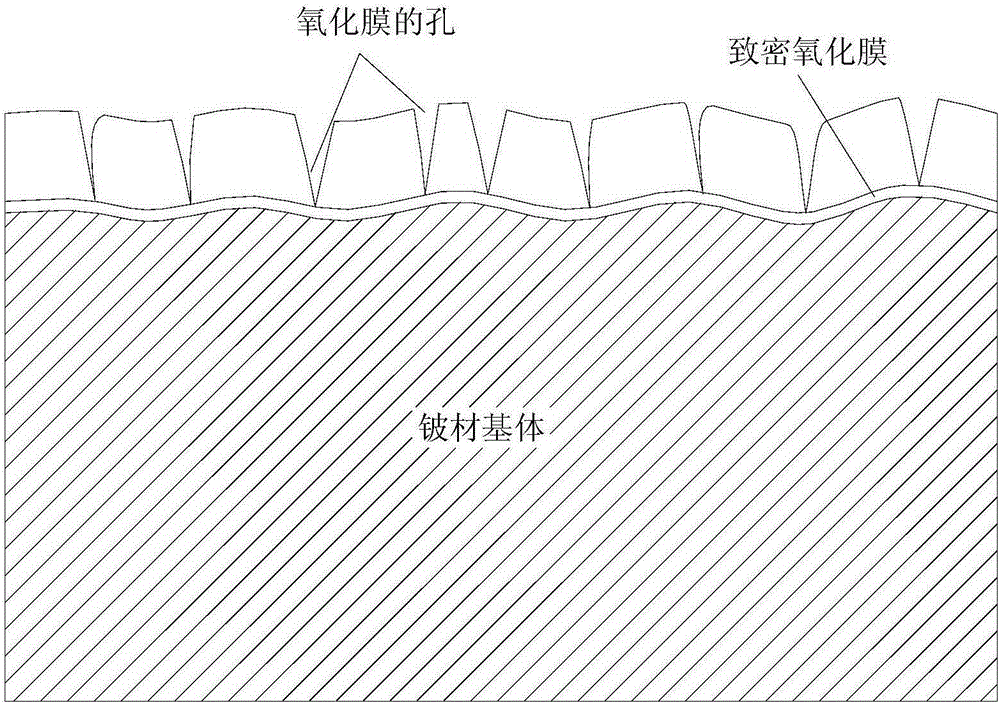

[0028] Wipe the beryllium parts with acetone, then dry the surface with a hair dryer at a temperature of 55 ° C, and then immerse the beryllium parts in 50% alcohol solution for ultrasonic cleaning for 15 minutes. The working power of the ultrasonic cleaning machine is 25KHz. Rinse the beryllium parts after ultrasonic cleaning with deionized water, and then carry out anodic pickling to remove oil. The oil removal solution is 500mL / L sulfuric acid solution, the solution temperature is 25°C, and the applied current density is 4A / dm 2 , anodic pickling degreasing time 2min. The beryllium parts after anodic pickling and degreasing are rinsed with deionized water again, and then the beryllium parts are immersed in 30% nitric acid solution for etching for 20s, and the temperature of the etching solution is 60°C. Rinse the etched beryllium parts with deionized water, and then immerse in a zinc immersion solution prepared by dissolving 20g of zinc sulfate, 5g of ferric chloride and 20...

Embodiment 2

[0031] Change the ultrasonic cleaning time of the alcohol solution in Example 1 to 20min, the working power of the ultrasonic cleaner to 40KHz, and the rest of the conditions are the same as in Example 1.

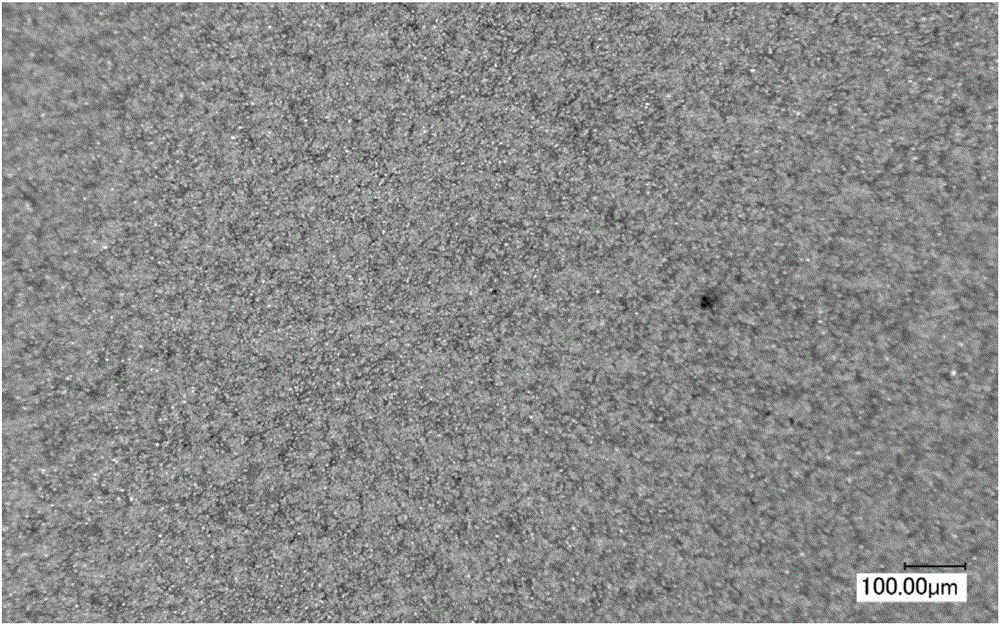

[0032] The electroless nickel plating layer obtained by this method is uniform and continuous, and has a compact surface. With reference to the standard "QJ479-90 Test Method for Bonding Strength of Metal Plating Layers", the thermal shock method is used for testing. Heat the part to 220°C and keep it warm for 30 minutes. After taking it out, put it into cold water immediately. The chemical nickel plating layer has no peeling or peeling phenomenon, and the bonding strength is good.

Embodiment 3

[0034] Change the etching time in the nitric acid solution of Example 2 to 30 s, and the temperature of the etching solution to 50° C., and the other conditions are the same as in Example 2.

[0035] The electroless nickel plating layer obtained by this method is uniform and continuous, and has a compact surface. With reference to the standard "QJ479-90 Test Method for Bonding Strength of Metal Plating Layers", the thermal shock method is used for testing. Heat the part to 220°C and keep it warm for 30 minutes. After taking it out, put it into cold water immediately. The chemical nickel plating layer has no peeling or peeling phenomenon, and the bonding strength is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com