Exhaust gas filter with an m-shaped filter medium

An exhaust gas filter and filter medium technology, applied in membrane filters, dispersed particle filtration, chemical instruments and methods, etc., can solve the problem of high cost of exhaust gas filtration and treatment equipment, high cost of treatment and operation, large filter volume, and large ventilation resistance, etc. problem, to achieve the effect of reducing power, large intercepting area and convenient filter body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

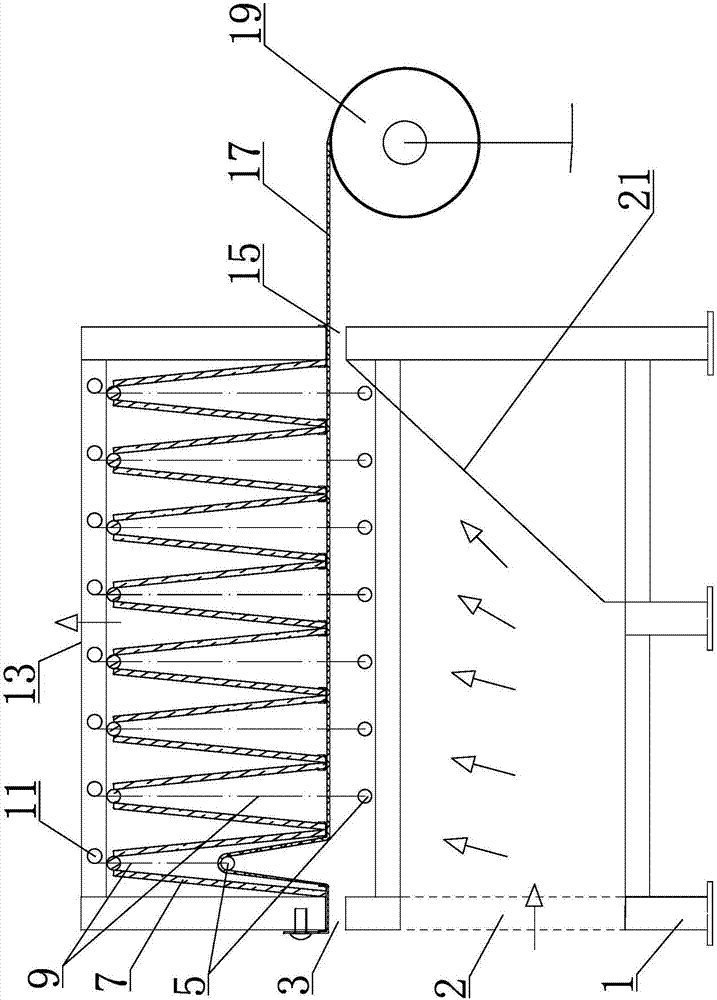

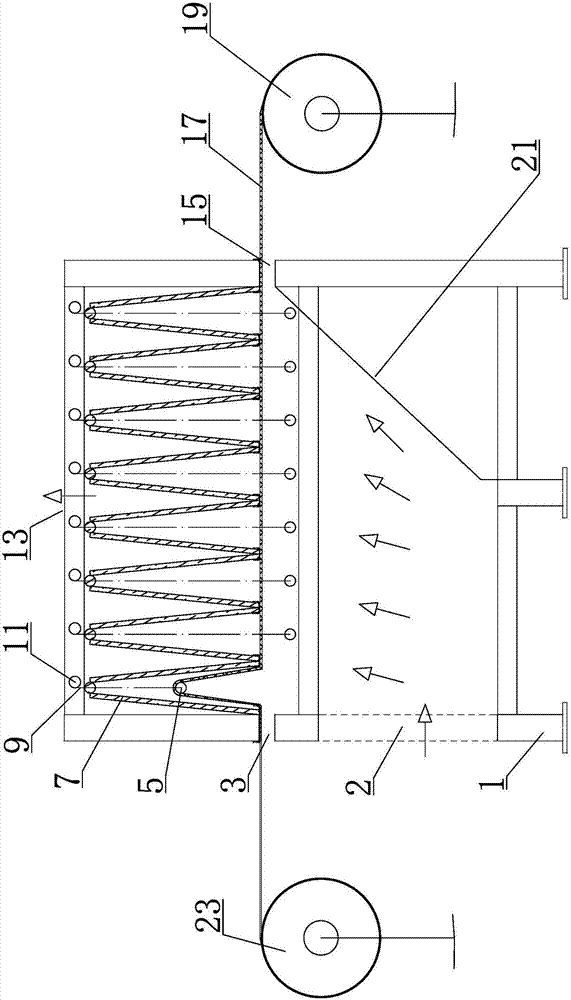

[0024] The filter medium is an M-shaped exhaust gas filter, comprising a base (1) and a filter body (17); the base (1) is provided with an exhaust gas inlet (2) and an exhaust gas outlet (13). Also includes M-shaped bracket (7). The device seat is the integral supporting part of the filter body, which is welded by channel steel and flat steel. According to the characteristics of the exhaust gas, the channel steel can be ordinary carbon steel or stainless steel, or a combination of the two. Standard profiles can be used, and steel plates can also be pressed. The M-shaped support (7) is installed inside the seat on the channel where exhaust gas flows from the exhaust gas inlet to the exhaust gas outlet; the filter body is attached to the working surfaces on both sides of each V-shaped mouth of the M-shaped support. As a flat medium, the filter body is folded into an M shape, which directly increases the interception area per unit space volume, improves the filtration efficiency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com