Patents

Literature

52results about How to "Easy to absorb and collect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

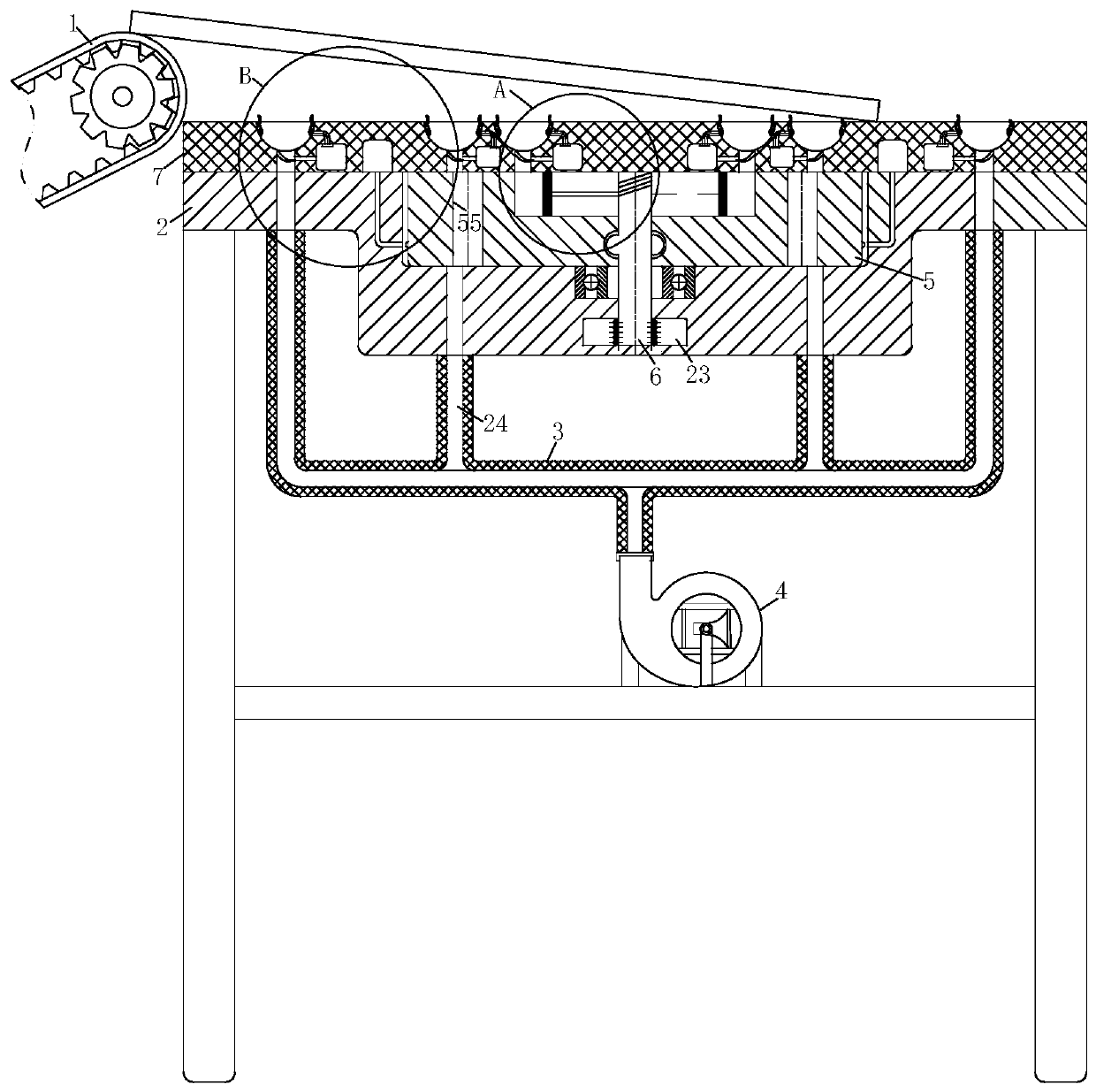

Ocean spilled oil collecting device

ActiveCN104895030AAvoid pollutionCollect thoroughlyWater cleaningGeneral water supply conservationEngineeringConveyor belt

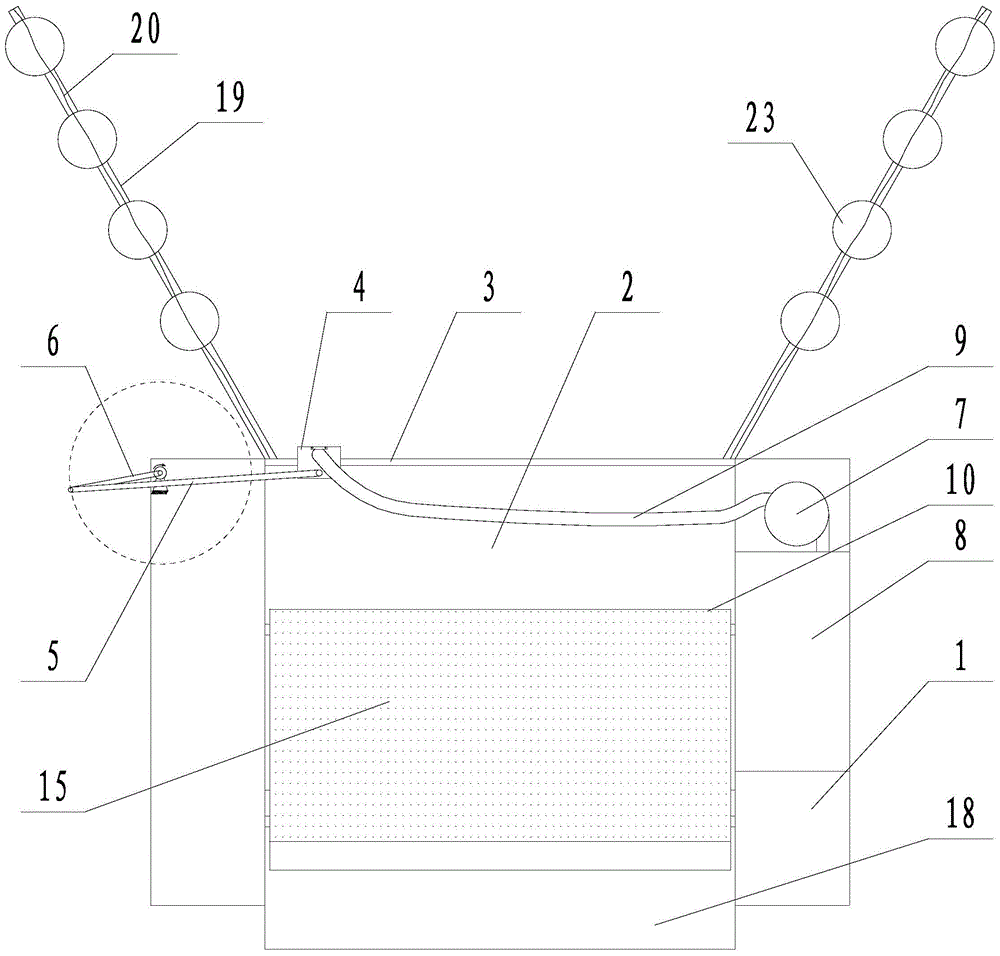

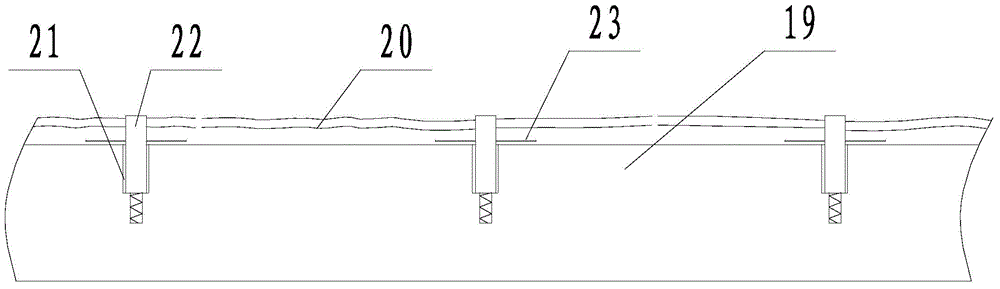

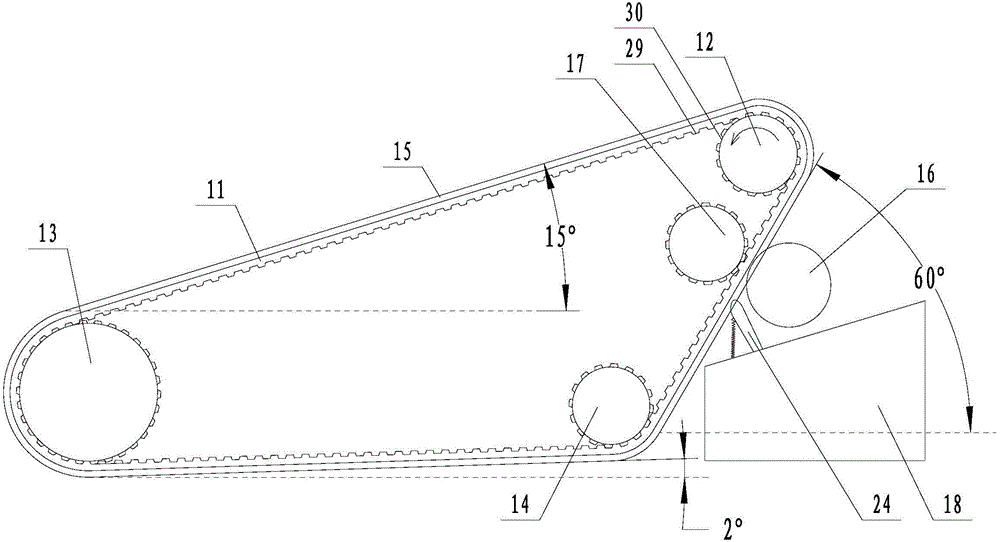

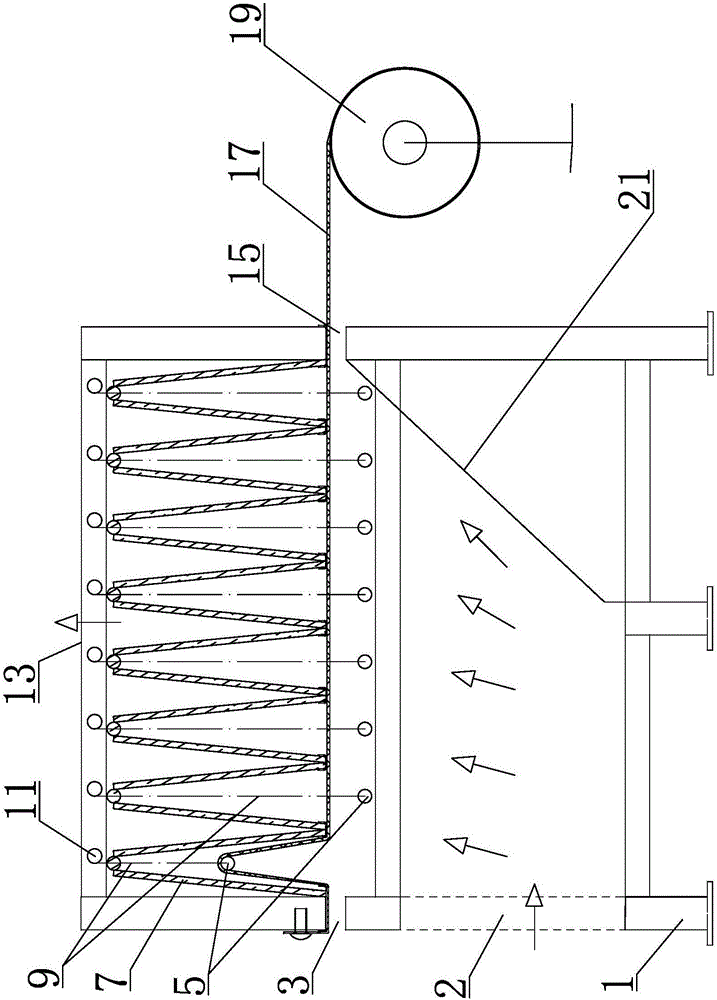

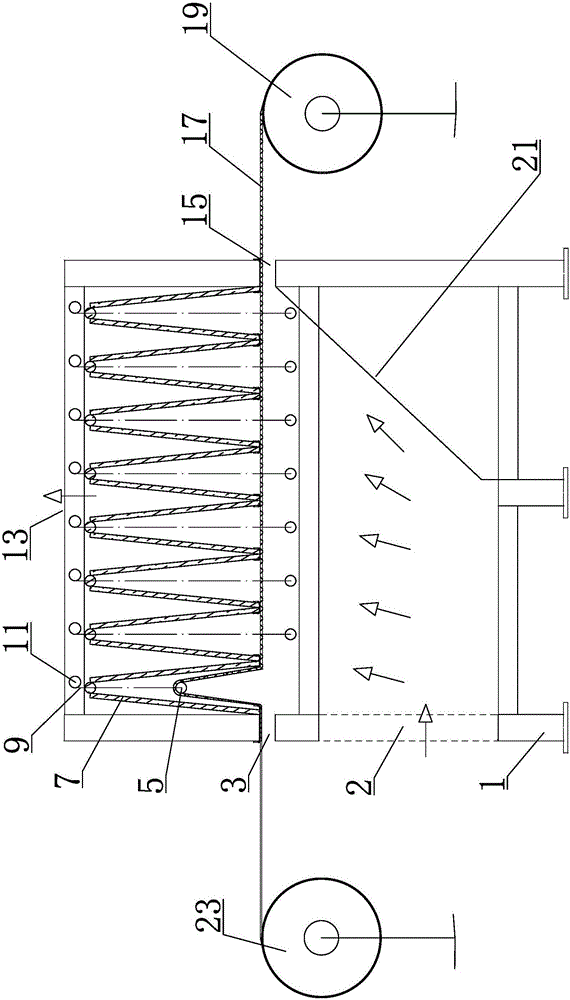

The invention discloses an ocean spilled oil collecting device. The invention discloses an ocean spilled oil collecting device. The objective of the invention is to solve a shortage that ocean spilled oil is not collected thoroughly by a current spilled collecting device. The collecting device comprises a floating block. An oil passing groove is arranged in the middle of the floating block. A slide rod is arranged on the front end of the oil passing groove. A slide block is slidably connected to the slide rod. An oil absorbing pump and an oil storage tank are installed on the floating block. A flexible oil absorbing pipe is installed on the oil absorbing pump. The front end of the oil absorbing pipe is installed on the slide block. A secondary oil absorbing mechanism is installed behind the slide rod in the oil passing groove. The secondary oil absorbing mechanism comprises a conveyor belt, a driving pulley, a driven pulley and a tensioning pulley. An oil absorbing belt is connected to the external surface of the conveyor belt. The conveyor belt between the driven pulley and the tensioning pulley is near the ocean surface. A squeezing wheel and a supporting belt pulley, which are oppositely arranged, are arranged between the tensioning pulley and the driving pulley. The supporting belt pulley is in transmission connection with the inner surface of the conveyor pulley. The squeezing pulley is abutted against the outer surface of the oil absorbing belt. An oil collecting groove is arranged under the squeezing pulley.

Owner:ZHEJIANG OCEAN UNIV

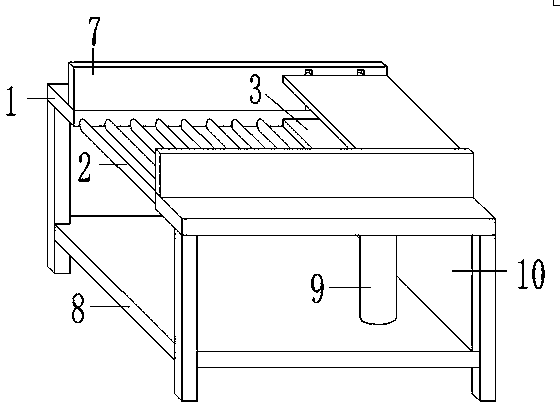

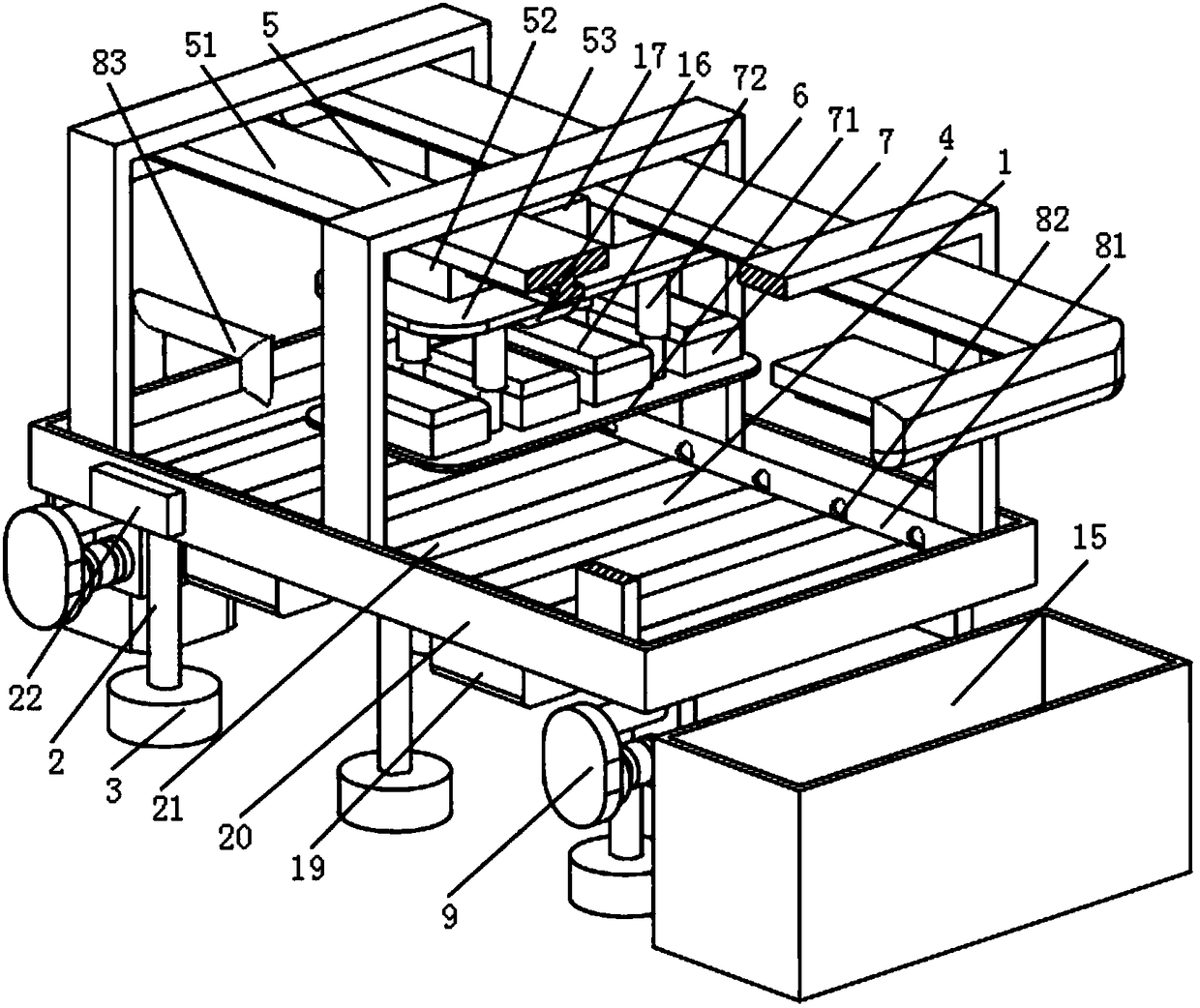

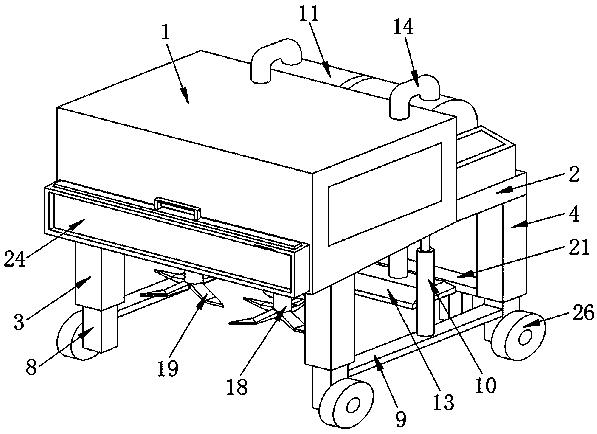

Sand screening device for building equipment

InactiveCN108435553APromote shakingAvoid affecting the efficiency of sand screeningSievingScreeningArchitectural engineeringDrive motor

The invention relates to the technical field of building equipment, and discloses a sand screening device for building equipment. The sand screening device comprises a bottom plate, wherein hydrauliclifting rods which are symmetrical with each other are uniformly distributed on the bottom of the bottom plate; the bottoms of the hydraulic lifting rods are fixedly equipped with circular table supporting discs; a gasket between the hydraulic lifting rods is uniformly distributed on the bottom of the bottom plate; universal wheels are fixedly mounted on the bottom of the gasket; four supporting plates which are symmetrical with each other fixedly sleeve the top of the bottom plate; the tops of the four supporting plates are fixedly connected through the bottom of a rack plate; and the back surfaces of the two supporting plates are fixedly connected with the front surfaces of the two supporting plates through the two sides of a fixed plate. According to the sand screening device for building equipment disclosed by the invention, a drive motor, a rotary rod and an extrusion wheel are matched for use, so that sand poured to the top of a sieve tray is conveniently vibrated to vibrate anddrop sand, and the problem that sand screening efficiency is affected as the sand is blocked on a screen and cannot drop is avoided.

Owner:徐佳东

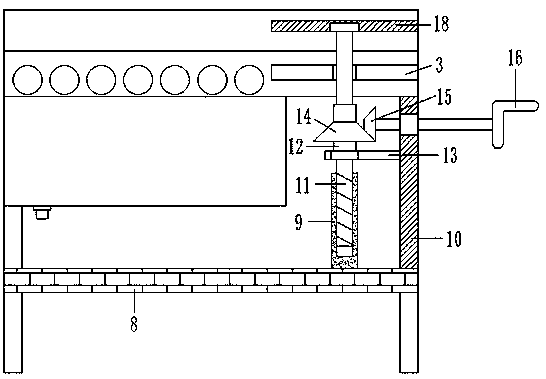

Bridge deck cleaning system for a bridge and cleaning method thereof

InactiveCN109083065AEasy to install and placeAvoid tilting, toppling, etc.Road cleaningBridge deckEngineering

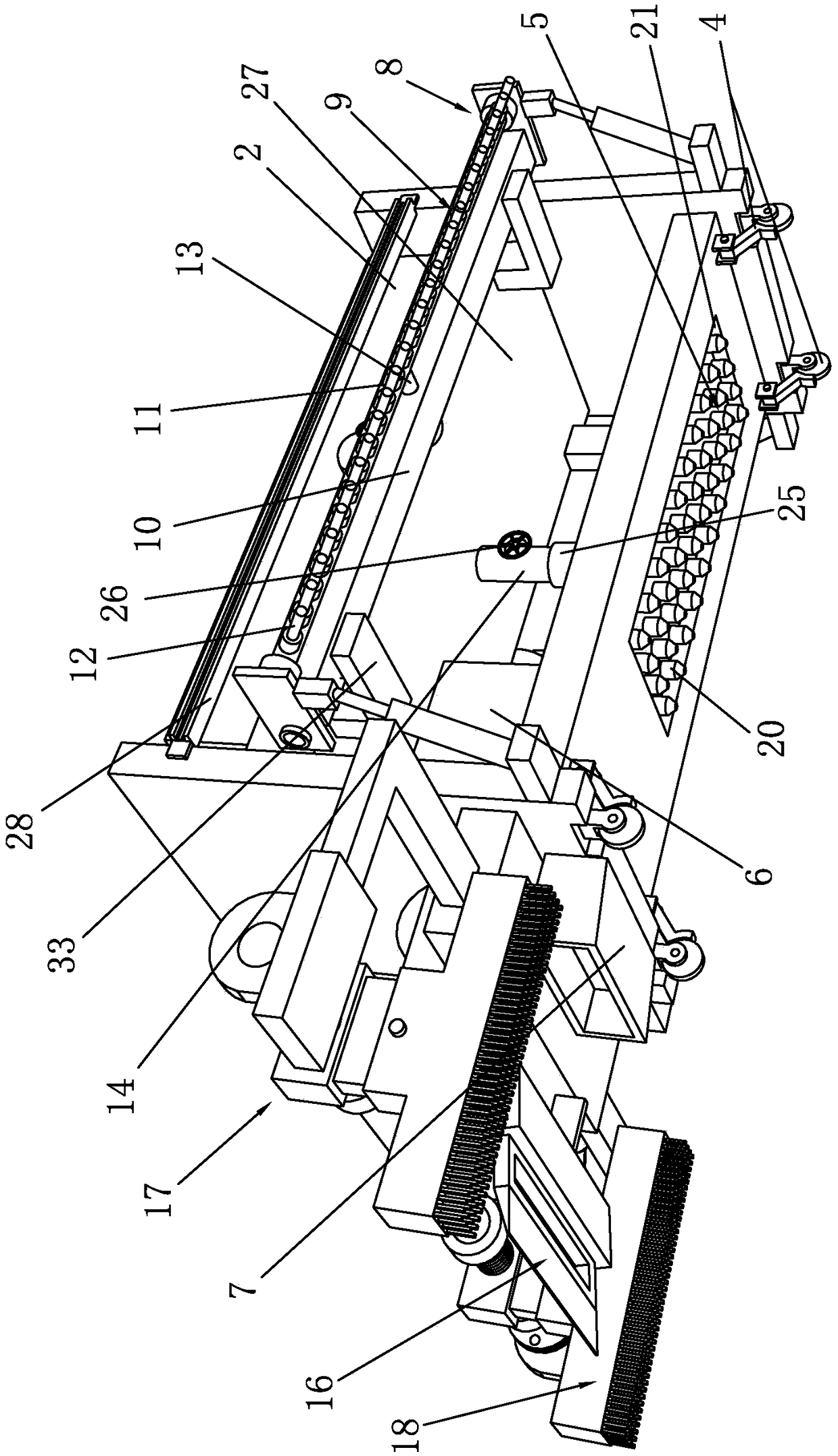

The invention discloses a bridge deck cleaning system for a bridge comprising a washing rack, a water tank arranged on the washing rack, a lower washing assembly and a collection tank arranged on thebottom surface of the washing rack, the lower washing assembly is communicated with the water tank, side washing assemblies are arranged on the left and right sides of the washing rack, the two side washing assemblies are communicated with the water tank, and a blade assembly and a cleaning assembly are arranged on the front end of the washing rack. The cleaning method comprises the following steps: a, adjusting the angle of the side cleaning assembly; B. Adjustment of blade assembly angle; C, adjusting the height of the cleaning head set; D, commissioning; E. Bridge deck cleaning operation. The whole structure design of the invention is reasonable, The automatic cleaning operation of the bridge is realized by the cleaning frame, the manual labor intensity is reduced, the garbage and the adhered impurities on the bridge surface can be removed by the blade assembly and the cleaning assembly, and the bridge deck can be cleaned and washed in all aspects by the double cleaning functions ofthe side cleaning assembly and the lower cleaning assembly.

Owner:ZHEJIANG COLLEGE OF CONSTR

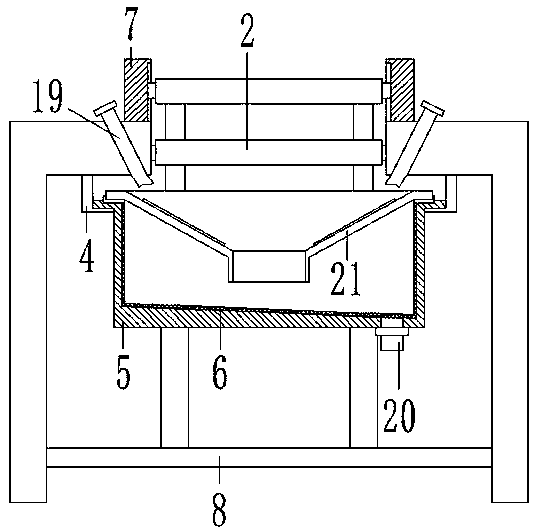

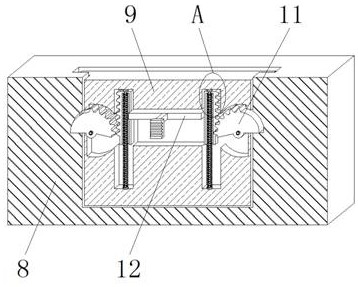

Heat preservation board waste chip processing device

The invention discloses a heat preservation board waste chip processing device. The device comprises a workbench, rolling shafts are arranged on the left side of the two groups of supporting tables of the working table, a lower clamping plate is arranged on the right side of the two groups of supporting tables of the working table, baffles are arranged at the tops of the two groups of supportingtables of the worktable, a bottom plate is arranged at the bottom of an inner cavity of the workbench, a lifting column is arranged at the top of the bottom plate, the inner cavity of the lifting column is in threaded connection with a lifting screw rod, the outer wall of the lifting screw rod is in threaded connection with a threaded sleeve, a supporting plate frame sleeves the outer wall of thethreaded sleeve, the top of the lifting screw rod penetrates through the lower clamping plate and is connected with an upper clamping plate, a sliding frame is arranged at the top of an inner cavity of the working table, a waste chip collecting box is connected between the sliding frames, the inner cavity of the scrap collecting box is sequentially sleeved with a collecting hopper and a filteringnet from top to bottom, and a magnet is arranged in an inner cavity of the collecting hopper. The structure design is reasonable, the metal materials in the scrap scraps are collected through filtration, the metal waste is recycled, the cost is reduced, and the environment is protected.

Owner:吴江市金搏保温材料厂(普通合伙)

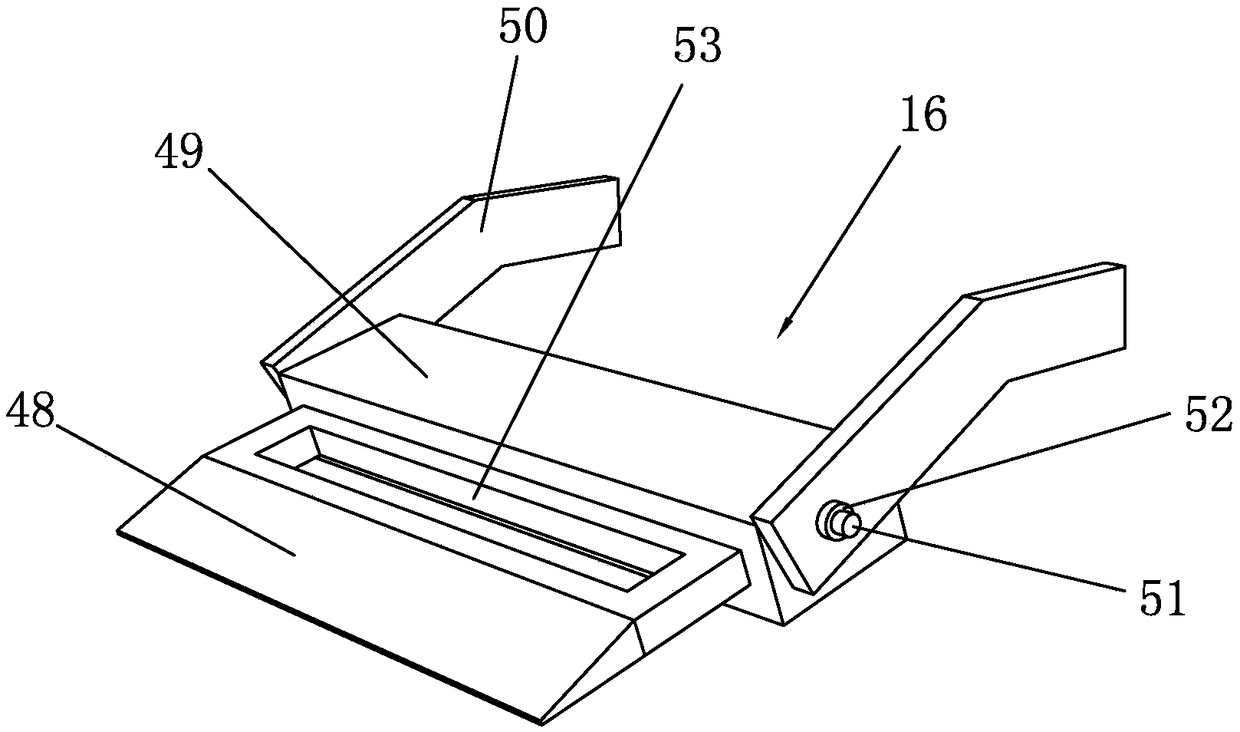

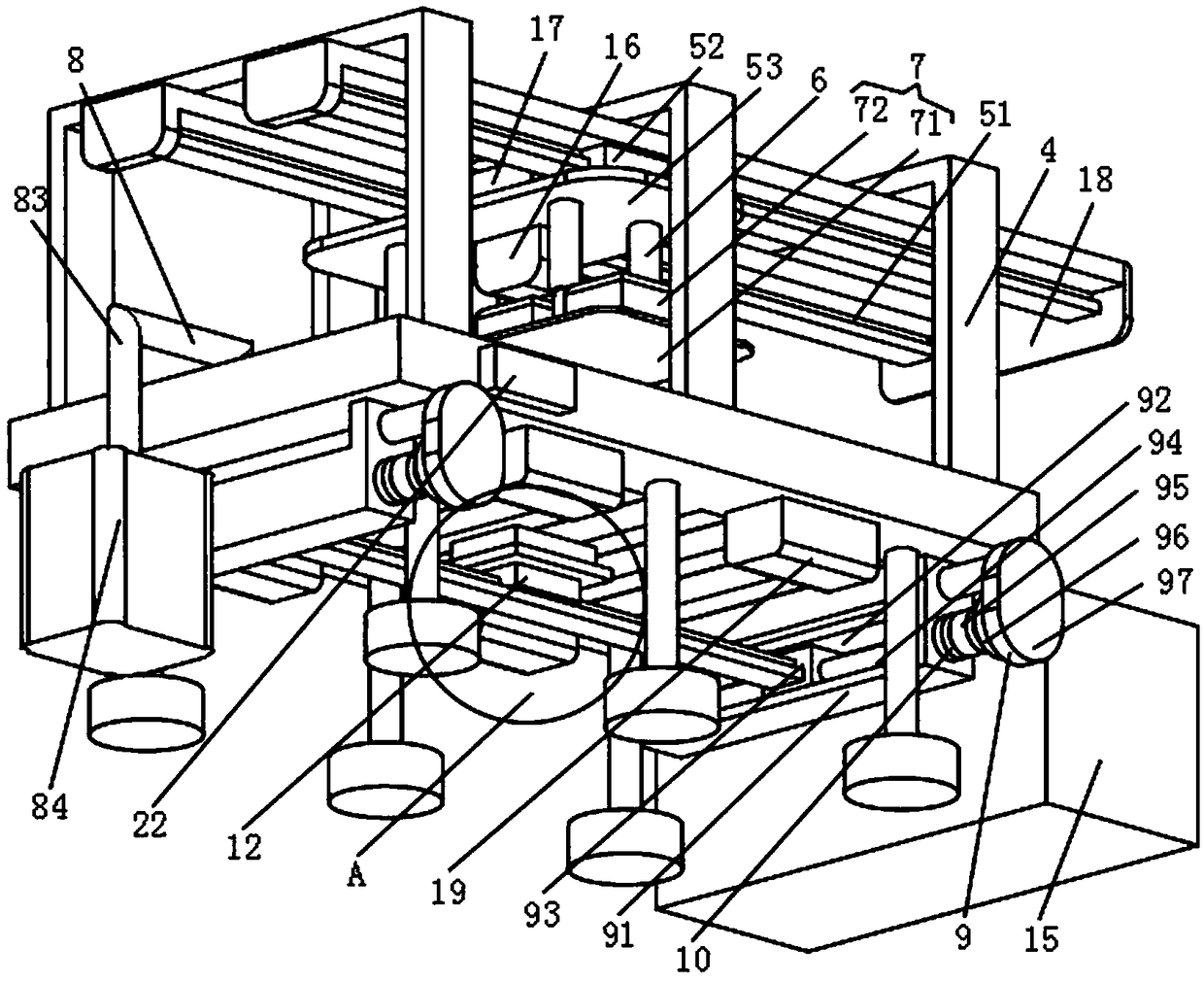

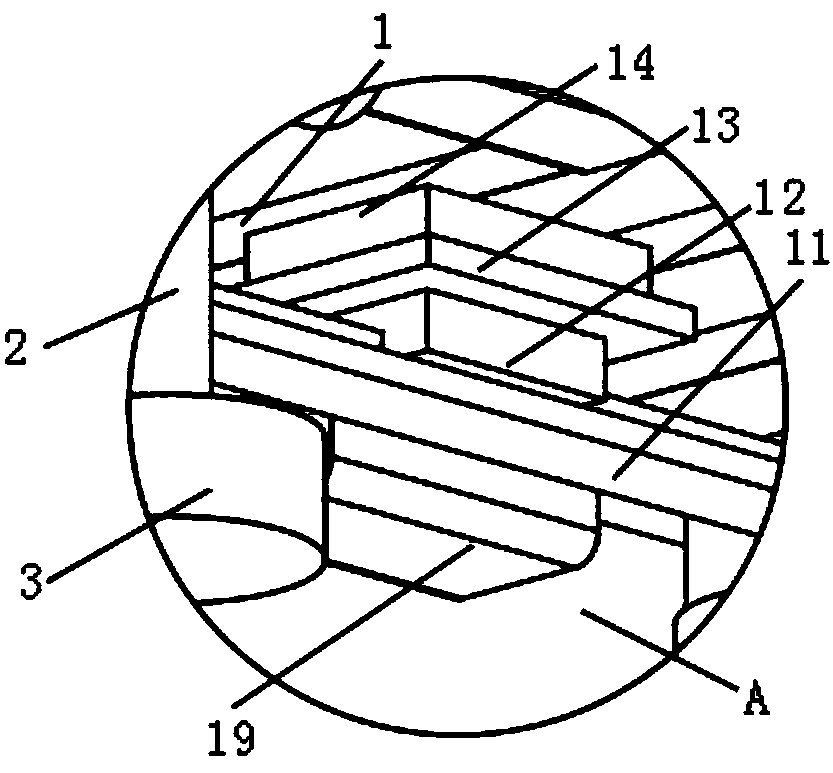

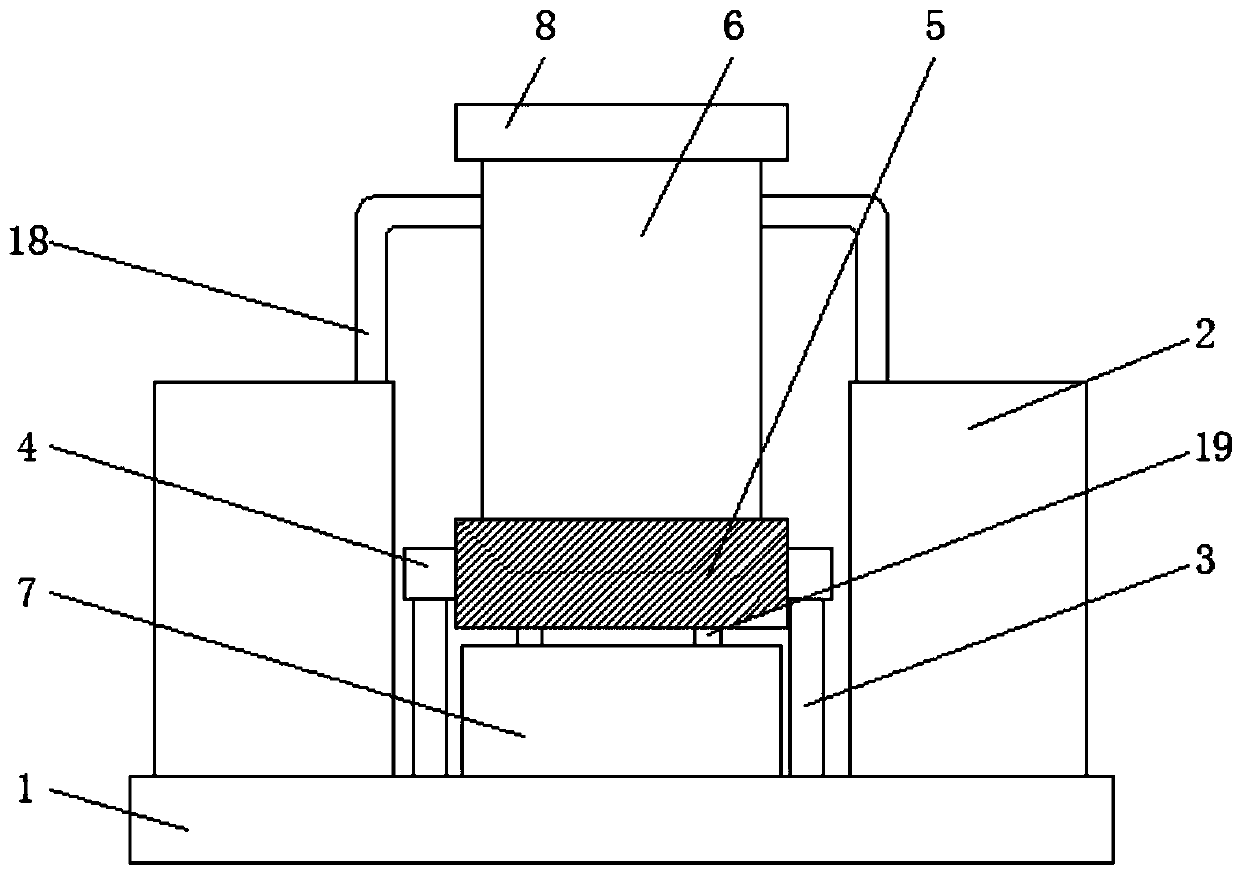

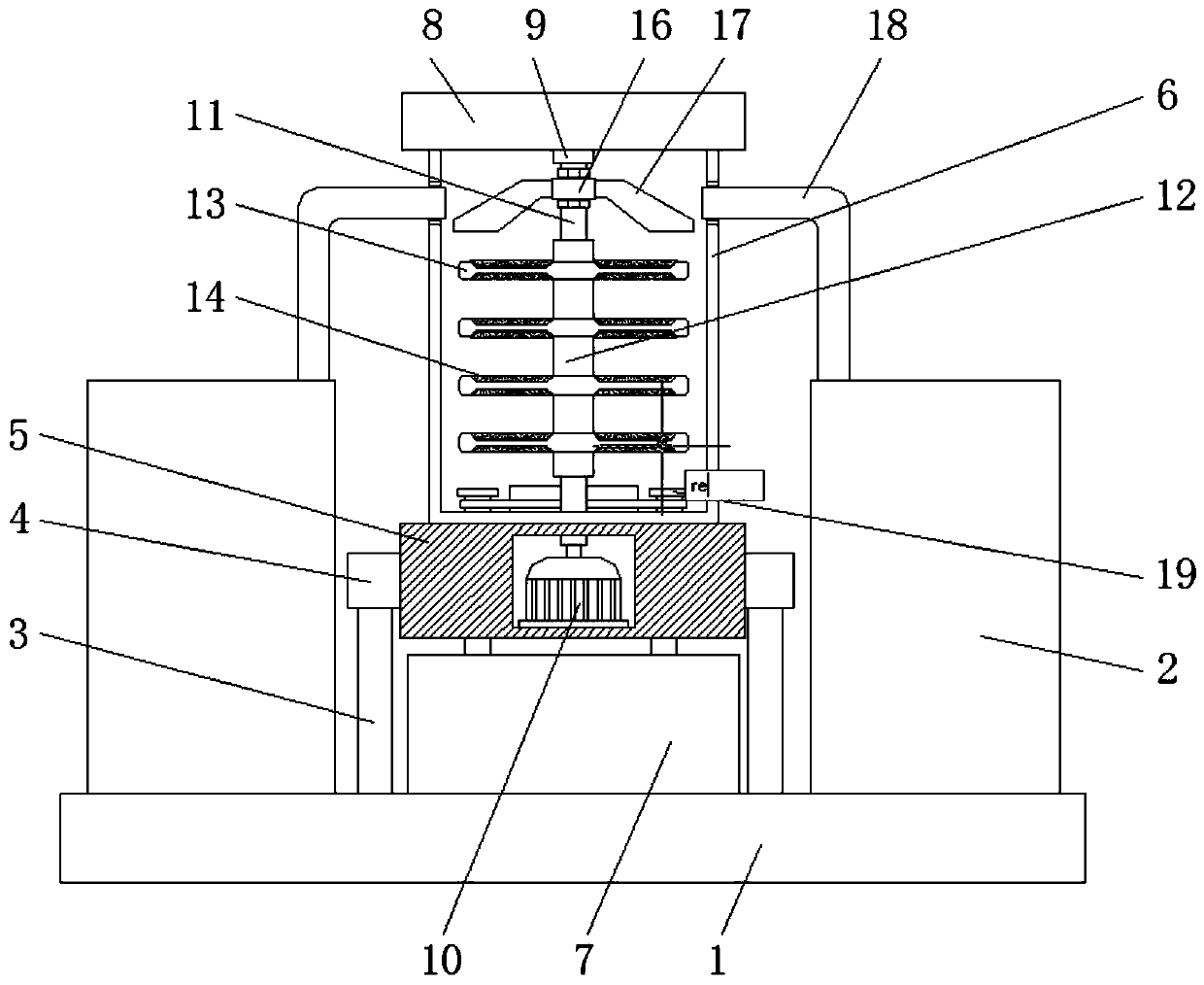

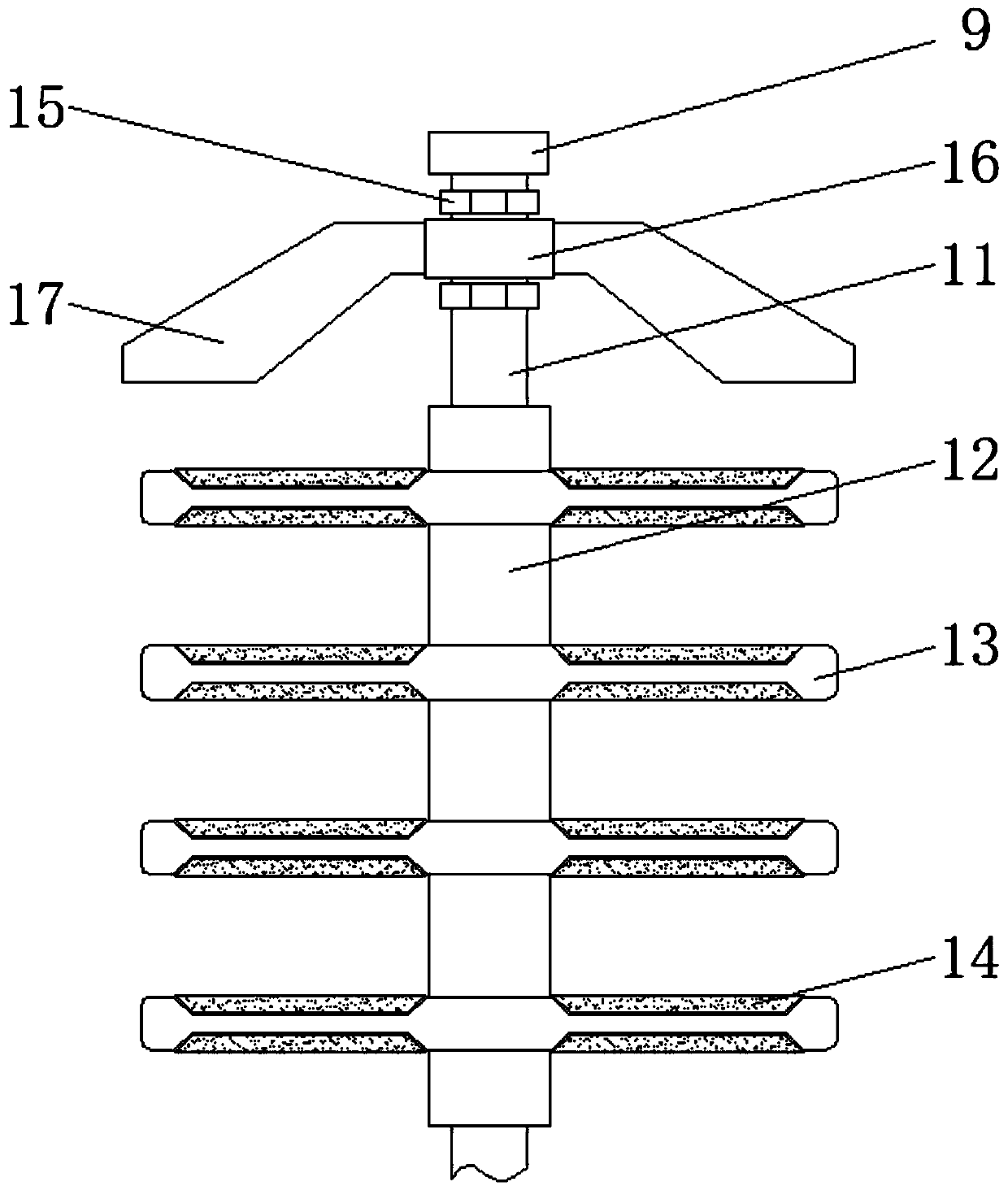

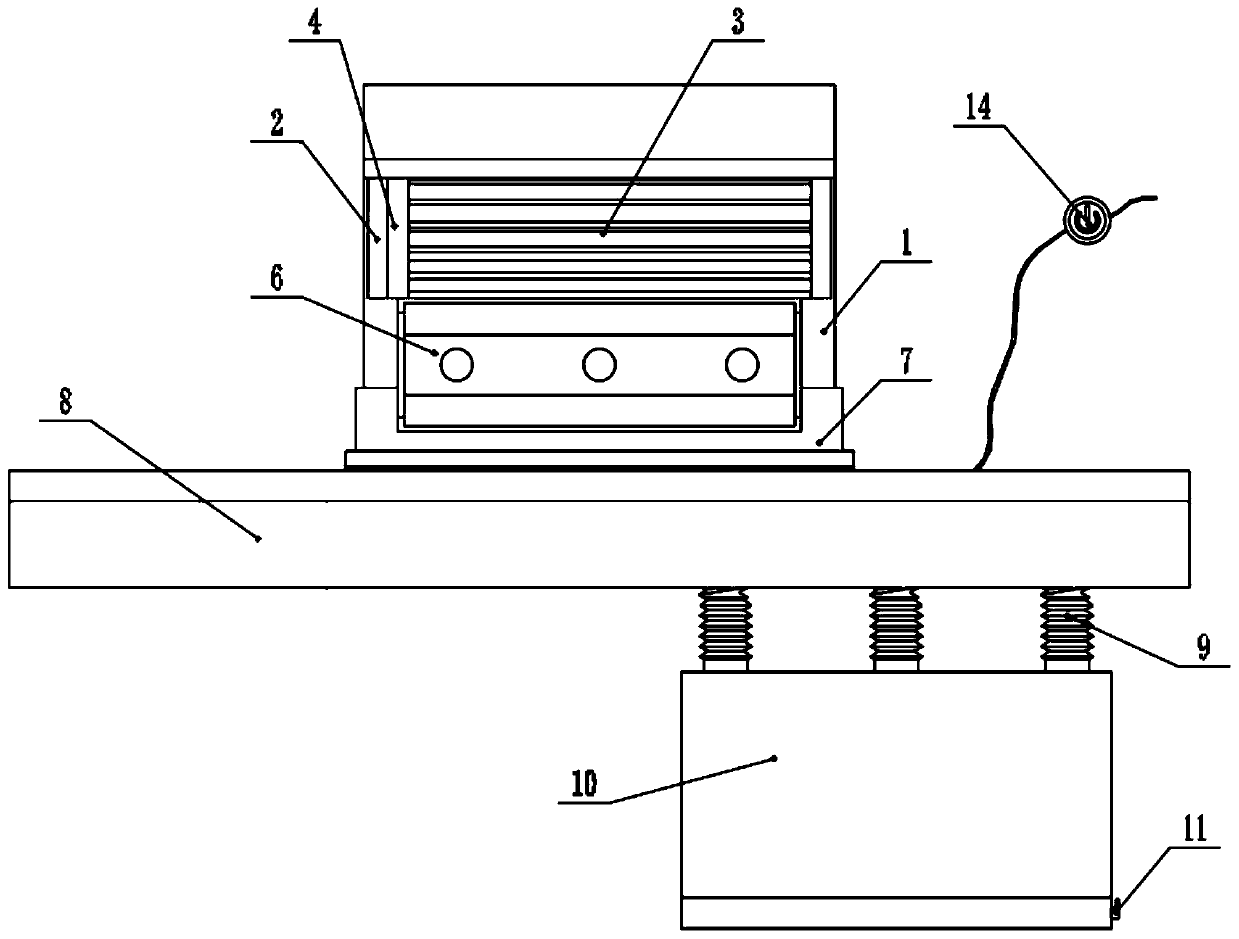

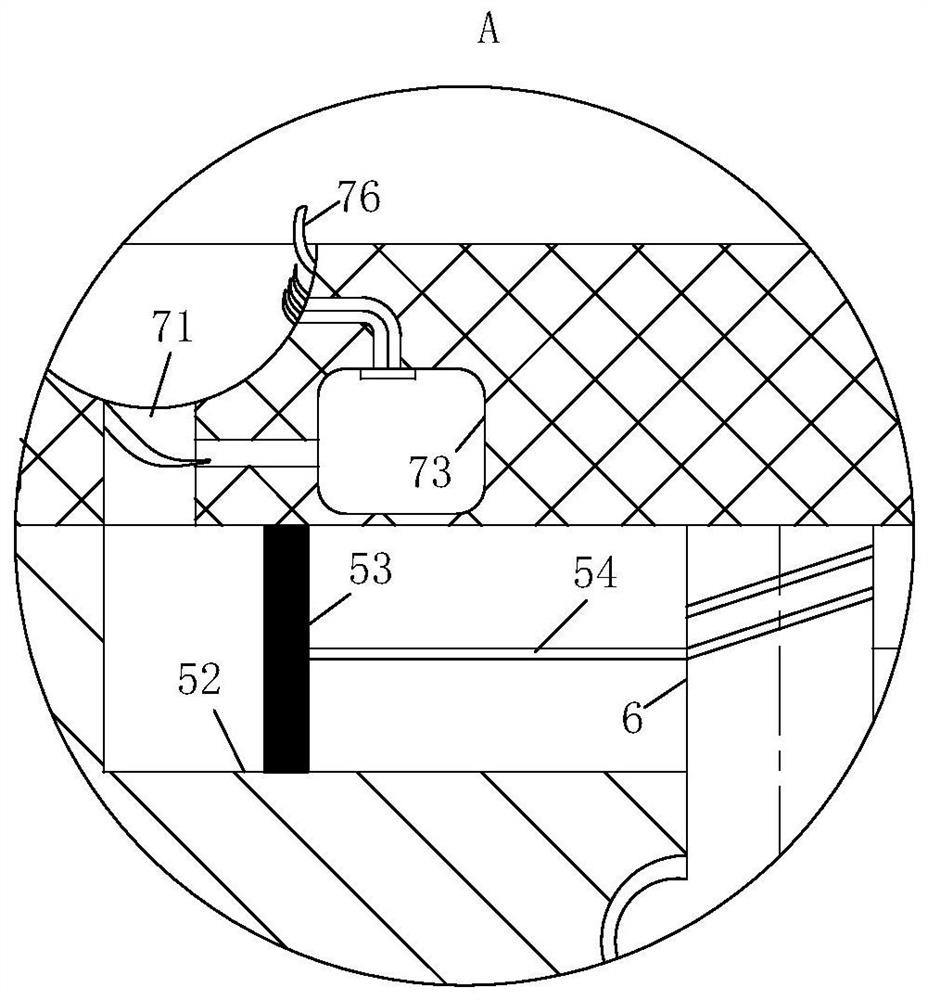

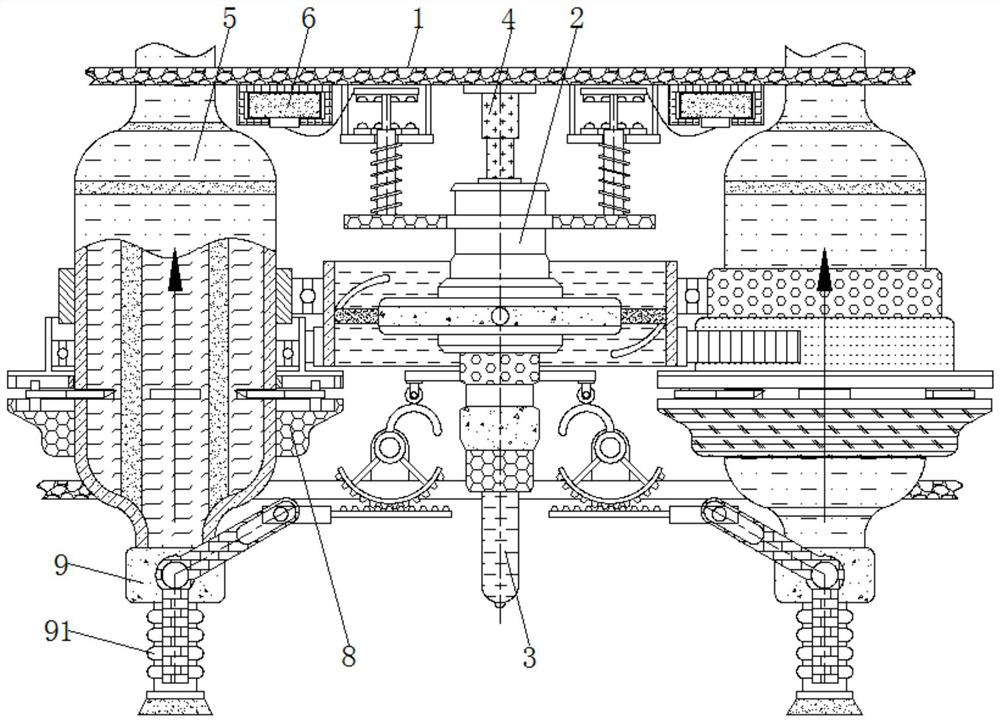

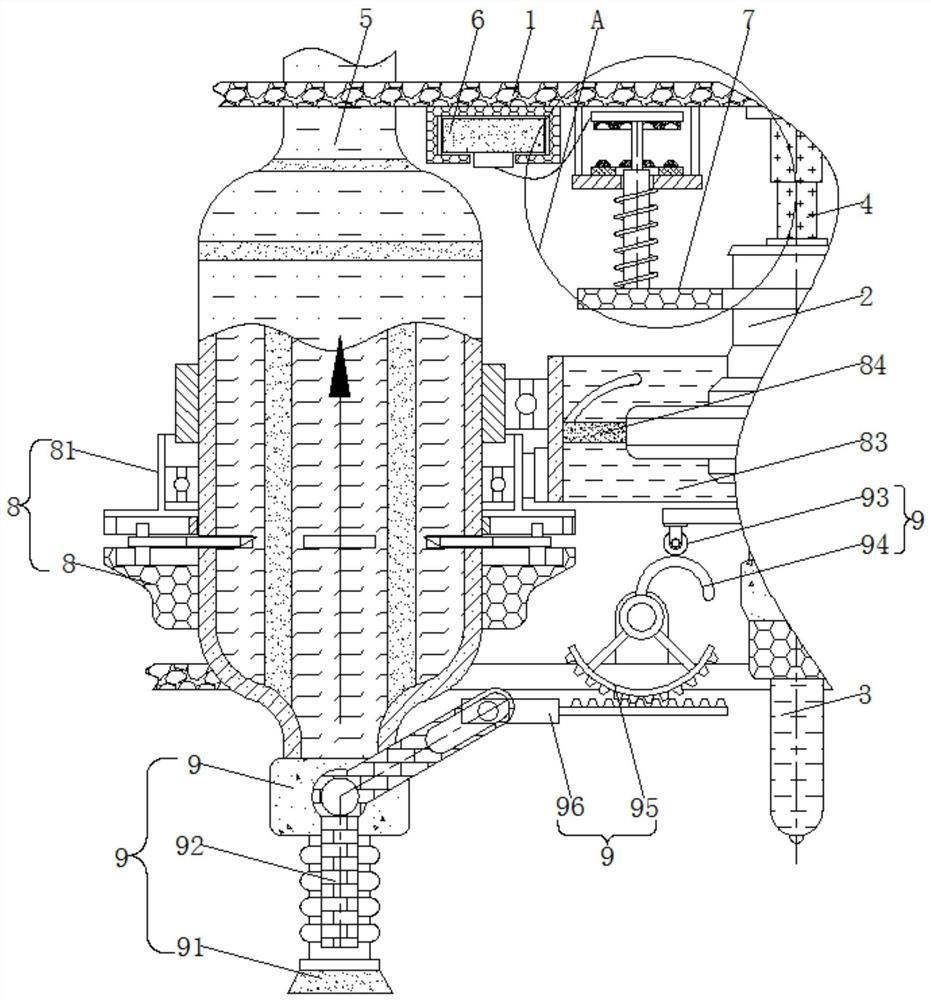

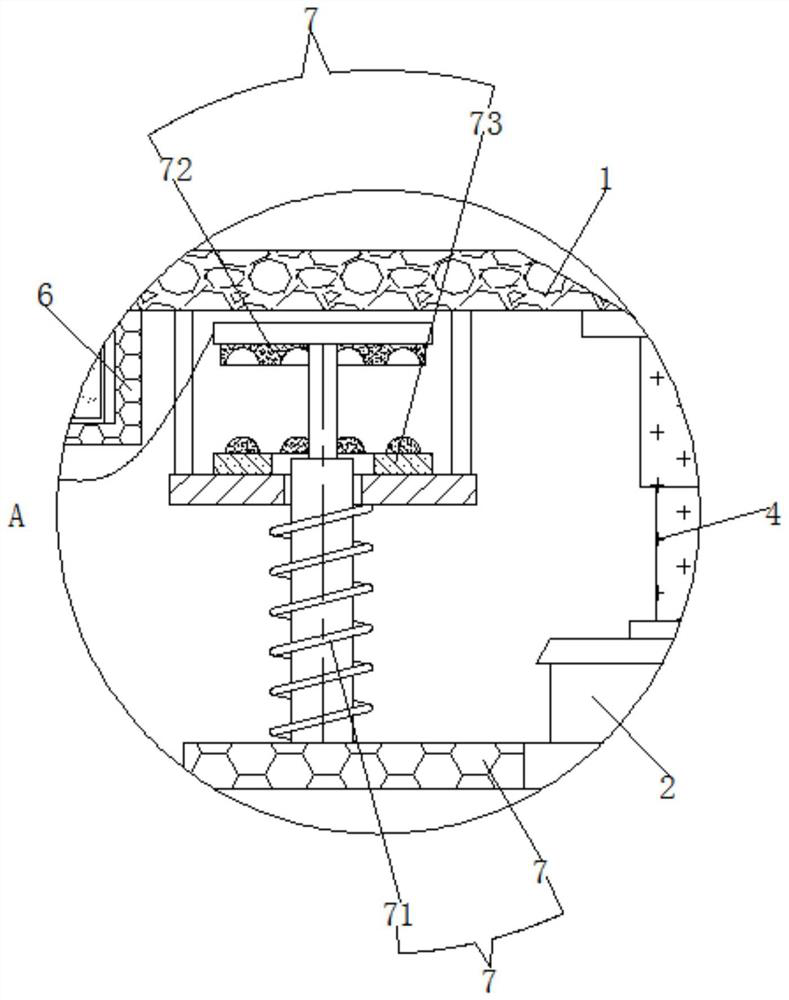

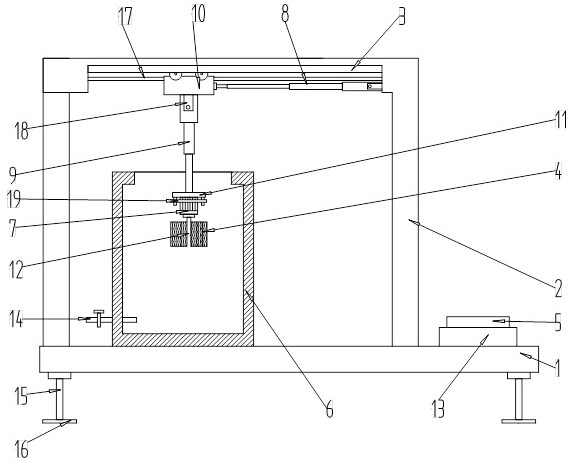

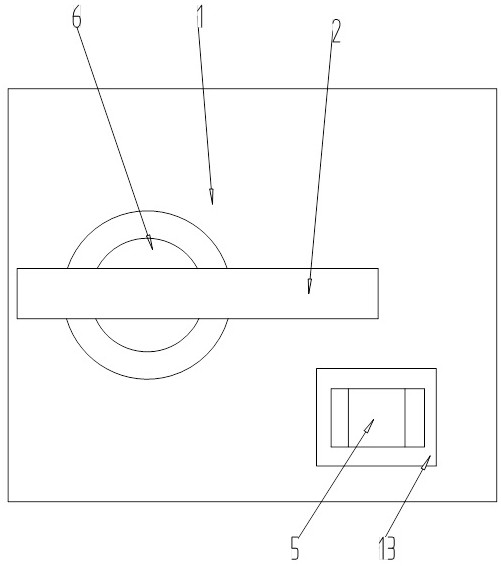

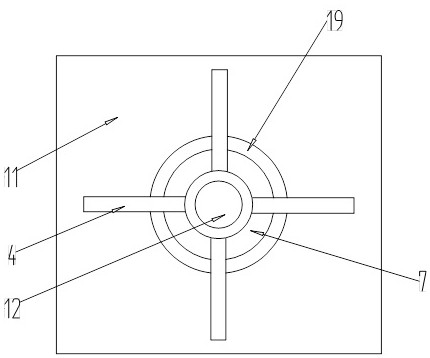

Numerical control machine tool workbench with cleaning mechanism

ActiveCN108161556AImprove stabilityEasy to absorb and collectMaintainance and safety accessoriesNumerical controlFixed frame

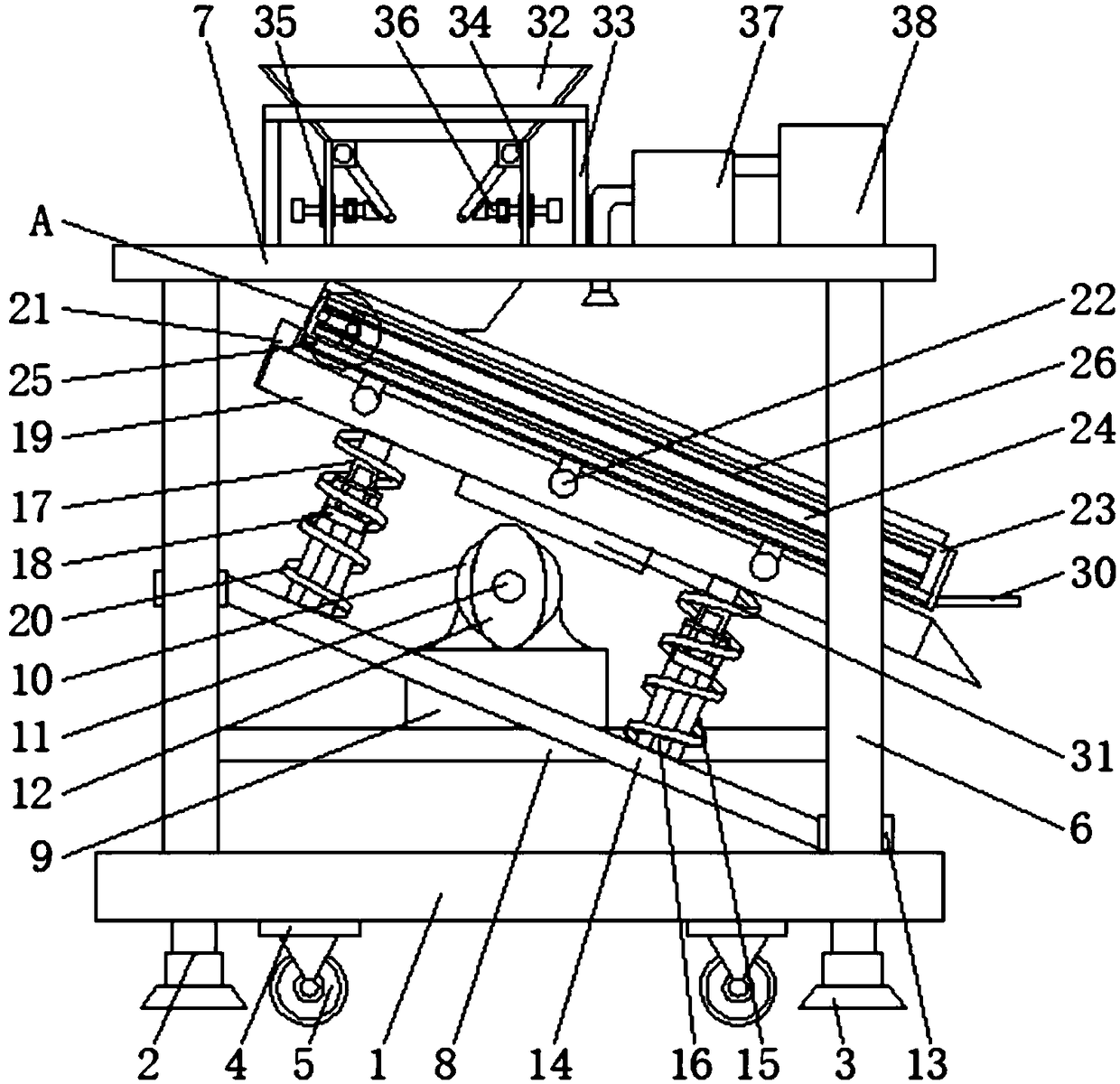

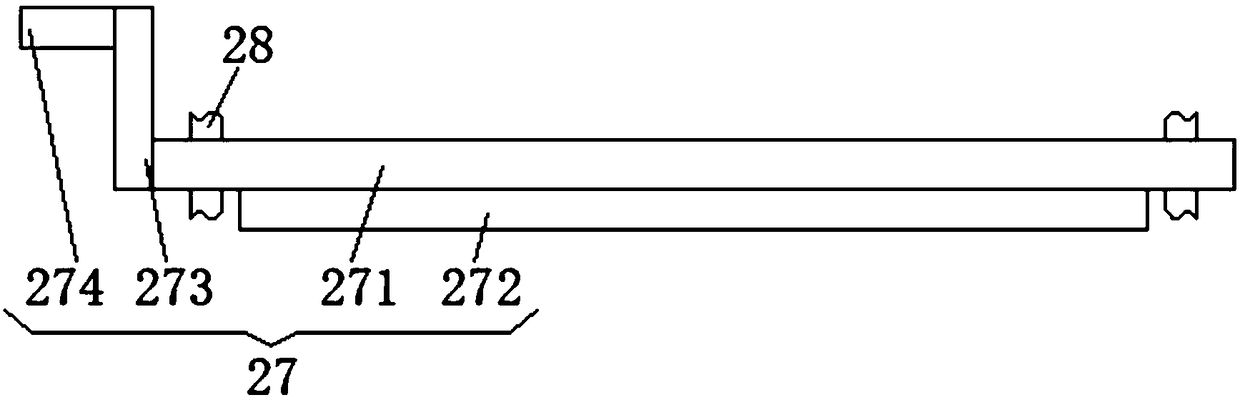

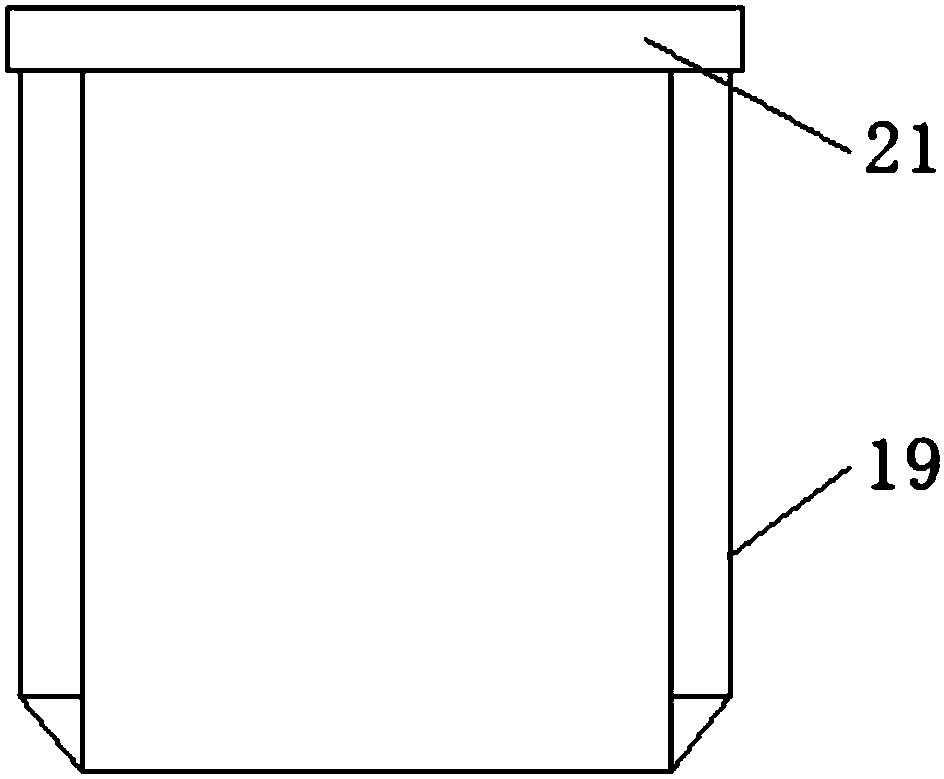

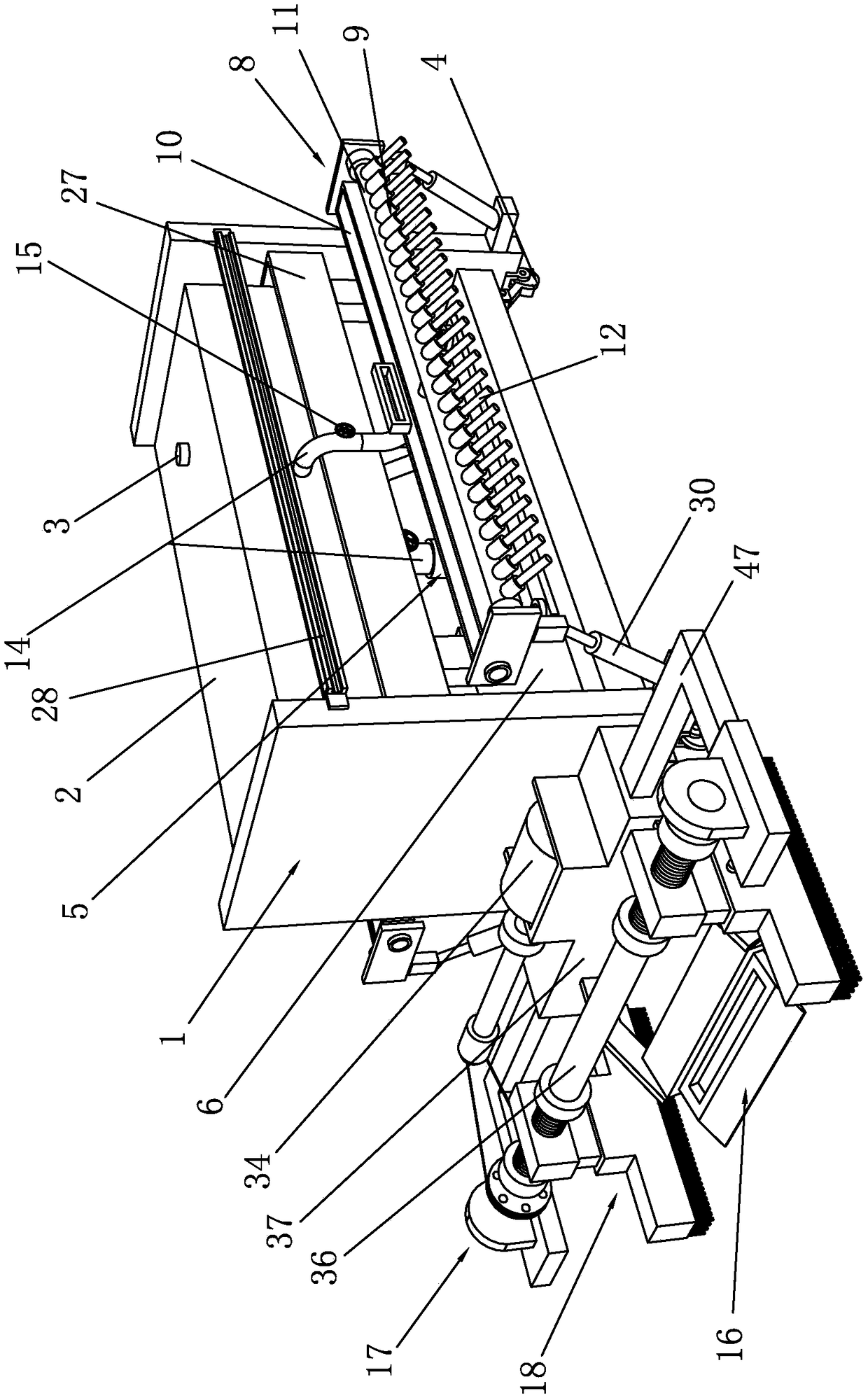

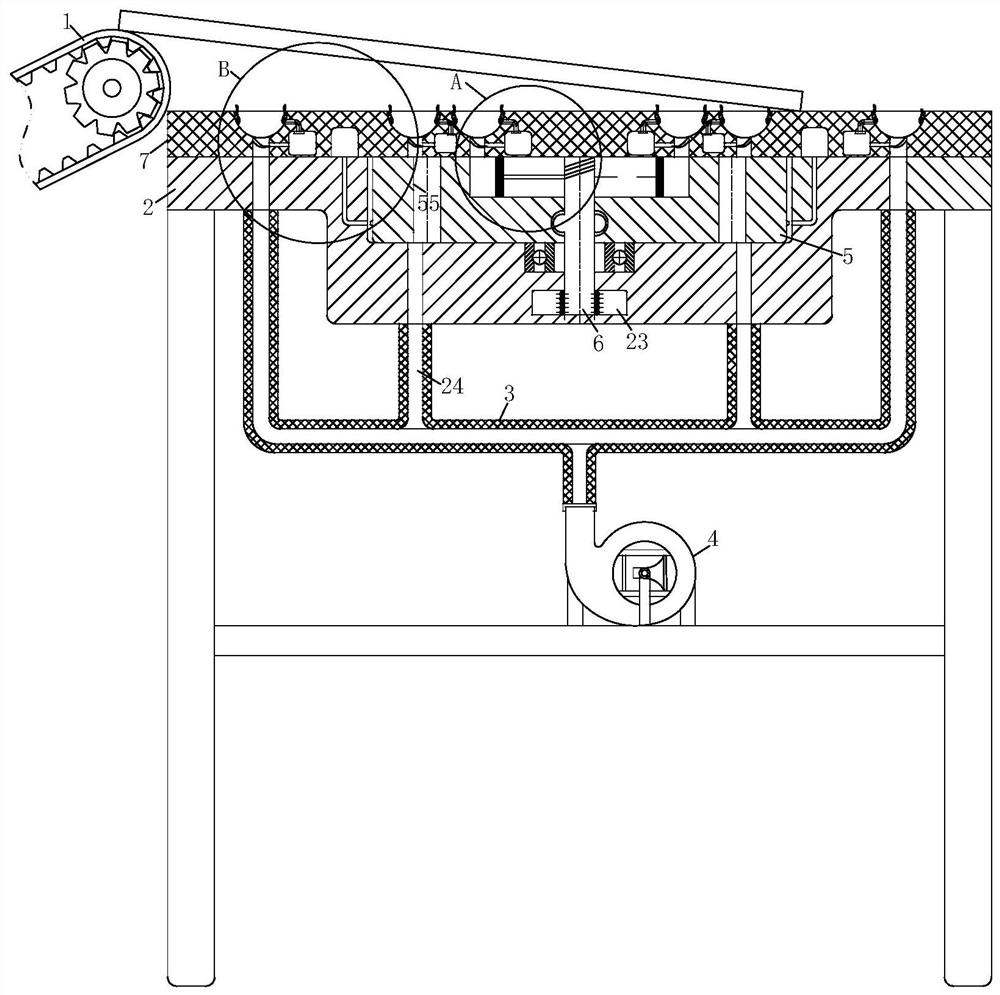

The invention discloses a numerical control machine tool workbench with a cleaning mechanism. The numerical control machine tool workbench comprises an operation table. Supporting columns are arrangedon the lower surface of the operation table. Two driving devices arranged symmetrically are arranged at the two ends of the lower surface of the operation table. Sliding blocks of the driving devicesare fixedly connected with the two ends of a second sliding rail. A second linear motor is slidably connected with the upper surface of the second sliding rail. A fixing plate is arranged on the upper surface of the second linear motor. A second electromagnet is arranged on the upper surface of the fixing plate. A rectangular frame is arranged on the edge of the upper surface of the operation table. A dust remover is arranged on the inner side face of the rectangular frame. Three fixing frames distributed at equal intervals are arranged on the upper surface of the operation table. Transversemoving devices are arranged in the middles of the lower surfaces of the fixing frames. Through the numerical control machine tool workbench with the cleaning mechanism, dust on the surface of the operation table can be collected and is prevented from hurting human bodies, iron chips can be transferred and recovered, resource waste is reduced, operation is simple, and application is convenient.

Owner:阜阳冈奇精密科技有限公司

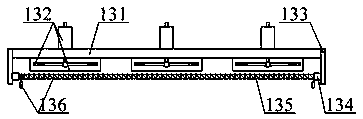

Suction disc type work table for mobile phone screen board production

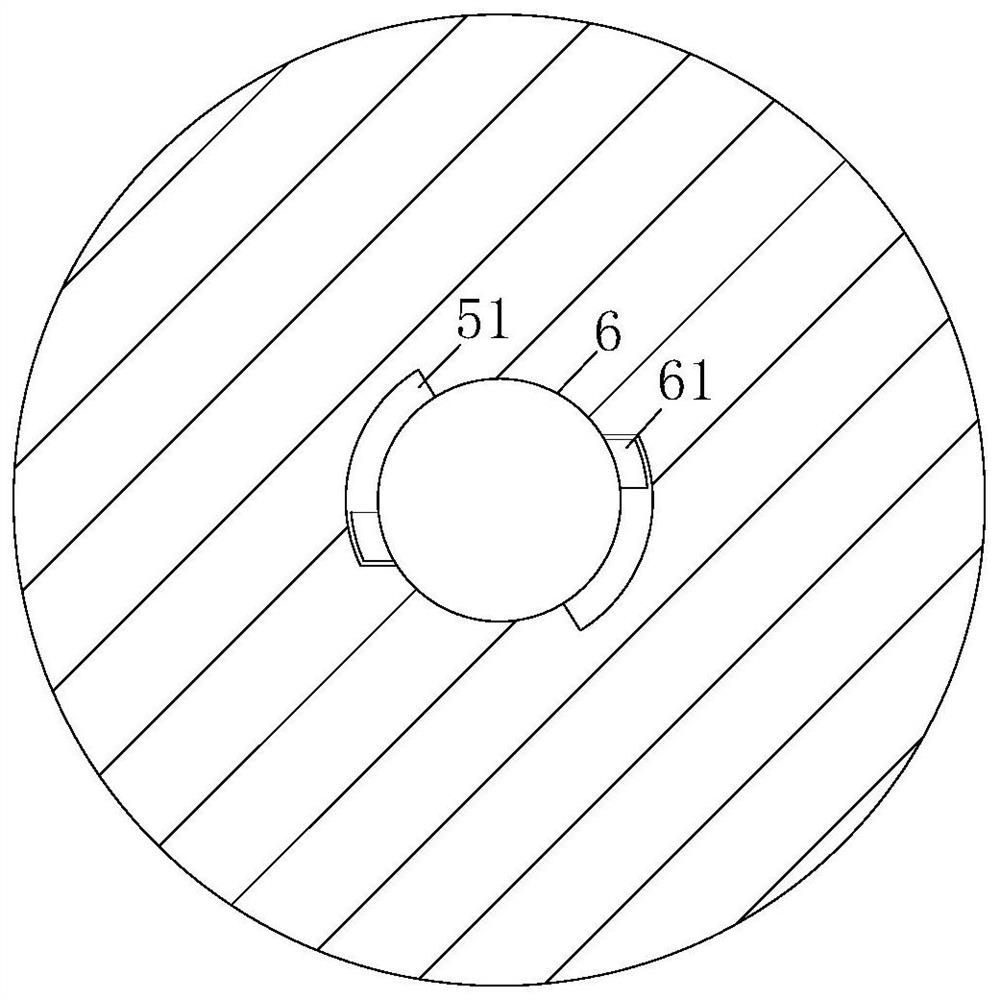

The invention belongs to the technical field of mobile phone production, in particular to a suction disc type work table for mobile phone screen board production. The work table comprises a conveyingbelt and a table body, wherein a first through hole is formed in the table body, an air pump is mounted on the table body, a cavity is formed in the upper surface of the table body, a rotating disc ismounted in the cavity, a rotating shaft is connected to the middle of the rotating disc, a second notch is formed in the rotating disc, and a piston is arranged in the second notch; negative pressureis formed between the first through hole and a screen board by air pumping on the first through hole by the air pump, and negative pressure is formed between the space on one side of a piston and thescreen board through cooperative movement of the rotating disc and the rotating shaft, so that the screen board is adsorbed and fixed by the table body; an elastic belt is arranged on the table bodyand provided with an arc-shaped groove, conductive burrs are arranged in the arc-shaped groove and connected with an electrode plate of a dust collection groove, and thus, dust on the screen board isadsorbed and collected by the dust collection groove while static electricity of the screen board is reduced.

Owner:江苏源成隆光电科技有限公司

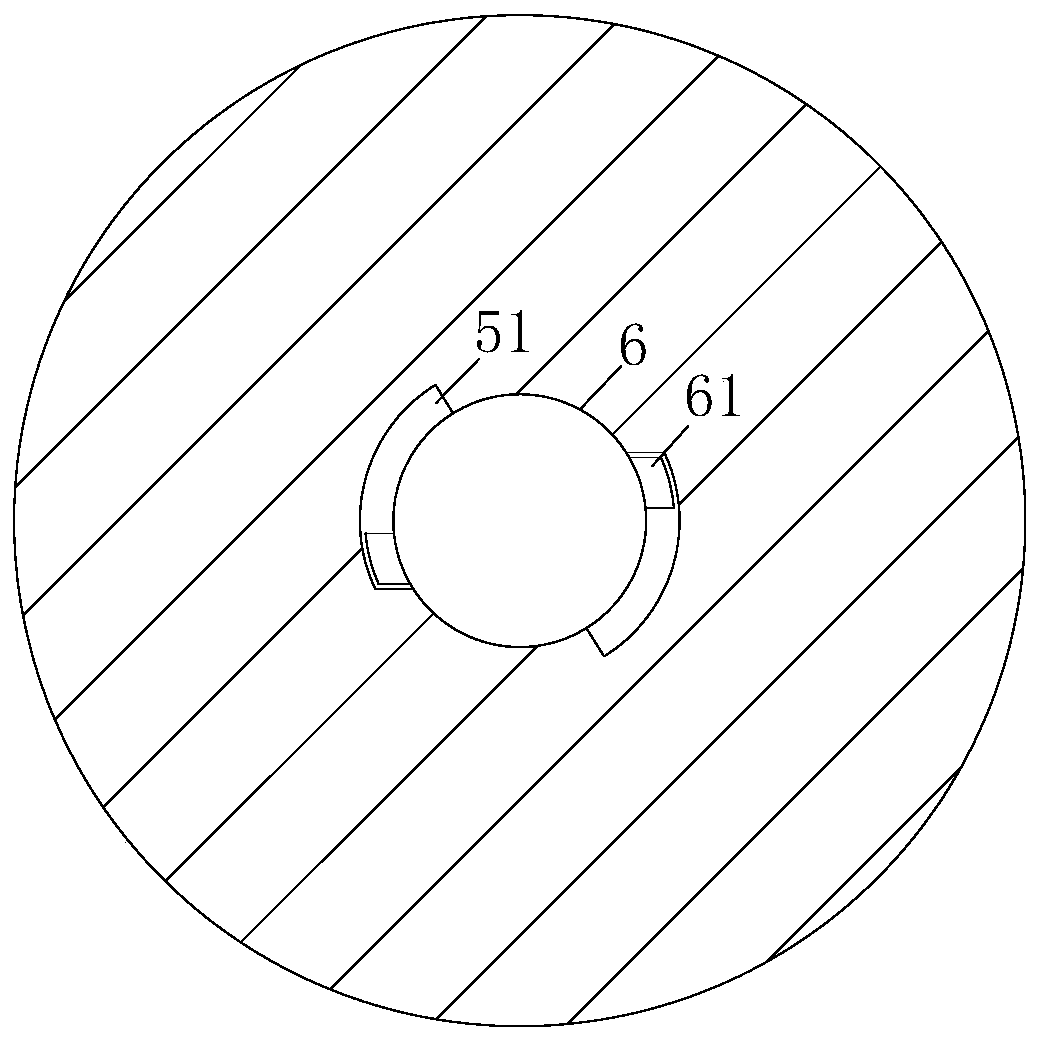

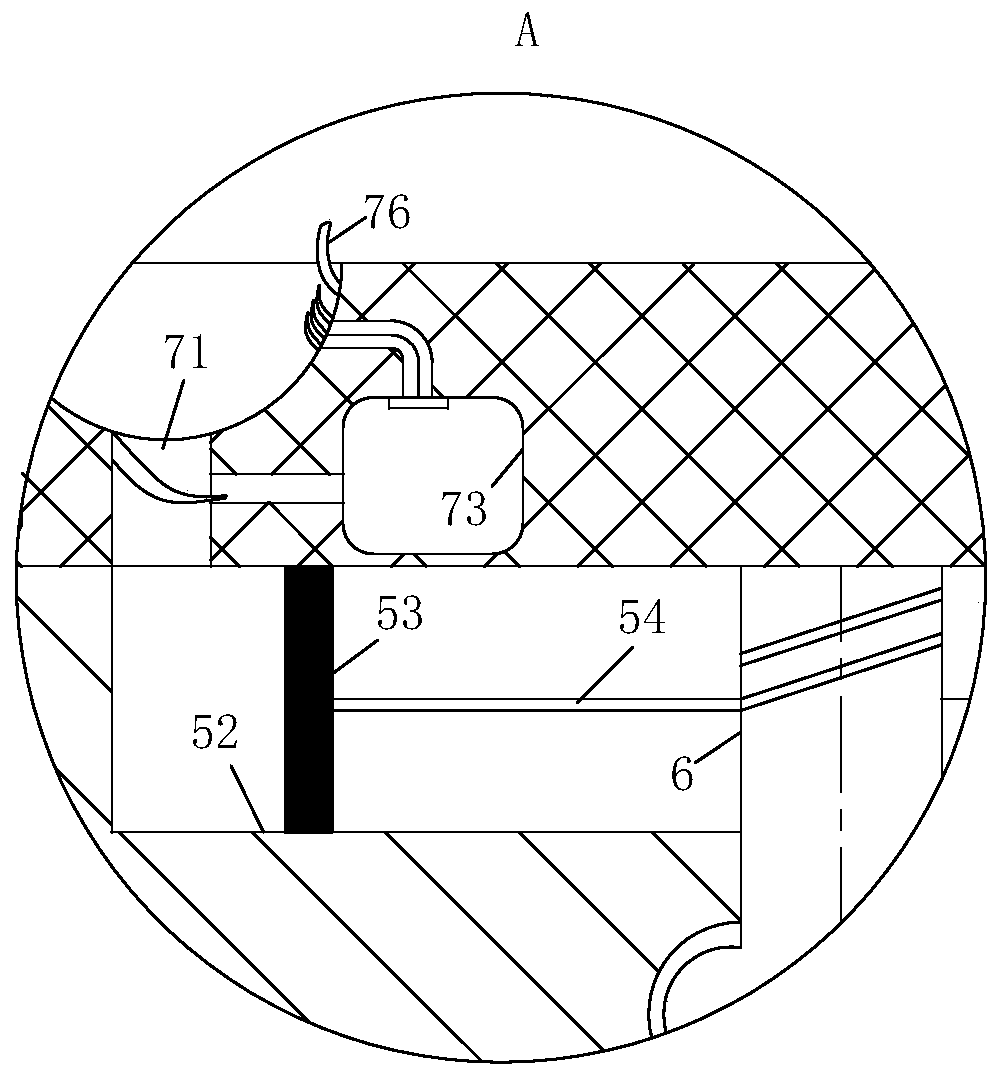

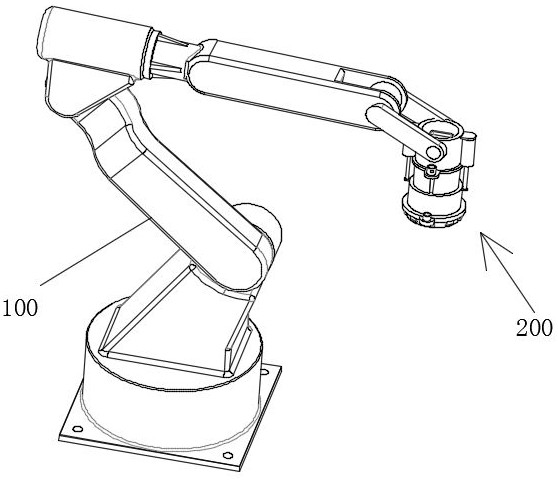

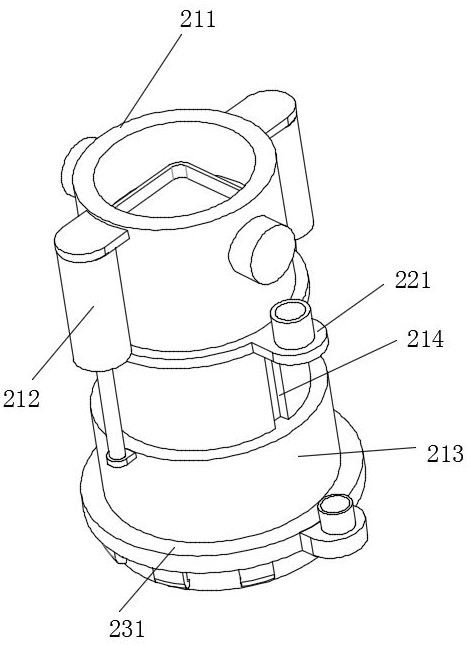

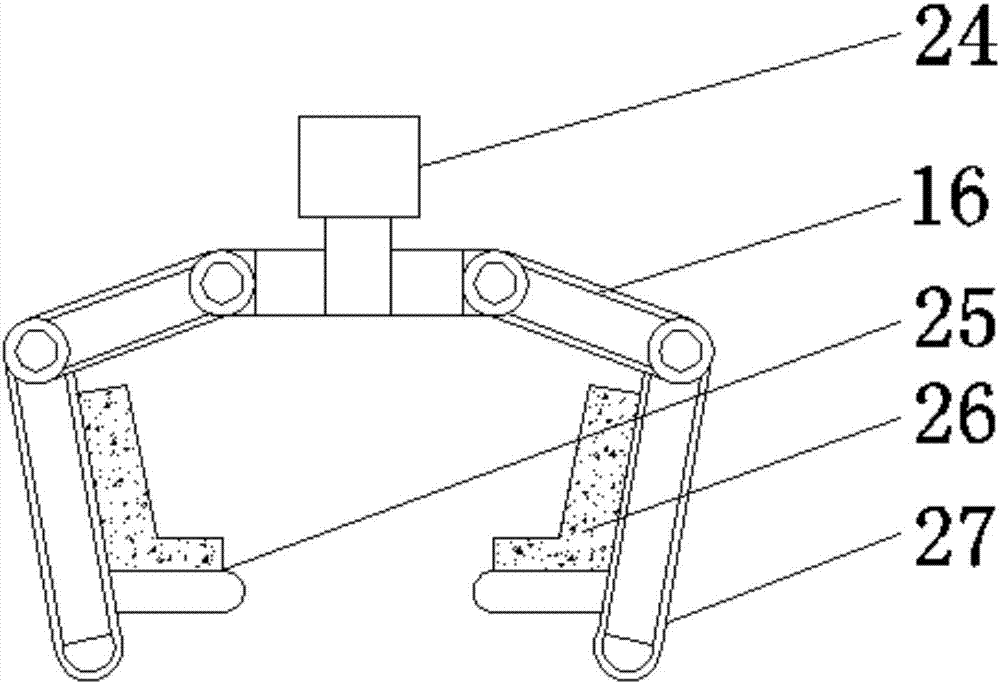

Detachable manipulator with dust removal mechanism

InactiveCN112207843APrevent proliferationEasy to collect and absorbStationary drilling machinesBark-zones/chip/dust/waste removalPhysicsDrill hole

The invention relates to the technical field of manipulators, in particular to a detachable manipulator with a dust removal mechanism. The detachable manipulator comprises a mechanical arm, wherein adrilling mechanism is fixedly connected to one end of the mechanical arm, the drilling mechanism comprises a pressing module, the pressing module comprises a fixed sleeve, and the top end of the annular outer side wall of the fixed sleeve is fixedly connected with the tail end of the mechanical arm. According to the detachable manipulator, a sliding sleeve is arranged, and the bottom surface of anannular dust collection plate makes contact with a working surface in advance of one step of a drill bit of a drilling machine so as to enclose and seal the drilling position, so that sweeps are prevented from diffusing, the collection and suction of the sweeps are facilitated, and additionally, the external environment is prevented from being polluted and damaged; a dust collection module is arranged, so that the sweeps generated by drilling are sucked, and the working surface is kept clean; and an air blowing module is arranged, so that the sweeps on the working surface are blown and then are sucked into the dust collection module along with air flow, the sweeps which cannot be sucked originally are sucked into the dust collection module, and the degree of cleanliness of the working surface is increased.

Owner:李俊义

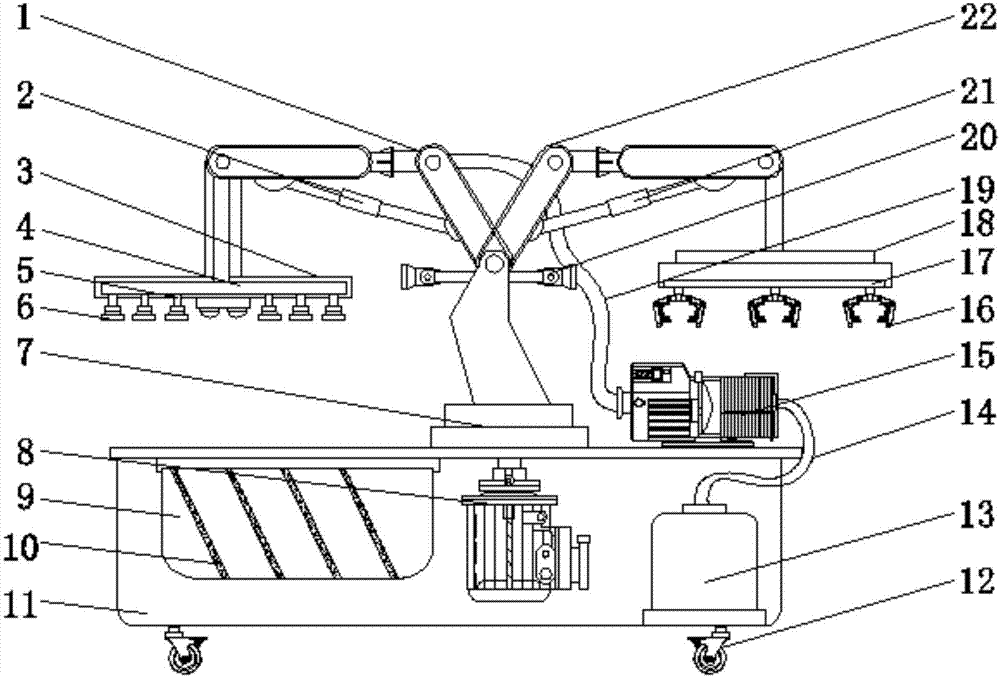

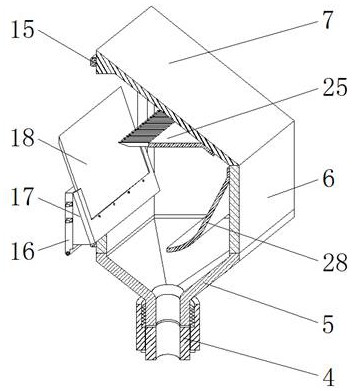

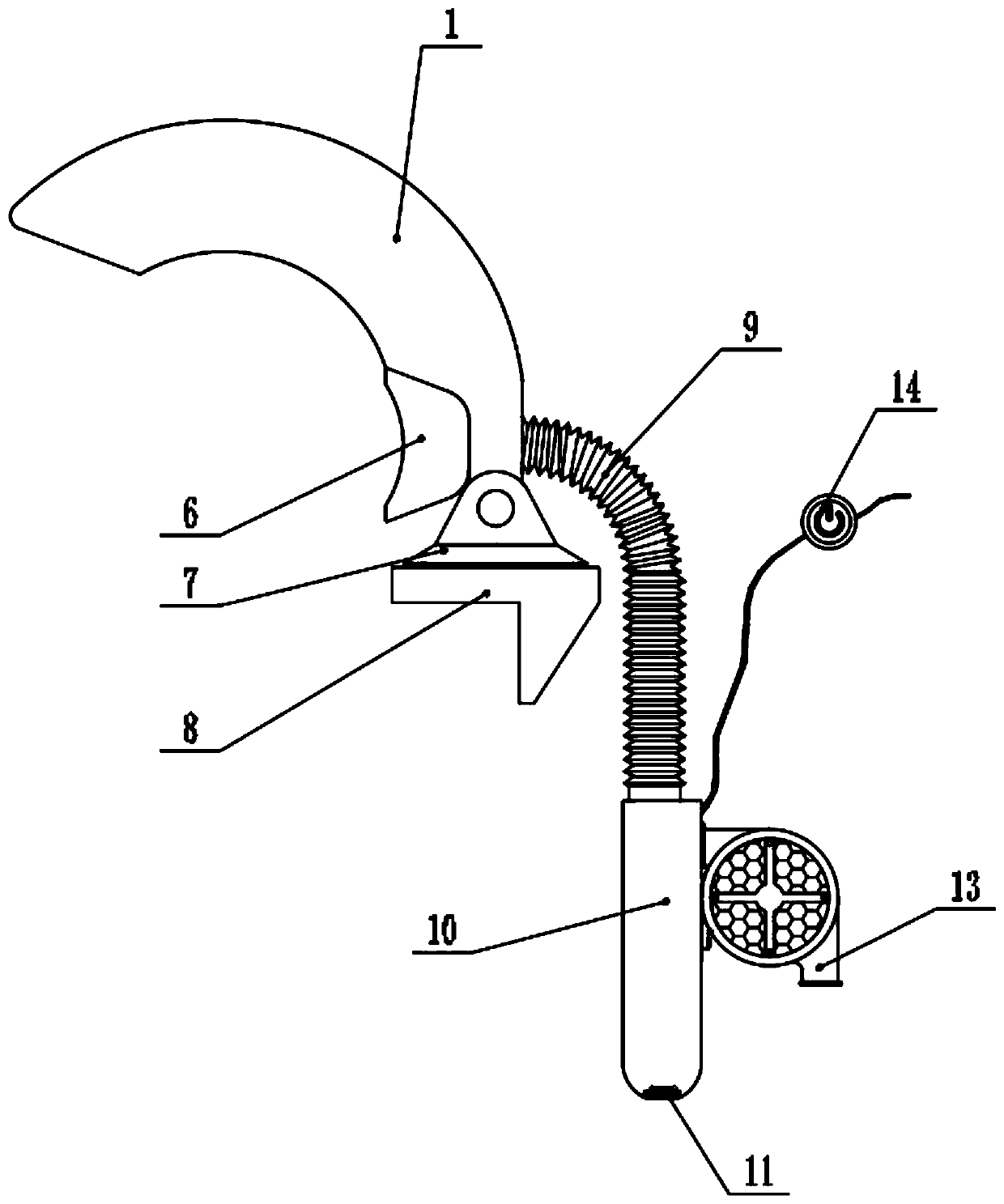

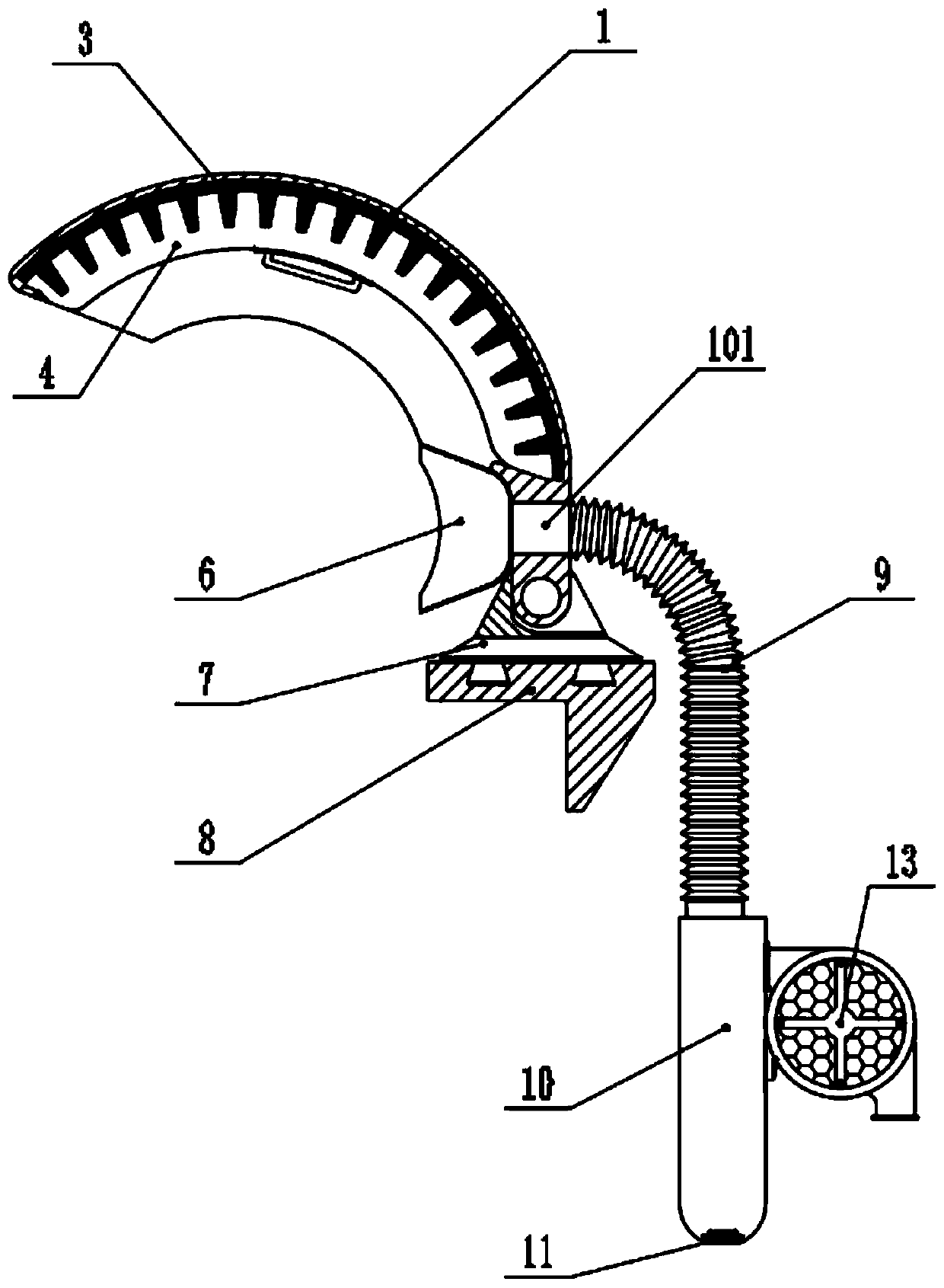

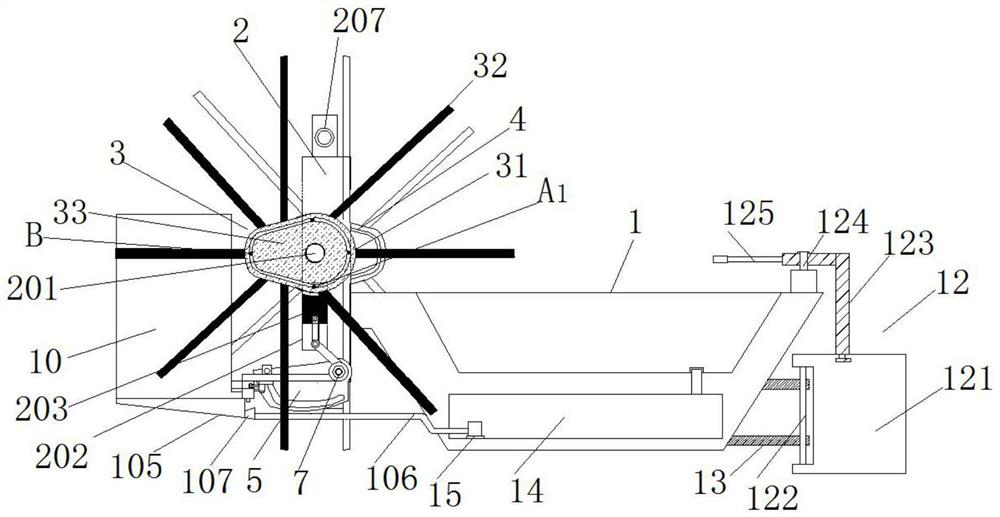

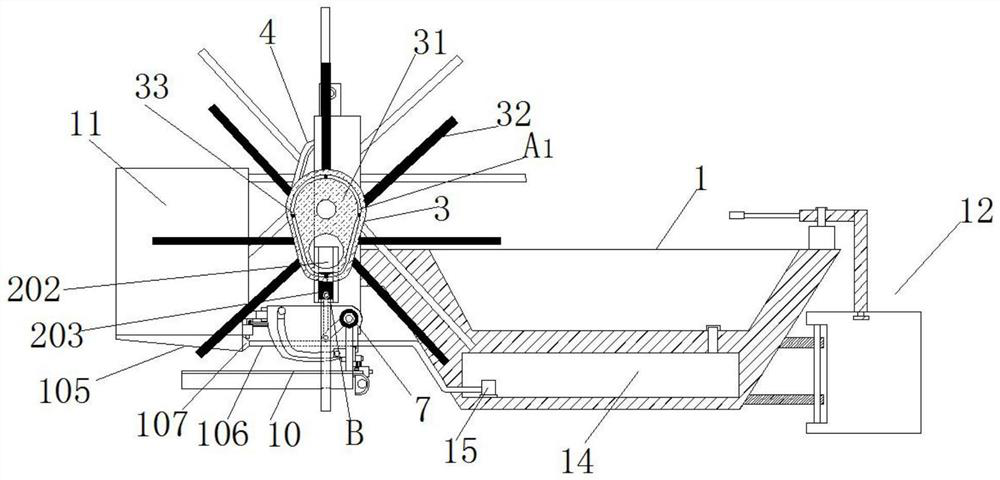

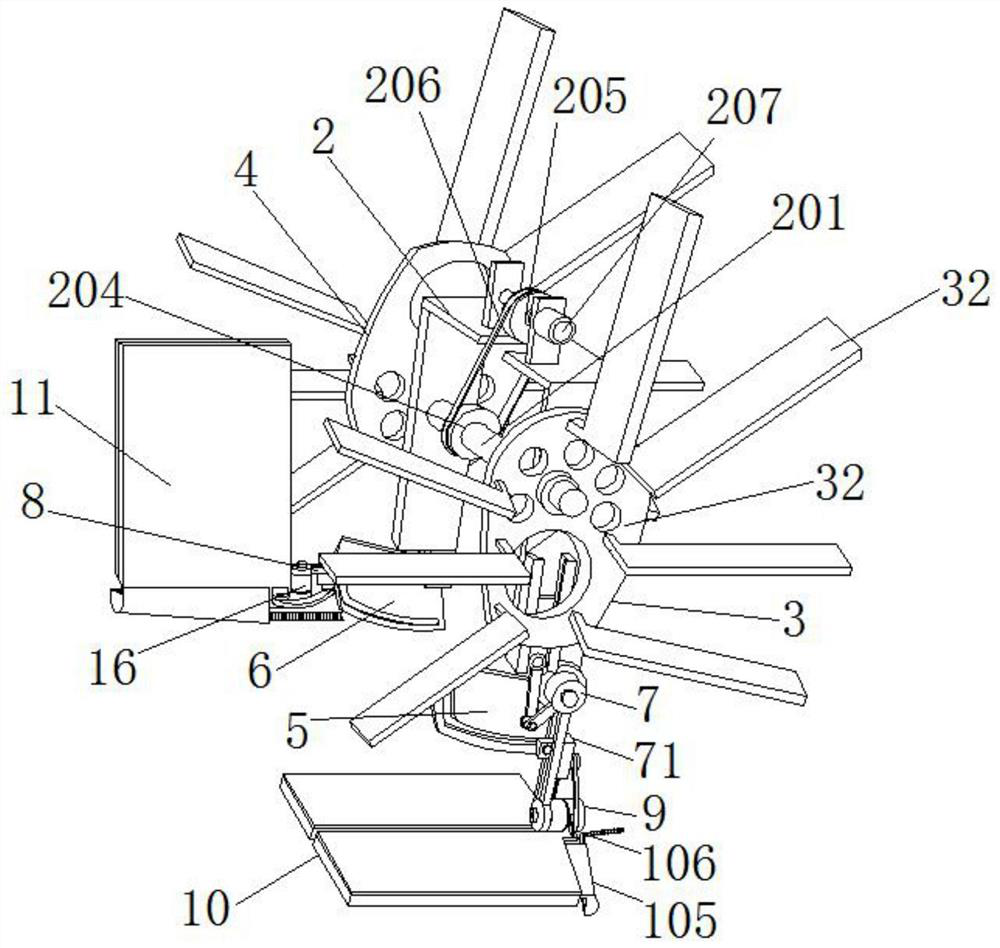

Nondestructive picking device of Coriolus versicolor

ActiveCN107318364AEasy to absorb and collectRealize acquisitionHarvestersCultivating equipmentsEngineeringDrive motor

The invention relates to a nondestructive picking device of Coriolus versicolor, comprising a rotary mounting seat, a base, a negative pressure generator and movable grippers; a collecting trough mounted at one end of the inside of the base, a pressurized gas generator is mounted at the other end of the inside of the base, a driving motor is mounted in the base between the pressurized gas generator and the collecting trough, the rotary mounting seat is mounted a the top end of the base right above the driving motor, a first fixed arm of force and a second fixed arm of force are hinged to the top end of the rotary mounting seat, one end of the first fixed arm of force far away from the rotary mounting seat is hinged to a first movable arm of force. The pressurized gas generator, the negative pressure generator, a first mounting disc, a main gas guide pipe, branch gas guide pipes and vacuum suckers, the negative pressure generator transmits compressed air around the vacuum suckers so that the ambient forms a negative pressure ambient, Coriolus versicolor is sucked and picked via the vacuum suckers, nondestructive picking of Coriolus versicolor is achieved, and picking is very convenient.

Owner:蔡茜茜

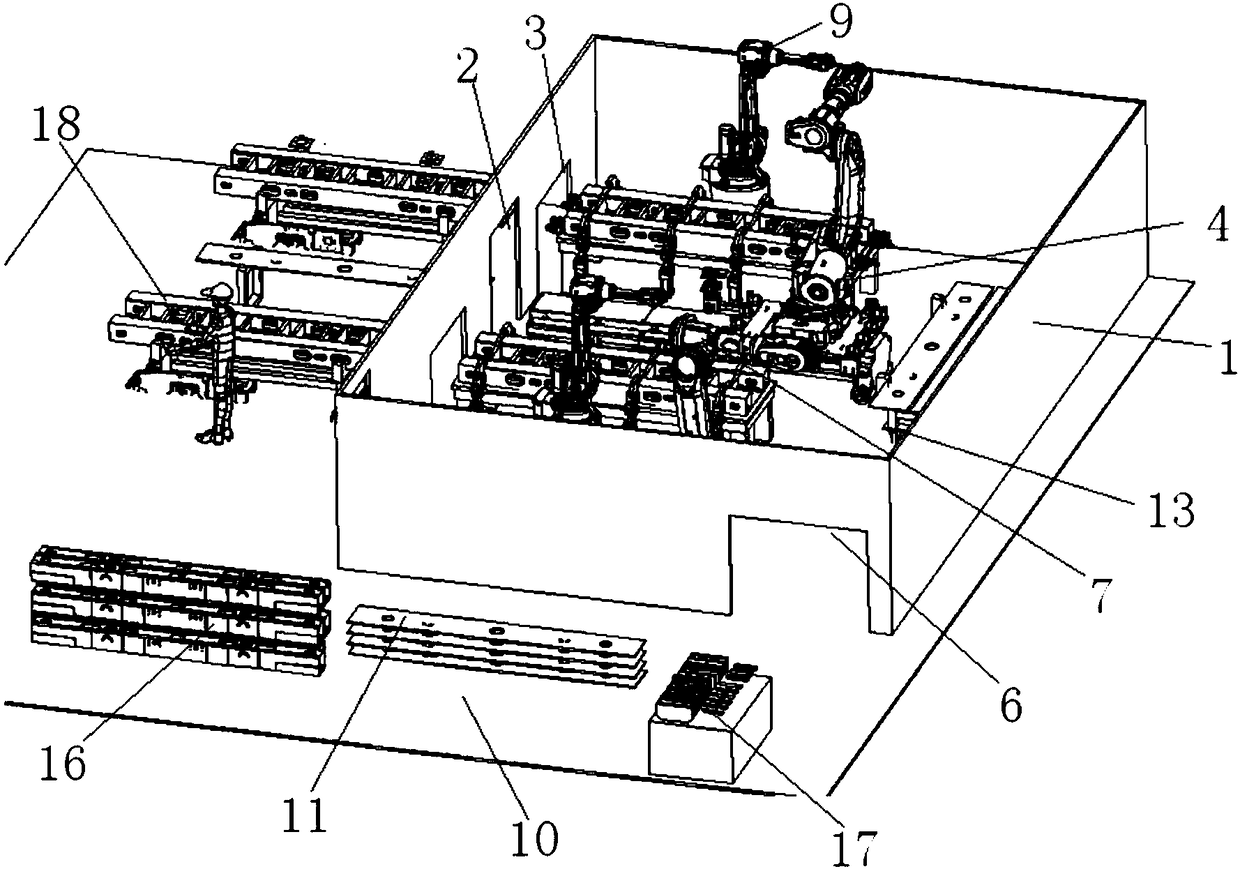

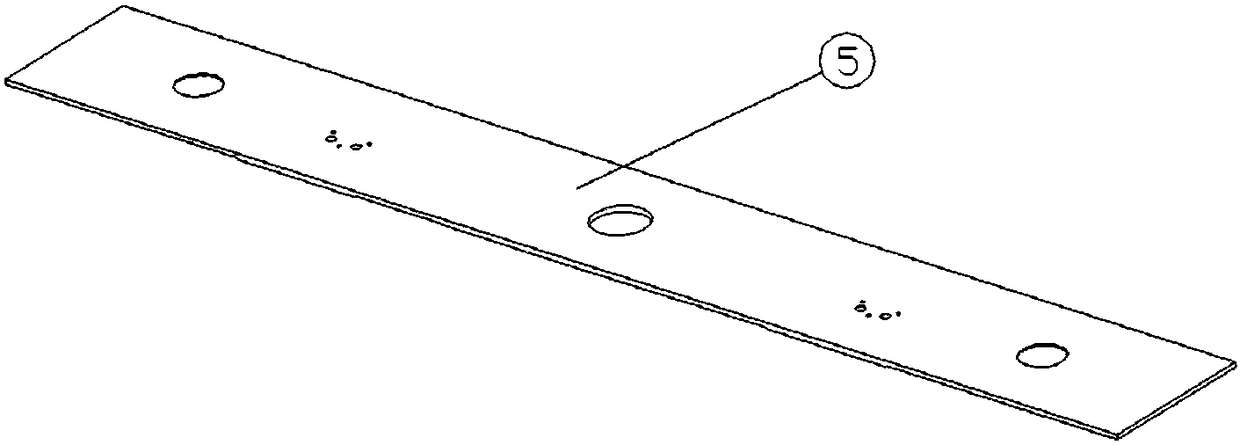

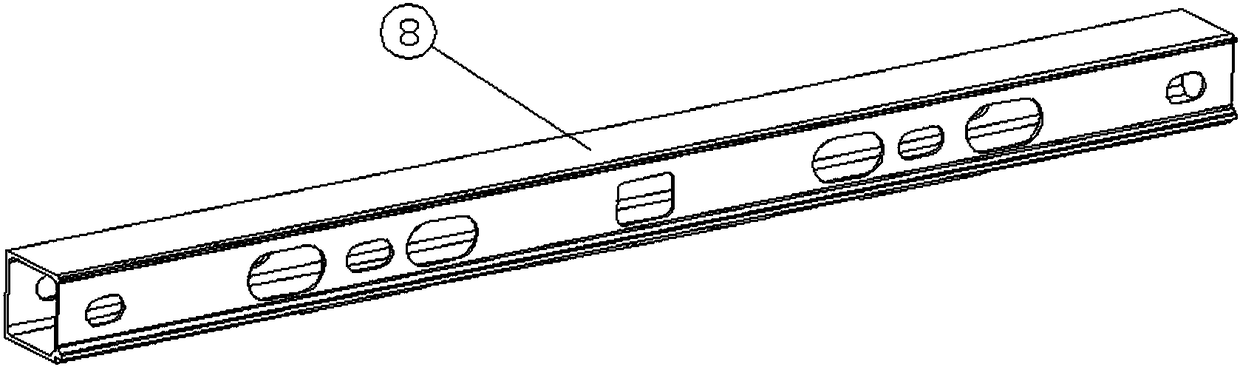

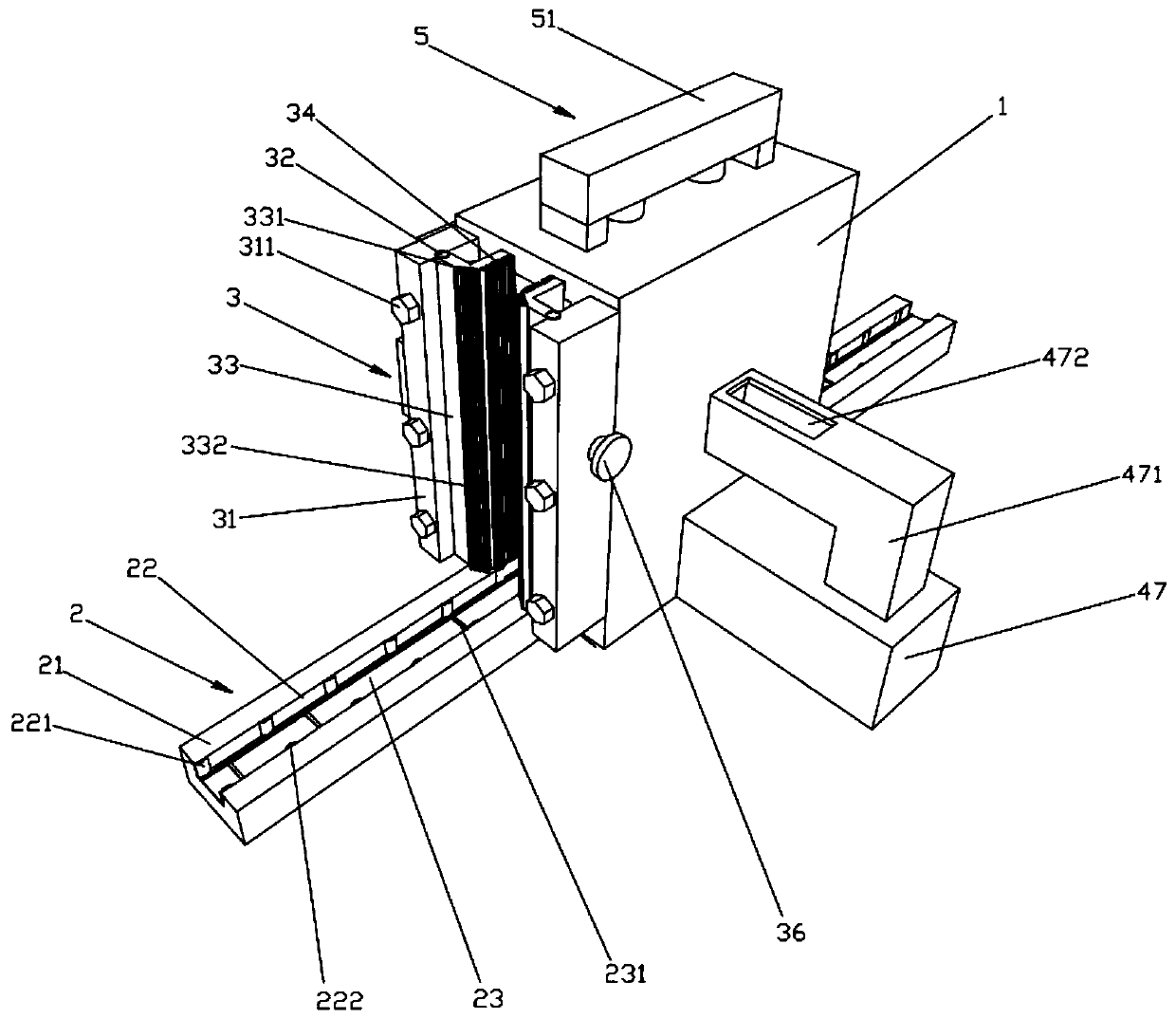

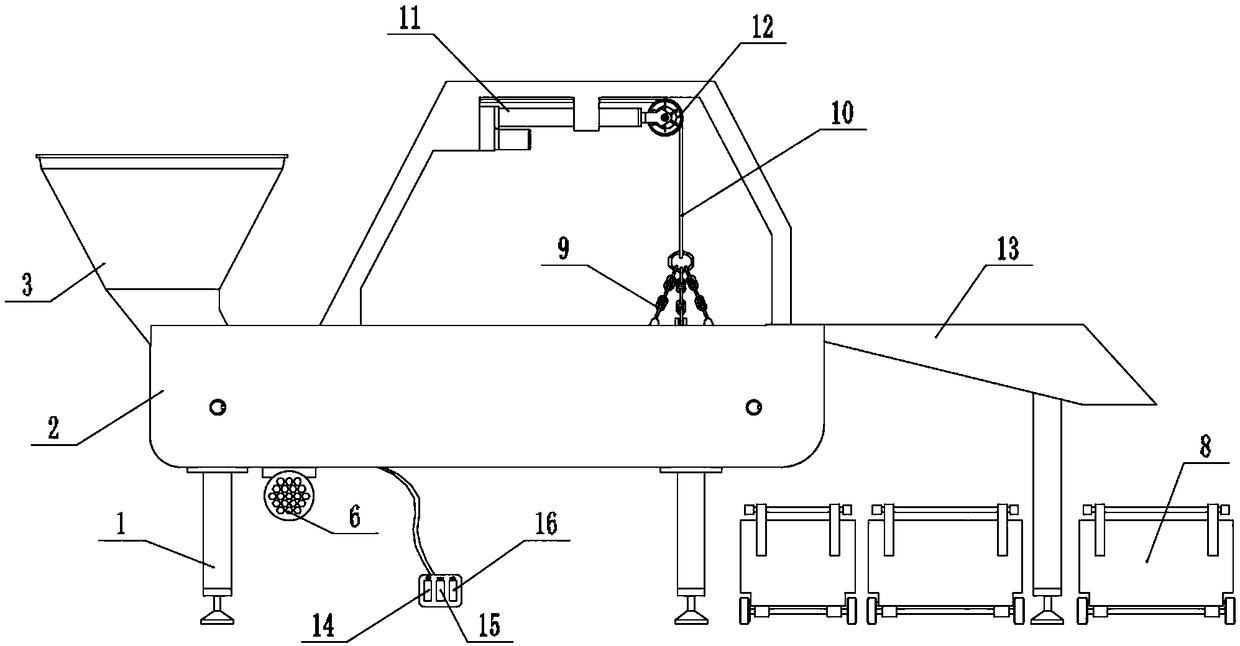

High-speed rail sleeper beam robot automated production line

PendingCN108145721AImprove labor efficiencyQuality assuranceArc welding apparatusOther manufacturing equipments/toolsProduction lineWorking environment

The invention relates to a high-speed rail sleeper beam robot automated production line. The high-speed rail sleeper beam robot automated production line comprises a closed work space, a first conveying and polishing robot, a second conveying and polishing robot and an automatic welding station. A first feeding inlet is formed in the middle of one side face of the closed work space, a piece feeding robot is arranged on the position, corresponding to the first feeding inlet, of the inner side of the closed work space and used for positioning and welding of lower cover plates and edge beams, andplatforms for storing the large lower cover plate and the small lower cover plates are arranged on the front side and the rear side of the piece feeding robot correspondingly. A second feeding inletis formed in the side face, adjacent to the first feeding inlet, of the closed work space, a polishing robot is arranged on the position, corresponding to the second feeding inlet, of the inner side of the closed work space and used for polishing the lower cover plates, the edge beams and stiffening plates, and discharging outlets are formed in the two sides of the first feeding inlet correspondingly. According to the high-speed rail sleeper beam robot automated production line, the severe production environment is improved, the robots work in the closed environment, thus dust is sucked and collected advantageously, and the work environment of workers is greatly improved.

Owner:SHANGHAI JUNYI IND AUTOMATION CO LTD

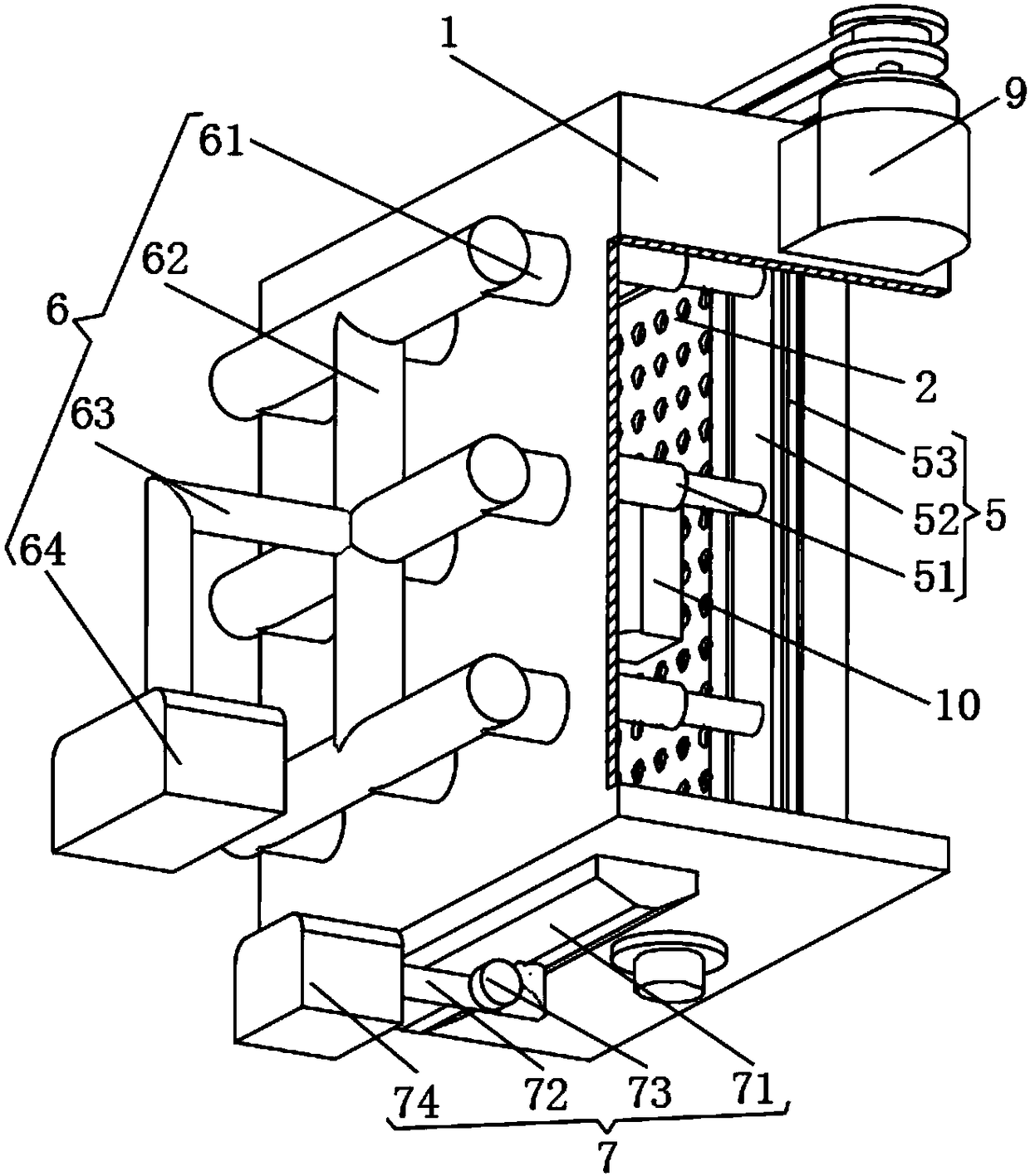

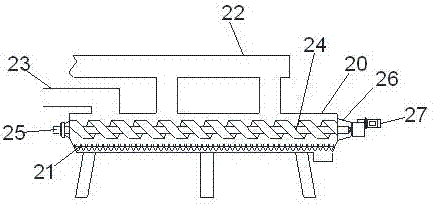

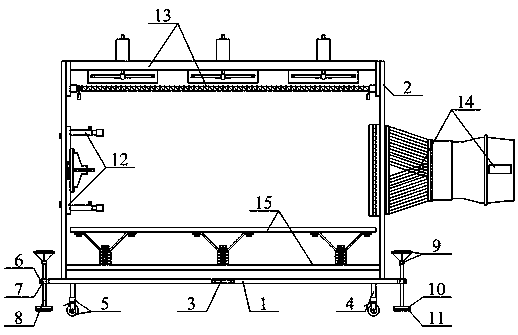

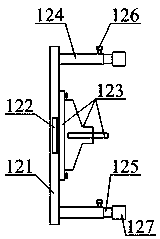

Double-sided dust removing device of furniture boards

ActiveCN111389781AEasy to cleanEasy to absorb and collectDirt cleaningCleaning using toolsDust controlStructural engineering

The invention provides a double-sided dust removing device of furniture boards and relates to the technical field of furniture machining equipment. The double-sided dust removing device comprises a dust removing box; the side walls of the two ends of the dust removing box are opened; a board conveying apparatus is disposed at the bottom of the dust removing box in a penetrating mode; the board conveying apparatus comprises a conveying belt base; the conveying belt base is disposed at the bottom of the dust removing box; the two ends of the conveying belt base are located outside the two ends of the dust removing box correspondingly; a conveying belt installing groove is formed in the top surface of the conveying belt base; a conveying belt is fixedly disposed at the bottom in the conveyingbelt installing groove; a plurality of board anti-sliding strips are arranged on the surface of the conveying belt at equal intervals; a plurality of left half cylinders and right half cylinders aredisposed on the opposite inner walls of the conveying belt installing groove correspondingly; ash scraping apparatuses are symmetrically disposed on the two side walls of the opening of one end of thedust removing box; and each ash scraping apparatus comprises an ash scraping base. The double-sided dust removing device has the advantages that dust and chippings on the surfaces of the boards can be effectively cleared and collected.

Owner:安徽省庆新家具有限公司

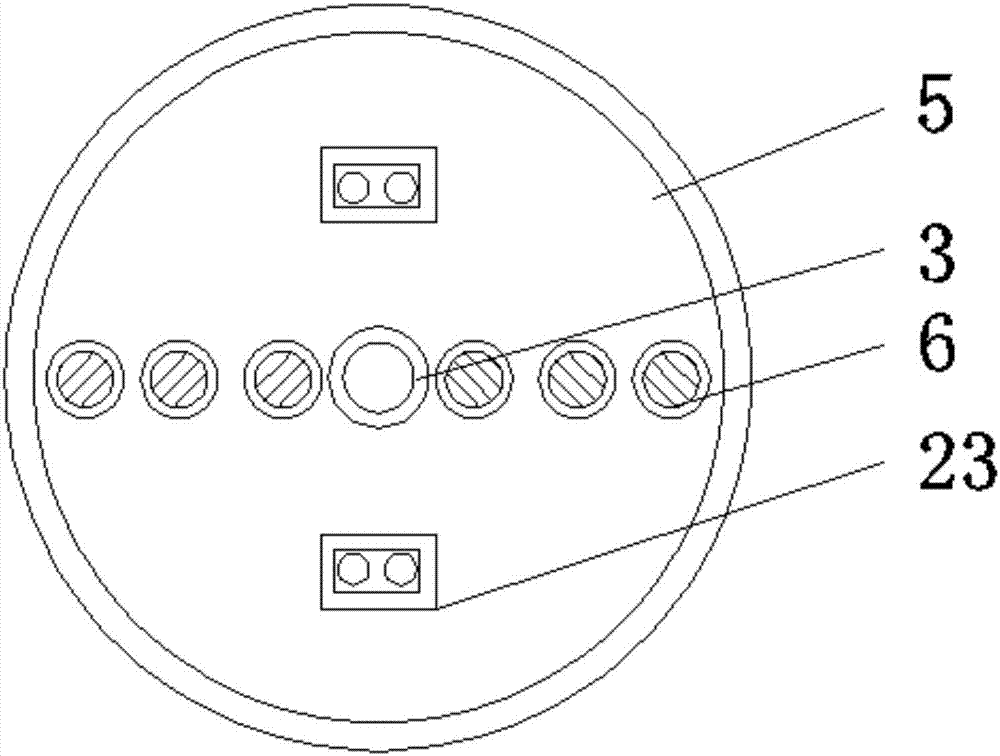

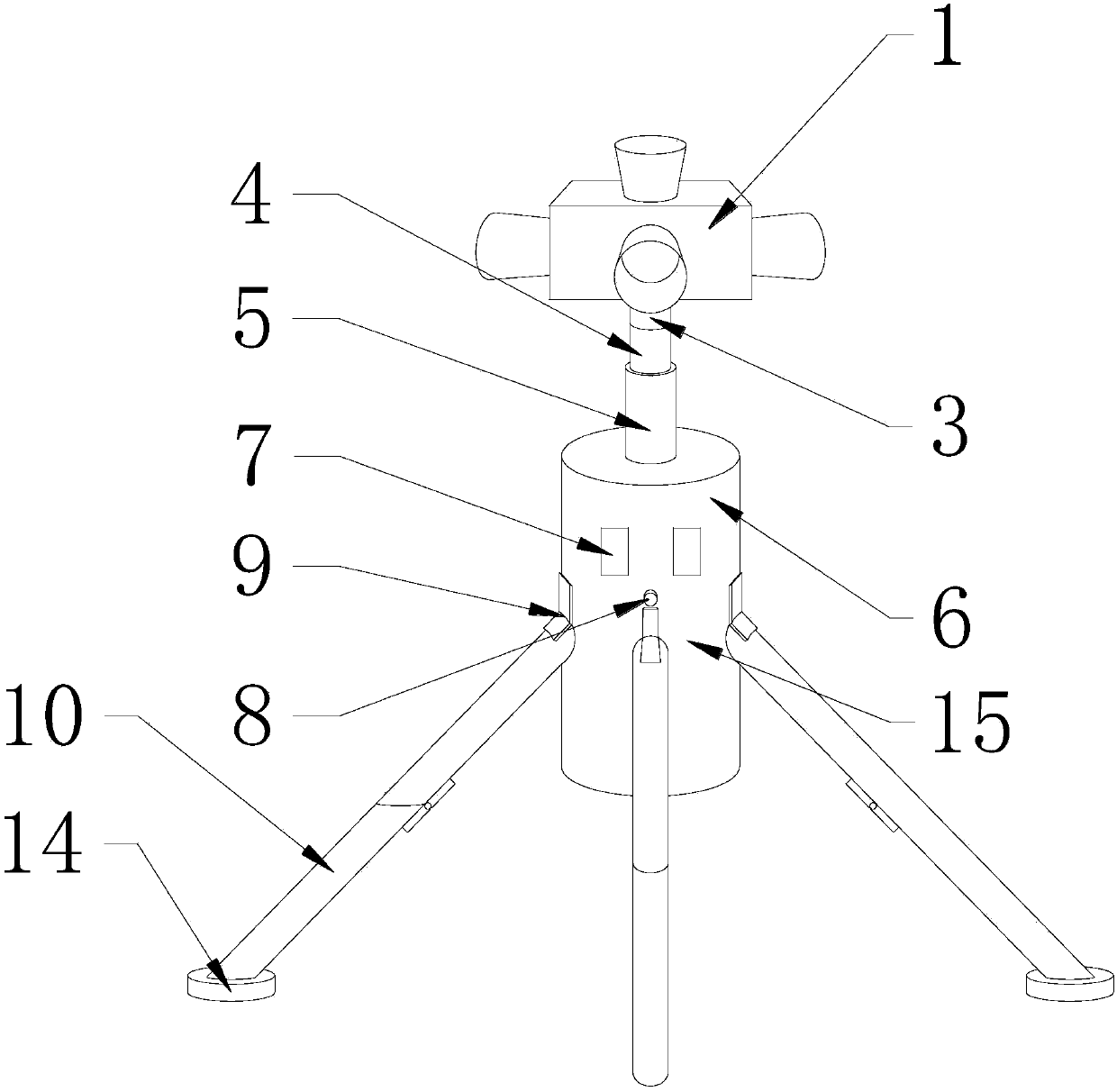

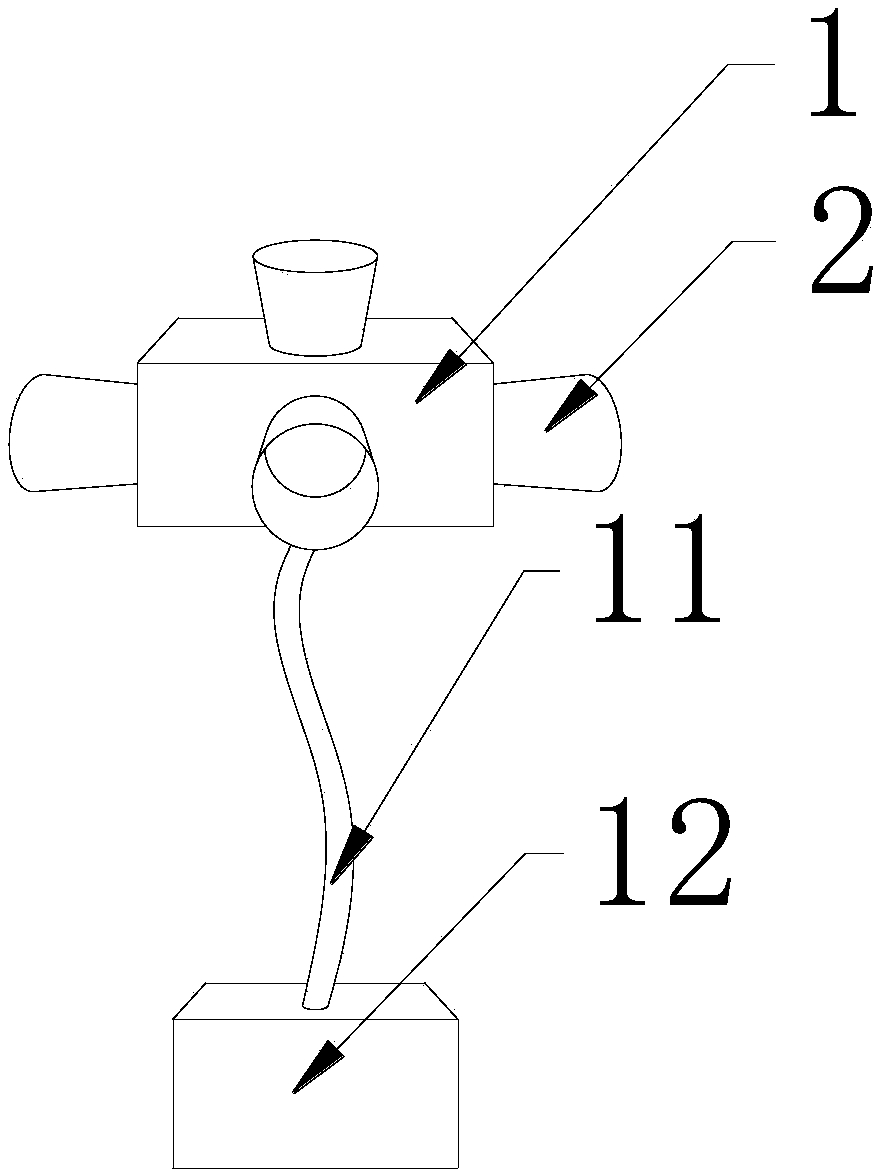

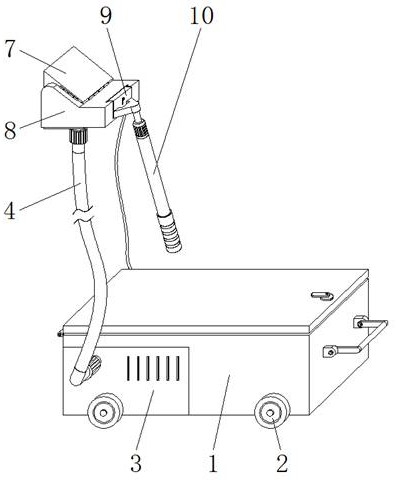

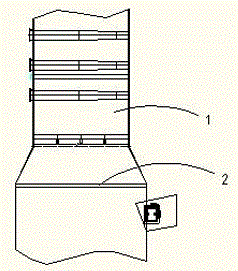

Acquisition system for atmosphere detection

PendingCN108036978AExpand the scope of absorptionUniform collectionWithdrawing sample devicesEngineeringAir pump

The invention discloses an acquisition system for atmosphere detection. The system comprises a system body, the top of the system body is provided with an air absorption pump which has a 'cuboid' shape, the middle part of bottom of the air absorption pump is provided with a rotating head, the swivel head can be used for rotating the air absorption pump, the bottom of the swivel head is fixedly connected with a telescoping rod, and the telescoping rod and the swivel head are connected by welded fixation; a second telescoping rod is fixed at the bottom of the telescoping rod, and the telescopingrod can be telescoped up and down in the second telescoping rod. The acquisition system for detection of atmosphere is provided with the swivel head and air absorption hoods, air absorption hoods arearranged at the top, the left end and the right end, as well as the front end and the back end, rotation speed of the swivel head can be set, so that uniform absorption and acquisition of air are facilitated, the air absorption pump can be manually held, the telescoping rod at the bottom of the air absorption pump can telescopically raise in the second telescoping rod, air at a certain height canbe conveniently acquired, effects for absorbing air at different areas are realized, and absorption ranges are widen.

Owner:YICHUN UNIVERSITY

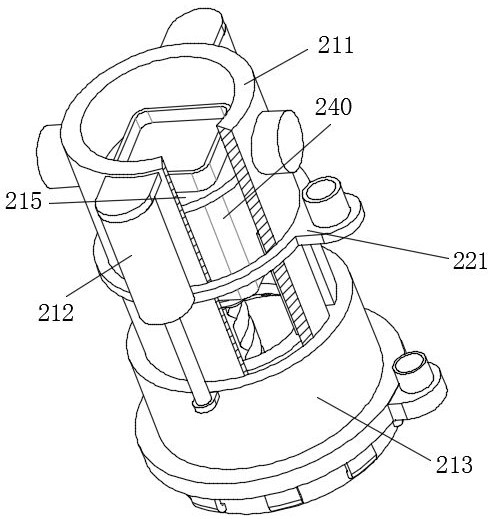

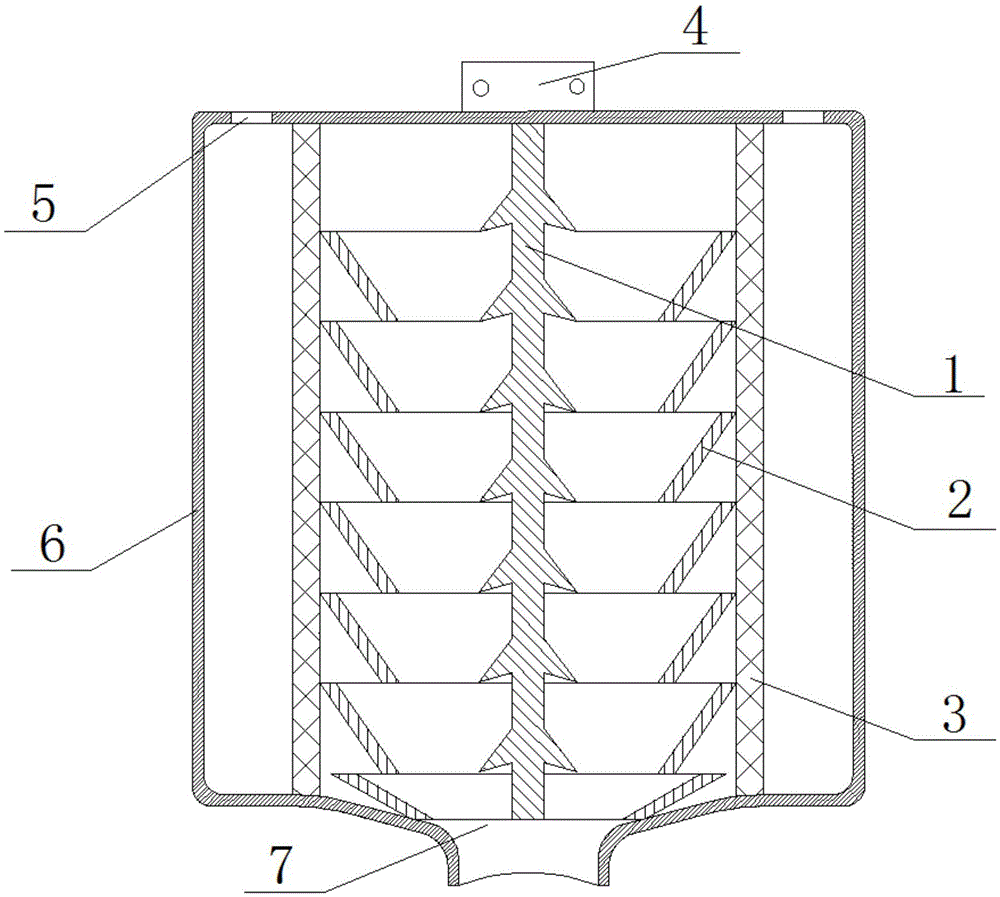

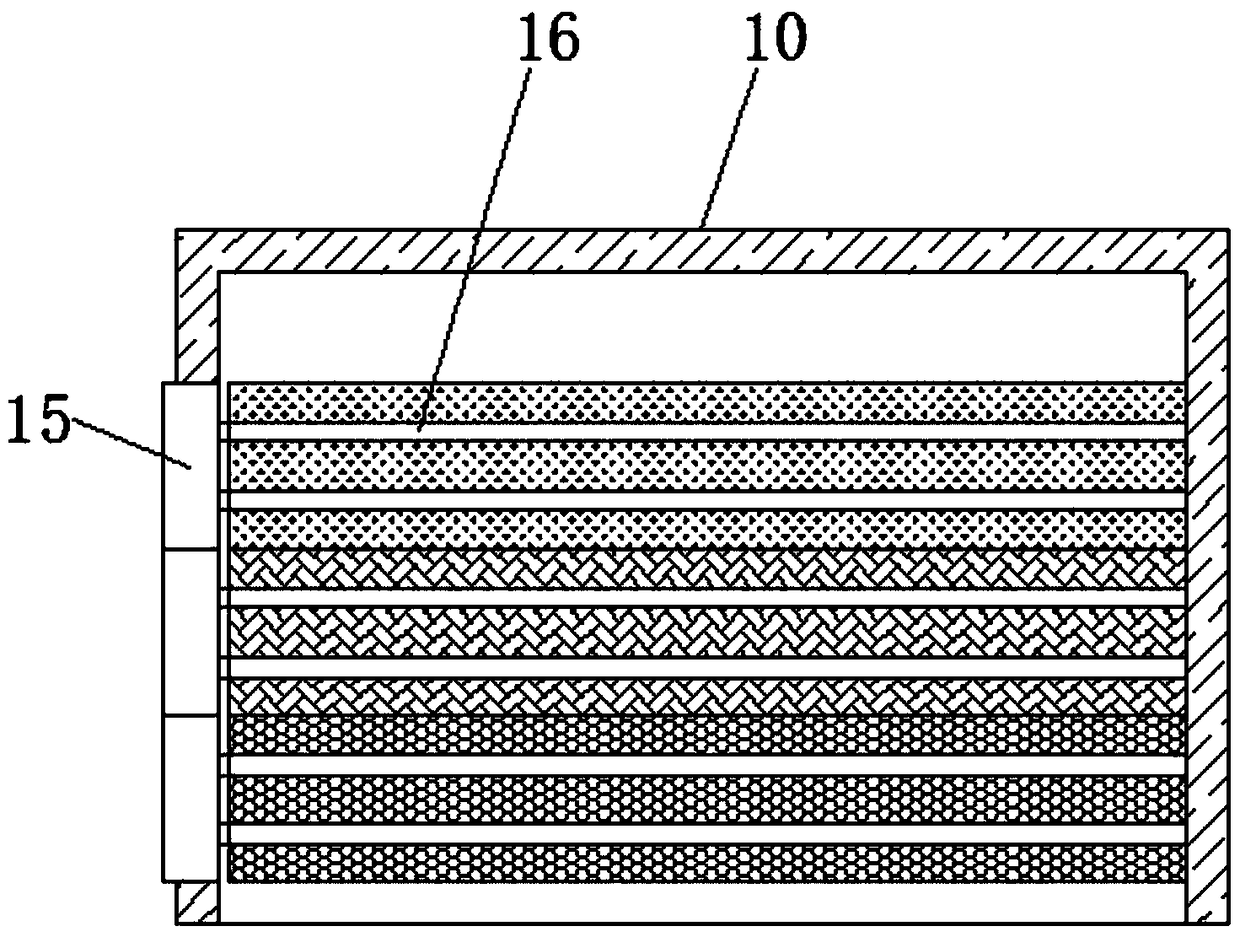

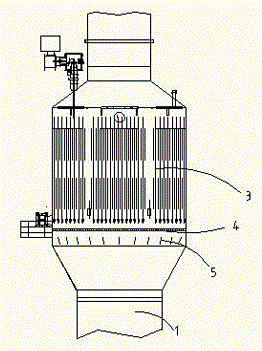

Combined air filter

ActiveCN105484905ACompact and reasonable structure designEasy to moveMachines/enginesAir cleaners for fuelAir filterEngineering

The invention discloses a combined air filter comprising a shell and an electrostatic dust suction device, wherein a filter screen cylinder is arranged in the shell; a corona electrode with a raised structure and a dust collecting electrode are arranged at the periphery of the shell; and air is effectively filtered through roughly filtering dust-containing air by using the filter screen cylinder and finely filtering the dust-containing air by using the electrostatic dust suction device in the air suction process. The combined air filter is compact and reasonable in structural design; the filter screen cylinder can be used for roughly filtering air and repeatedly cleaning and using the air; and due to the arrangement of the electrostatic dust suction device, the dust collecting effect is improved, meanwhile, the air inlet resistance is reduced, the performance of an engine is improved, the service life of the filter is prolonged, and the filtering efficiency is increased.

Owner:枞阳县美丙建材有限公司

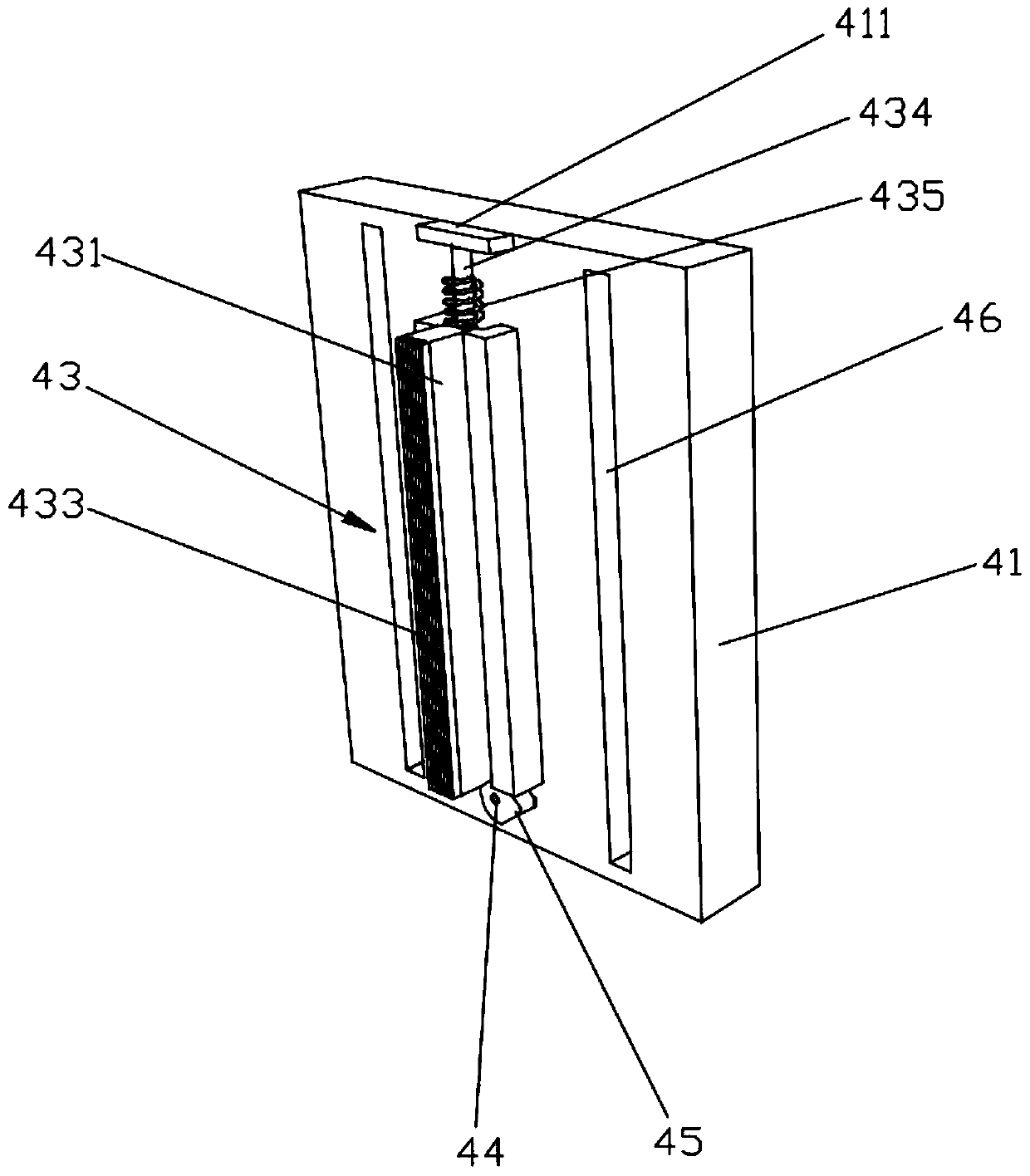

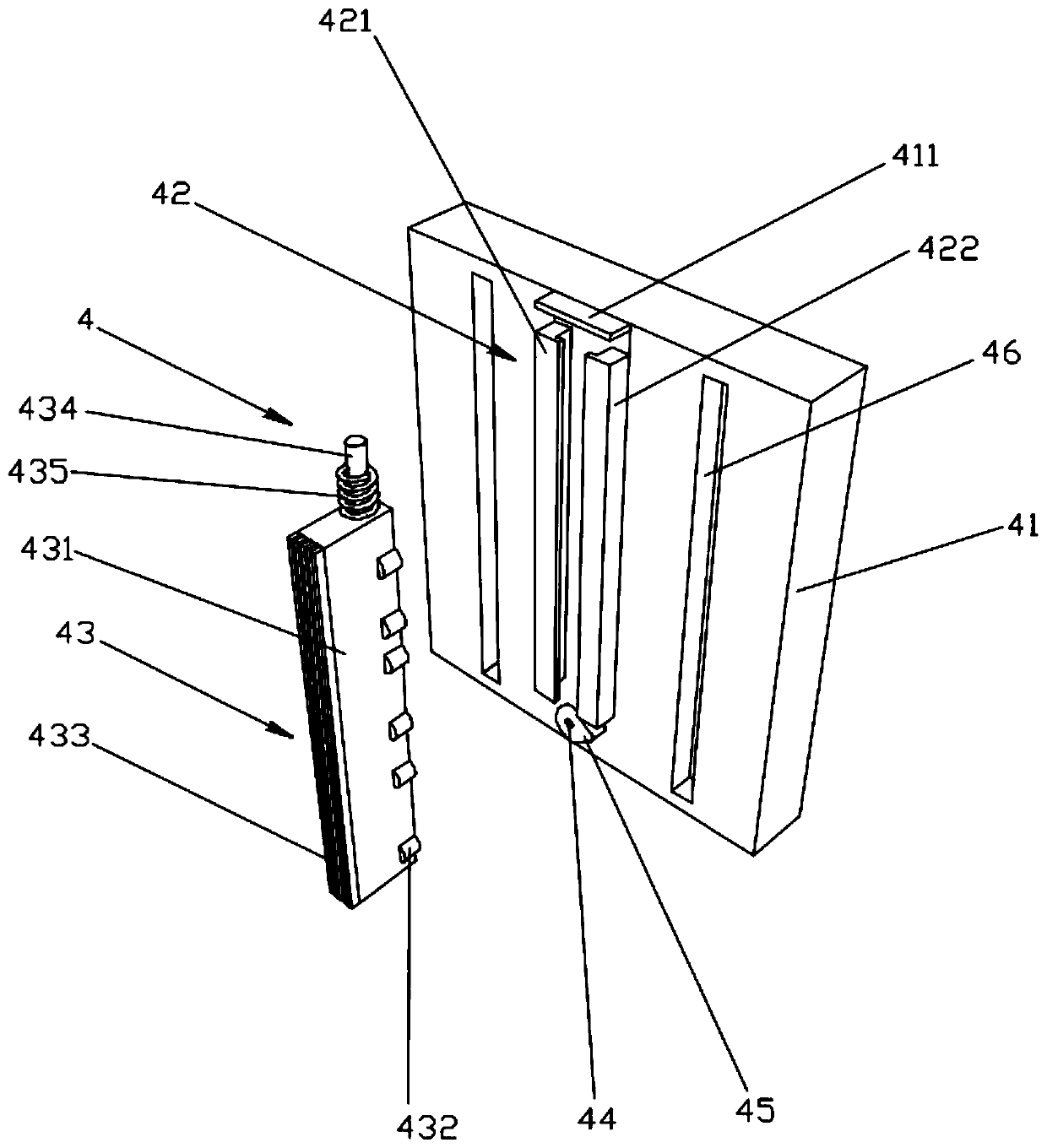

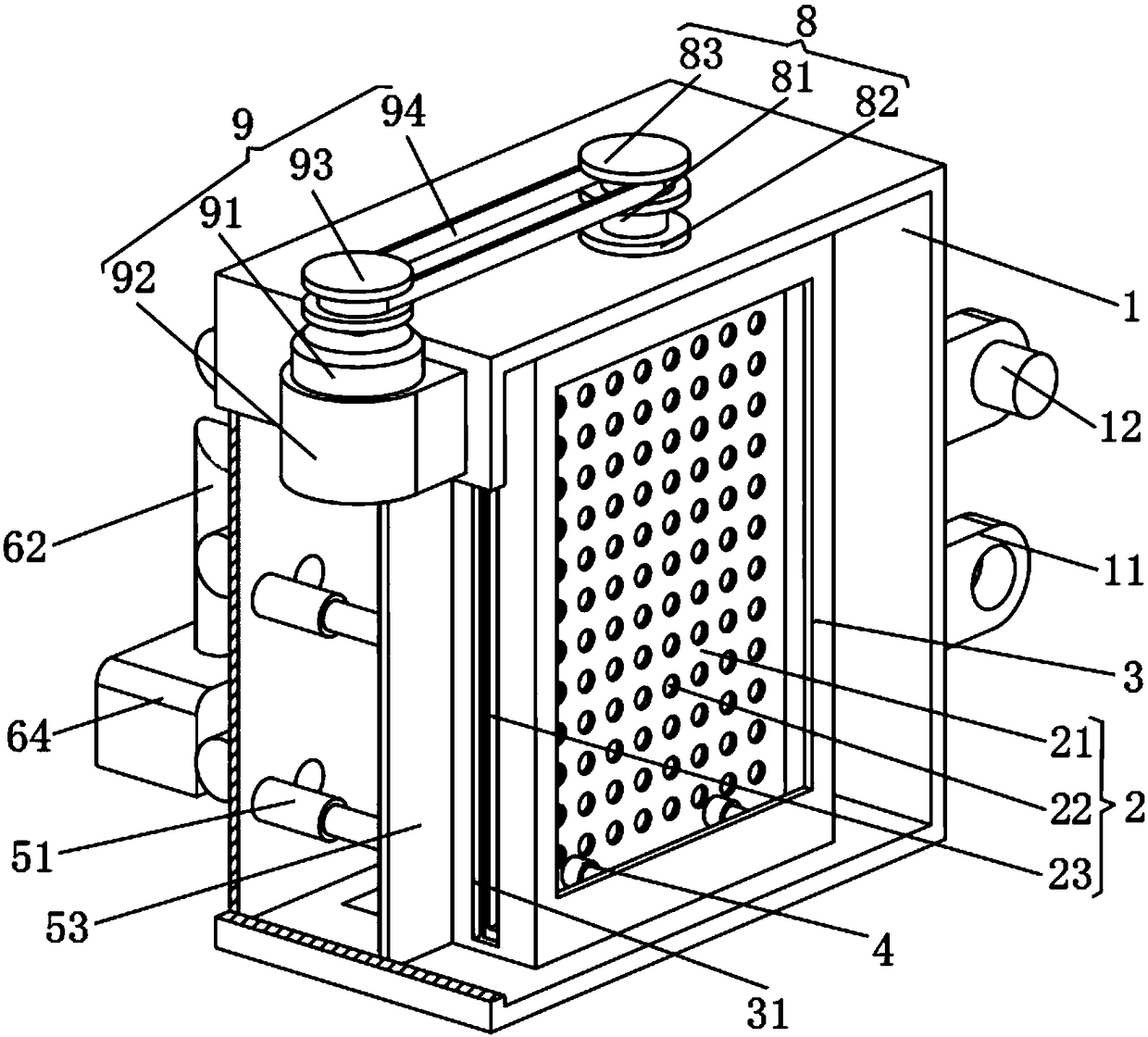

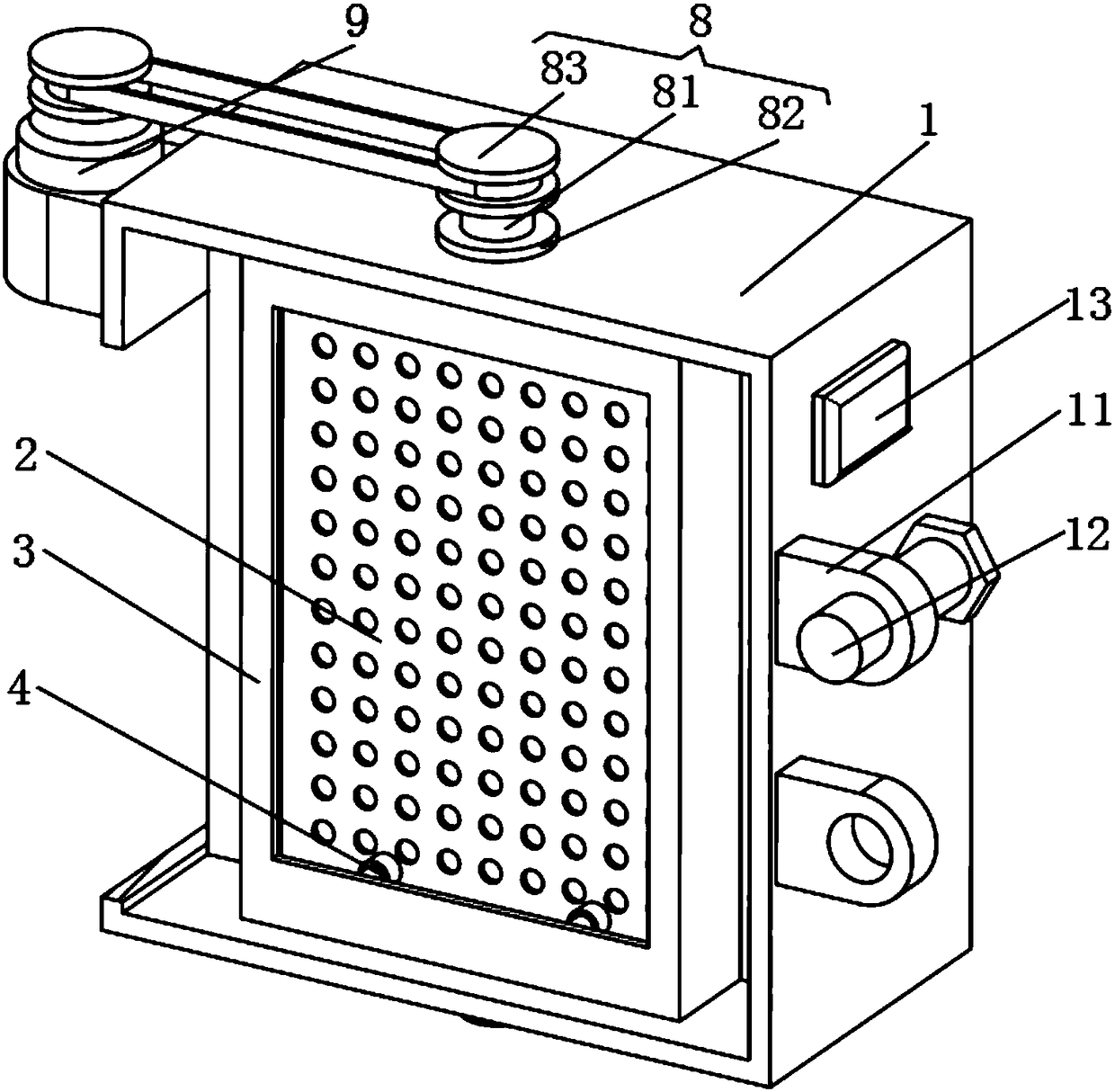

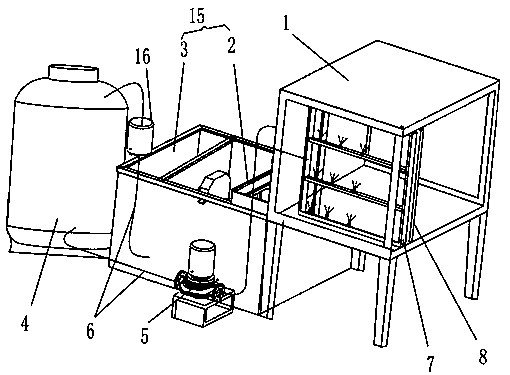

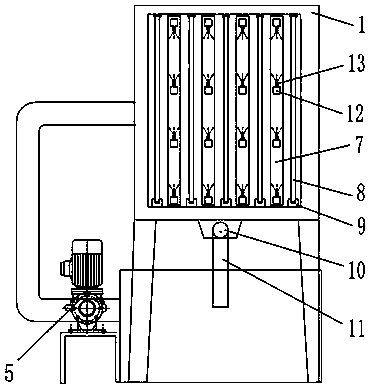

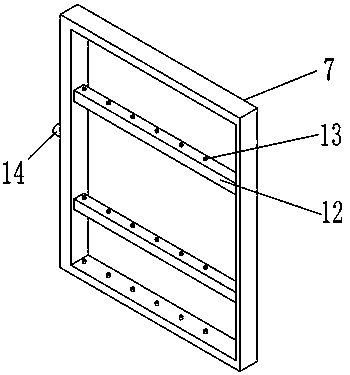

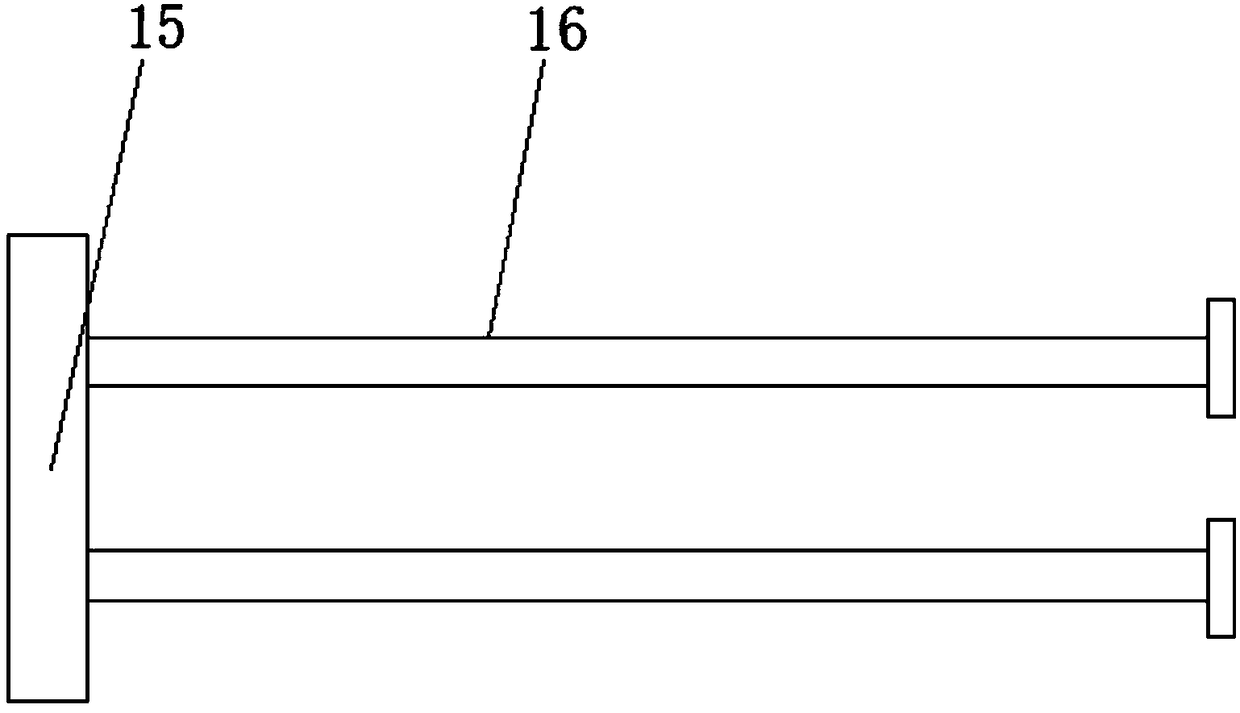

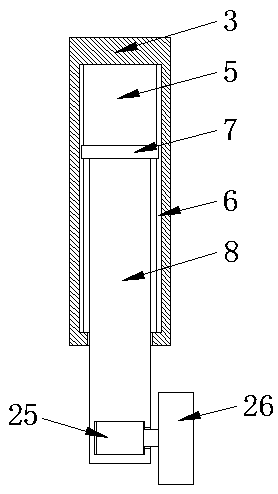

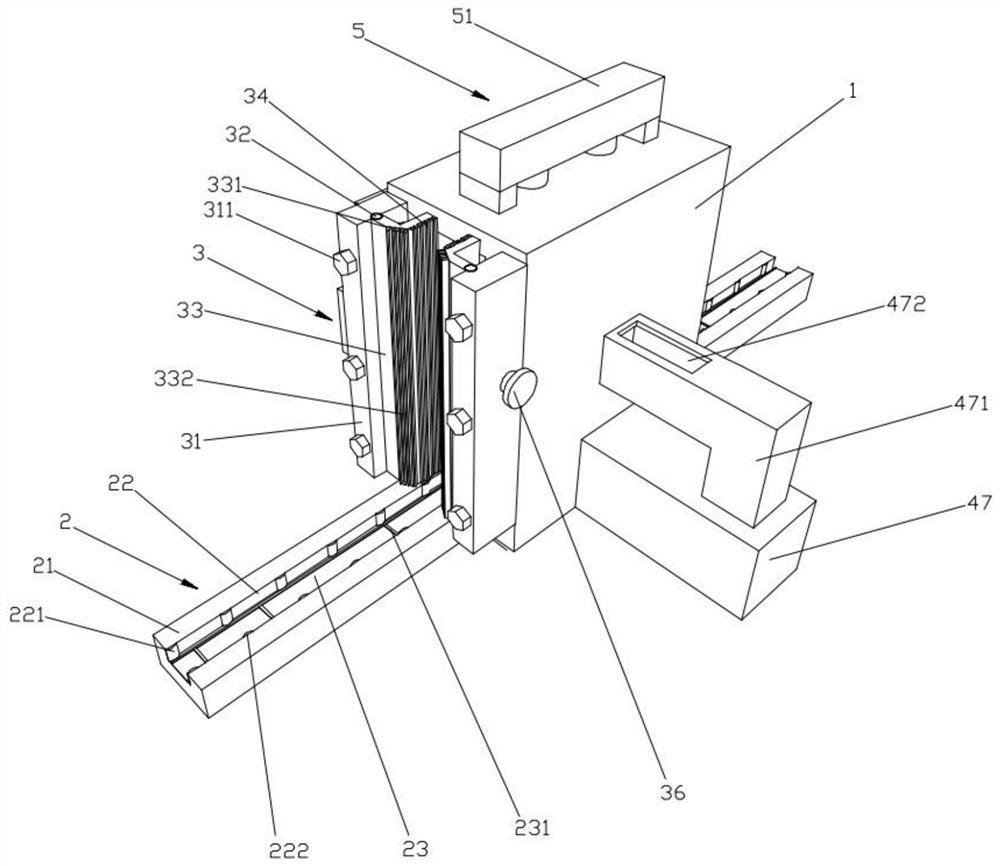

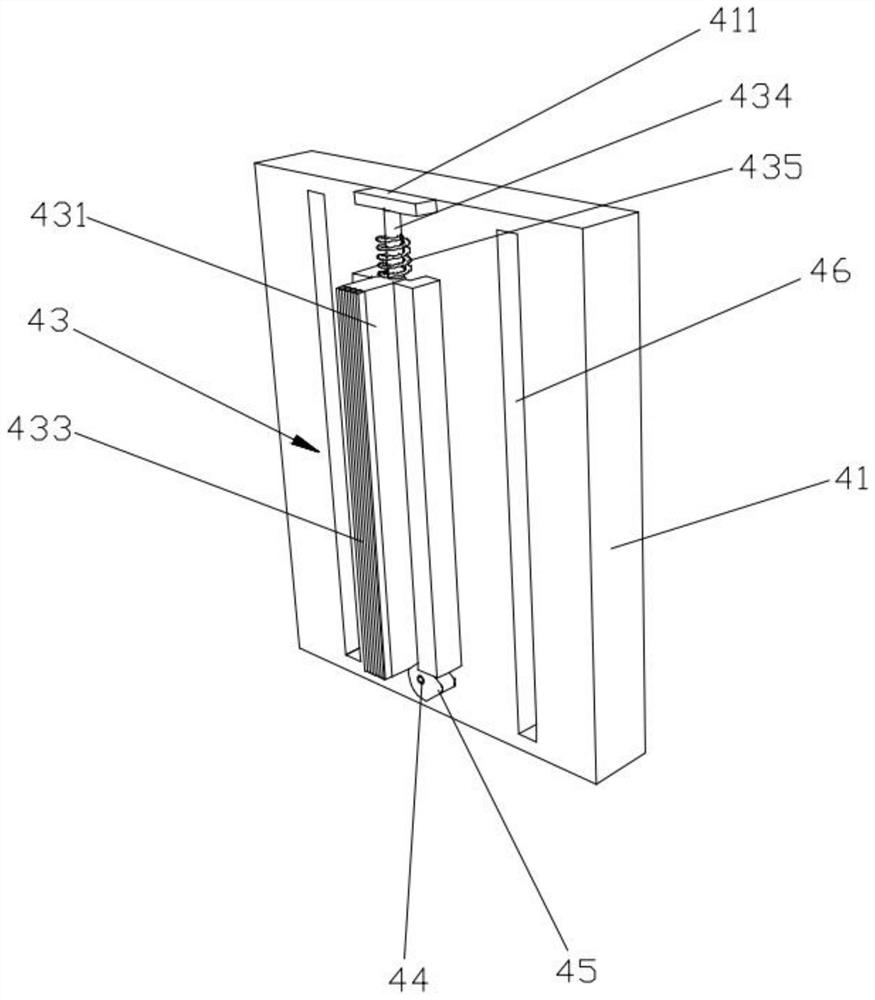

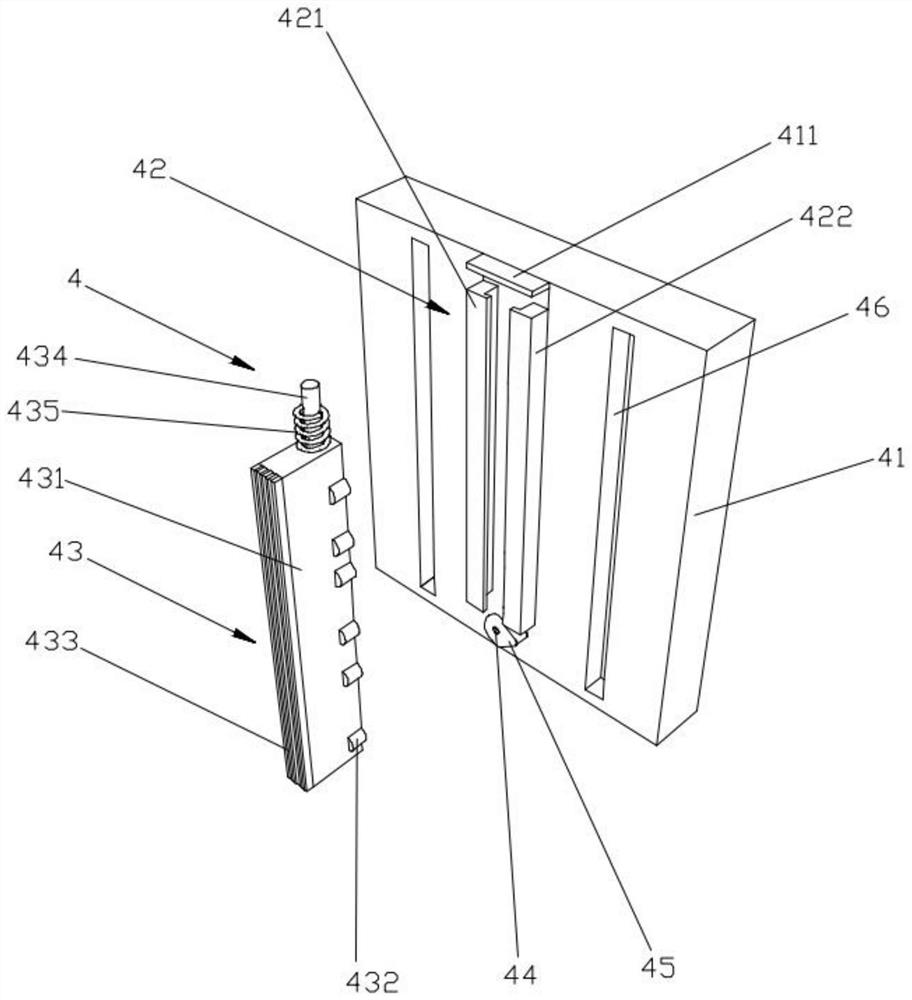

Self-dedusting ventilation filtration device used for intelligent substation

InactiveCN108365523AEasy to absorb and collectEasy to collectSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsSmart substationFiltration

The invention discloses a self-dedusting ventilation filtration device used for an intelligent substation. The self-dedusting ventilation filtration device comprises an outer frame, a fixing frame isarranged at the front end in the outer frame, a filter is arranged inside the fixing frame, and a second strip-shape groove is formed in the side, corresponding to a first strip-shape groove of the filter, of the fixing frame. A vibration motor is arranged in the middle of the rear surface of a filtering plate of the filter, sealing devices are arranged at the left end and the right end in the outer frame respectively, a positioning device is arranged at the upper end of the fixing frame, and a driving device is arranged at the upper end of the side, corresponding to the positioning device, ofthe outer frame. An air drawing device is arranged on the rear surface of the outer frame, and a rectangular hole is formed in the rear side of the lower end in the outer frame. The self-dedusting ventilation filtration device used for the intelligent substation is convenient to fix, the filtering plate can rotate, and dust is easily extracted and collected; dedusting cotton can be reused, the ventilation effect of the substation can be improved through an air drawing machine, the operation is simple, and the self-dedusting ventilation filtration device is convenient to use.

Owner:浙江双鸿新能源科技有限公司

Ceramic tile seam beautifying agent cleaning device capable of collecting for building construction

InactiveCN112196237AEasy replacement handlingEasy to crushBuilding constructionsArchitectural engineeringElectric machinery

The invention discloses a ceramic tile seam beautifying agent cleaning device capable of collecting for building construction. The ceramic tile seam beautifying agent cleaning device comprises a storage box, a dust suction device body, a telescopic rod and a driving motor, wherein walking wheels are rotationally connected to the front side wall and the rear side wall of the storage box, the dust suction device body is installed on the lower side of the left end of the storage box, a dust suction pipe is in threaded connection with an air inlet of the dust suction device body, a fixing cover iswelded to the upper side of a square-to-round connecting cover, an auxiliary cover is welded to the upper side of the fixing cover, a mounting box is installed on the outer side wall of the fixing cover through bolts, and the telescopic rod is fixedly connected to the lower end of the right side of a mounting base. According to the ceramic tile seam beautifying agent cleaning device capable of collecting for building construction, large pieces of seam beautifying agent residues can be conveniently crushed, the seam beautifying agent residues can be conveniently swept and conveyed, so that thesubsequent absorption and collection are more convenient, in addition, the cleaning device can be conveniently disassembled, the subsequent storage is facilitated, and the practicability is improved.

Owner:马蕴玲

Efficient zinc powder production device

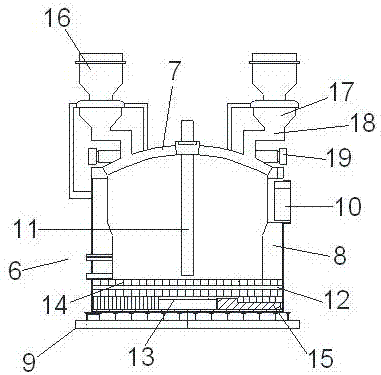

PendingCN107354320AImprove production and processing efficiencyWarm up evenlyProcess efficiency improvementElectric arc furnaceElectric machinery

The invention discloses an efficient zinc powder production device which comprises an automatic-feeding electric zinc furnace, an electric raw material heating device, a condenser, a pulse dust collection device and a screening and packing apparatus. The automatic-feeding electric zinc furnace comprises an electric-arc furnace and a feeding device, the electric-arc furnace comprises a furnace cover, a furnace body and a furnace bottom electrode, an exhausting port is formed in one side wall of the furnace body, and a cathode is arranged in the furnace body. The furnace bottom electrode comprises a fire-resistant furnace liner, a conductive flow equalizing plate is arranged below the fire-resistant furnace liner, a group of anode plates are arranged on the fire-resistant furnace liner, the lower portions of the anode plates penetrate through the fire-resistant furnace liner to be connected with the conductive flow equalizing plate, and one side of the conductive flow equalizing plate is connected with a conductive cast steel rod. The feeding device comprises a containing cylinder, a feeding hopper, a feeding pipe and a feeding motor arranged on one side of the feeding pipe. The efficient zinc powder production device has the advantages of being higher in mechanical automatic degree, stronger in integrality and high in zinc powder producing and processing efficiency, the processing cost is reduced, the producing and processing efficiency is improved, and the product quality is improved.

Owner:贵州明峰工业废渣综合回收再利用有限公司

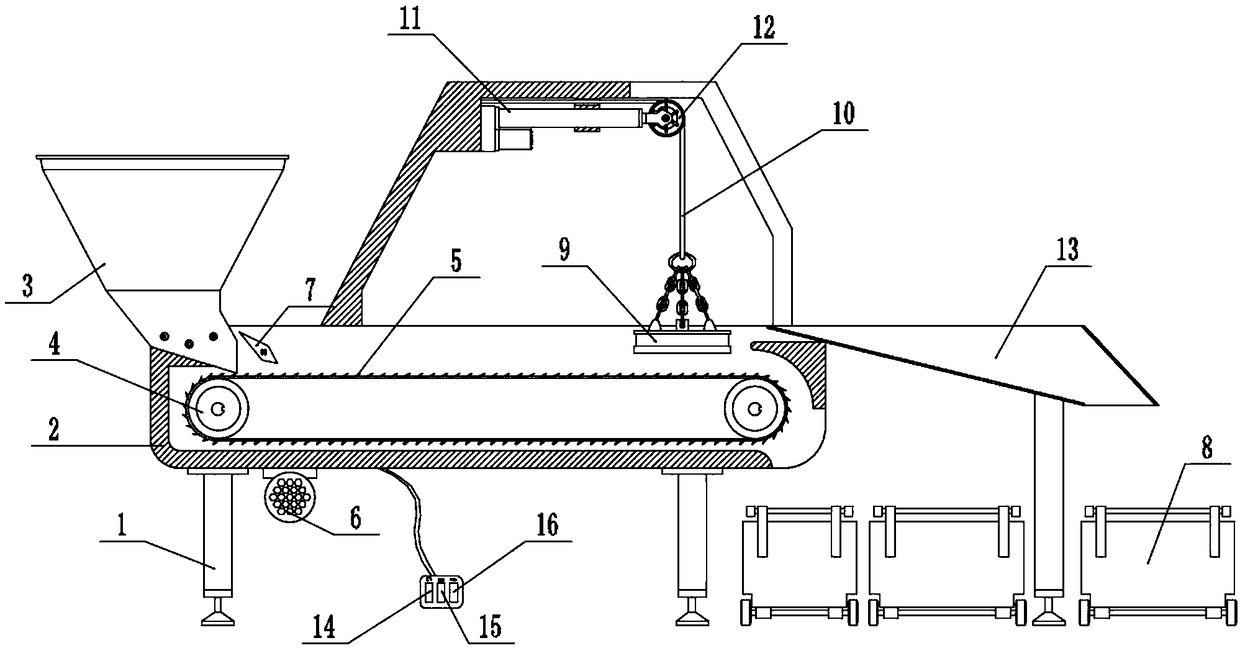

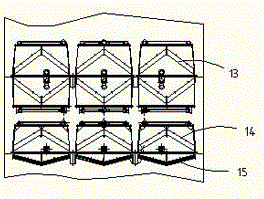

Environmental-friendly separating equipment for granular iron slag processing

The invention provides environmental-friendly separating equipment for granular iron slag processing. The environmental-friendly separating equipment for granular iron slag processing comprises a magnetic adsorption switch and an extension and retraction control switch. Six supporting frames are arranged on the bottom end face of a main body and an iron slag screening groove. The bottom of the main body is of a groove-shaped structure, and a material storage funnel is installed at the top position of the left end of the material storage funnel through screws. Two conveying wheels are located at the left end and the right end in the main body correspondingly. The furnace slag stored in the device is advantageously and continuously conveyed to the bottom of an electromagnet, and the situation that the electromagnet attracts the iron slag contained in the furnace slag, and consequently the loss of iron resources is reduced is avoided; and by means of the arrangement of reversed barbs on the exterior of a conveyor belt, the friction coefficient between the conveyor belt and the furnace slag can be increased, the furnace slag can be conveyed to the bottom of the electromagnet better, and the situation that the furnace slag on the bottom of the material storage funnel is accumulated too much, and consequently the bottom of the material storage funnel is blocked and the conveying effect of the furnace slag is affected is avoided.

Owner:严凤河

Electromechanical equipment static electricity and dust removal device

ActiveCN111330916AEliminate spacingGuarantee job stabilityDispersed particle filtrationTransportation and packagingVoltage generatorDust control

The invention provides an electromechanical equipment static electricity and dust removal device. The electromechanical equipment static electricity and dust removal device comprises a rack, a vertical base, a control switch, supporting legs, movable trundles, a connecting lining base, a fixing nut, a supporting screw, a hand wheel, a supporting base and an anti-skid pad. According to the electromechanical equipment static electricity and dust removal device, the connecting base, a high-voltage generator, an ion air gun, a fixing sleeve, an adjusting rod, an adjusting bolt and a static electricity elimination contact block are arranged, so that static electricity generated by electromechanical equipment can be eliminated; according to the size or the installation position of the electromechanical equipment, the adjusting bolt can be loosened, the distance between the fixing sleeve and the adjusting rod is adjusted, so that the static electricity elimination contact block is in contactwith the surface of the electromechanical equipment, and then the adjusting bolt is locked; and if the electromechanical equipment generates static electricity, the static electricity can be guided out; and meanwhile, the ion air gun is controlled to act through the high-voltage generator, ion air can be generated, dust on the surface of the electromechanical equipment can be blown, and meanwhile,the static electricity is removed so as to ensure the working stability of the electromechanical equipment.

Owner:合肥龙智机电科技有限公司

Paper making device realizing cyclic utilization of waste paper

InactiveCN109537339AEasy to absorb and collectEasy to operatePaper recyclingRaw material divisionDrive shaftIron removal

The invention relates to the technical field of environmental protection, and discloses a paper making device realizing cyclic utilization of waste paper. The device comprises a base, wherein pollution discharging barrels are fixedly arranged at the two sides of the top of the base; support legs positioned on the top of the base are fixedly arranged at the inner sides of the two pollution discharging barrels; the top end of each support leg is fixedly provided with a fixing block; a bottom plate is fixedly connected between the two fixing blocks. A transmission shaft and a middle rod are driven to rotate through a motor, so that a middle rod drives stirring blade paddles and permanent magnets to rotate; the waste paper pulp is conveniently stirred; meanwhile, iron chips in the waste paperpulp can be subjected to adsorption collection; the treatment effect of the device on the iron chips can be favorably improved; the device is used for synchronously performing stirring pulp crushing and magnetic adsorption iron removal; the production cost increase by using a pulp crushing machine and other equipment is avoided; the popularized use is convenient; through the characteristic of oneset automatic iron removal of the device, the operation by workers is convenient; the practicability and the use convenience of the device are favorably improved.

Owner:YIWU YINAN PAPER IND CO LTD

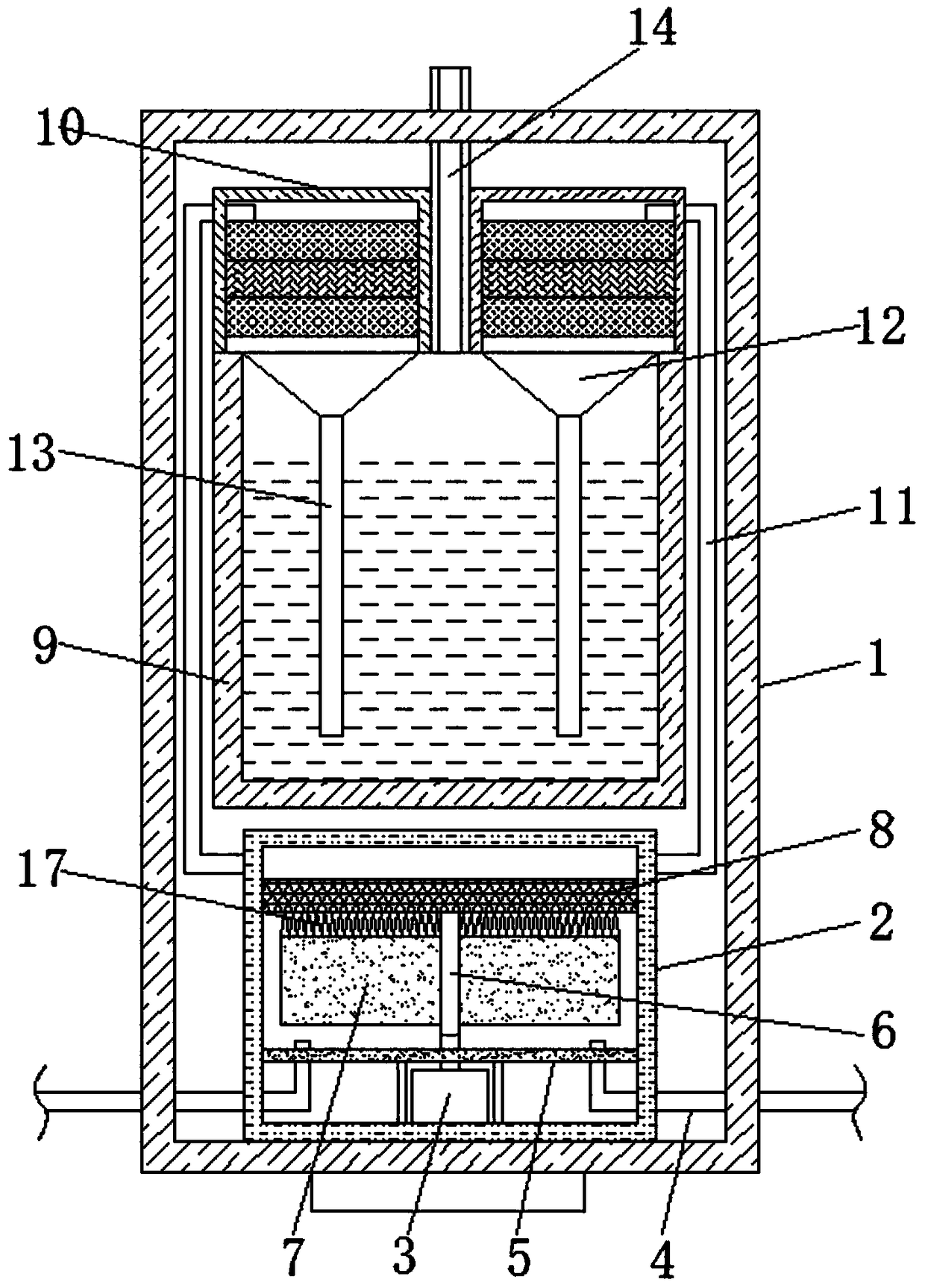

Horizontal type water spraying device with cooling effect for purifying lampblack

PendingCN109269317AAchieve cycleReduce wasteUsing liquid separation agentCorrosion preventionCooling towerWater discharge

The invention discloses a horizontal type water spraying device with a cooling effect for purifying lampblack. The horizontal type water spraying device comprises a shell which is arranged in front ofan electrostatic type purifier, wherein a plurality of filler plates are arranged in the shell; a spraying nozzle is arranged between the filler plates; the spraying nozzle is connected with a waterpassing pipeline; a cooling tower is connected with a water inlet end of the water passing pipeline and a water discharging opening is arranged at the lower end of the shell; the water discharging opening is connected with an oil-water separation module; the oil-water separation module is connected with the cooling tower; the water spraying device is connected with the front side of existing lampblack purification equipment in series, so that flue gas with relatively high temperature, which is produced by industrial production equipment, is cooled through the water spraying device, the temperature of the flue gas is relatively low when the flue gas passes through the electrostatic type purifier and oil stain in the flue gas is conveniently adsorbed and collected; the shell is internally provided with the plurality of filler plates, so that the flue gas relatively uniformly enters the electrostatic type purifier and the purification effect is better; the load and energy consumption of the lampblack purification equipment are reduced through primary purification of the water spraying device.

Owner:KELAN TECHNICS ENVIRONMENTAL PROD CO LTD

Environmentally-friendly dust-removing desulfurizing device

The invention discloses an environmentally-friendly dust-removing desulfurizing device comprising a mounting box. The bottom inner wall of the mounting box is fixedly connected with a fixing box. Thebottom inner wall of the fixing box is provided with a driving motor with an output shaft facing upward, air intake pipes running through the fixing box are arranged on both sides of the driving motor, a horizontally disposed partition plate welded to the inner wall of the fixing box is arranged above the driving motor, a rotating shaft fixedly connected with the output shaft of the driving motoris arranged above the partition plate, a vertically-arranged fixing plate is symmetrically welded along the outer ring of the rotating shaft, a brush is connected to the top of the fixing plate, a filter net connected to the inner wall of the side wall of the fixing box is arranged above the brush, and an air guide pipe connected to the outer walls of both sides of the fixing box is arranged abovethe filter net. The environmentally-friendly dust-removing desulfurizing device has the advantages of simple structure, novel design and low cost, is convenient for absorbing and collecting of dust,and is also convenient for absorbing of a sulfur-containing gas, and a device for collecting the dust is convenient for replacement and cleaning, and is suitable for use in a small factory.

Owner:佛山杰致信息科技有限公司

Machined Metal Dust Collection Devices

InactiveCN108704763BAffect the effect of magnetic adsorptionEasy to absorb and collectDirt cleaningMagnetic separationEngineeringBlock structure

Owner:安徽航毅金属制品加工有限责任公司

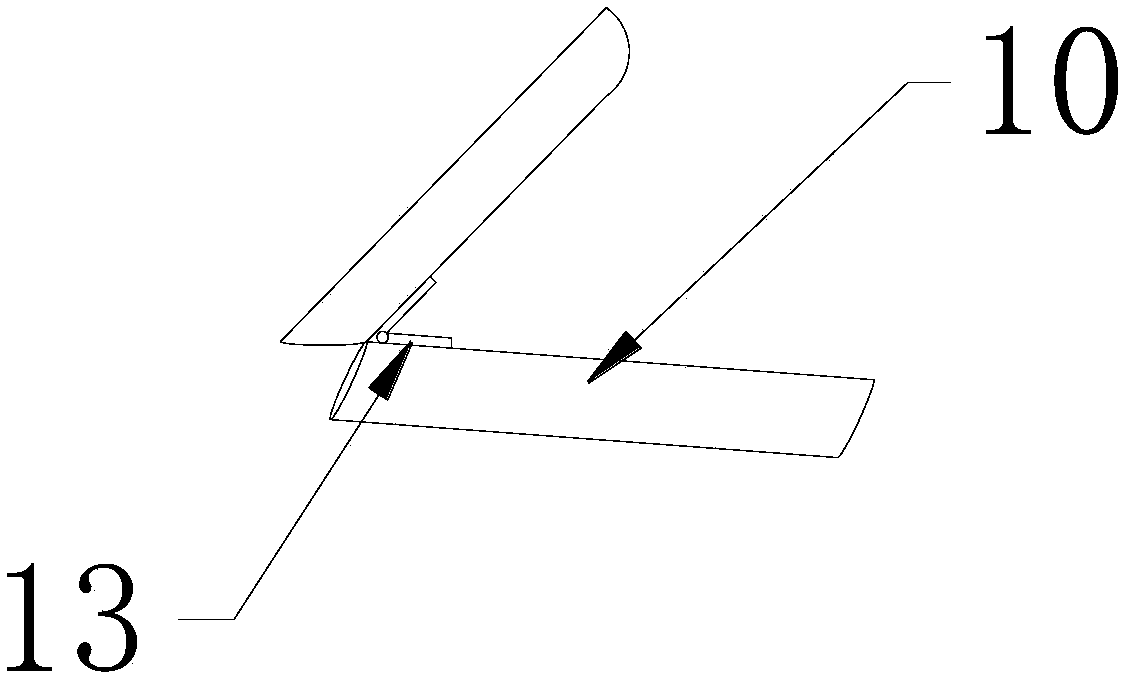

Autonomous weeding equipment and method based on internet of things

InactiveCN110972682ALarge trimming areaImprove work efficiencyMowersAgricultural scienceAgricultural engineering

The invention discloses autonomous weeding equipment and method based on the internet of things. The equipment comprises a material box, a supporting plate is fixedly connected to the back face of thematerial box, first supporting legs are fixedly connected to the two sides of the bottom of the material box, second supporting legs are fixedly connected to the two sides of the bottom of the supporting plate, fixing grooves are formed in the first supporting legs and the second supporting legs separately, and sliding rails are fixedly connected to the two sides of the inner walls of the fixinggrooves. The invention relates to the technical field of agricultural machinery. According to the autonomous weeding equipment and method based on the internet of things, weeds with different heightscan be pruned, the equipment is suitable for more environments, and the application range is enlarged; a dust collector works to collect the pruned weeds, manual cleaning is not needed, the functionsare rich, and the practicability is higher; a first motor works to drive two blades to rotate, the single pruning area is large, the working efficiency is high, a worker only needs to pull out a baffle, then the weeds in the material box can be discharged, and the equipment is convenient to use.

Owner:GUIZHOU EDUCATION UNIV

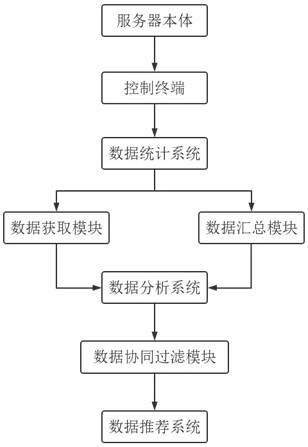

News media data recommendation management system based on artificial intelligence

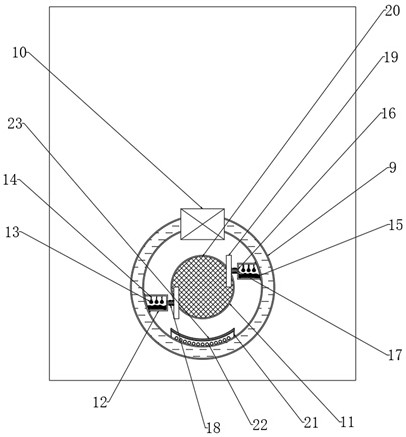

ActiveCN113961051AImprove recommendation efficiencyImprove recommendation accuracyDispersed particle filtrationTransportation and packagingFiberWater circulation

The invention discloses a news media data recommendation management system based on artificial intelligence, and belongs to the field of news media. In the working process of a server body, firstly, a circulating device drives cooling water to circularly flow and drives a heat removal fan to carry out heat dissipation treatment, and along with continuous heat dissipation, the temperature of the cooling water rises; the deformation memory spring extends to drive the material storage bag to be punctured by the spine, so that ammonium chloride powder and barium hydroxide octahydrate powder are mixed to react and absorb heat for cooling, heat absorption and cooling of cooling water are facilitated, and meanwhile, ammonia gas is generated to be blown into the elastic telescopic flat bag to extend and push the cleaning brush body to move, so that dust on the surface of the dustproof net is cleaned; and vibration generated when the circulating device and the heat extraction fan work is transmitted into the arc-shaped frame, collision small balls collide and rub to generate static electricity, dust is adsorbed and collected through the cooperation of the electrostatic adsorption capacity and the superfine fiber layer, air circulation is facilitated, the heat extraction effect of the heat extraction fan is enhanced, and work of the server body is facilitated.

Owner:NANCHANG INST OF TECH

Water body oil stain cleaning robot

InactiveCN112323752ASave human effortSave cleanup timeWater cleaningWaterborne vesselsHigh energyStructural engineering

The invention discloses a water body oil stain cleaning robot and particularly relates to the field of water area cleaning. The robot comprises a ship body and a rack; the rack is installed at the topof one end of the ship body; a rotating shaft is installed in an inner cavity of the rack in a penetrating mode; a first driving mechanism and a second driving mechanism are installed on two sides ofthe rotating shaft correspondingly; the first driving mechanism and the second driving mechanism are located on two sides of one end of the ship body correspondingly; sliding rails are installed at the bottom ends of two sides of the rack; and sliding blocks are installed in inner cavities in the sliding rails in a sliding mode. By arranging the first driving mechanism and the second driving mechanism, automatic cleaning of oil stains on the surface of a water area and automatic extrusion of the absorbed oil stains are achieved, manpower and cleaning time are saved, and working efficiency isimproved; and the first driving mechanism and the second driving mechanism are matched with driving blades in the rotating process, so that the first driving mechanism and the second driving mechanismhave the function of automatically driving the ship body in the rotating process, and the problems that high energy consumption is caused by adding a driving device to drive the ship body, the cost is increased, and later maintenance and repair are increased are solved.

Owner:李虎

Desulfurization and dedusting integrated system

ActiveCN105964129APrevent scalingSystem resistance is smallCombination devicesGas treatmentFlueIntegrated systems

The invention provides a desulfurization and dedusting integrated system. The desulfurization and dedusting integrated system comprises a desulfurization tower, the bottom of the desulfurization tower is provided with a flue gas inlet, the desulfurization tower is internally provided with a spraying layer, a flue gas flow rectifier is arranged between the flue gas inlet and the spraying layer, the top of the desulfurization tower is provided with a flue gas outlet, a wet electrostatic precipitator is arranged at the flue gas outlet, and a flue gas rectification grille and a flue gas guide plate are arranged sequentially between the wet electrostatic precipitator and the flue gas outlet. A plurality of atomizing nozzles are arranged on the spraying layer, and each atomizing nozzle is a one-direction double-head structured nozzle and comprises a nozzle body and two spraying holes symmetrically and relatively obliquely formed in the nozzle body. A clearing mechanism is arranged between the flue gas rectification grille and the flue gas guide plate, and accordingly liquid drop scaling, flue blockage and corrosion of two reactors can be avoided effectively, system resistance is greatly reduced, and scales on the flue gas rectification grille and the flue gas guide plate can be cleared timely.

Owner:JIANGSU YIJIN ENVIRONMENTAL PROTECTION TECH CO LTD

A double-sided dust removal device for furniture panels

ActiveCN111389781BEasy to cleanEasy to absorb and collectDirt cleaningCleaning using toolsDust controlStructural engineering

The invention provides a double-sided dust removal device for furniture panels, which relates to the technical field of furniture processing equipment, and includes a dust removal box. The conveying device includes a conveyor belt base, which is fixed on the bottom of the dust removal box, and the two ends of the conveyor belt base are respectively located outside the two ends of the dust removal box, and a conveyor belt installation groove is arranged on the top surface of the conveyor belt base. The bottom of the belt installation groove is fixed with a conveyor belt, and the surface of the conveyor belt is provided with a number of plate anti-skid strips at equidistant intervals. The opposite inner walls of the conveyor belt installation groove are respectively provided with a number of left half cylinders and right half cylinders. A dust-scraping device is symmetrically arranged on both side walls of the opening at one end of the box body, and the dust-scraping device includes a dust-scraping base. The invention has the advantages of being able to effectively clean and collect the dust and debris on the surface of the plate.

Owner:安徽省庆新家具有限公司

Waste gas filter with M-shaped filtering medium

ActiveCN105854451AIncrease interception areaReduce energy lossDispersed particle filtrationMembrane filtersFilter mediaEngineering

The invention relates to a waste gas filter with an M-shaped filtering medium. The waste gas filter is applied to treatment or recycling of organic waste gases or inorganic waste gases generated in spraying and painting processes of industrial manufacturing of furniture, automobiles, containers, shipbuilding and the like. The waste gas filter comprises a base and filters, wherein a waste gas inlet and a waste gas outlet are formed in the base. The waste gas filter is characterized by further comprising an M-shaped bracket; the M-shaped bracket is mounted on a channel through which a waste gas flows to the waste gas outlet from the waste gas inlet inside the base; the filters are adhered to working surfaces on two inner sides of each V-shaped hole of the M-shaped bracket. The waste gas filter has the advantages that the baffling area of unit volume of each filter is large, the filtering efficiency is improved, the size of a filter in the prior art is reduced, meanwhile, as the filters are arranged in the flowing direction of the waste gas, the energy loss of the flowing waste gas is reduced, the power of a fan is reduced, the filtration effect is stable, and the like.

Owner:FUJIAN LEBEN ENVIRONMENTAL PROTECTION TECH & EQUIP

A suction cup workbench for the production of mobile phone screen panels

Owner:江苏源成隆光电科技有限公司

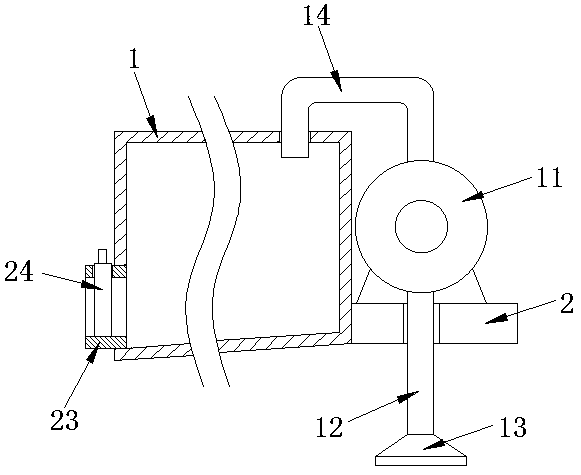

High-safety auxiliary purification control system for welding smoke of cable distribution box

PendingCN113977154APromote absorptionPrevent backflowWelding/cutting auxillary devicesDirt cleaningControl systemWorking environment

The invention relates to the technical field of cables, and discloses a high-safety auxiliary purification control system for welding smoke of a cable distribution box. The control system comprises an opening and closing assembly, a rotating ring is arranged in the opening and closing assembly, a fluted disc is arranged on the surface of the rotating ring, a rotating cylinder is arranged on the inner surface of the fluted disc, a sliding rod is slidably connected to the inner surface of the rotating cylinder, and the lower part of the rotating ring is provided with a grooved plate. According to the high-safety auxiliary purification control system for welding smoke of the cable distribution box, through cooperative use of a welding support and a pressing rod, cooperative use of a rotating wheel and a gear ring, cooperative use of the gear ring and a gear rod, cooperative use of a rotating rod and a hose and cooperative use of the hose and a negative pressure pipe, when the cable distribution box is welded, smoke generated by welding can be absorbed in time, the smoke is prevented from being diffused into the air, pollution of the smoke to the working environment can be effectively reduced, and the safety of the working environment where workers are located can be improved.

Owner:江苏德鲁特电气设备有限公司

Water pollution collecting device

InactiveCN114516671AEasy to absorb and collectGeneral water supply conservationWater/sewage treatment by flocculation/precipitationStructural engineeringMechanical engineering

The invention discloses a water pollution collecting device which comprises a rectangular base, and a collecting mechanism is arranged on the rectangular base; the collecting mechanism mainly comprises a door-shaped frame, a strip-shaped sliding rail, an adsorption plate, a scraping piece, a circular box body, a servo motor, a first electric push rod and a second electric push rod. The circular box body is arranged on the upper wall surface of the rectangular base, a circular through hole is formed in the upper wall surface of the circular box body, the door-shaped frame is arranged on the rectangular base and stretches across the upper part of the circular box body, and a strip-shaped groove is formed in the lower wall surface of a cross beam of the door-shaped frame. Impurities in water can be conveniently adsorbed and collected.

Owner:WM ENVIRONMENTAL MOLECULAR DIAGNOSIS CHANGSHU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com