Patents

Literature

53results about How to "Small transmission resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

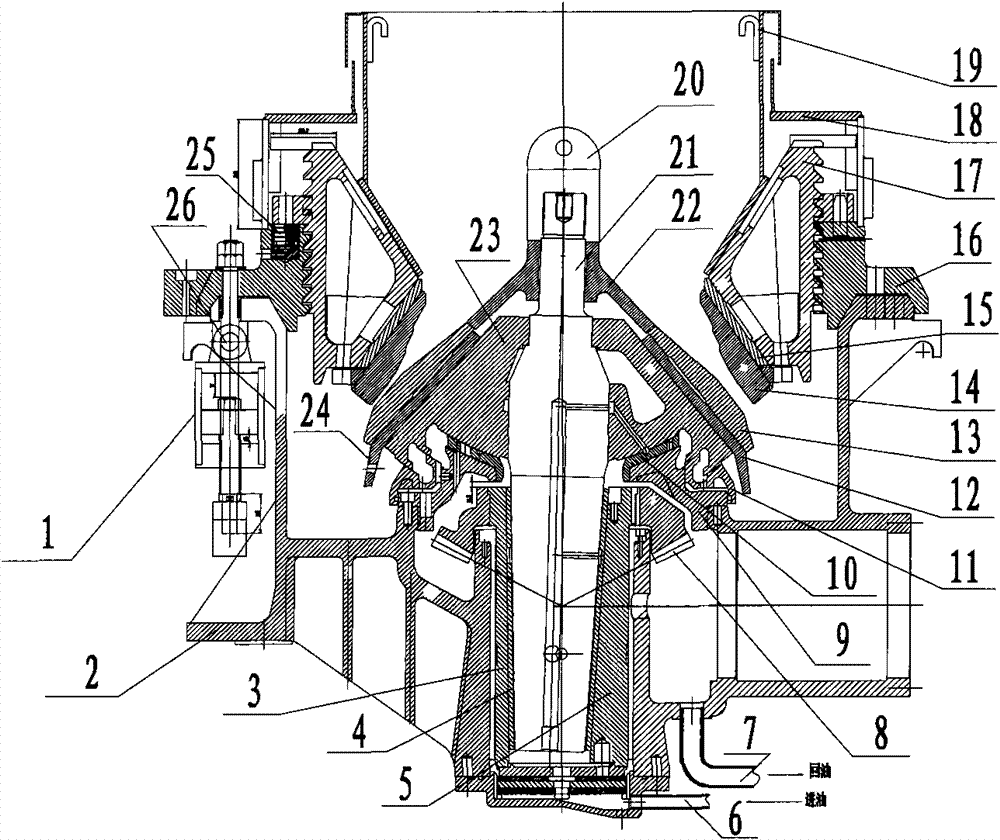

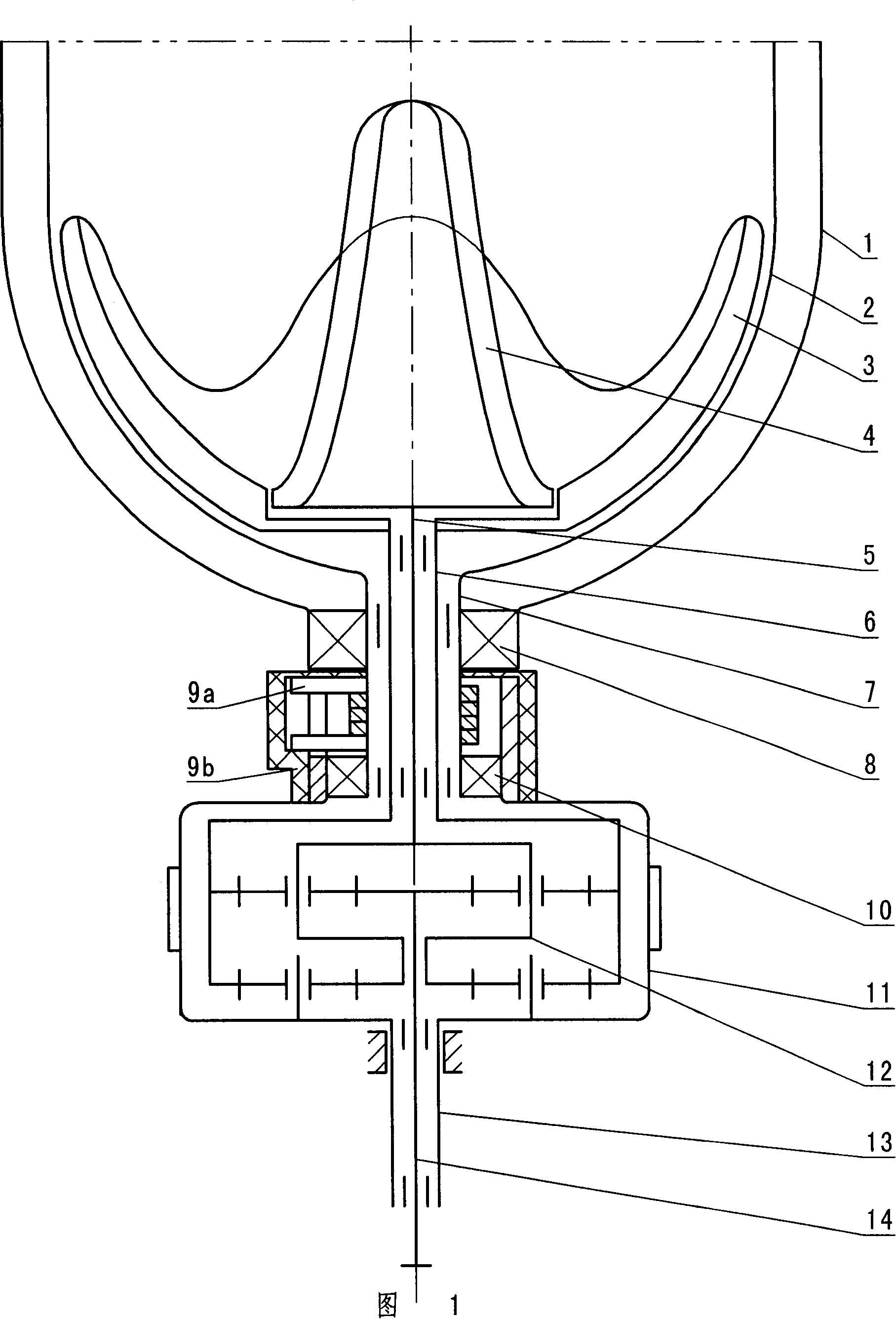

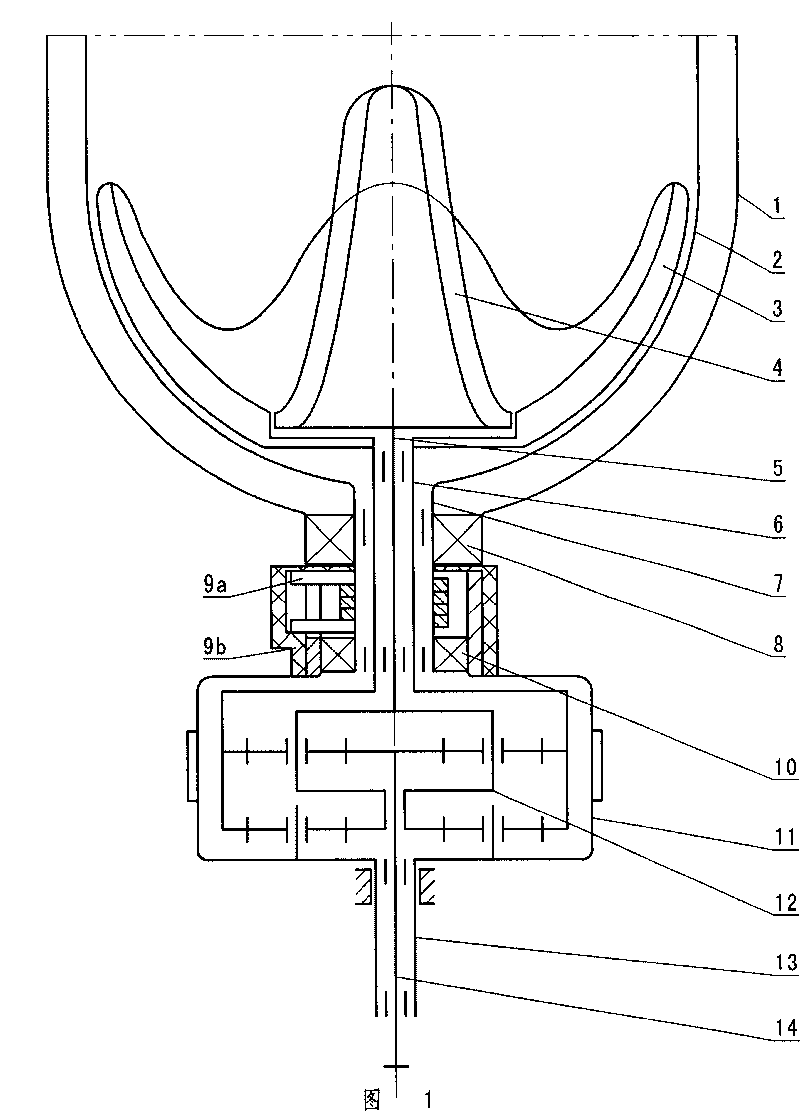

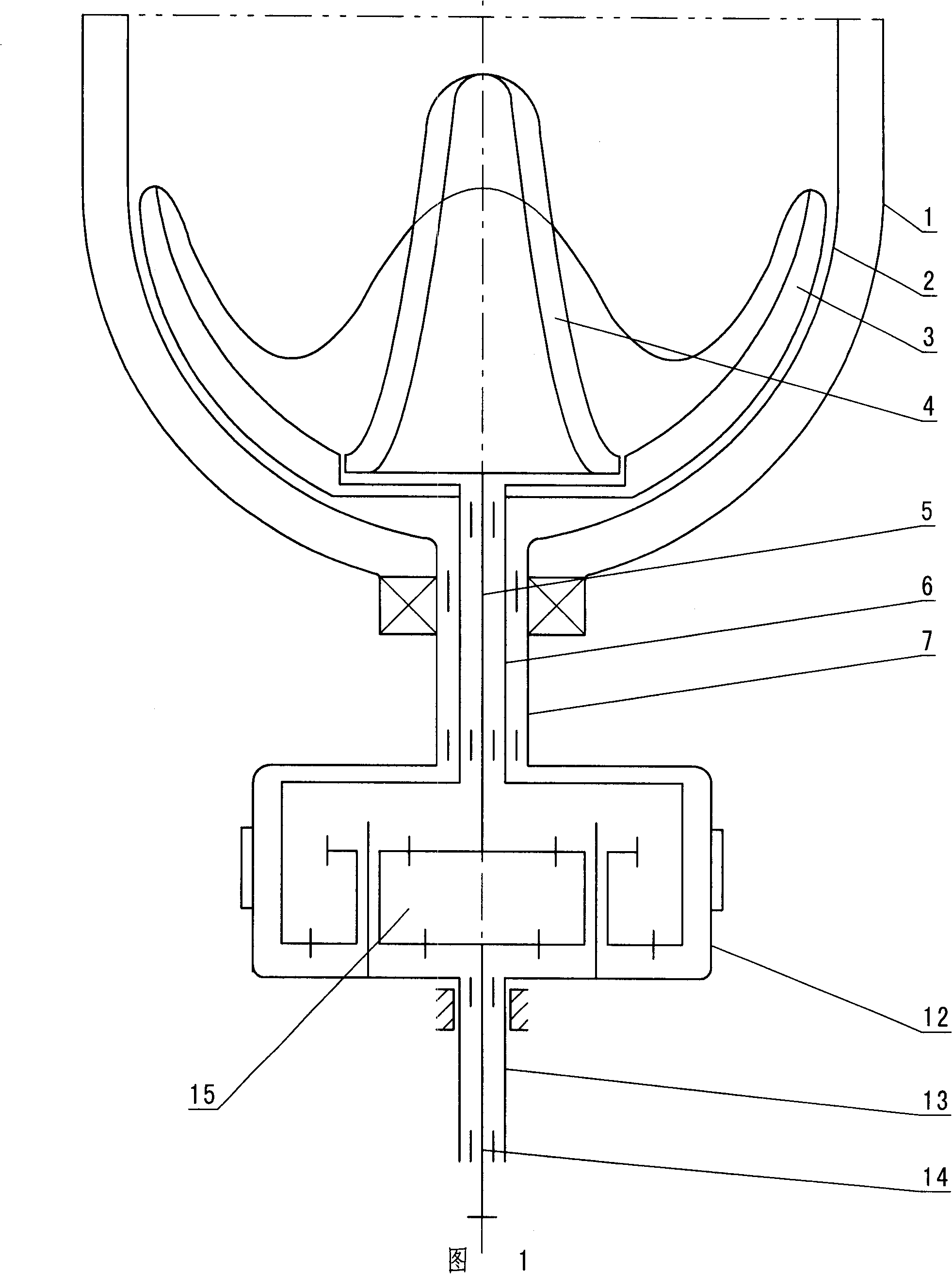

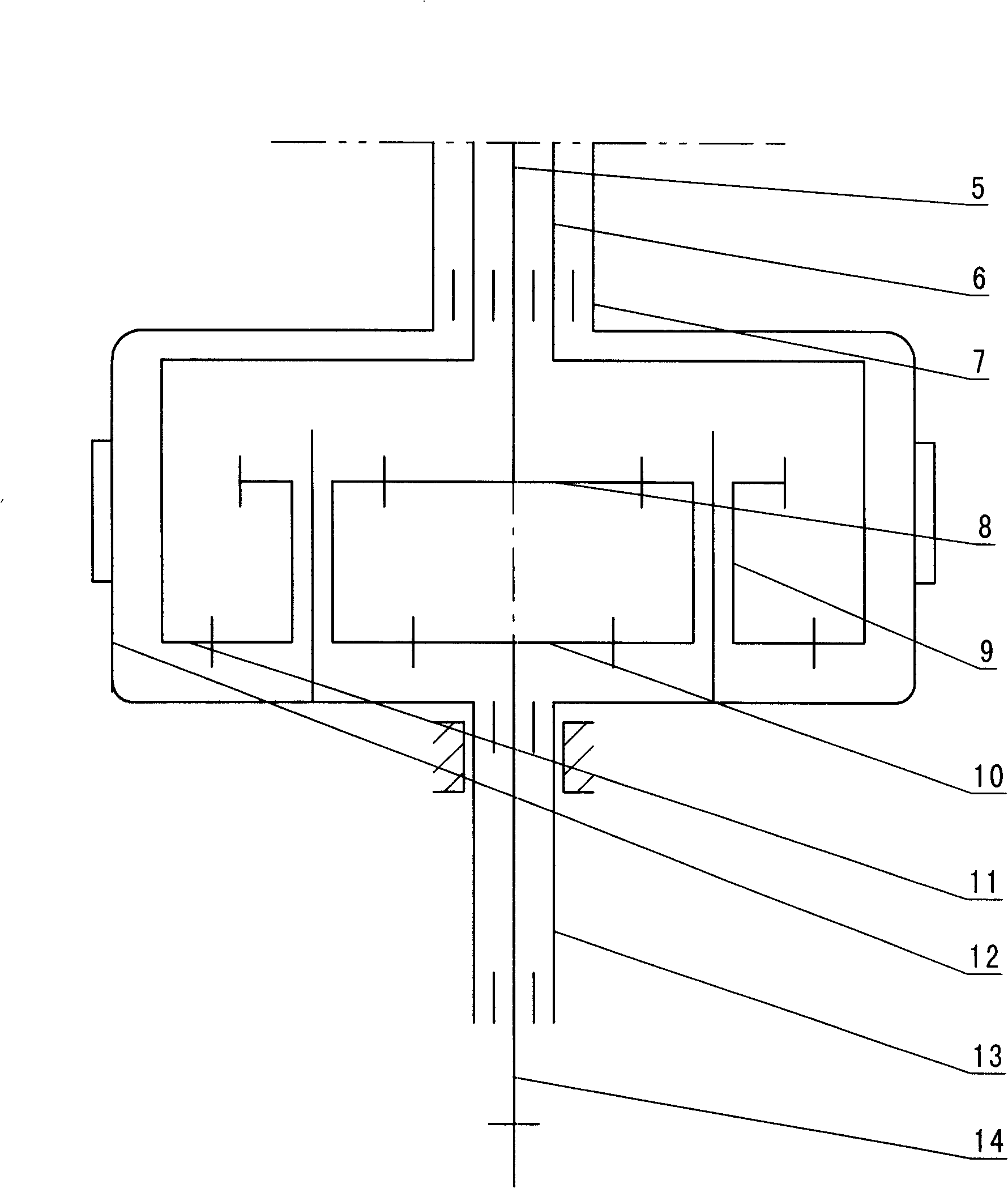

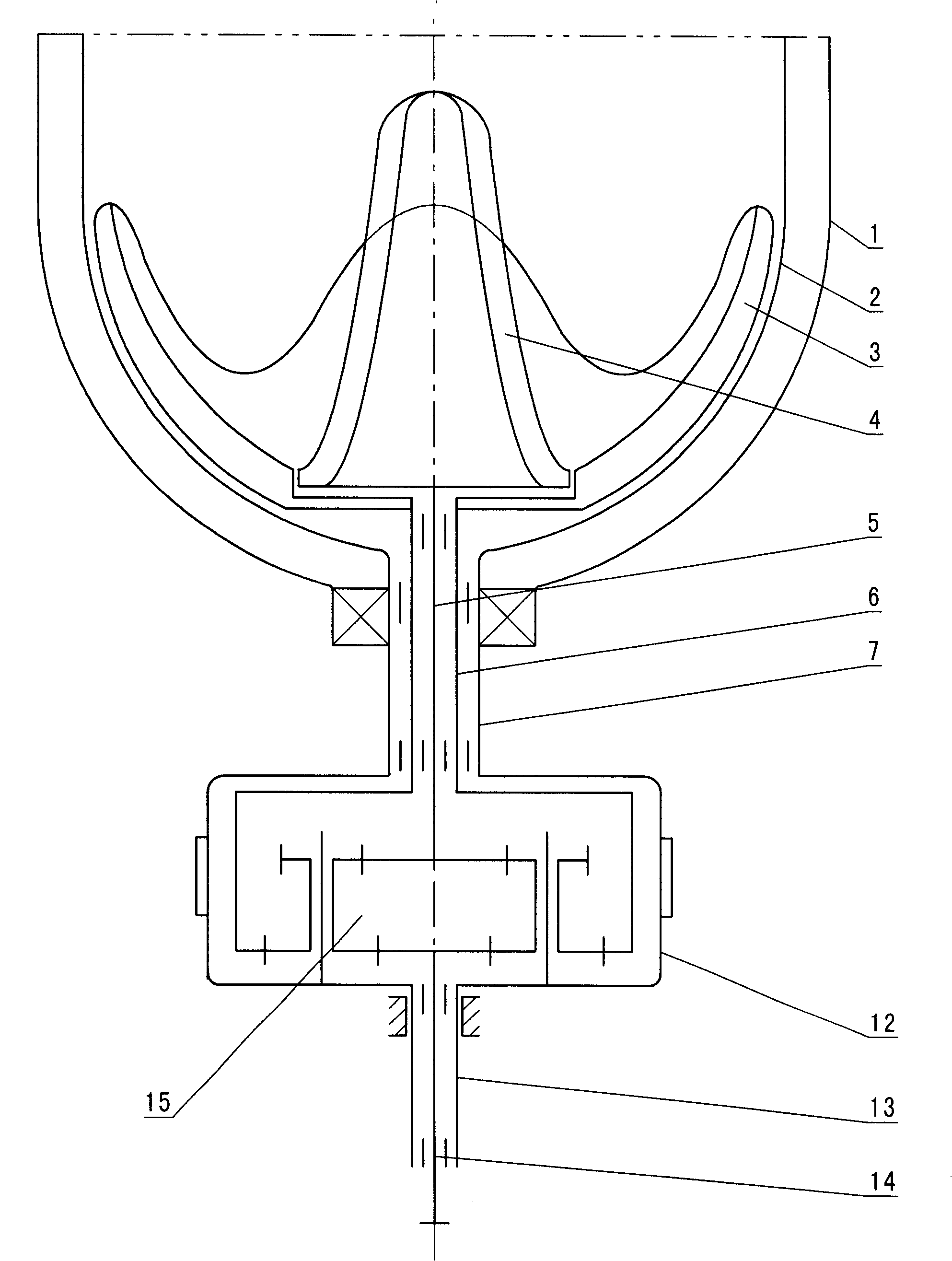

Cone sand making machine and sand making method

The invention relates to a cone sand making machine and a sand making method with high efficiency, low energy consumption and high sand making yield. A big bevel gear is sleeved on an eccentric shaft sleeve which is sleeved in an axle hole in the centre of a lower shell through a copper jacket; a main shaft is positioned in the eccentric shaft sleeve through an inner copper sleeve; a spherical seat is positioned on a shell supporting ring of the positioning axle hole in the lower shell; a movable cone is sleeved on the main shaft through a spherical copper bearing bush and pushed by the main shaft to swing; a movable sleeve bushing is sleeved on the conical surface of the movable cone; an anti-wear movable sleeve is sleeved on the conical surface of the movable sleeve bushing; an inserteris sleeved on the main shaft and locked by a locking nut; an upper shell and the lower shell are connected together and three or more adjusting oil cylinders are arranged between the outer turned edges of the upper and lower shells; the inner wall of the upper shell is provided with annular spiral sawteeth which are engaged with those on the outer wall of an adjusting screw sleeve; and the adjusting screw sleeve has a double-trumpet structure, the lower trumpet-shaped wall of the adjusting screw sleeve is connected with an anti-wear fixed sleeve through a fixed sleeve bushing, and the upper trumpet-shaped wall of the adjusting screw sleeve is used for supporting a hopper assembly.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

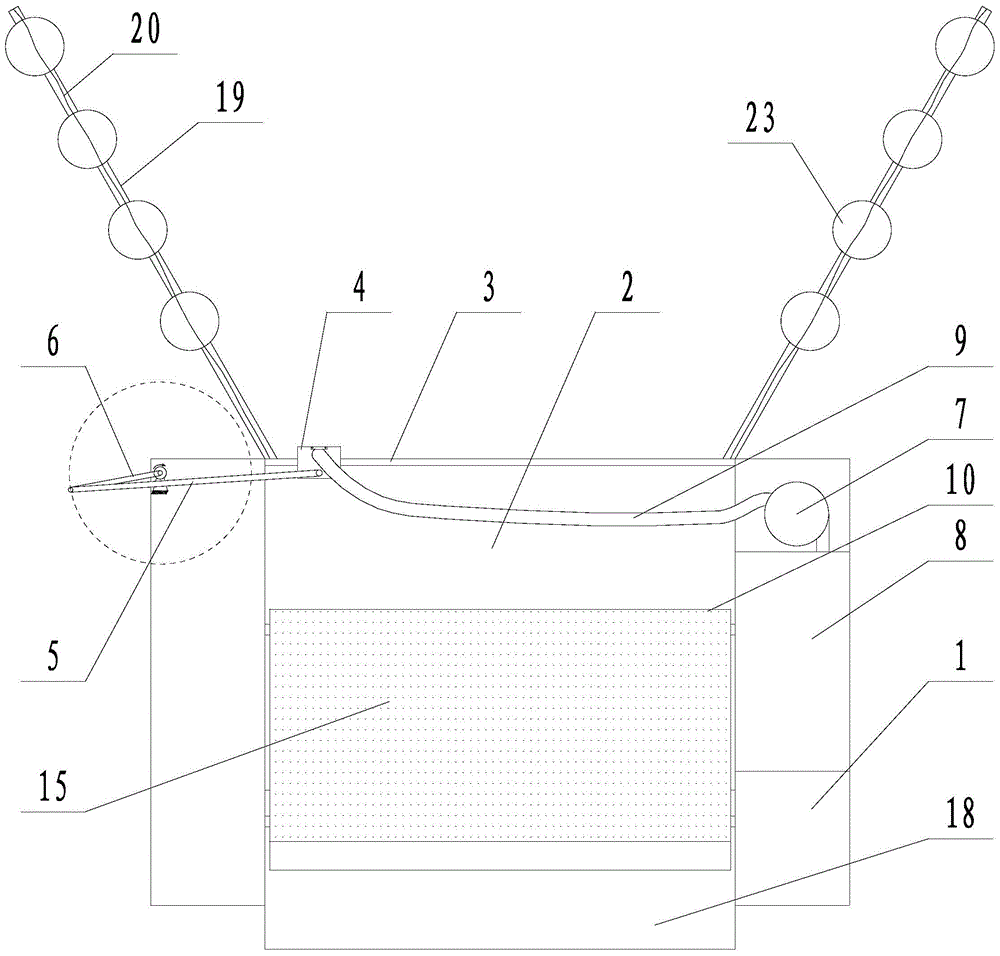

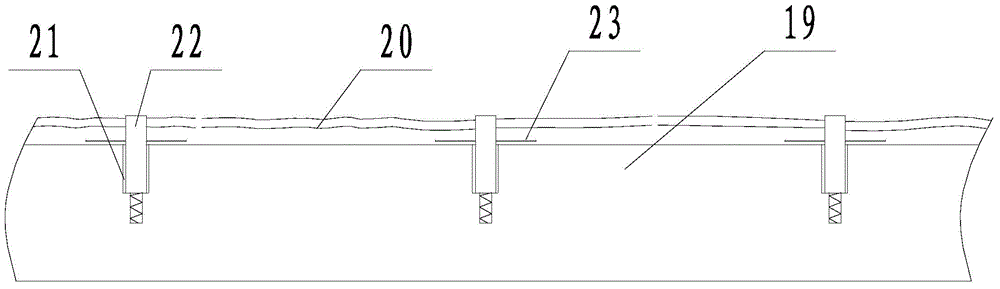

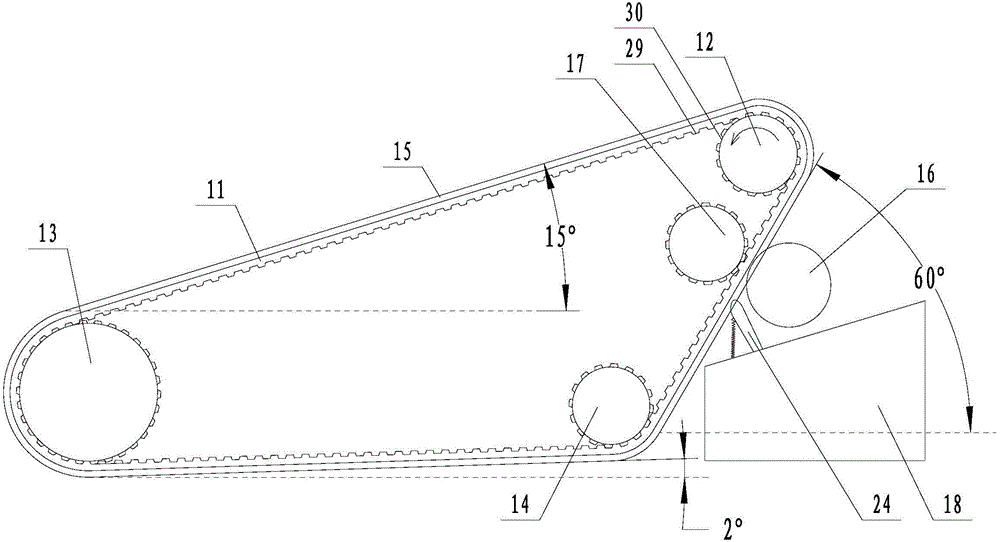

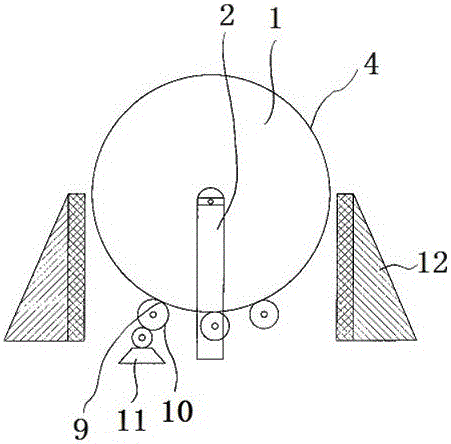

Ocean spilled oil collecting device

ActiveCN104895030AAvoid pollutionCollect thoroughlyWater cleaningGeneral water supply conservationEngineeringConveyor belt

The invention discloses an ocean spilled oil collecting device. The invention discloses an ocean spilled oil collecting device. The objective of the invention is to solve a shortage that ocean spilled oil is not collected thoroughly by a current spilled collecting device. The collecting device comprises a floating block. An oil passing groove is arranged in the middle of the floating block. A slide rod is arranged on the front end of the oil passing groove. A slide block is slidably connected to the slide rod. An oil absorbing pump and an oil storage tank are installed on the floating block. A flexible oil absorbing pipe is installed on the oil absorbing pump. The front end of the oil absorbing pipe is installed on the slide block. A secondary oil absorbing mechanism is installed behind the slide rod in the oil passing groove. The secondary oil absorbing mechanism comprises a conveyor belt, a driving pulley, a driven pulley and a tensioning pulley. An oil absorbing belt is connected to the external surface of the conveyor belt. The conveyor belt between the driven pulley and the tensioning pulley is near the ocean surface. A squeezing wheel and a supporting belt pulley, which are oppositely arranged, are arranged between the tensioning pulley and the driving pulley. The supporting belt pulley is in transmission connection with the inner surface of the conveyor pulley. The squeezing pulley is abutted against the outer surface of the oil absorbing belt. An oil collecting groove is arranged under the squeezing pulley.

Owner:ZHEJIANG OCEAN UNIV

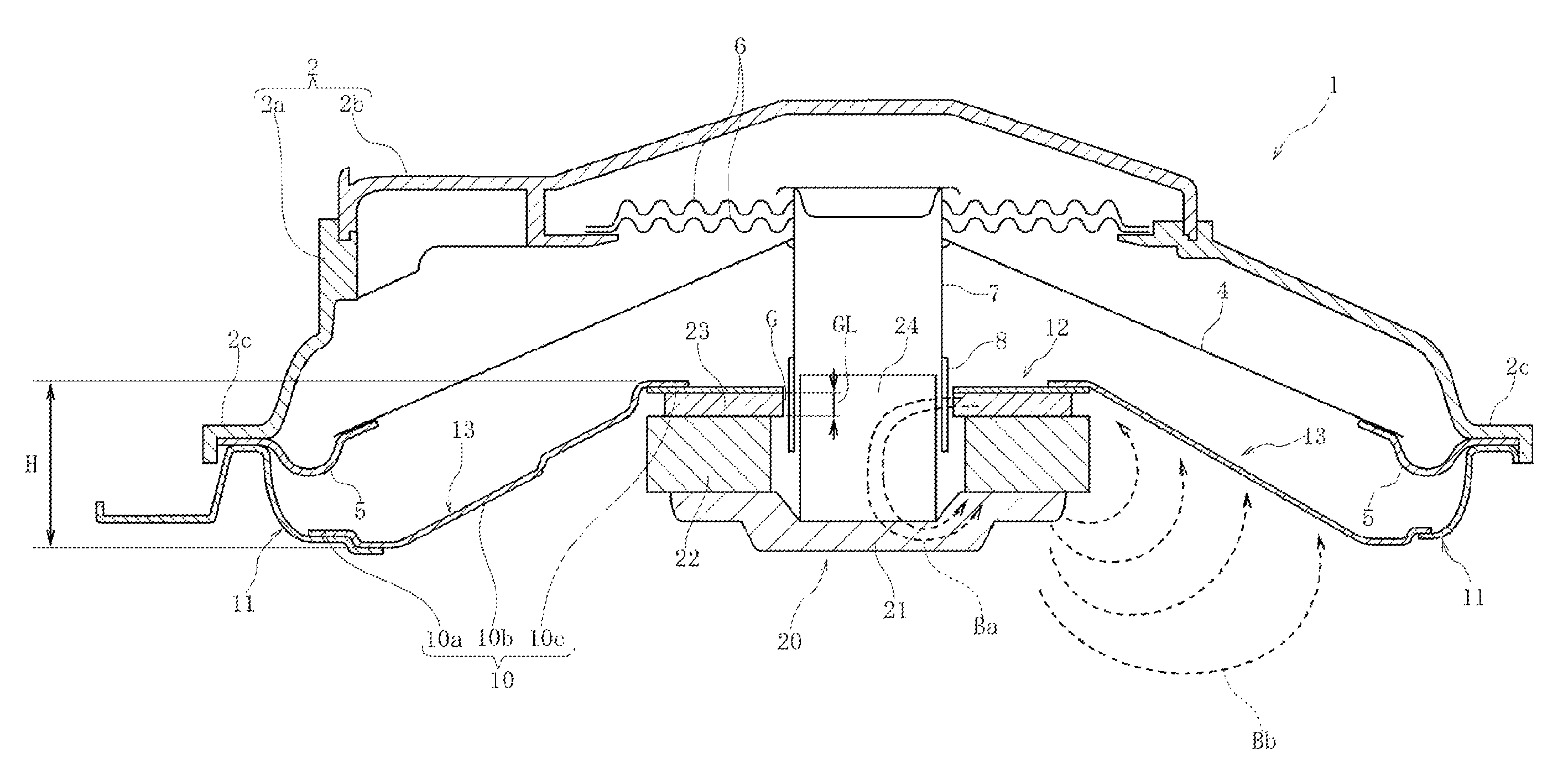

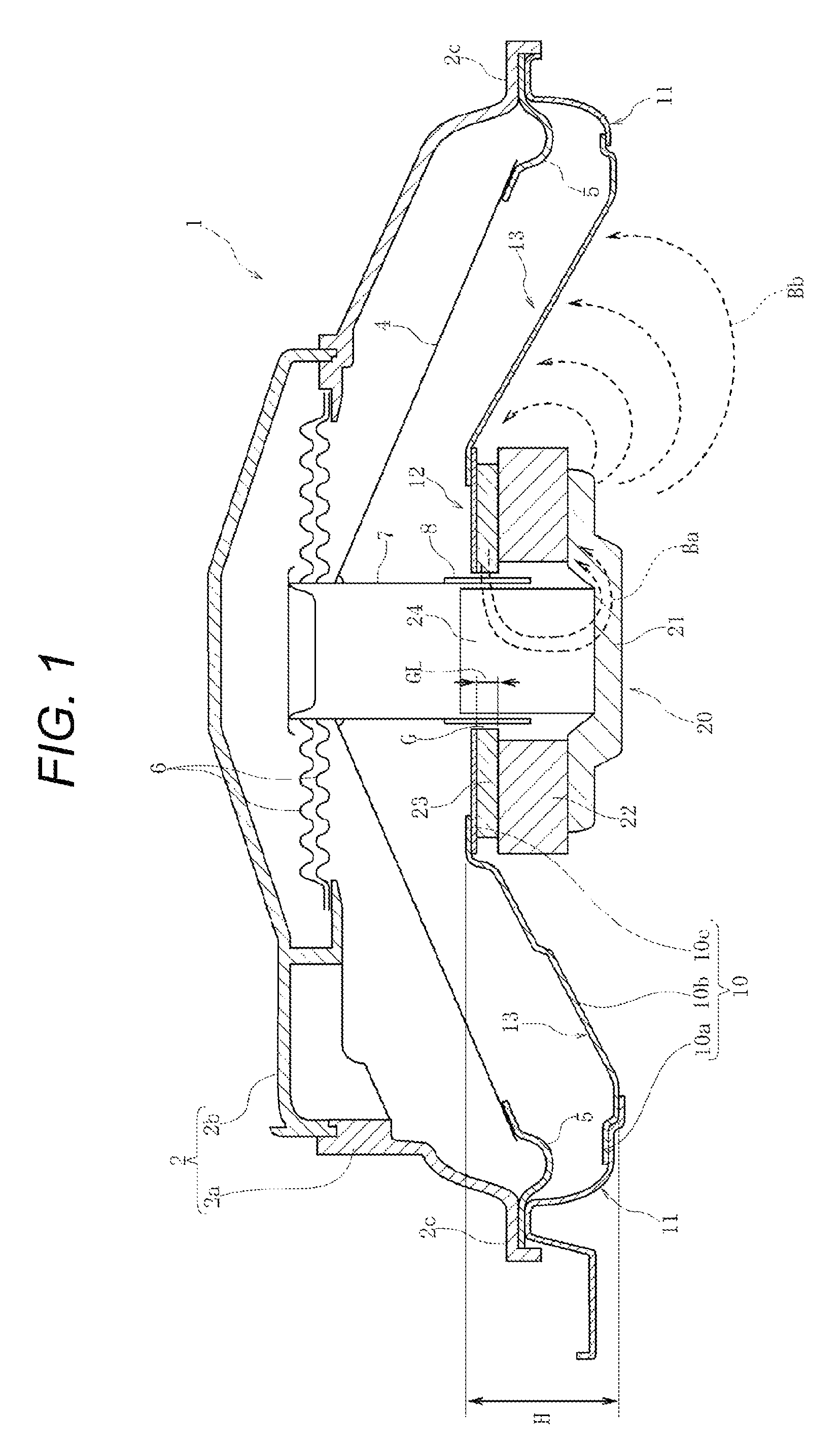

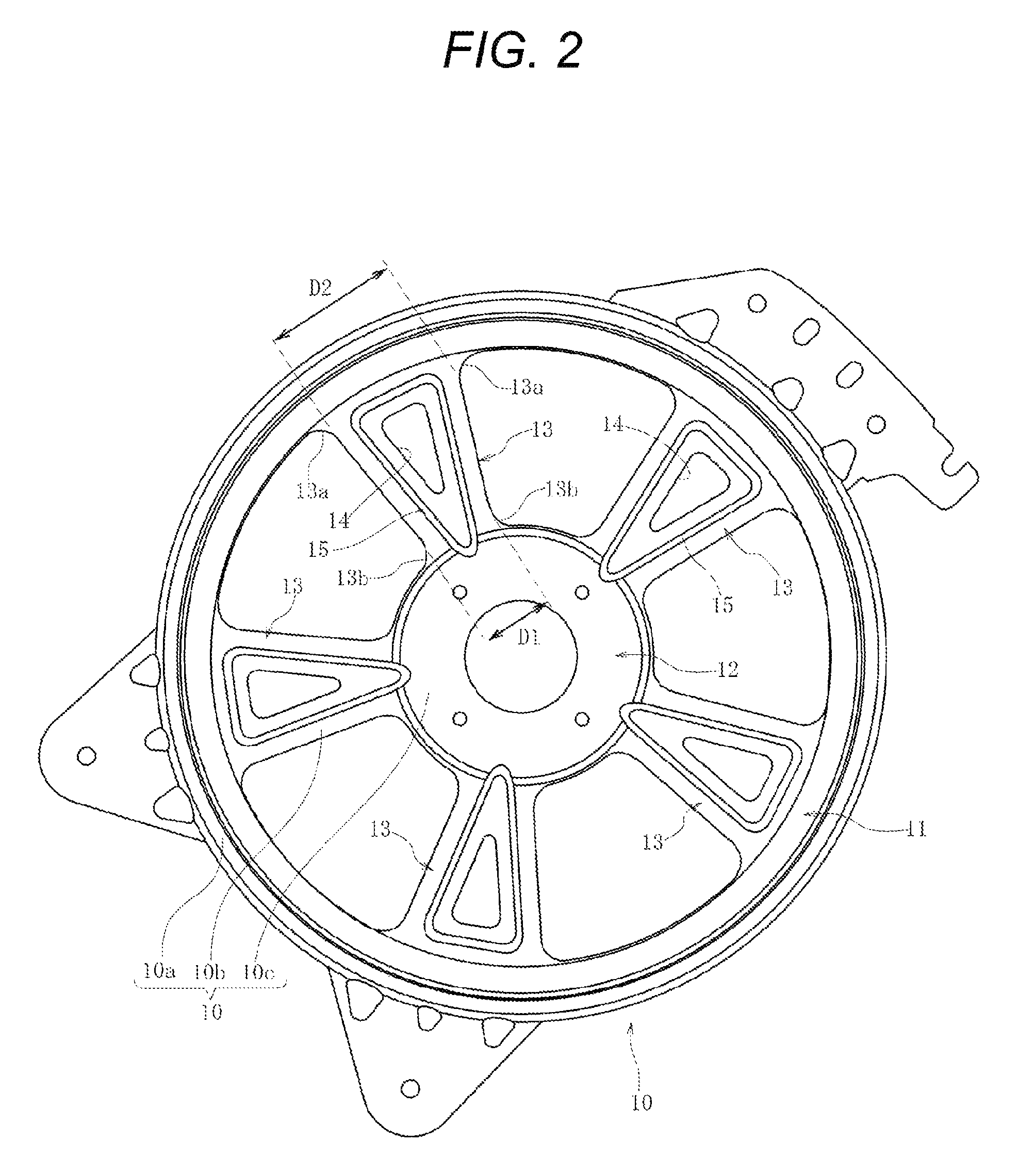

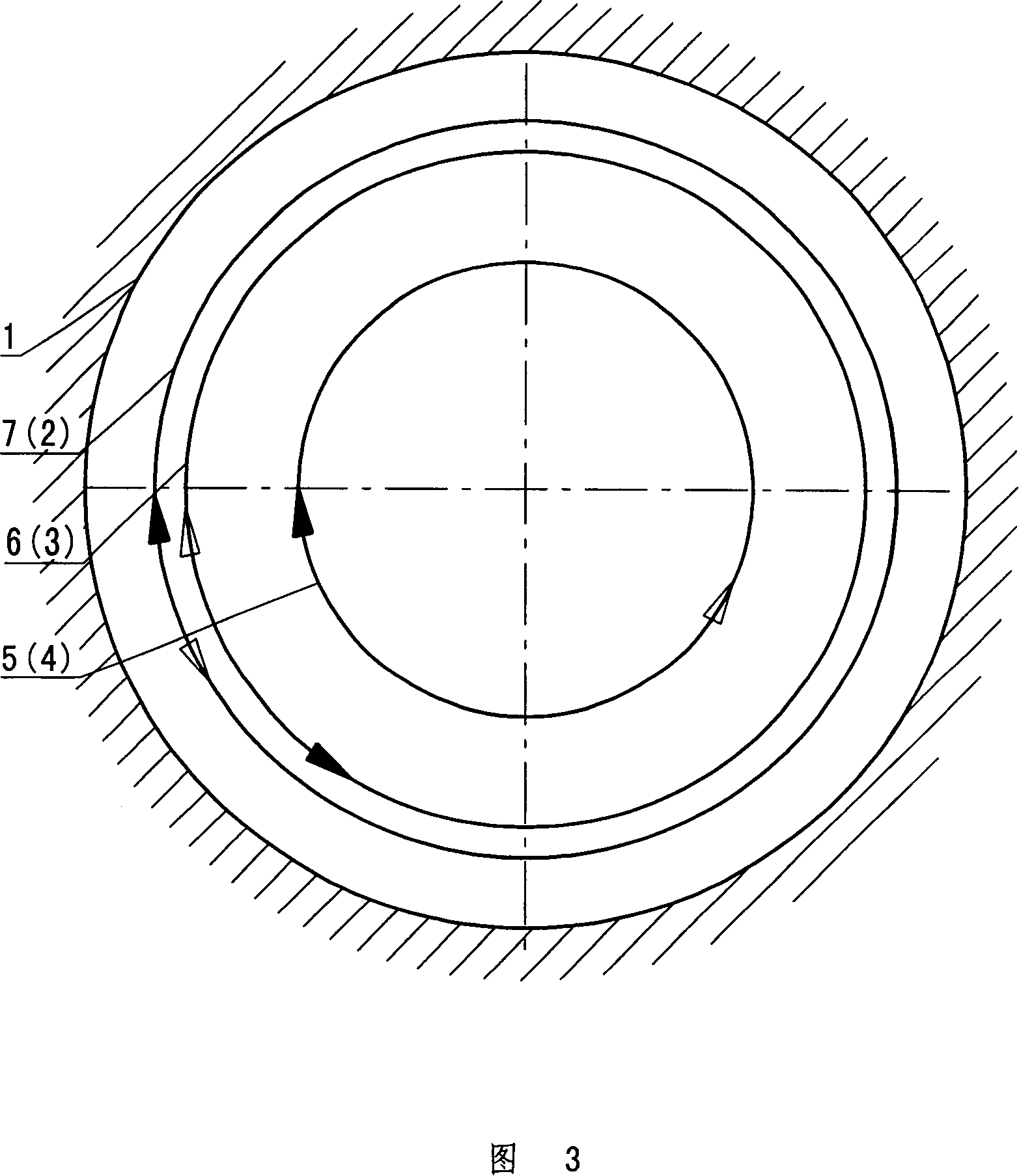

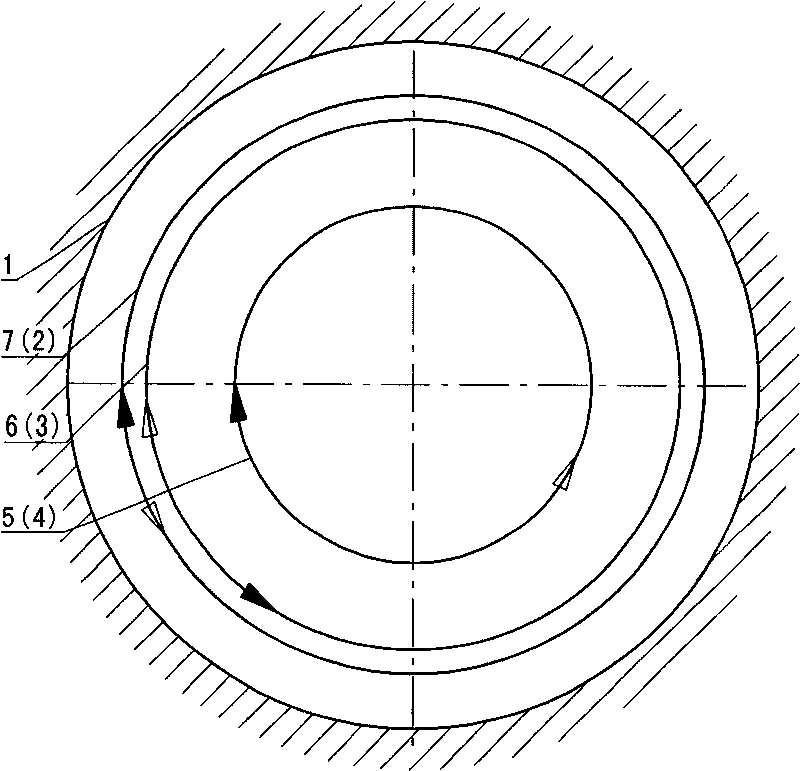

Speaker apparatus

ActiveUS9479873B2Small transmission resistanceEasy to attractLoudspeakersTransducer casings/cabinets/supportsEngineeringLoudspeaker

A support chassis mounted on a sounding side of a speaker apparatus is formed of an iron material. The support chassis is formed in a shape in which a central supporting part nears a main-body chassis. A magnetic field generating unit is fixed to the central supporting part on a side of a recess of the support chassis. The support chassis includes a frame part, the central supporting part, and spoke parts. In the spoke part, a width dimension D1 of an inner end part is formed narrower than a width dimension D2 of an outer end part. Therefore, a resistance in a case where a magnetic flux passes through the spoke part increases, and the leaked magnetic field is hardly induced from the magnetic field generating unit to the spoke part. Therefore, a reduction in a speaker output can be prevented.

Owner:ALPINE ELECTRONICS INC

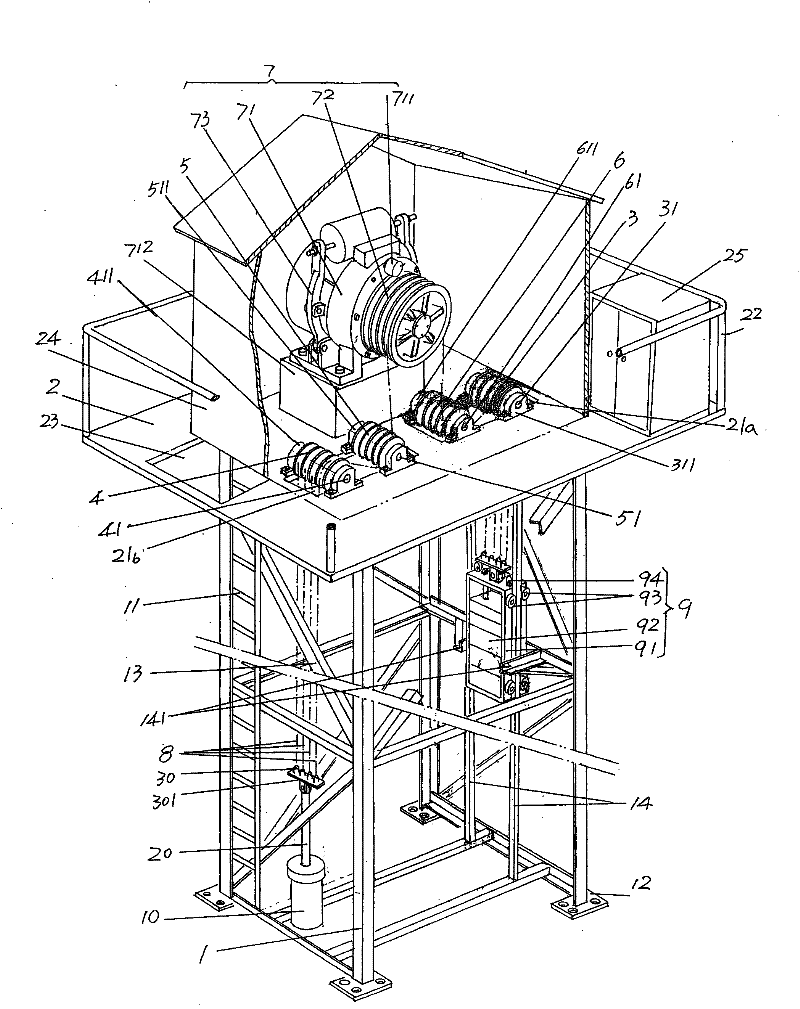

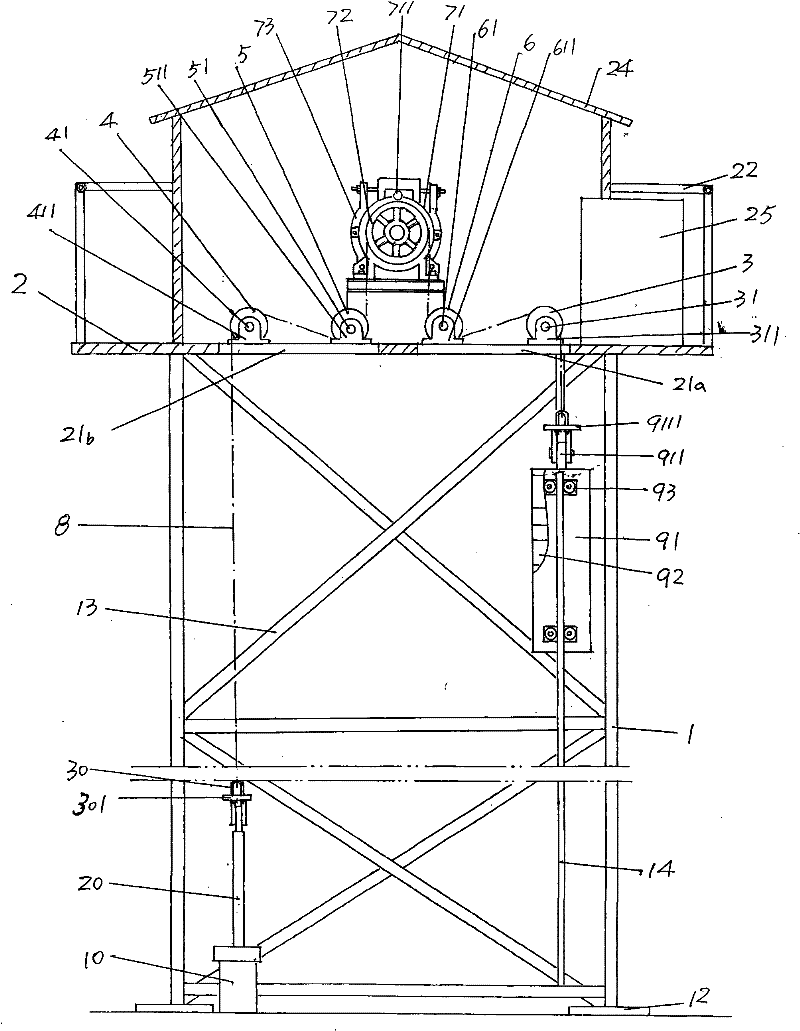

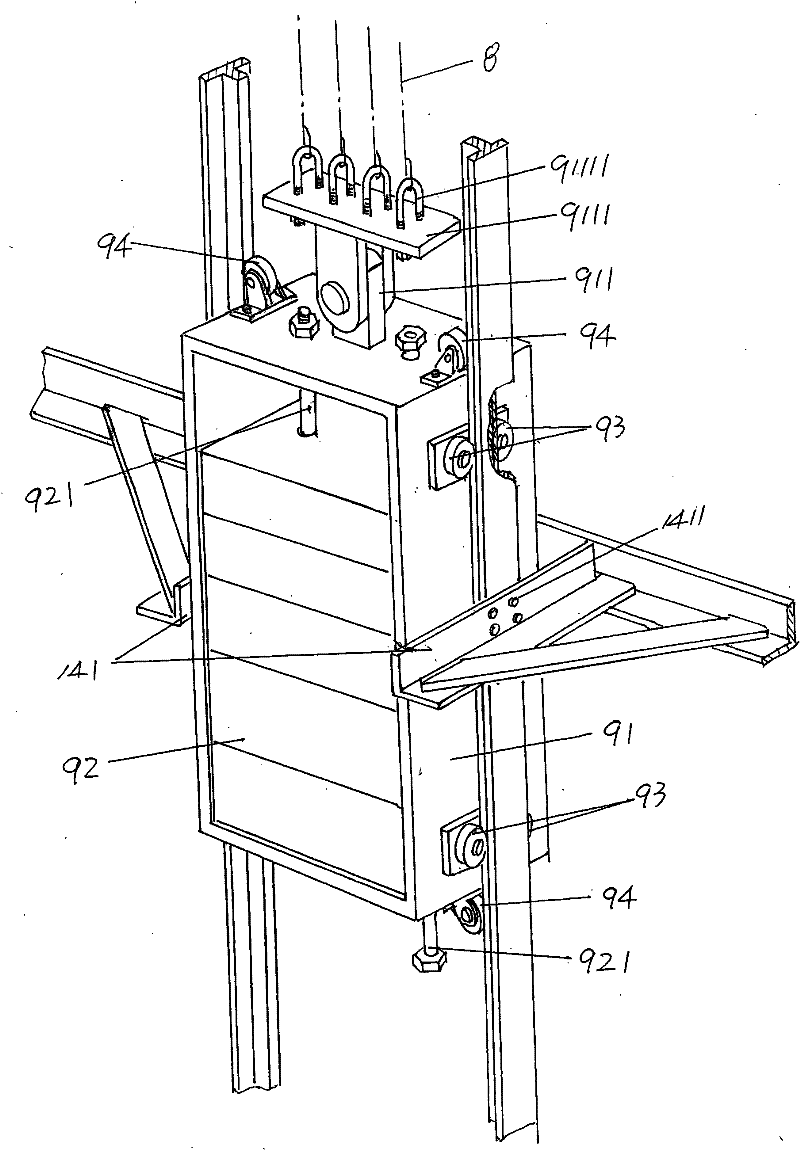

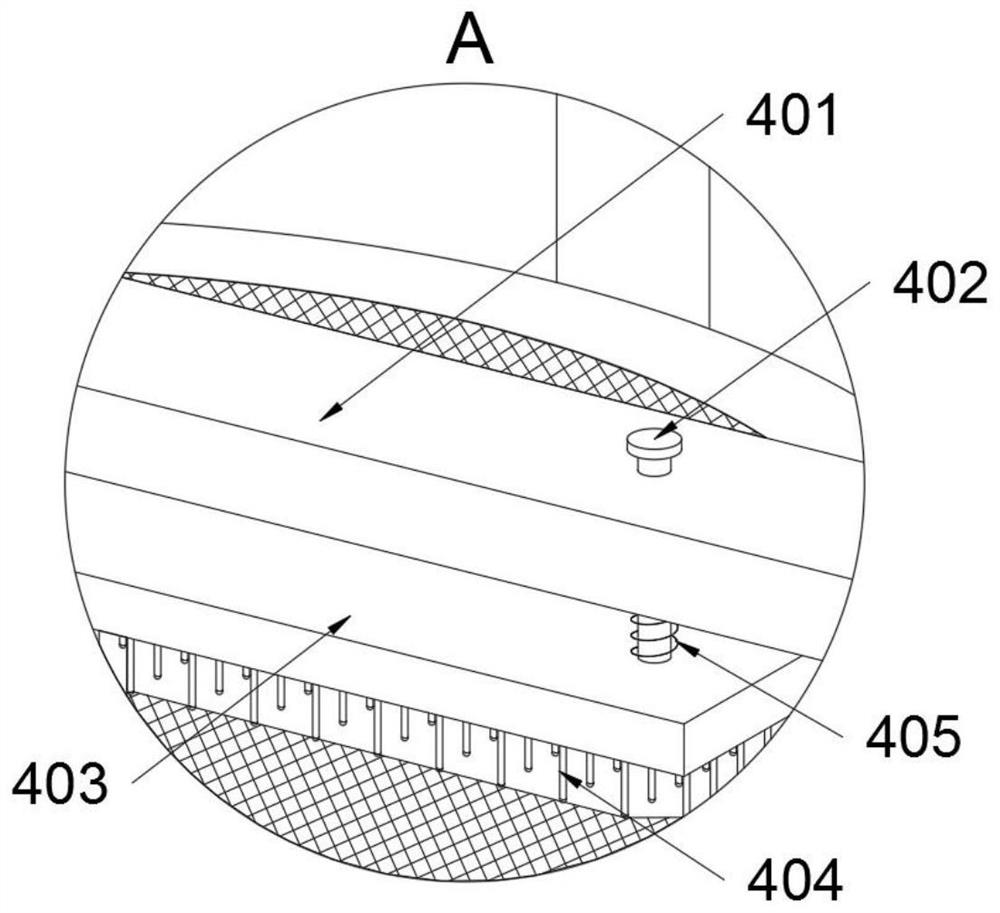

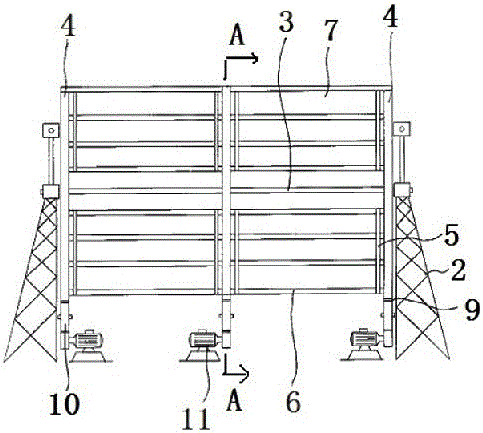

Energy-saving oil pumping mechanism used for oil field

The invention discloses an energy-saving oil pumping mechanism used for oil field, which belongs to the technical field of oil exploitation machinery and includes a derrick, a machine platform, a first head block assembly and a second head block assembly, a first transition block assembly, and a second transition block assembly, a power device, and a hauling cable. The machine platform is provided with a first hauling cable hole and a second hauling cable hole on a platform surface and is provided with barriers on the surrounding of the platform surface; and the machine platform is fixed on the top of the derrick. The first head block assembly and the second head block assembly are fixed on the machine platform; the first transition block assembly and the second transition block assembly are arranged on the machine platform; the power device consists of a tractor, a traction sheave and a brake, and is arranged on the machine platform; one end of the hauling cable is connected with a sucker rod and the other end is twisted on the second head block assembly, the first transition block assembly, the traction sheave, the second transition block assembly and the first head block assembly, and then is induced into the first hauling cable hole and is connected with the sucker rod of another oil well pipe or is connected with a counterweight device. The energy-saving oil pumping mechanism used for oil field has a high transmission efficiency, is convenient, safe and convenient to be used, has a simple integral structure, is convenient to be managed and protected, can realize to configure two wells for one machine, has high mechatronics degree and saves power energy.

Owner:张墅

Gear grease prepared from petrolatum

InactiveCN105733776ASmall transmission resistanceHigh transmission efficiencyLubricant compositionLubricationPetroleum

The invention discloses gear grease prepared from petrolatum and relates to the technical field of petrochemical engineering. The gear grease is prepared from, by weight, 40-50 parts of petrolatum, 10-15 parts of linseed oil, 10-15 parts of hydroxyethyl cellulose, 8-13 parts of carbomer resin, 6-10 parts of attapulgite, 6-10 parts of polyoxyethylene lauryl ether, 5-8 parts of cetanol, 5-8 parts of styrene-butadiene rubber, 4-6 parts of gelatin, 3-5 parts of nanosized ceramic powder, 3-5 parts of rust-proof auxiliaries, 1-2 parts of amine oxide, 10-15 parts of propanediol butyl ether and 20-25 parts of residual oil. The gear grease prepared from the petrolatum has the advantages that the gear grease is moderate in viscosity and can quickly form a protecting film layer on the surface after being applied to a gear so as to play a role in lubrication to reduce transmission resistance and improve transmission efficiency; the gear grease is stable in viscosity and high in corrosion resistance and cannot corrode the gear so as to be beneficial to prolongation of service life of the gear.

Owner:ANHUI HAIDE PETROCHEM

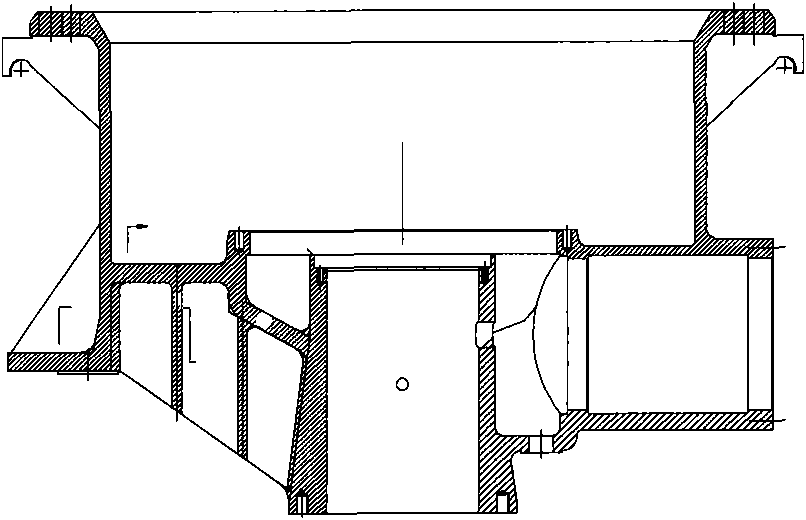

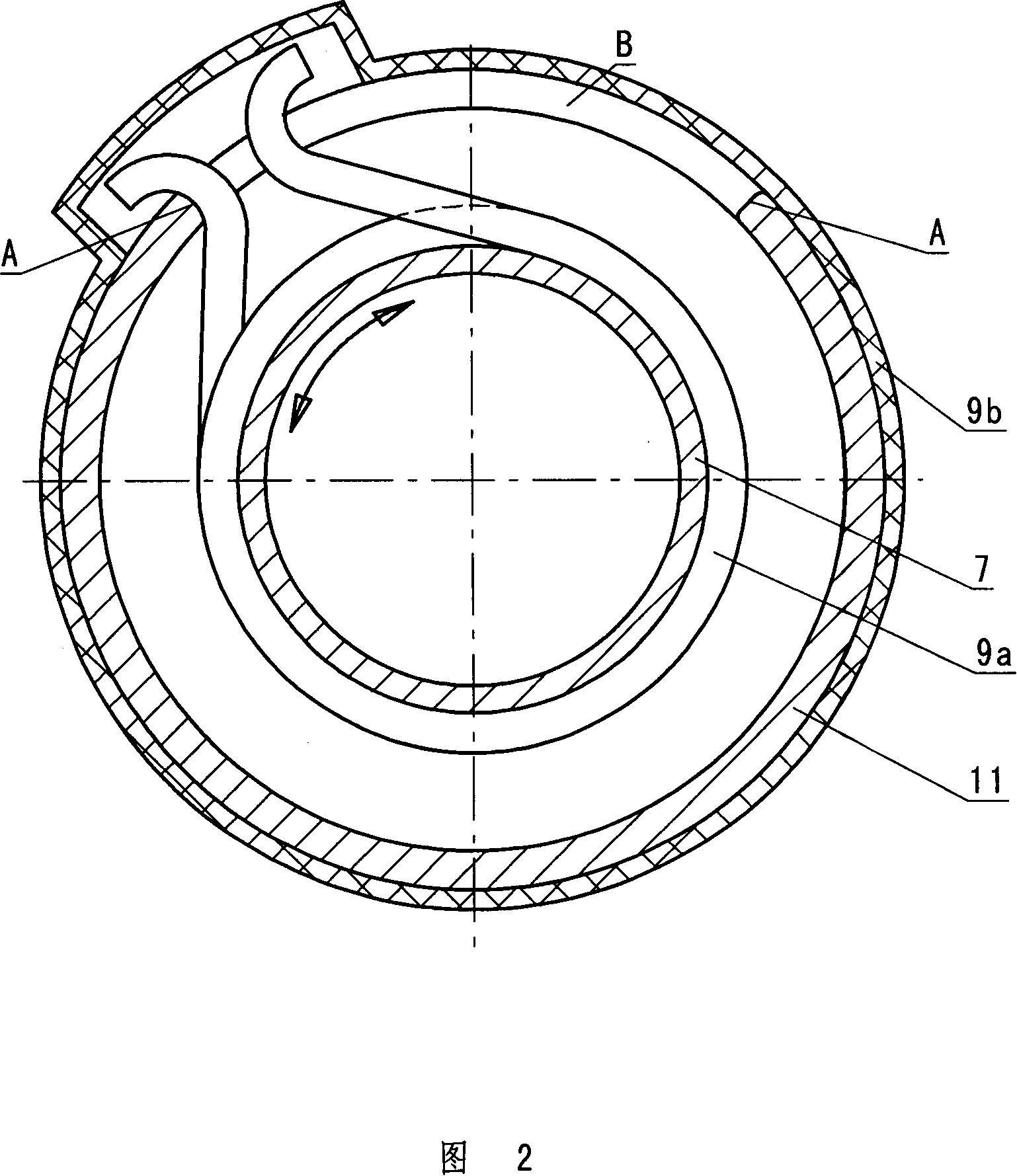

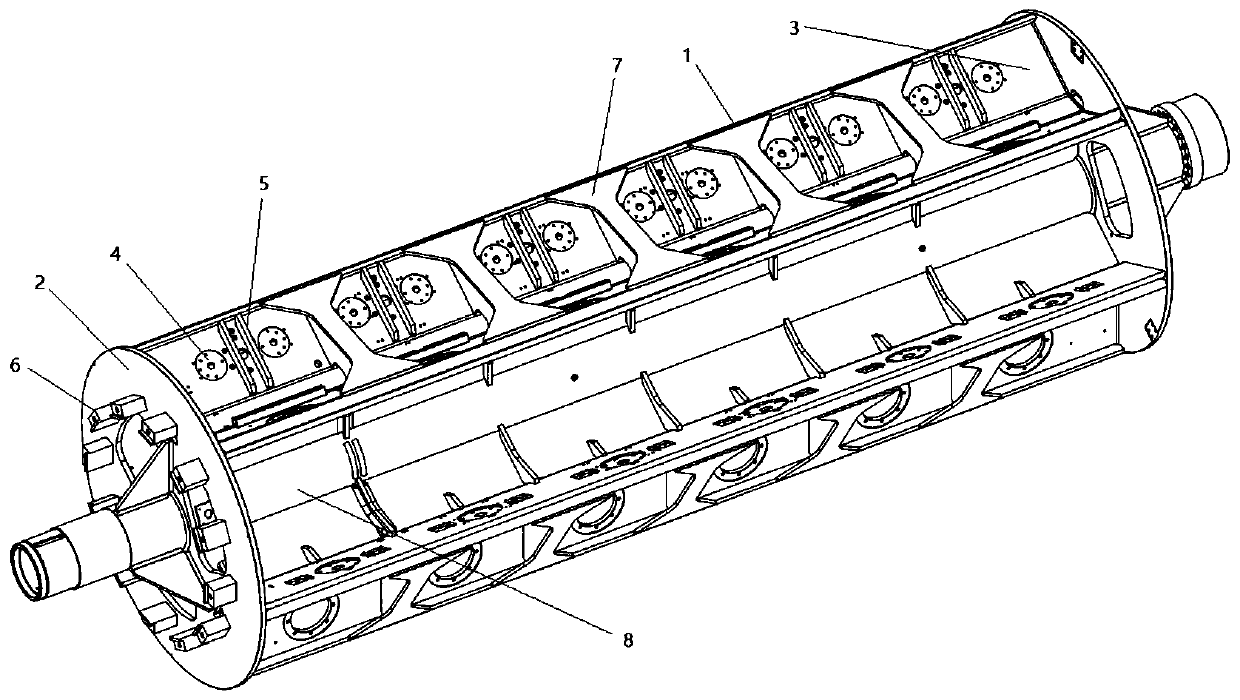

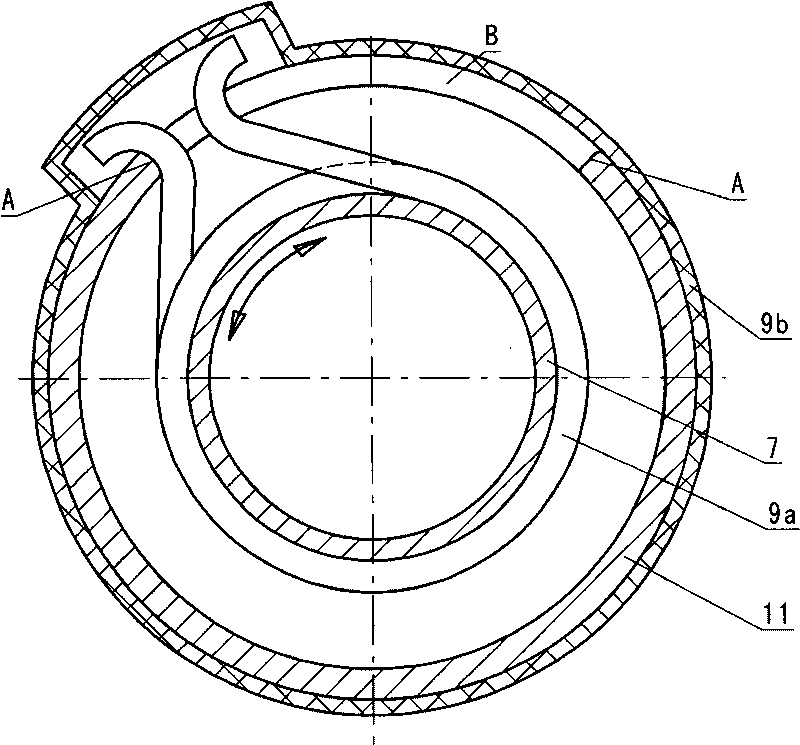

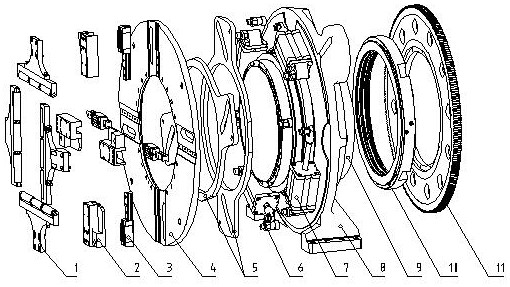

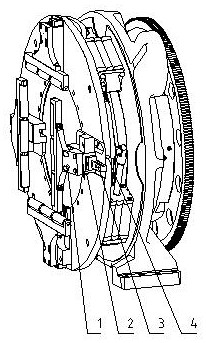

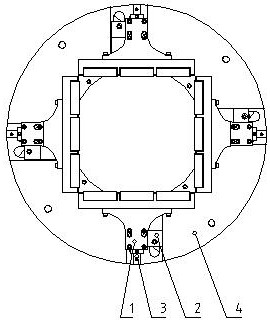

Full-automatic deceleration clutch and washing machine thereof

ActiveCN101113558ASave raw materialsLow costOther washing machinesWashing machine with receptaclesWater flowEngineering

A wholly automatic decelerating clutch and a washing machine thereof pertain to washing machine technical field; an output shaft of the wholly automatic decelerating clutch consists of a small whirlpool agitator shaft, a large whirlpool agitator shaft and a dewatering shaft that are sleeved concentrically; the whirlpool agitator of the washing machine adopting the wholly automatic decelerating clutch is a small whirlpool agitator and a large whirlpool agitator, wherein the small whirlpool agitator is fixedly arranged on the small whirlpool agitator shaft and in the center part of the large whirlpool agitator, and the large whirlpool agitator is fixedly arranged on the large whirlpool agitator shaft, and an inner bucket is fixedly arranged on the dewatering shaft. The washing manner of the washing machine adopting the wholly automatic decelerating clutch is that: the small whirlpool agitator, the large whirlpool agitator and the inner bucket are mutually, reversely and bidirectionally rotated to and fro at a certain ratio, different speeds and different rotating angles, to produce complicated, vertically and horizontally crossed impacting water flow, to strike and rinse clothes, and fully roll, strongly rub and sway the clothes, thus improving the cleanness rate of clothes and not twisting the clothes; when the clothes are dewatered, a torsional spring automatically integrates the decelerating clutch into a whole, and decenters and dewater the clothes in high speed, without needing a whole set of clutch parts and operating mechanisms of the normal decelerating clutch.

Owner:NINGGUO JULONG IND

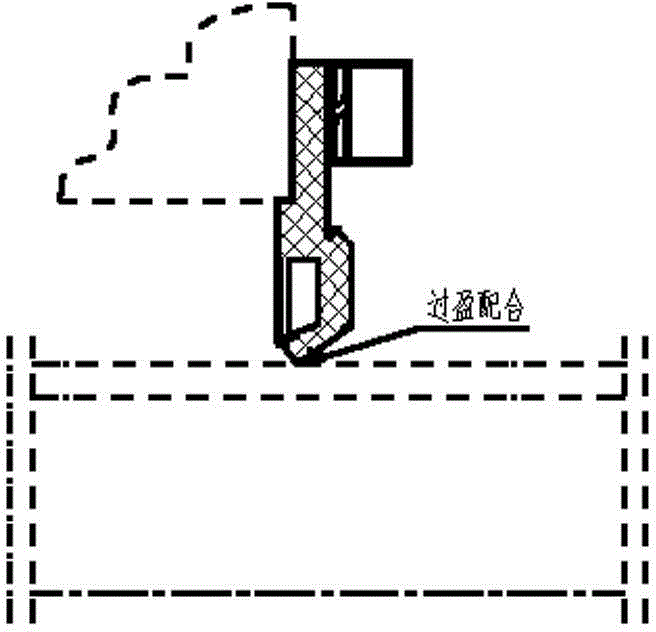

Water-saving mechanical seal device

InactiveCN105782455AReduced axial installation sizeGood followabilityEngine sealsWater savingEngineering

Disclosed is a water-saving mechanical seal device. A static ring is arranged in a static ring seat, a static ring seal ring is arranged on the static ring, a moving ring assembly is arranged at the corresponding position of the inner side of the static ring, a limiting plate is arranged on the static ring, and a gland pad is arranged on the outer side on the static ring seat; an integration structure is adopted, mounting is facilitated, and meanwhile the compression amount of a main seal of a medium side is adjusted; and a pin is riveted on a transmission ring of the moving ring assembly, and the guide and anti-rotation effects are achieved. A push ring used in a normal mechanical seal is not needed, transmission resistance is reduced, the transmission efficiency is improved, the axial mounting size of the mechanical seal is reduced, following performance of the mechanical seal is better, and the compensation performance is more excellent. A protection cover is formed on the outer circle of the transmission ring, a moving ring and a spring in the moving ring assembly are included inwards, and the phenomenon that overmuch dust in atmosphere falls in the moving ring assembly, the spring is blocked and lacks elasticity, or dust is adhered to a shaft sleeve, slippage of a moving ring O-shaped ring on the shaft sleeve is affected, and consequently, a water-saving mechanical seal fails is avoided.

Owner:张昌盛

Gearbox improvement structure for electric vehicle

InactiveCN101885366ASmall transmission resistanceConvenient cartWheel based transmissionGear wheelDrive shaft

The invention discloses a gearbox improvement structure for an electric vehicle, which comprises a gearbox, and a transmission shaft and an output shaft arranged on the gearbox. A driving gear is arranged on the transmission shaft; a driven gear which is engaged with the driving gear is arranged on the output shaft; the driven gear is connected on the output shaft in a sliding mode; and a clutch device which controls the driven gear and the driving gear to be disengaged and engaged is arranged on the gearbox. Because the clutch device which makes the driven gear to slide along a wheel axle so as to be disengaged from the driving gear is arranged on the gearbox, the electric vehicle gearbox improvement structure reduces the transmission resistance between gears during riding when the battery power is exhausted, and brings convenience to manual riding or pushing.

Owner:许晓华

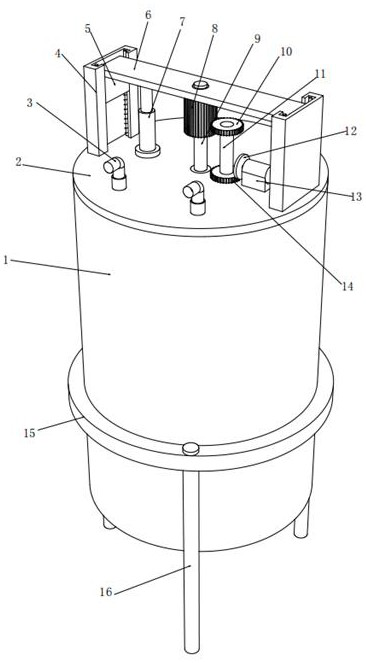

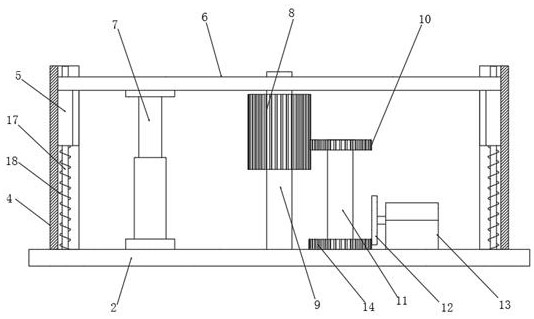

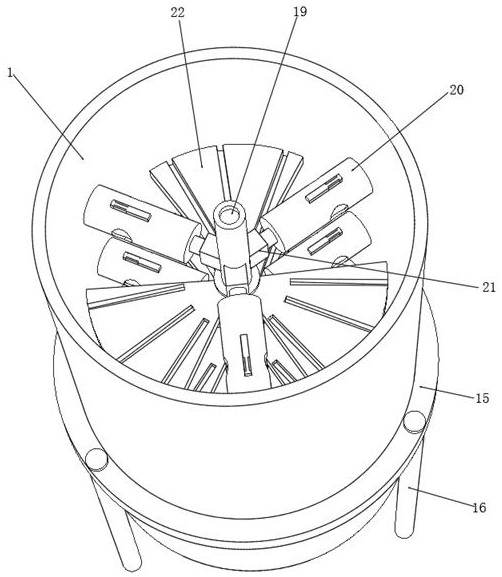

Stirring kettle for preparing tetrabromobisphenol A

ActiveCN113856530AIncrease the pushing areaIncrease resistance to movementRotary stirring mixersTetrabromobisphenol AElectric machinery

The invention discloses a stirring kettle for preparing tetrabromobisphenol A, and relates to the technical field of stirring kettles. The stirring kettle comprises a stirring kettle body, a cover plate installed at the top of the stirring kettle body and a discharging mechanism installed at the bottom of the stirring kettle body, a plurality of feeding pipes are installed on the cover plate, a lifting mechanism is fixed to the top of the cover plate, a transmission mechanism is rotatably mounted at the lifting end of the lifting mechanism, one side of the transmission mechanism is in transmission connection with a driving mechanism, and the bottom end of the transmission mechanism penetrates through the inner wall of the bottom of the cover plate and is in transmission connection with a stirring shaft; a plurality of groups of stirring mechanisms which are distributed at equal intervals are mounted on the circumferential outer wall of the stirring shaft, and three stirring mechanisms form one group and are distributed circumferentially. The motion resistance between the stirring pipe and the reaction liquid can be increased, so that the rotating speed of the stirring shaft can be rapidly reduced, the transmission resistance is reduced when the motor is restarted to carry out anticlockwise driving work of the stirring shaft, and the motor is protected.

Owner:山东金宜善新材料有限公司

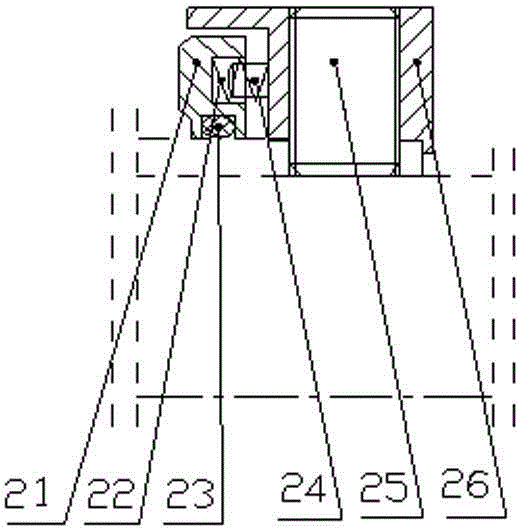

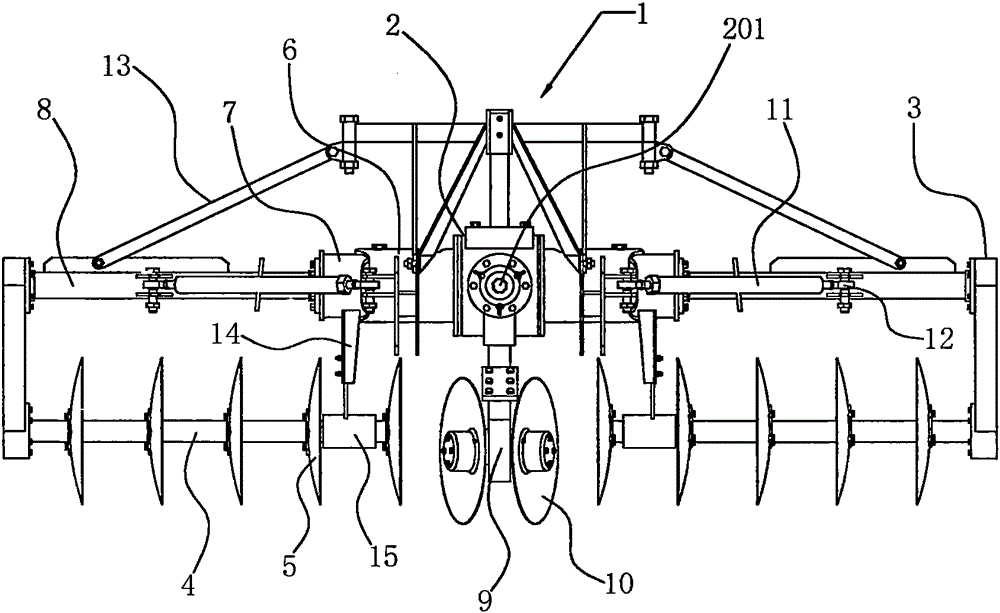

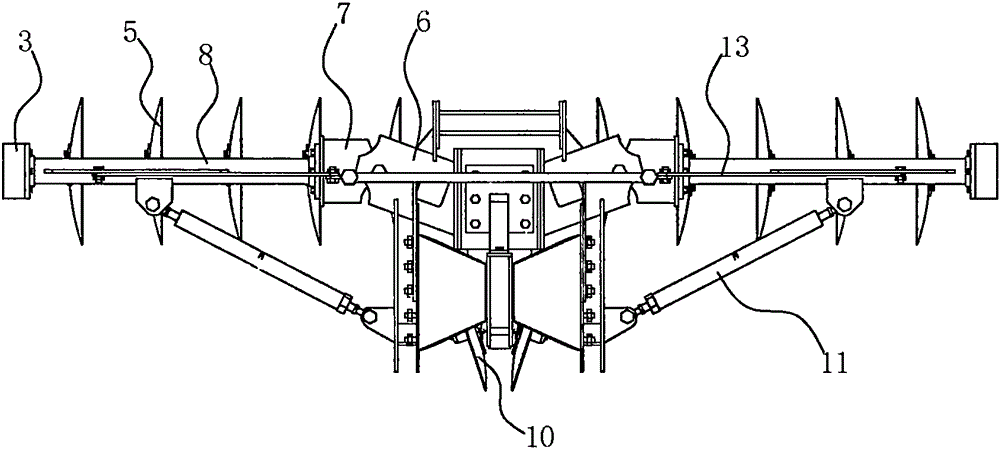

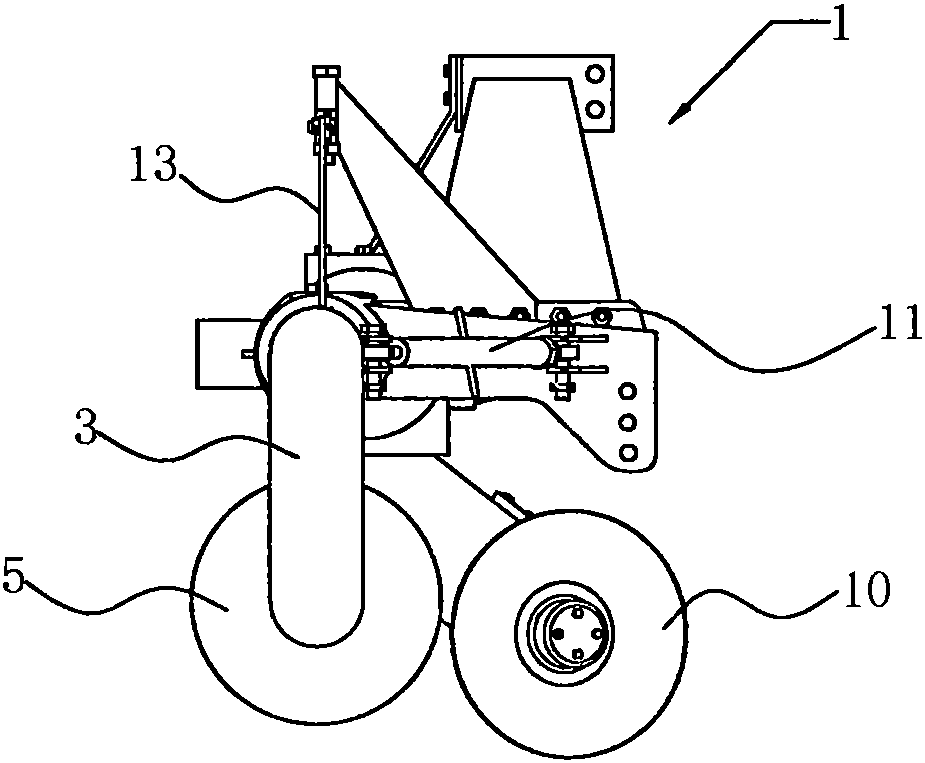

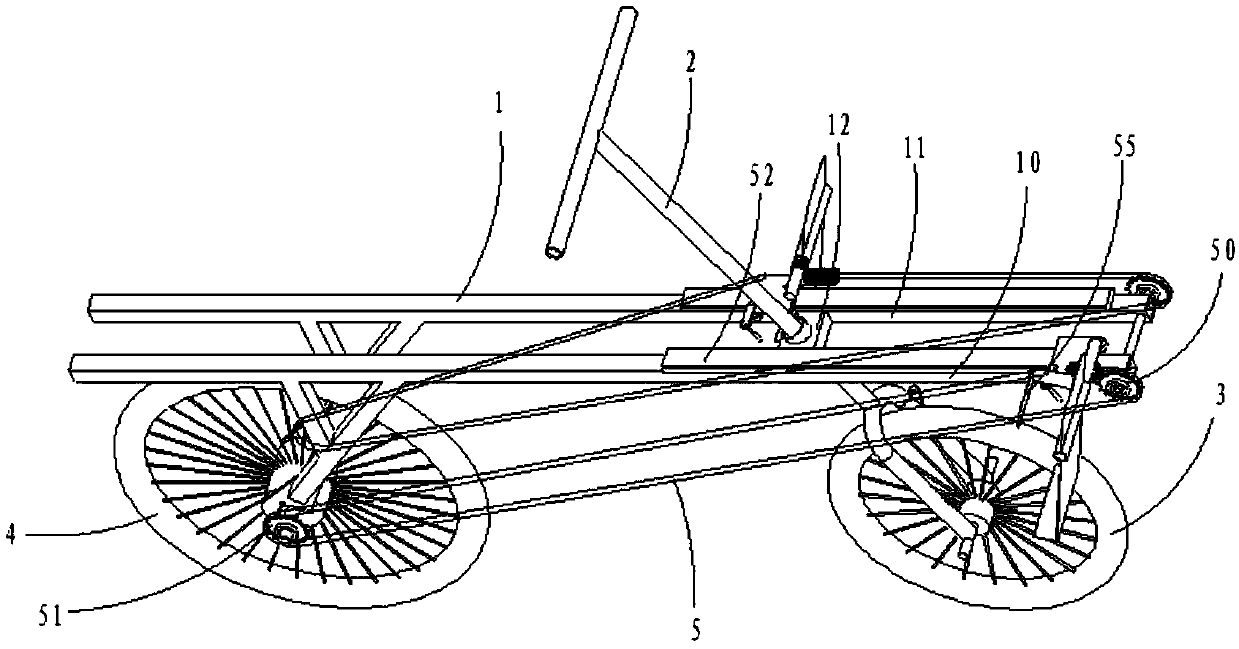

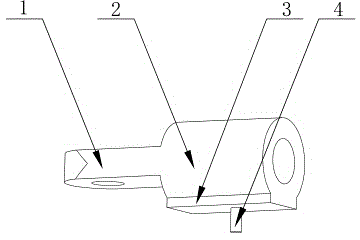

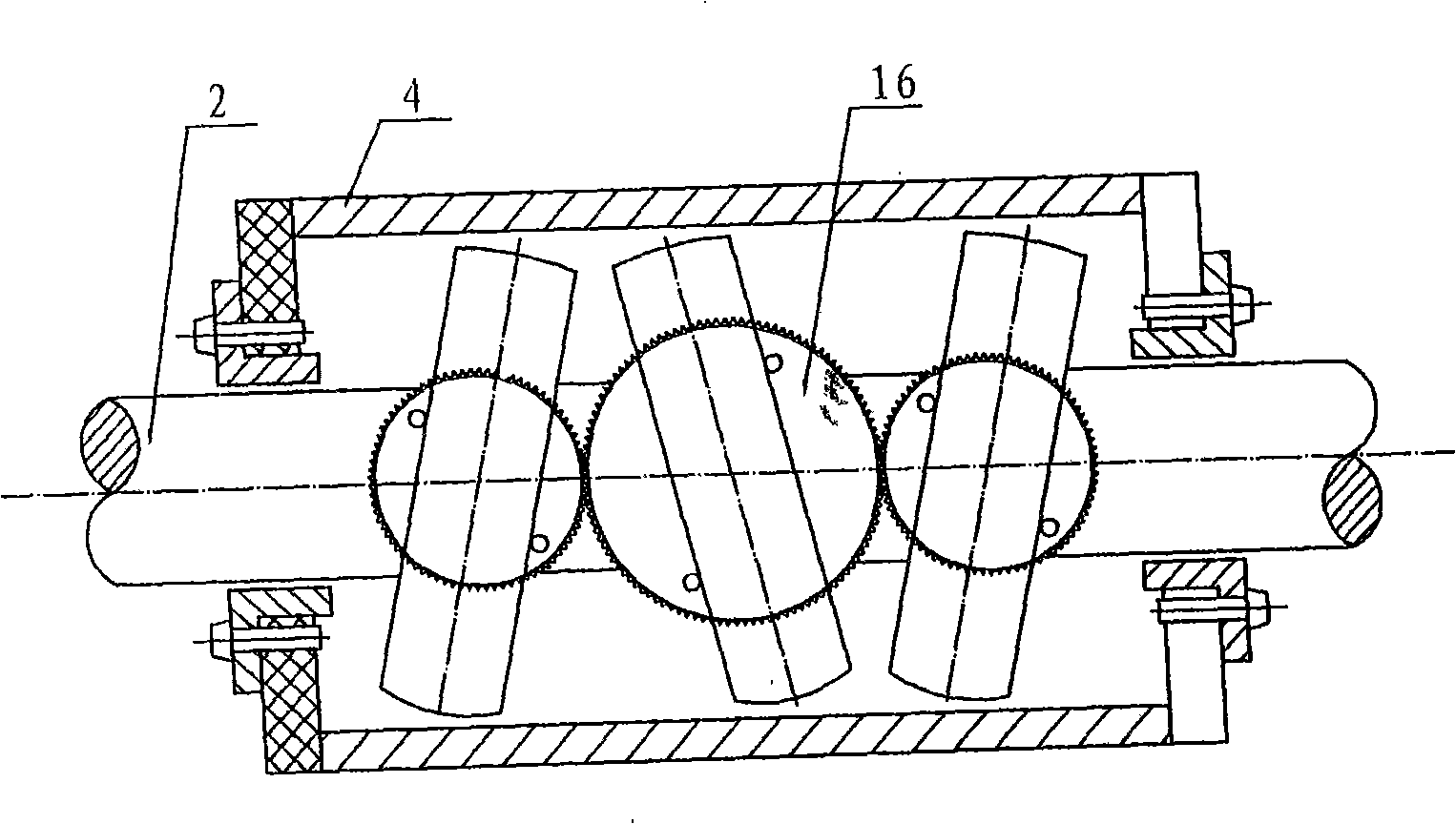

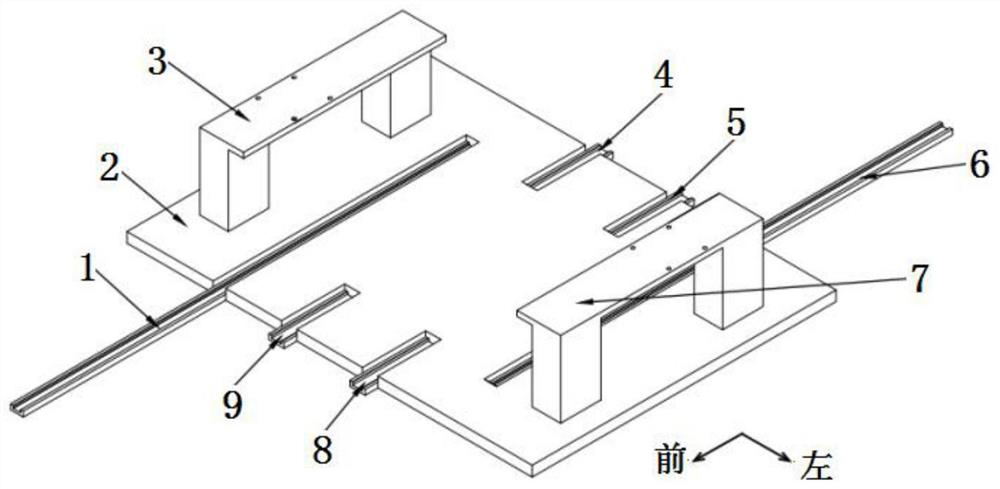

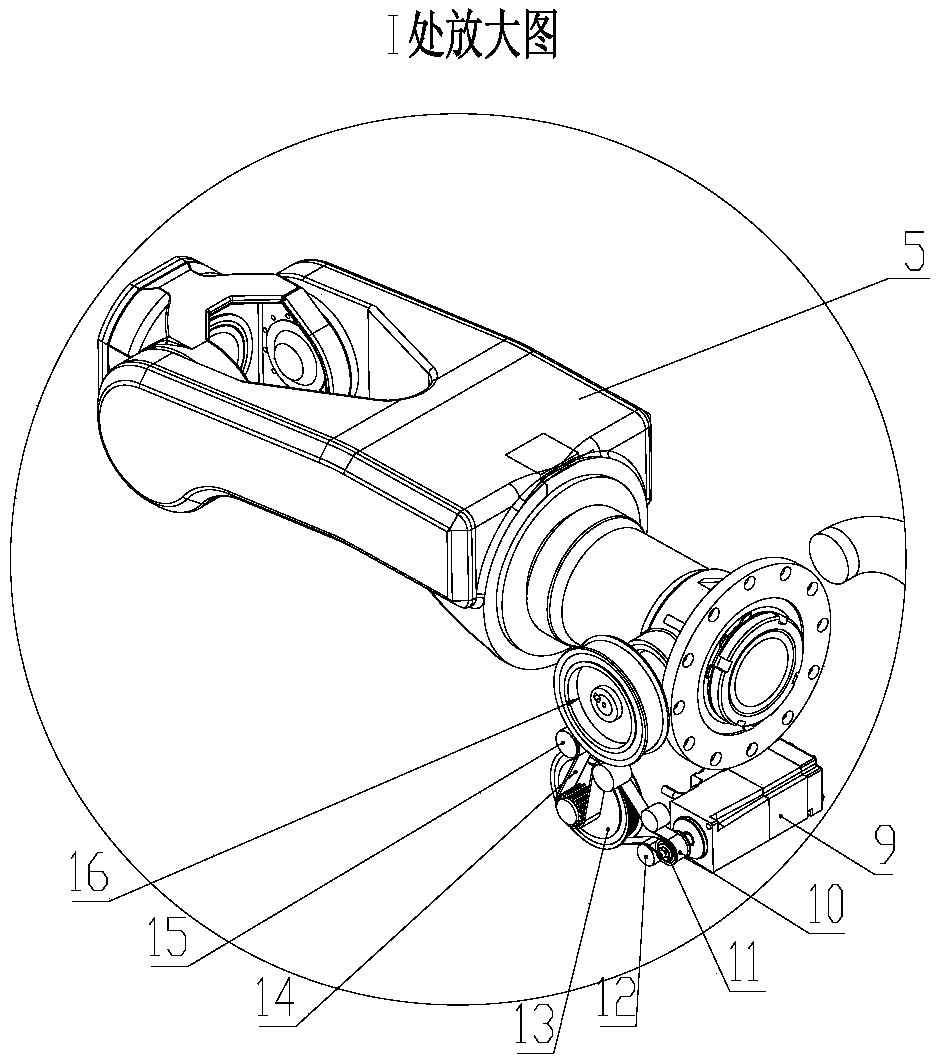

Coulter assembly of disc plow

The invention discloses a coulter assembly of a disc plow and the coulter assembly of a disc plow is used for performing ploughing on the soil. The coulter assembly of a disc plow has small transmission resistance. By use of the coulter assembly of a disc plow, a tractor is subjected to even pressure during plowing. The coulter assembly of a disc plow comprises two disc plow coulter shaft assemblies and a middle coulter (10). The two disc plow coulter shaft assemblies are respectively arranged on two sides of a ride frame (1) of the disc plow. The middle coulter (10) is arranged between the two disc plow coulter shaft assemblies. The coulter assembly of a disc plow also comprises: a middle transmission case (2), a middle coulter assembly gear case (9) and two side transmission cases (3).

Owner:NANZHANG HENGDA MACHINERY MFG SALES

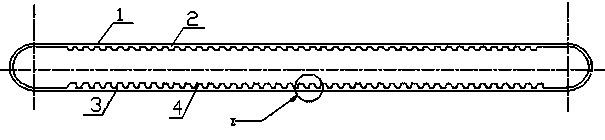

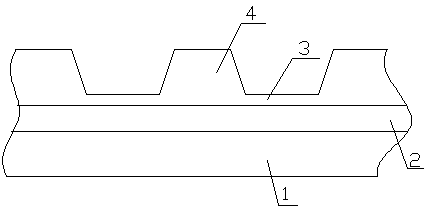

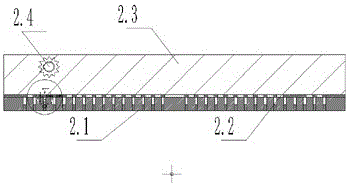

Rubber concave-convex inner tooth guiding type synchronous polyester conveying belt

InactiveCN103991672AMesh closelyAvoid problems such as poor bondingConveyorsIsosceles trapezoidPolyester

A rubber concave-convex inner tooth guiding type synchronous polyester conveying belt comprises upper covering rubber, a framework layer and lower covering rubber which are attached to one another in sequence. The rubber concave-convex inner tooth guiding type synchronous polyester conveying belt is characterized in that concave-convex inner tooth guiding bars are evenly distributed on the outer side of the lower covering rubber in the horizontal direction; the length of each concave-convex inner tooth guiding bar is the same as the width of a conveying belt body; the section of each concave-convex inner tooth guiding bar is in an isosceles trapezoid shape, and the wide bottom face of each concave-convex inner tooth guiding bar and the lower covering rubber are combined. The rubber concave-convex inner tooth guiding type synchronous polyester conveying belt has the advantages that a special metal mold is used for vulcanization, the concave-convex inner tooth guiding bars and the conveying belt body are integrally formed and vulcanized in one time, the problem that the concave-convex inner tooth guiding bars and the lower covering rubber are not firmly bonded due to secondary vulcanization is avoided, the concave-convex inner tooth guiding bars are firm and durable, precise power transmission can be guaranteed, meshing is tight, slipping is avoided, transmission efficiency is high, operation is stable, reliability is good, vibration is low, noise is low, bending rigidity is low, transmission resistance can be reduced, energy saving is facilitated, and fatigue life is greatly prolonged.

Owner:山东道远橡胶科技有限公司

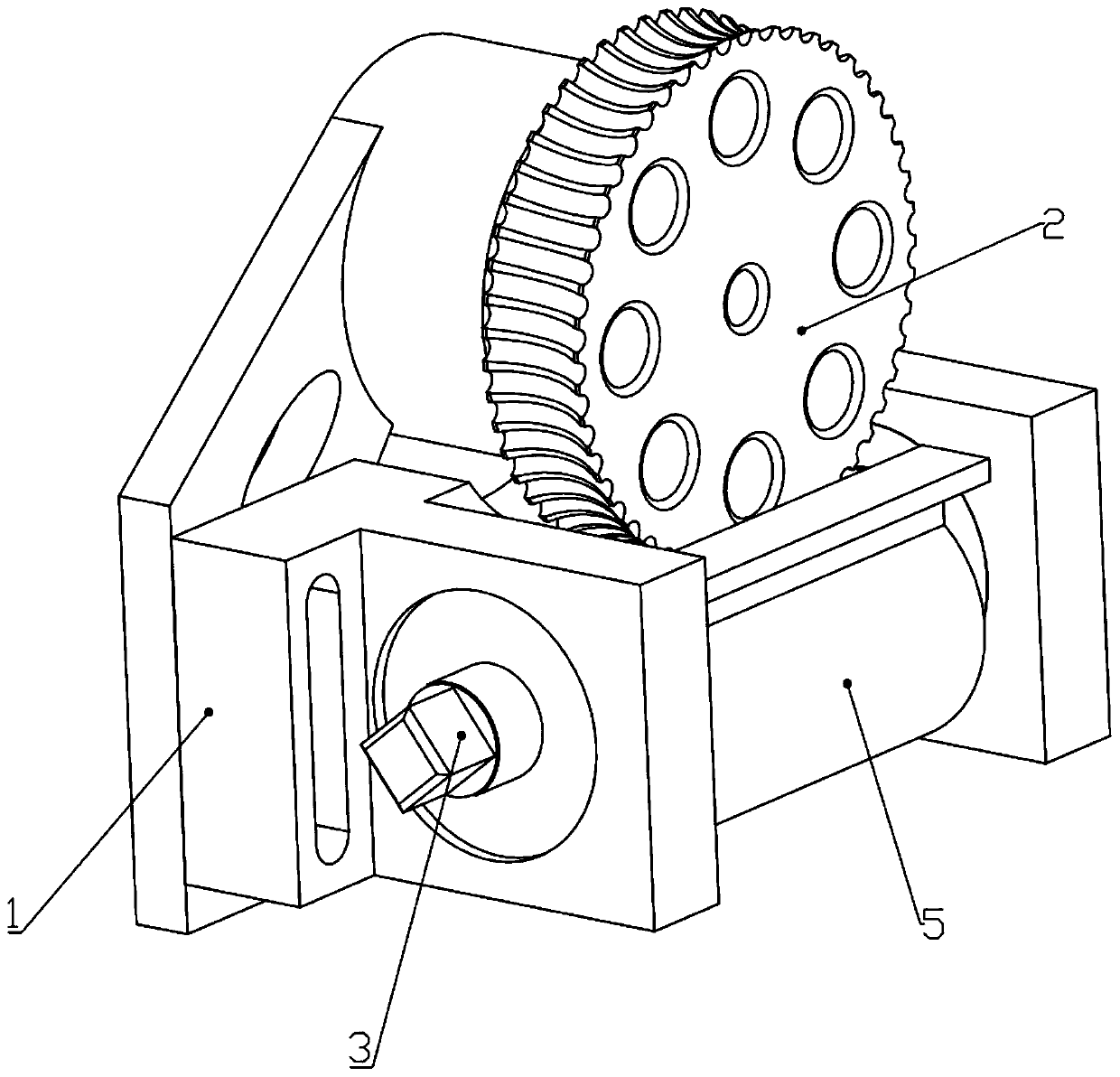

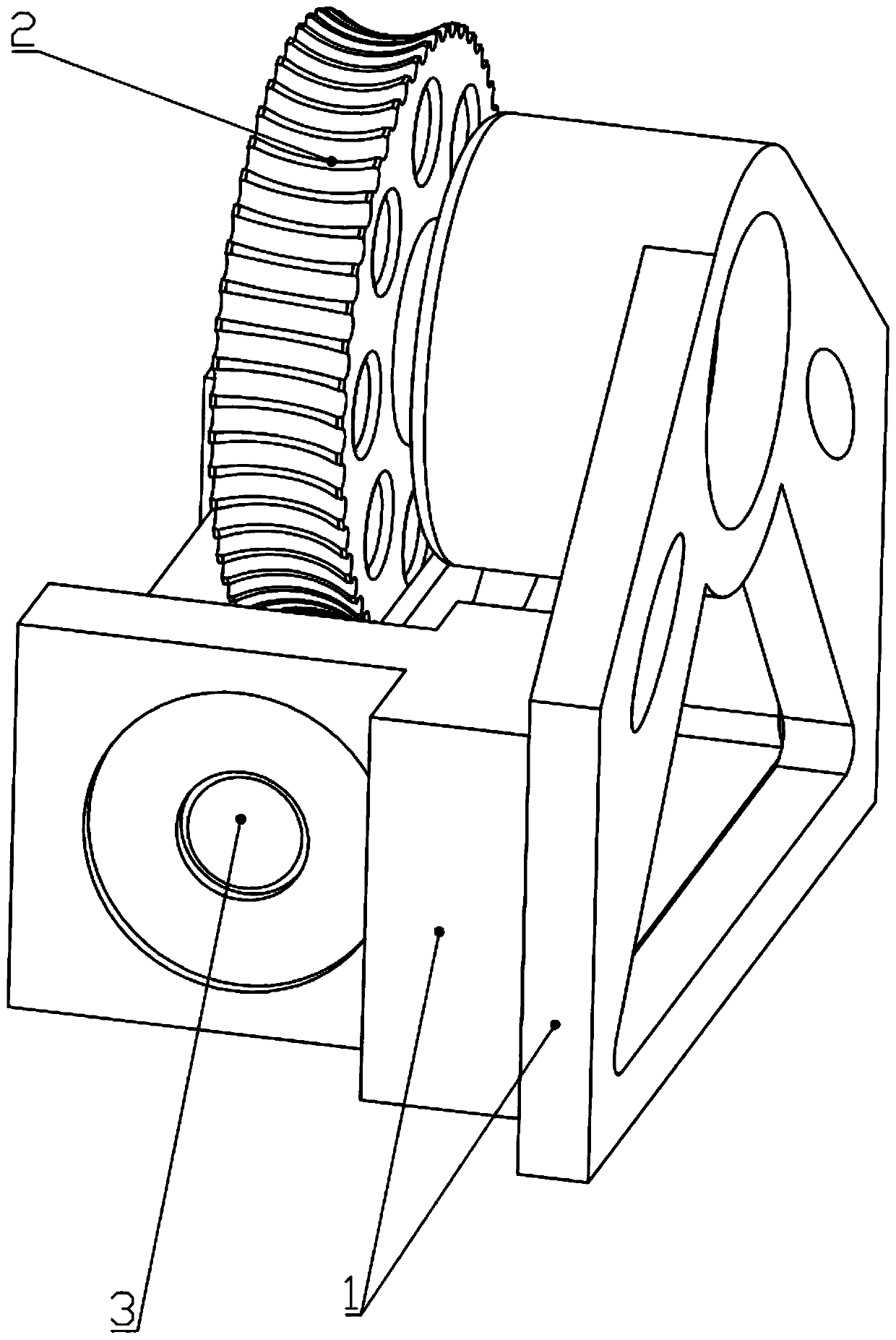

Circular steel ball worm gear structure and speed reducer provided with same

The invention discloses a circulating steel ball worm gear structure. The structure comprises a base, a worm gear and a worm; both the worm gear and the worm are rotationally connected with the base;a spiral groove of the worm is in a circular arc shape; and the spiral groove is provided with two inlets / outlets allowing balls to enter and exit from therein. The two inlets / outlets communicate withthe two ends of a circulating pipeline disposed inside the worm correspondingly; a retainer is arranged on the outer side of the worm in the extending direction; grooves between all teeth of the wormgear are each in a circular arc shape; the balls are arranged in the position, between the two inlets / outlets, in the spiral groove and in the circulating pipeline in sequence, and the balls can circulate along the position, between the two inlets / outlets, in the spiral groove and the circulating pipeline; part of the balls in the position, between the two inlets / outlets, in the spiral groove aredefined in the spiral groove by the inner side wall of the retainer, and the other part of the balls are defined in the spiral groove by the grooves; and the worm gear, the balls and the worm are incooperative transmission. The circulating steel ball worm gear structure is simple in structure, convenient to use, high in transmission efficiency, small in friction heating, not prone to abrasion and low in cost.

Owner:石雅 +1

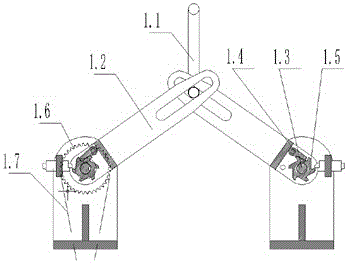

Cabling mechanism of frame-type strander

InactiveCN111091935AFlexible slidingSmall transmission resistanceCable/conductor manufactureWire wrap

Owner:NANTONG HONGFENG ELECTRO MECHANIC

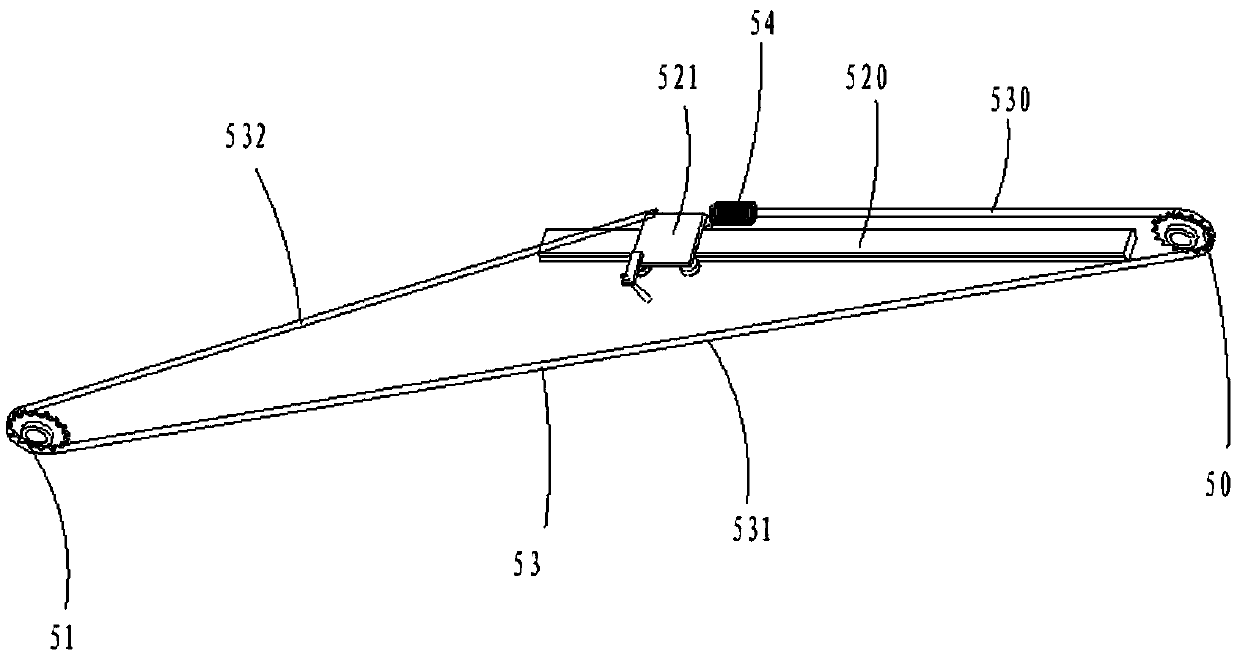

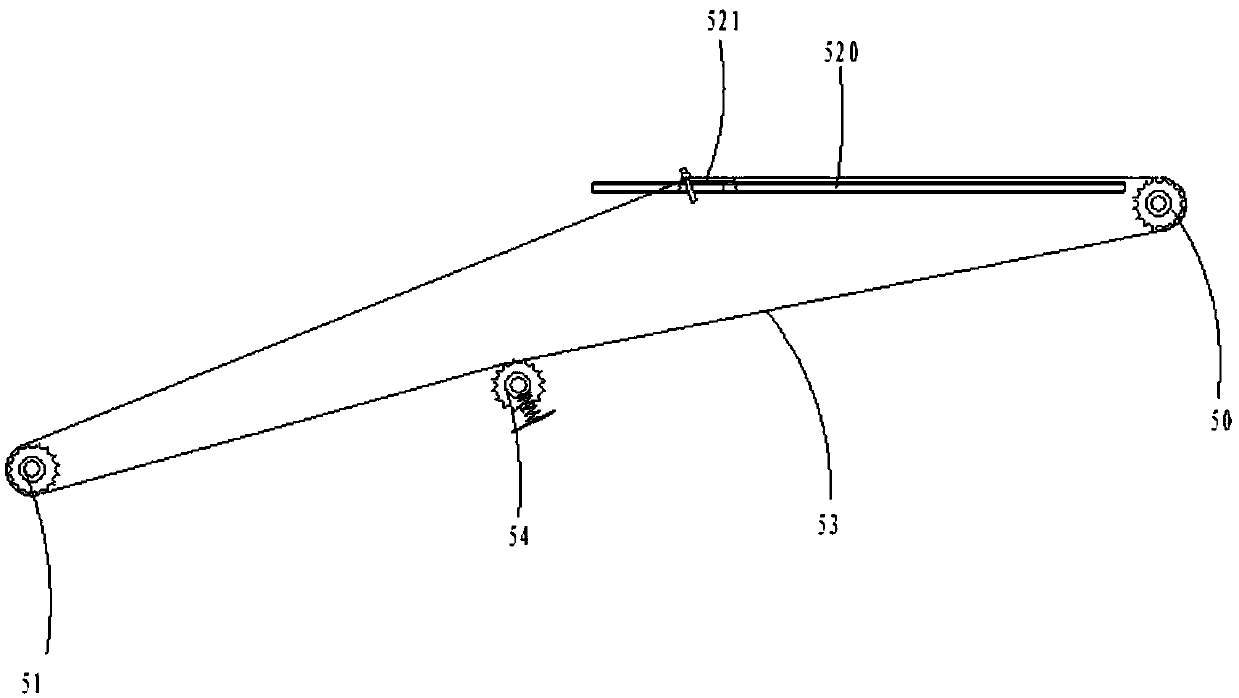

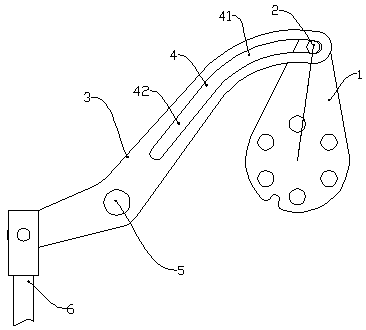

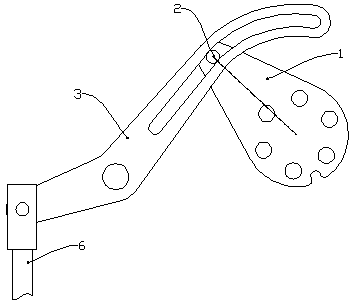

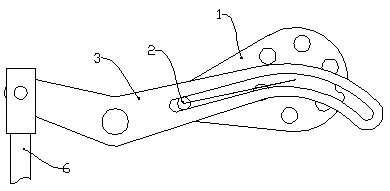

Linear pedaling transmission device and two-wheeled bicycle with same

PendingCN108674565ASimple structureReduce Rigid ConnectorsChain/belt transmissionRider propulsionTransmission beltEngineering

The invention relates to a linear pedaling transmission device and a two-wheeled bicycle with the same. The linear pedaling transmission device comprises a front guide wheel, a rear transmission wheel, a sliding block mechanism, a transmission belt, a tensioning mechanism and a pedaling member. The pedaling member is fixedly connected with the sliding block mechanism, and the head end and the tailend of the transmission belt are separately and fixedly connected with the sliding block mechanism. The transmission belt is disposed on the front guide wheel and the rear transmission wheel in a winding mode, and the transmission belt comprises a first section disposed between the sliding block mechanism and the front guide wheel, a second section disposed between the front guide wheel and the rear transmission wheel and a third section disposed between the rear transmission wheel and the sliding block mechanism. The tensioning mechanism is disposed on the first section or the second sectionof the transmission belt to reduce transmission resistance.

Owner:ZHANGJIAGANG CHUANJUN VEHICLE IND CO LTD

Full-automatic deceleration clutch and washing machine thereof

ActiveCN101113558BFunction increaseFlip fullOther washing machinesWashing machine with receptaclesLaundry washing machineControl engineering

A wholly automatic decelerating clutch and a washing machine thereof pertain to washing machine technical field; an output shaft of the wholly automatic decelerating clutch consists of a small whirlpool agitator shaft, a large whirlpool agitator shaft and a dewatering shaft that are sleeved concentrically; the whirlpool agitator of the washing machine adopting the wholly automatic decelerating clutch is a small whirlpool agitator and a large whirlpool agitator, wherein the small whirlpool agitator is fixedly arranged on the small whirlpool agitator shaft and in the center part of the large whirlpool agitator, and the large whirlpool agitator is fixedly arranged on the large whirlpool agitator shaft, and an inner bucket is fixedly arranged on the dewatering shaft. The washing manner of thewashing machine adopting the wholly automatic decelerating clutch is that: the small whirlpool agitator, the large whirlpool agitator and the inner bucket are mutually, reversely and bidirectionally rotated to and fro at a certain ratio, different speeds and different rotating angles, to produce complicated, vertically and horizontally crossed impacting water flow, to strike and rinse clothes, and fully roll, strongly rub and sway the clothes, thus improving the cleanness rate of clothes and not twisting the clothes; when the clothes are dewatered, a torsional spring automatically integrates the decelerating clutch into a whole, and decenters and dewater the clothes in high speed, without needing a whole set of clutch parts and operating mechanisms of the normal decelerating clutch.

Owner:NINGGUO JULONG IND

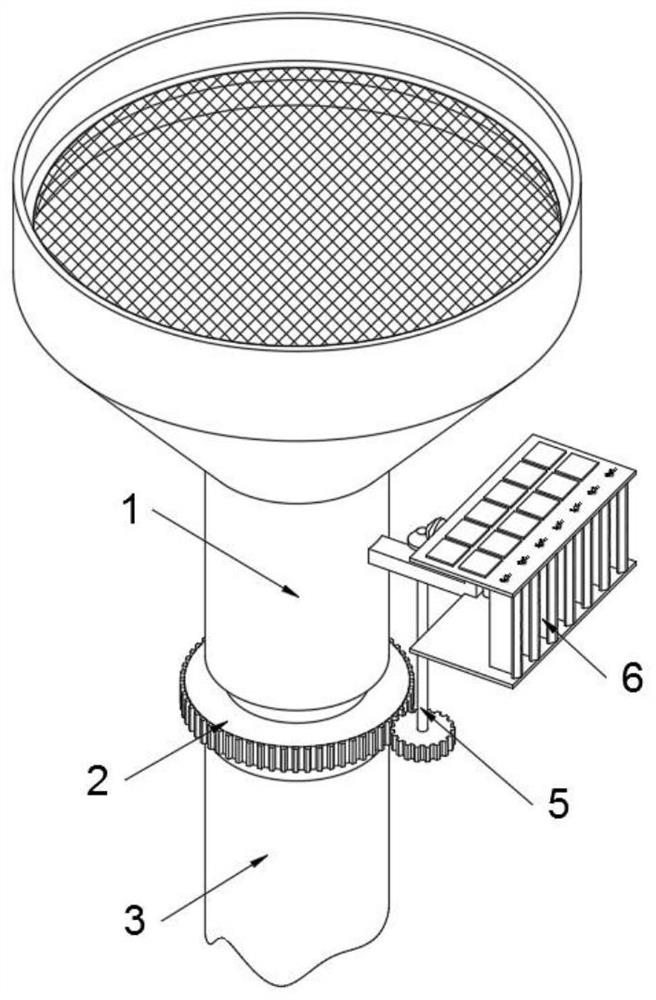

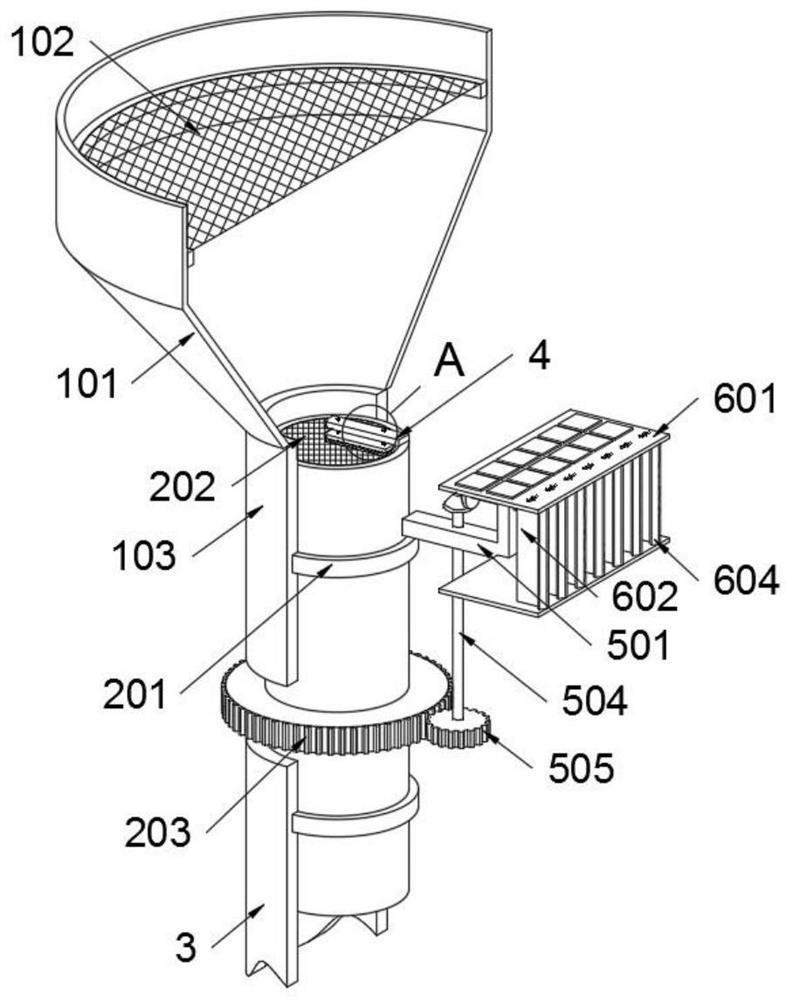

Quick blockage clearing device of energy-saving building rainwater collecting and purifying device

InactiveCN111945821AImprove rotation efficiencyAchieve angular rotationGeneral water supply conservationStationary filtering element filtersPropellerEngineering

The invention provides a quick blockage clearing device of an energy-saving building rainwater collecting and purifying device, and relates to the technical field of rainwater collecting and blockageclearing. The quick blockage clearing device solves the problem that soil residues on a filter screen cannot be automatically cleared under the action of natural wind through structural improvement, and solves the problem that the wind collecting efficiency of a wind power rotating element and the rotating efficiency of a propeller cannot be improved through structural improvement. The quick blockage clearing device of the energy-saving building rainwater collecting and purifying device comprises a collecting structure and an air guide piece, the collecting structure is connected with a connecting pipe B, and the connecting pipe B is connected with a water guide pipe. Due to the fact that the number of rectangular plates is two, the two rectangular plates are both welded to a mounting base, the two rectangular plates are located at the upper position and the lower position of a propeller correspondingly, and the two rectangular plates jointly form a narrow air channel, and therefore the rotating efficiency of the propeller is improved.

Owner:诸慧

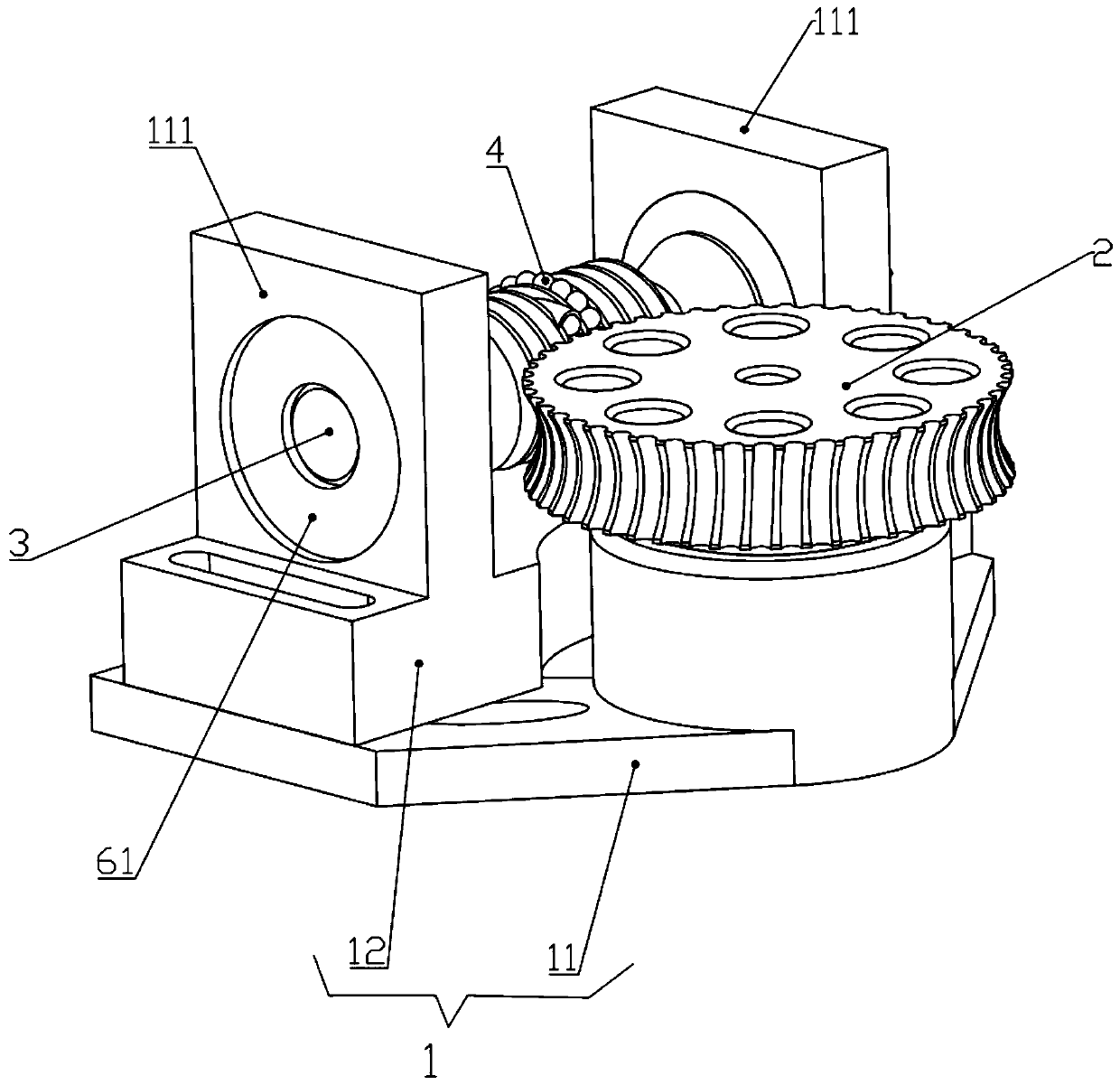

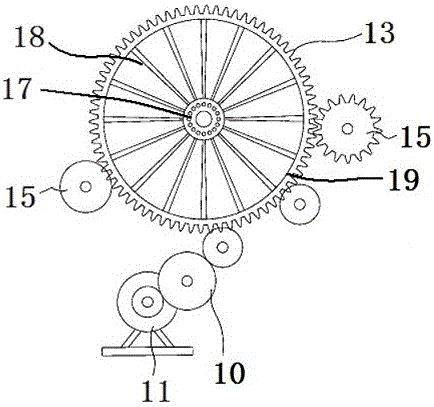

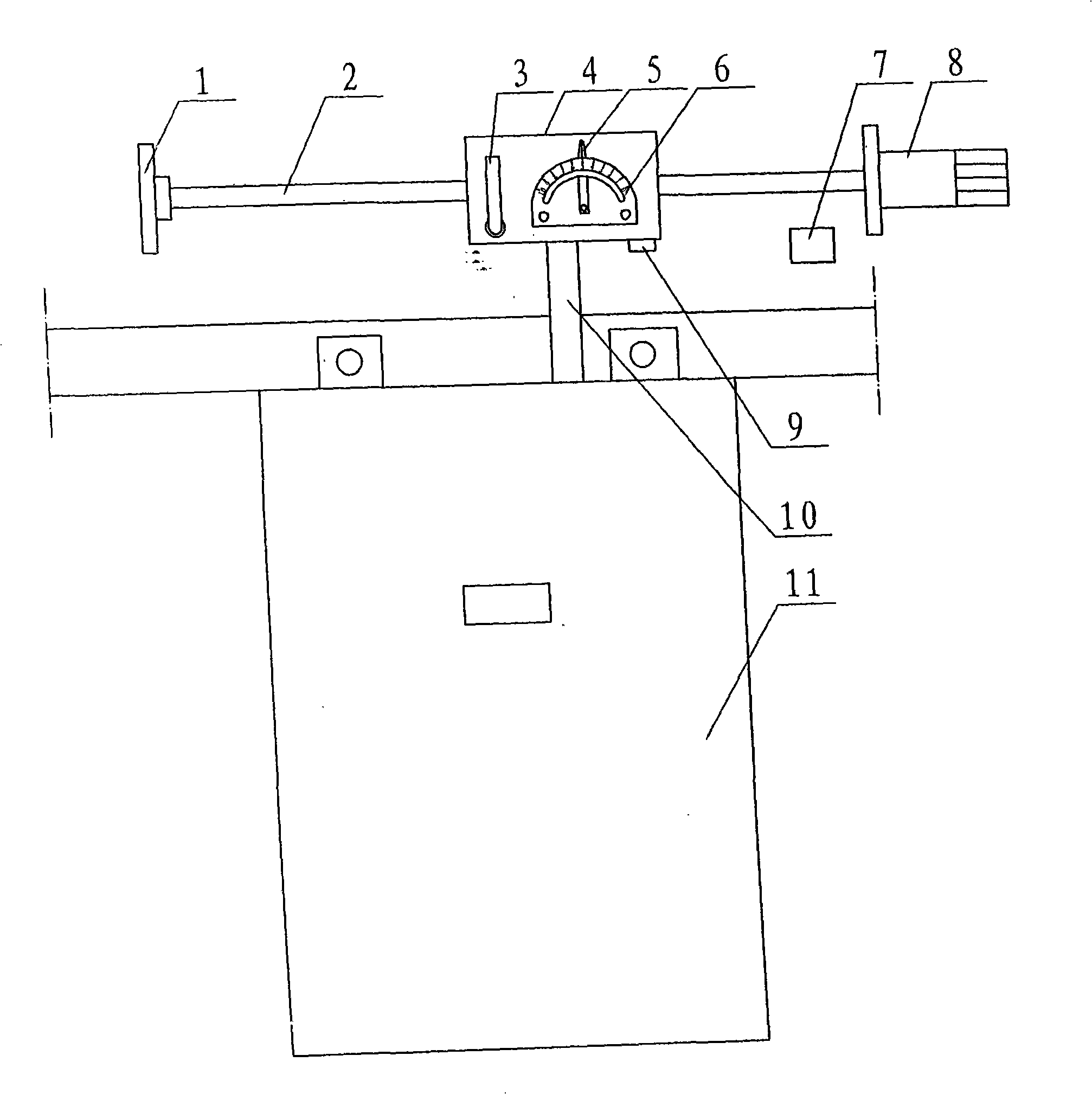

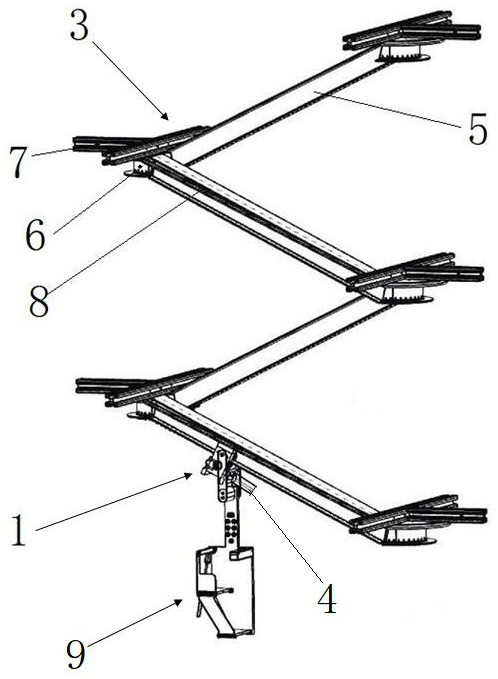

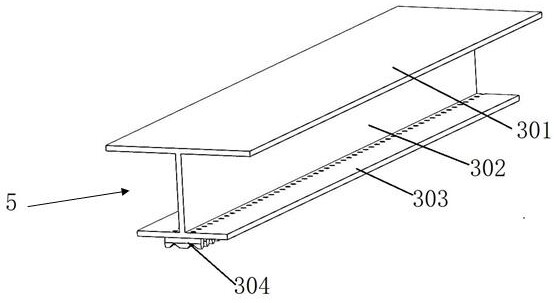

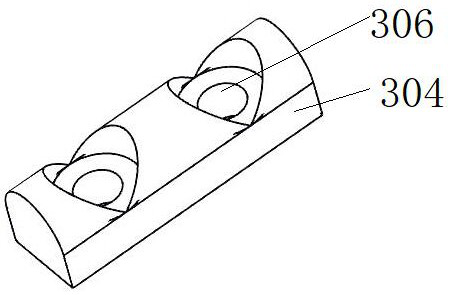

Magnetic unit vertical combination method of permanent magnetic spreader

InactiveCN106586798ASolve the problem of synchronizationSmall transmission resistancePermanent magnetsLoad-engaging elementsTransmission systemCombination method

The invention discloses a magnetic unit vertical combination method of a permanent magnetic spreader. The magnetic unit vertical combination method is characterized in that a magnetic system of the permanent magnetic spreader is arranged into an upper layer, a middle layer, a lower layer and a shaft transmission system, wherein the upper layer is a thick iron plate which can communicate with a magnetic path; the middle layer is a movable permanent magnet unit; the lower layer is a longitudinally arranged permanent magnet unit; external force can enable the middle layer magnet to tangentially move through the shaft transmission system so as to reach switching between a magnetizing state and a demagnetizing state; as the magnetic field directions of the middle layer permanent magnets and the lower layer permanent magnets to be mutually perpendicular, when the middle layer permanent magnets move a pitch, the middle layer and the lower layer can have two states same as or opposite to each other in magnetic field directions, i.e. the state of magnetizing or demagnetizing occurs on the working surface of the permanent magnetic spreader, so that the advantages of the circulating magnetizing and demagnetizing of the traditional permanent magnetic spreader can be kept, the benefit of greatly reducing the processing cost during production manufacturing can also be obtained; and meanwhile, as the magnets tangentially move, the magnetizing resistance and demagnetizing resistance are much weaker than those of the traditional spreader, the problem of non-synchronous single machine can be solved, and use is more flexible and convenient.

Owner:YUEYANG YONGJIN ELEVATORING PERMANENT MAGNET

Constant-rotating connection rod head of civil air defense door

InactiveCN105332553AReduce wearSmall transmission resistanceBuilding locksCivil engineeringEngineering

Owner:TIANJIN LISHIDE HYDRAULIC MACHINERY

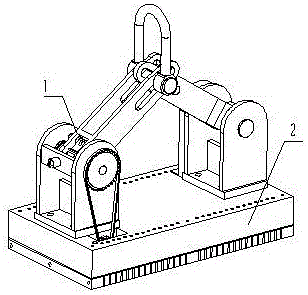

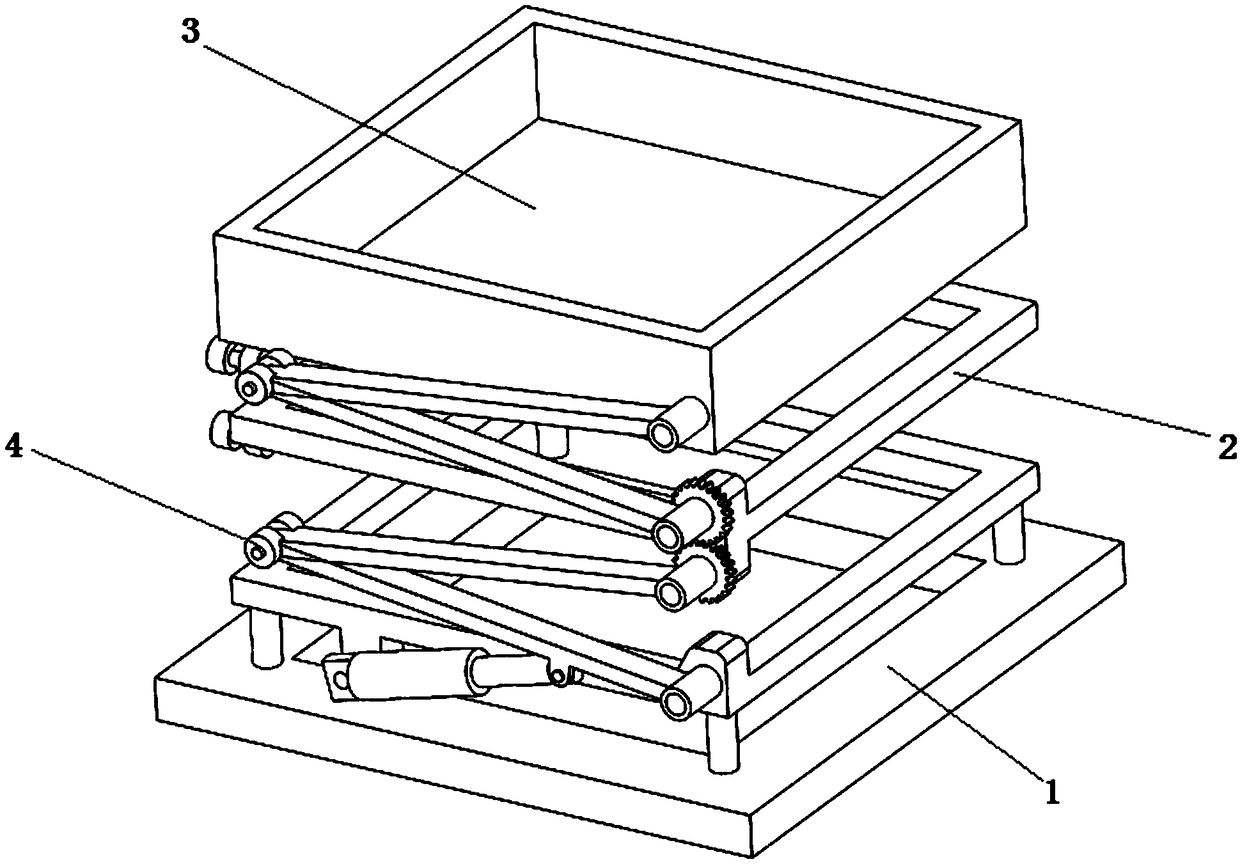

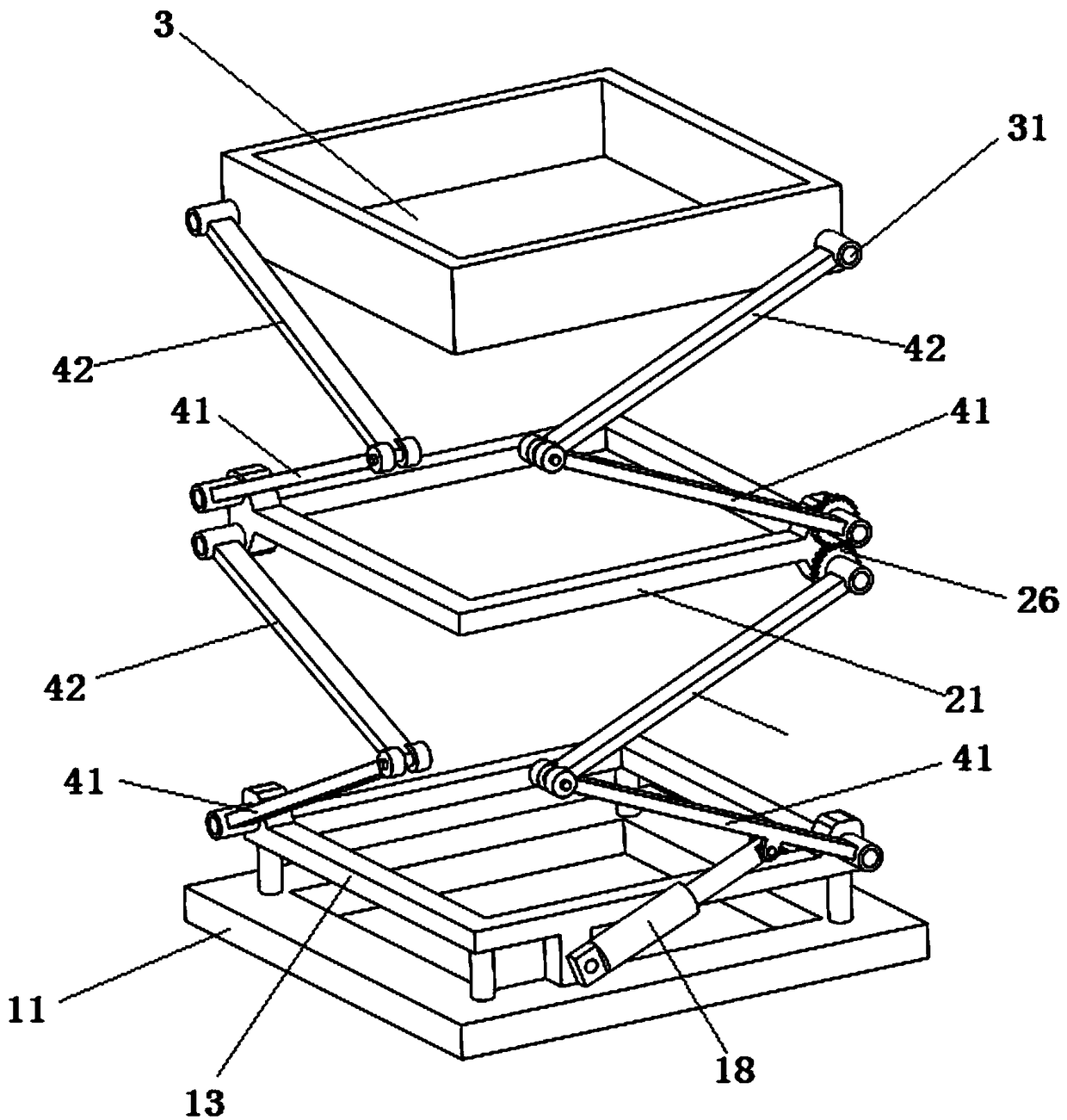

Fruit tree branch trimming assisting tool

The invention discloses a fruit tree branch trimming assisting tool comprising a supporting seat, a connection frame and a load bearing frame, the supporting seat, the connection frame and the load bearing frame are arranged from bottom to top in sequence, and the supporting seat, the connection frame and the load bearing frame are all connected through connection rod mechanisms. The supporting seat comprises a supporting frame plate and supporting pillars vertically fixed to the upper surface of the supporting frame plate. Each connection rod mechanism comprises a first connection rod and a second connection rod. A supporting frame is movably provided with the first connection rods, and an electric push rod mechanism is movably arranged on the corresponding first connection rod. The surface of the load bearing frame is fixedly provided with sixth shaft rods, and the sixth shaft rods are movably provided with the second connection rods. The fruit tree branch trimming assisting tool issimple in structure and easy to operate, the height of the load bearing frame can be adjusted conveniently and rapidly through control over stretching and contracting of the electric push rod and thetransmission mechanism of the connection rods, a fruit grower stands in the load bearing frame, adjusts the height of the load bearing frame for different heights of fruit trees and trim the fruit tree branches.

Owner:凤台县农之梦家庭农场有限公司

Wind power generation drive cabinet

InactiveCN106194590AReduce vibrationImprove wind energy utilizationWind motor supports/mountsRenewable energy generationEngineeringThrough transmission

The invention belongs to the technical field of power generators, and discloses a wind power generation drive cabinet. The wind power generation drive cabinet is mainly technically characterized by comprising a wind power generator, and the wind power generator comprises a supporting frame, a rotating shaft and at least two rotating wheels fixed to the rotating shaft; at least two frames consistent with the rotating wheels in the radial direction are arranged between every two adjacent rotating wheels; the frames are provided with transverse rods, the transverse rods divide the frames into a plurality of adjacent air inlets, wind blocking sheets are fixed to the air inlets, and the rotating wheels are connected with power generator bodies through transmission mechanisms and speed change mechanisms; and wind blocking devices roughly equivalent to the rotating shaft in height are arranged on the side face of the wind power generator. During wind blowing, the wind blocking sheets and the frames located above the rotating shaft are blown, the rotating wheels are driven to rotate, the wind blocking sheets below the rotating shaft are hardly stressed under blocking of the wind blocking devices, and the rotating wheels rotate and drive the power generator bodies to rotate and generate power. The wind power generation drive cabinet is small in vibration and high in wind energy utilization rate; and the power generator bodies and a brake are all arranged on the ground, and maintaining is convenient.

Owner:曹淅

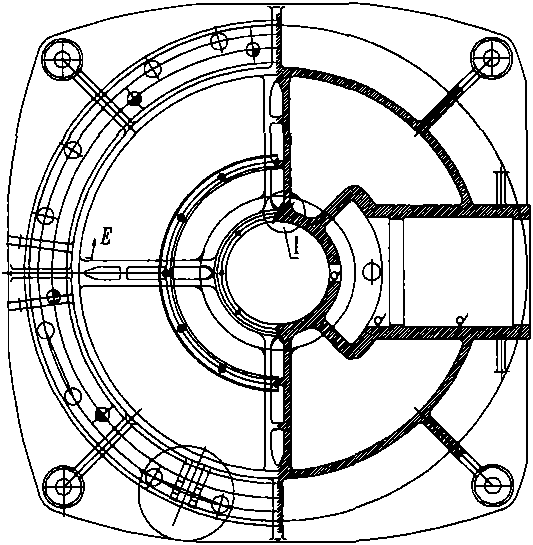

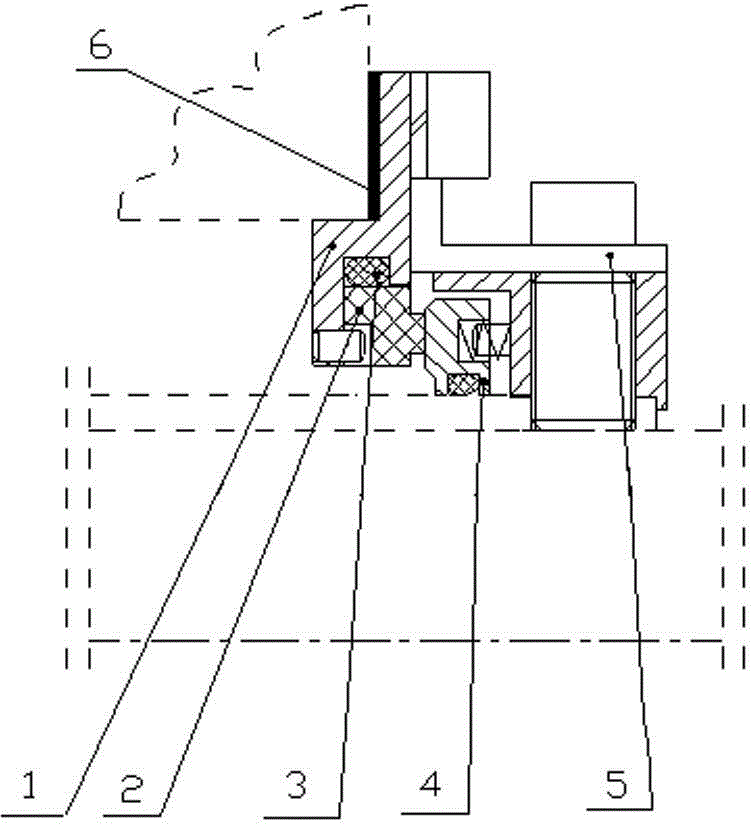

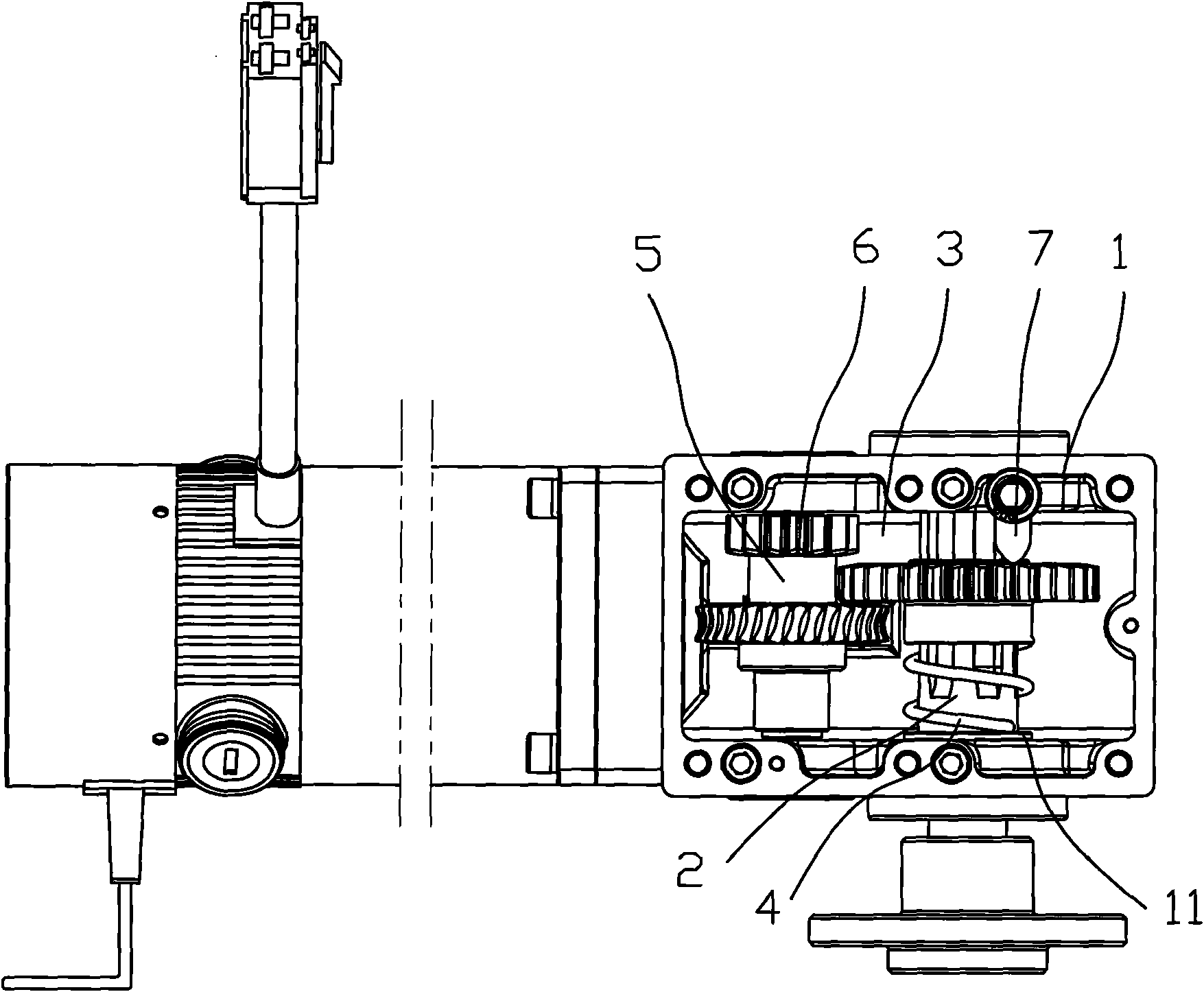

Offset driving heavy-load pneumatic four-jaw chuck

The invention relates to an offset driving heavy-load pneumatic four-jaw chuck. The four-jaw chuck comprises clamping jaws, a guide rail mechanism, a centering disc, a driving mechanism, an air inlet ring and a gear. The clamping jaws are connected to the guide rail connecting base, the guide rail connecting base is connected with a sliding base of the linear guide rail, and the linear guide rail is fixed to the guide rail fixing plate. One end of the pneumatic driving module is connected with the guide rail fixing plate, the other end of the pneumatic driving module is connected with the two centering discs respectively, the centering discs are connected to one end of the rotating main shaft respectively, one end of the driving wheel is connected to the guide rail connecting seat, and the other end of the driving wheel can move in the centering discs; the gear is connected to one end of the rotating main shaft, and the rotating main shaft is connected with the guide rail fixing plate. The pneumatic clamping cost is low, the stroke of the clamping jaws is large, the rolling transmission mode is free of the blocking phenomenon, and the pneumatic clamping device has the large application prospect on the heavy-load large-pipe-diameter laser pipe cutting machine with the high clamping force requirement and the large stroke range requirement.

Owner:JIANGSU YAWEI MACHINE TOOL

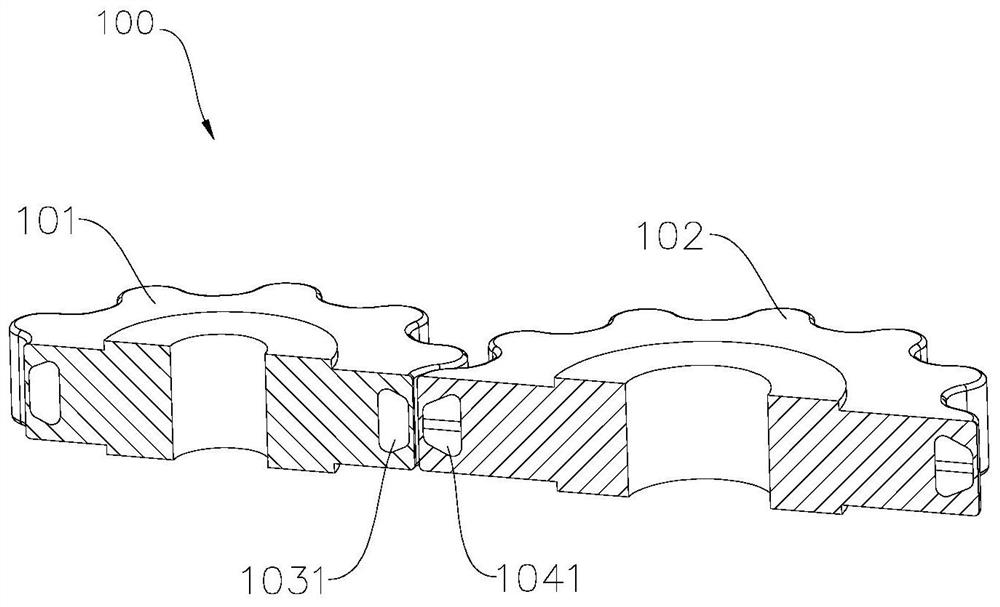

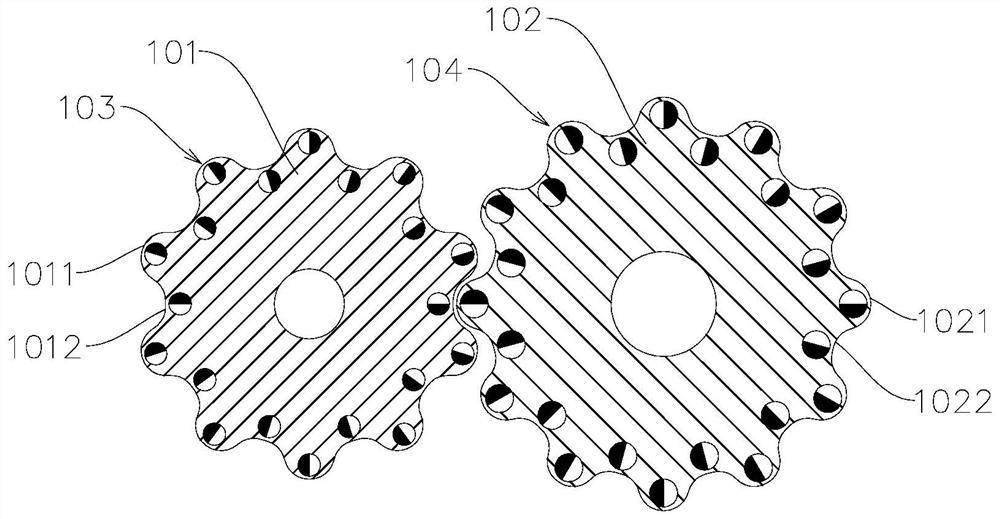

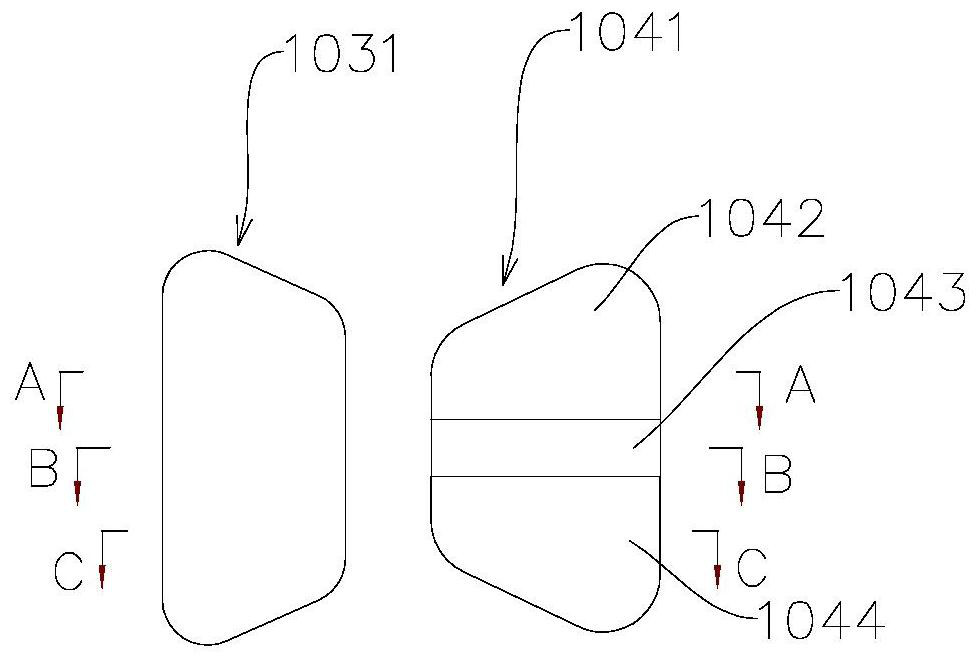

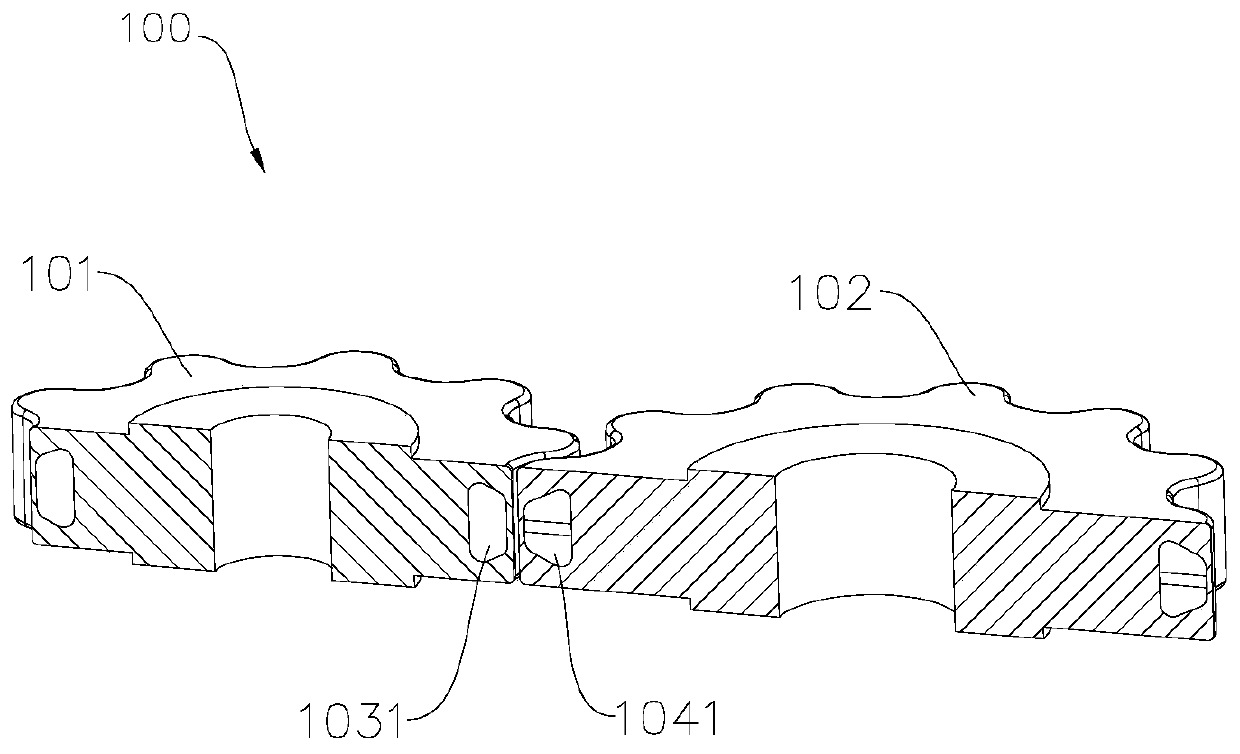

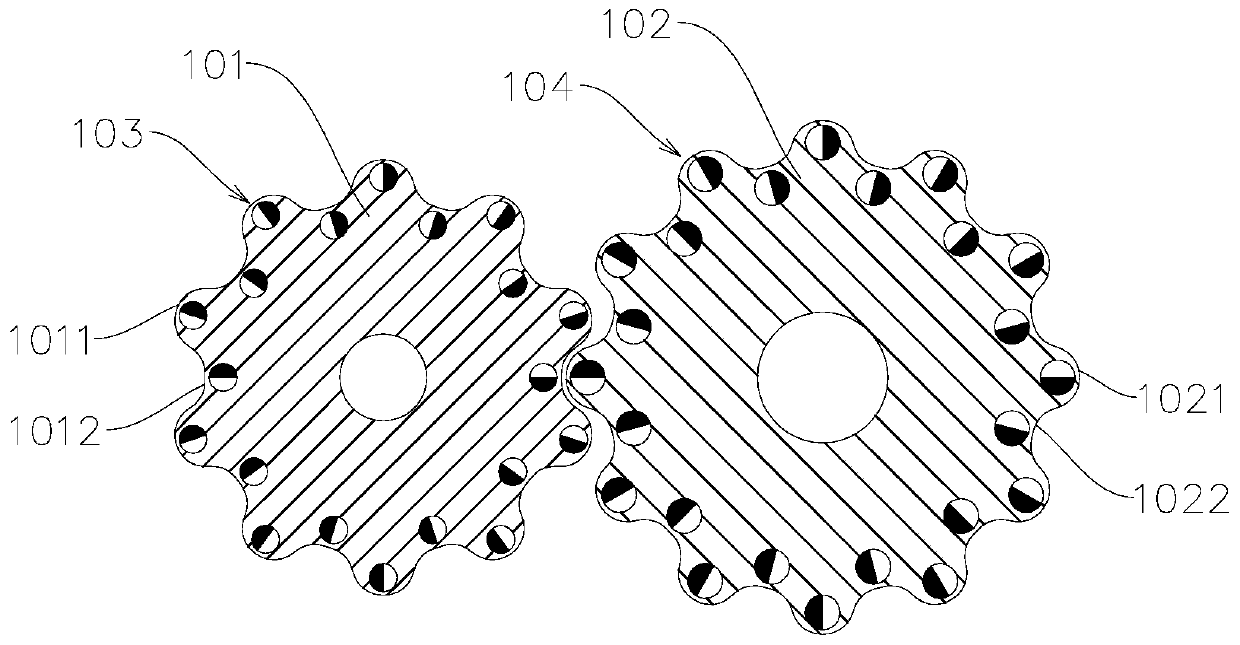

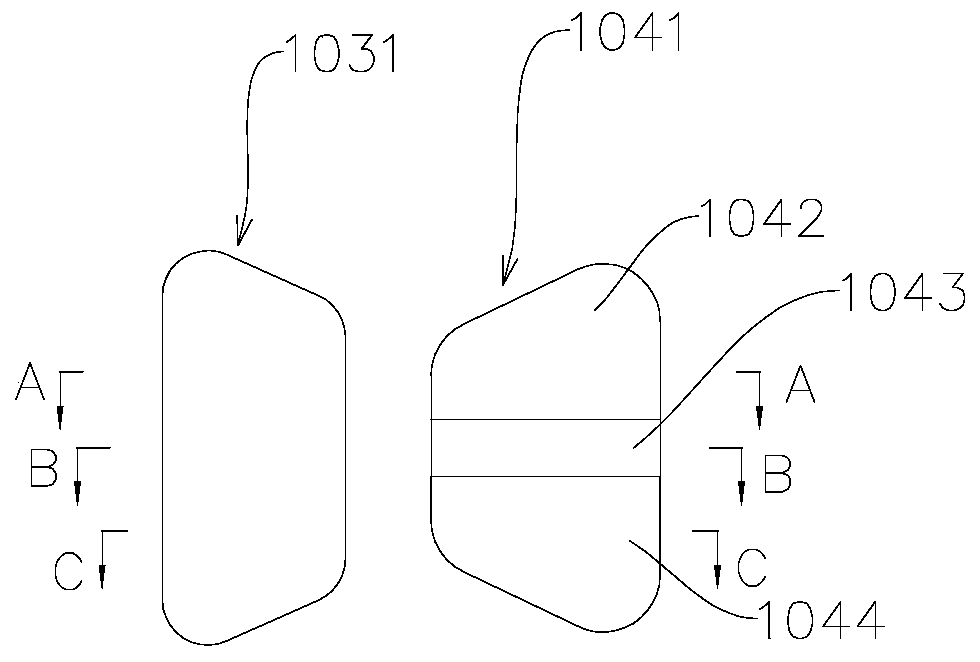

Magnetic gear

ActiveCN110112957BSmooth transmissionSmall transmission resistanceGenerators/motorsMagnetic sourceGear wheel

The present invention provides a magnetic gear, which includes a gear body and a magnetic source. The gear body includes a first gear body and a second gear body, a first magnetic source array is uniformly distributed along the circumferential direction of the first gear body, and a second magnetic source array is uniformly distributed along the circumferential direction of the second gear body. Along the axial direction of the gear body, the first magnetic source of the first magnetic source array cooperates with the middle of the second magnetic source of the second magnetic source array to produce an attractive force; the two ends of the first magnetic source and the second magnetic source cooperate to produce repulsion respectively. force. In the working position, repulsive force and attractive force are simultaneously generated between the magnetic source and the magnetic source. The repulsive force is generated at both ends of the magnetic source, the driving force for driving the driven gear to rotate by the driving gear is improved, and the stability of the transmission between the gears is improved. Through the attractive force generated in the middle of the magnetic source, the phase alignment when the gears are engaged with the gears is realized, and the reliability of the gear engagement is improved.

Owner:ZHUHAI PANSHI ELECTRONICS TECH CO LTD

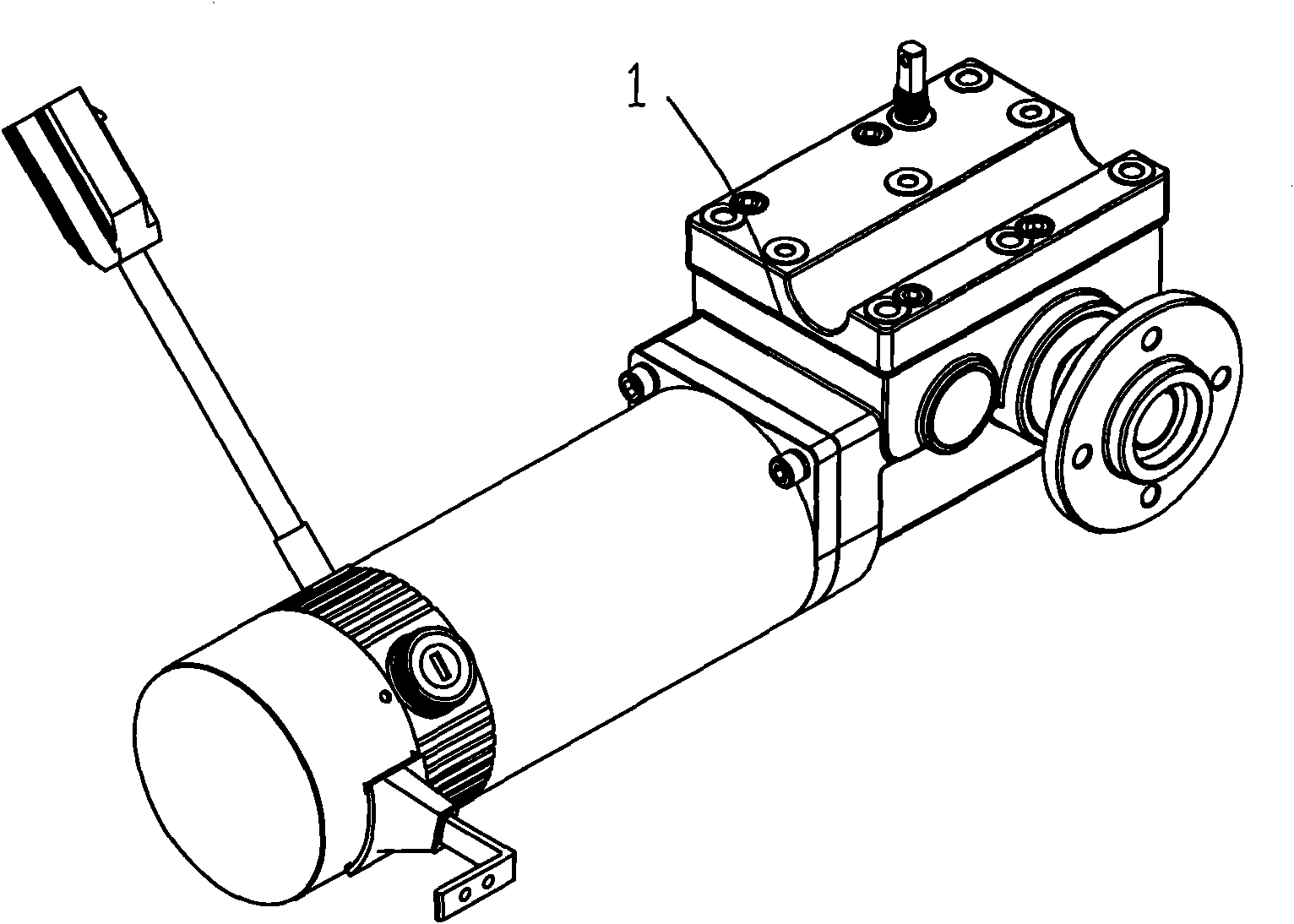

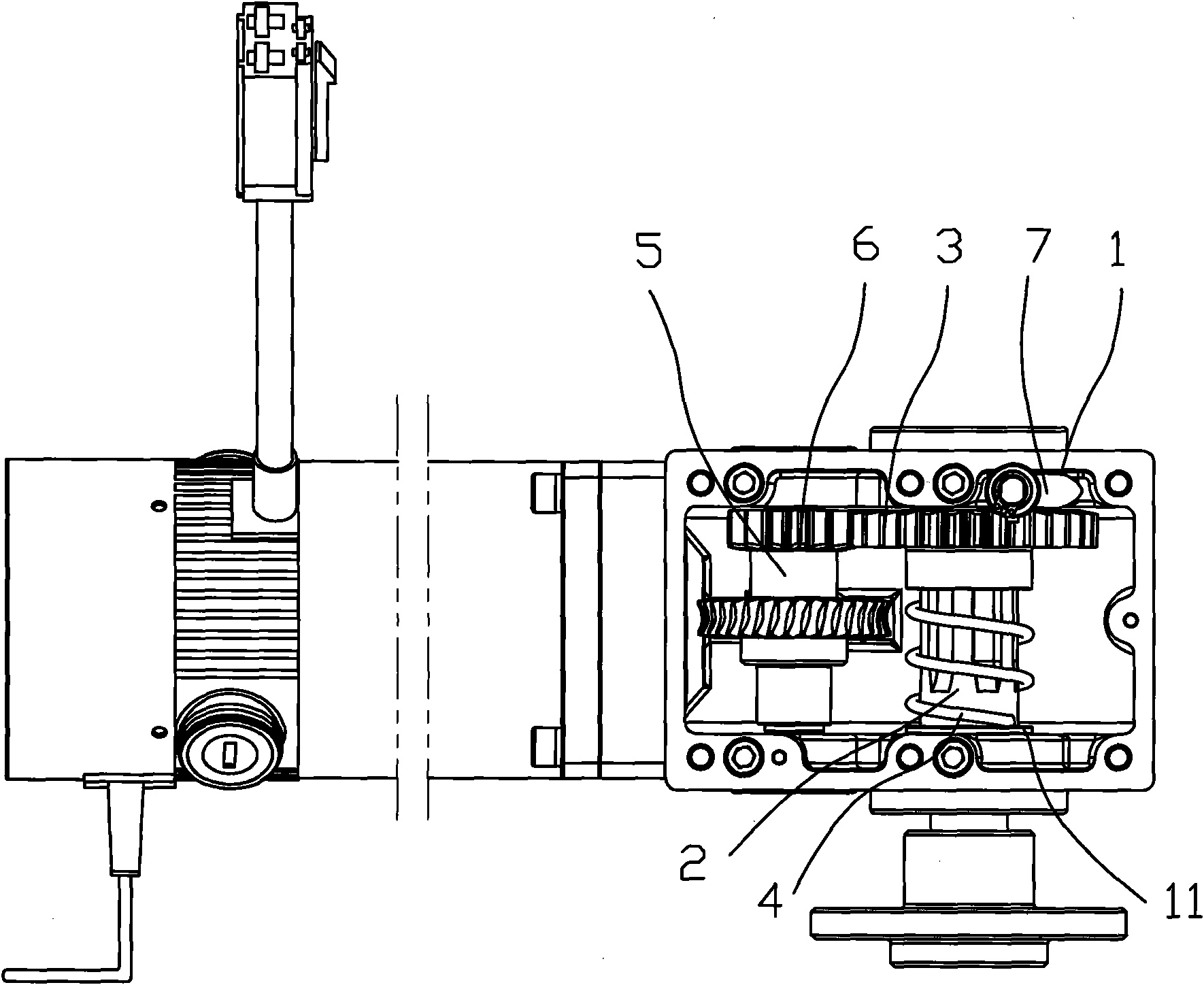

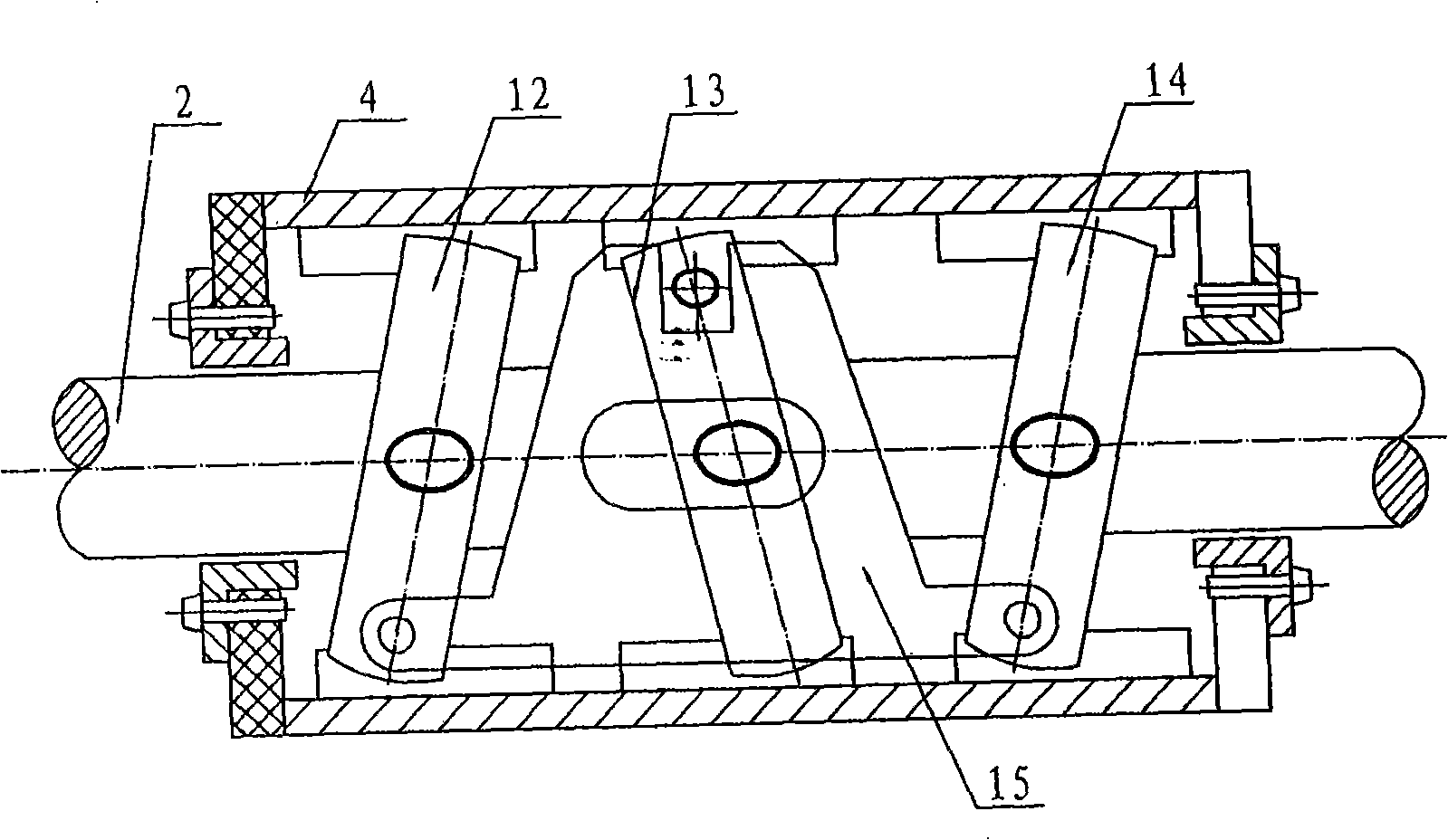

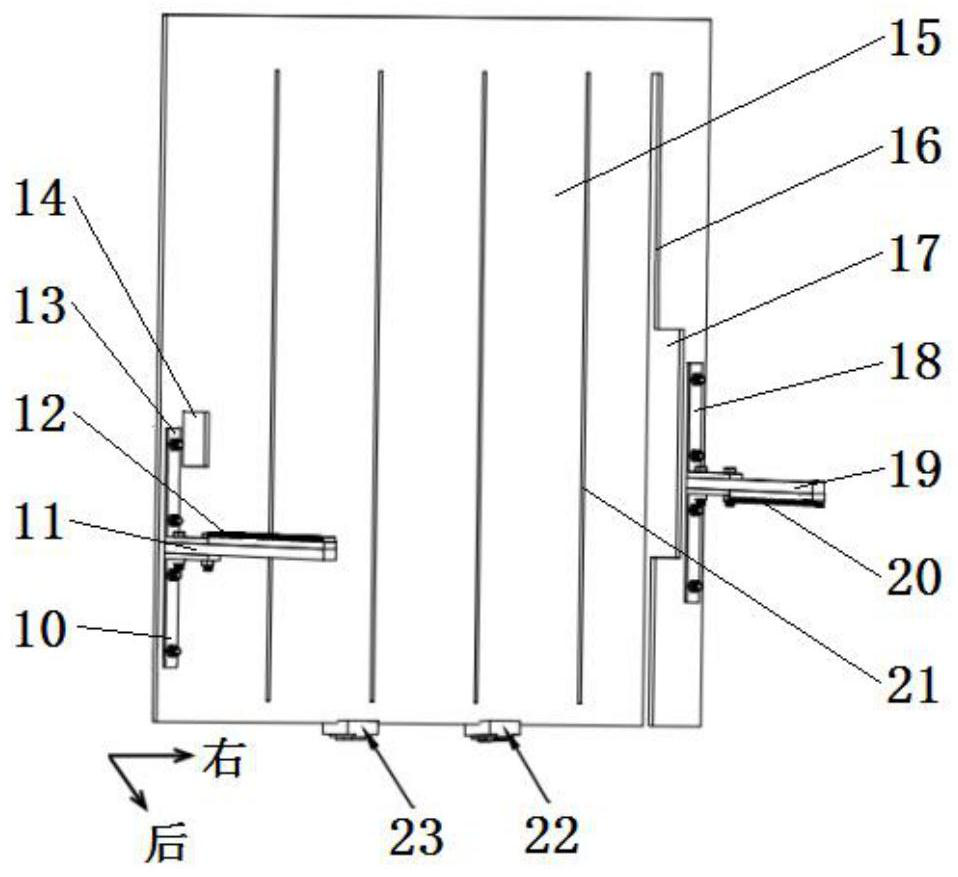

Warehouse door driving device regulated by driver

ActiveCN101403269AReduced service lifeAchieve closureToothed gearingsPower-operated mechanismLow noiseDrive shaft

The invention pertains to a warehouse door driving device speed-regulated by a driver, the problems to be solved by the invention are: in the background art, the electric warehouse door has big transmission resistance, poor stability and inconvenient operation, and is easy to break down. The main point of the technical proposal for solving the problems is that: the driver is at least internally provided with an A bearing, a B bearing and an c bearing which are contacted with a transmission shaft obliquely, wherein, the A bearing and the c bearing are oblique in the same direction and contacted with the transmission shaft in an apposition, while the B bearing is oblique in the reverse direction and contacted with the transmission shaft in a reversed position, and the A bearing, the B bearing and the c bearing are respectively articulated by shift forks and respectively arranged on three speed control gears jogged with each other. The driving device can be applied to the manufacture and usage of all types of warehouse doors, and has the remarkable advantages of small transmission resistance, convenient speed control and wide control scope, low noise and long service life.

Owner:吴家伟

Washing machine deceleration clutch, washing machine and washing mode thereof

ActiveCN101210373BSimple internal structureReduce manufacturing costOther washing machinesToothed gearingsLaundry washing machineControl engineering

Owner:NINGGUO JULONG IND

High-precision ultrathin aluminum profile with corner combining cavities

InactiveCN113107945ARapid positioningEasy to installGear lubrication/coolingRod connectionsEngineeringStructural engineering

Owner:张家港市旭德铝制品有限公司

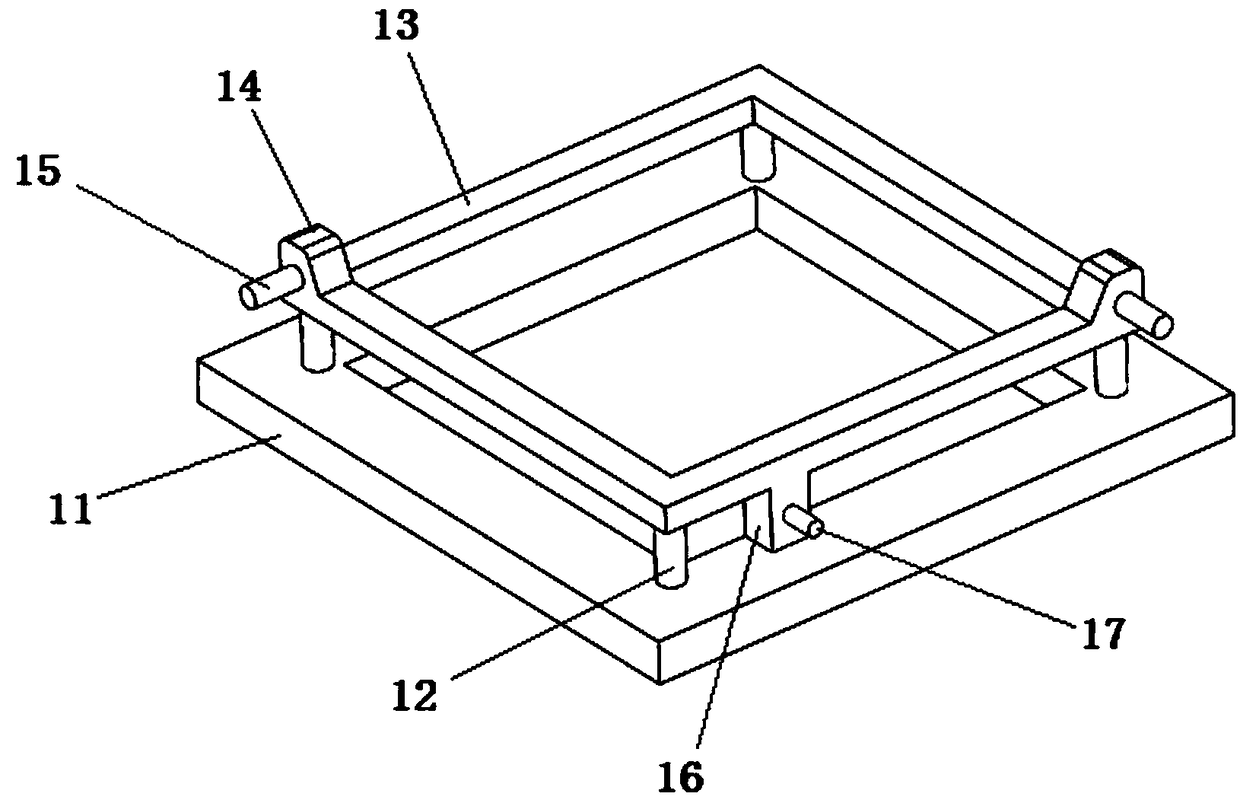

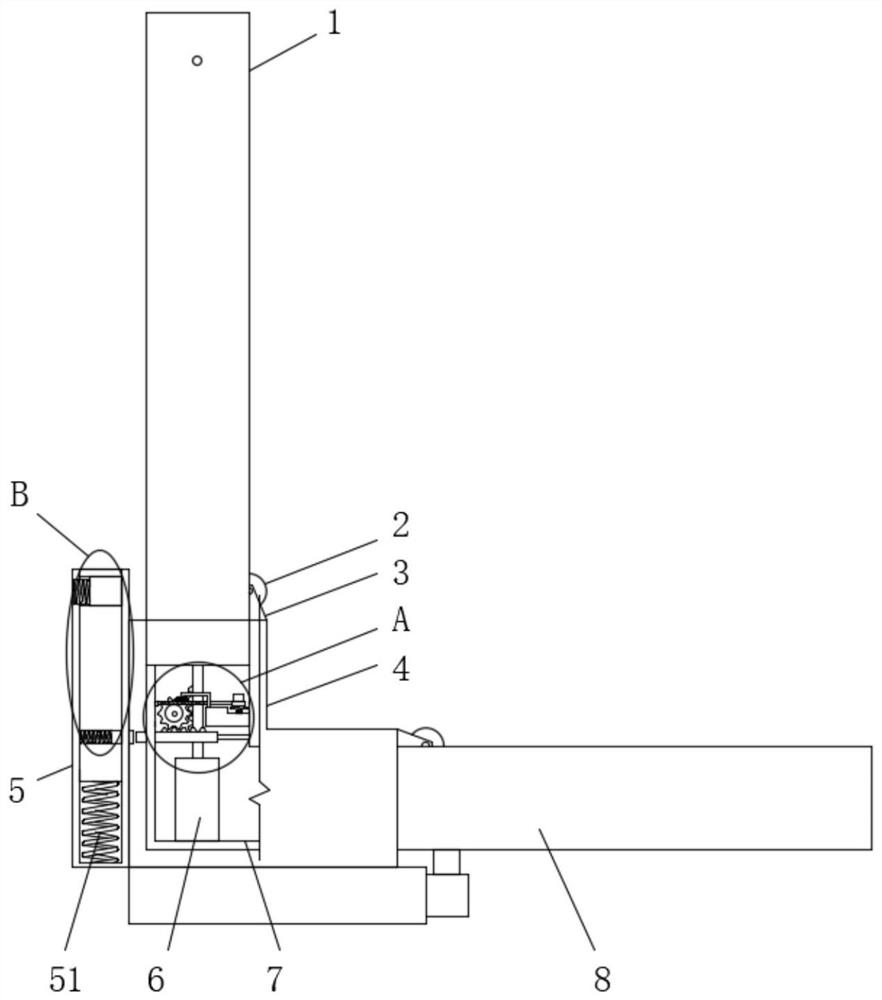

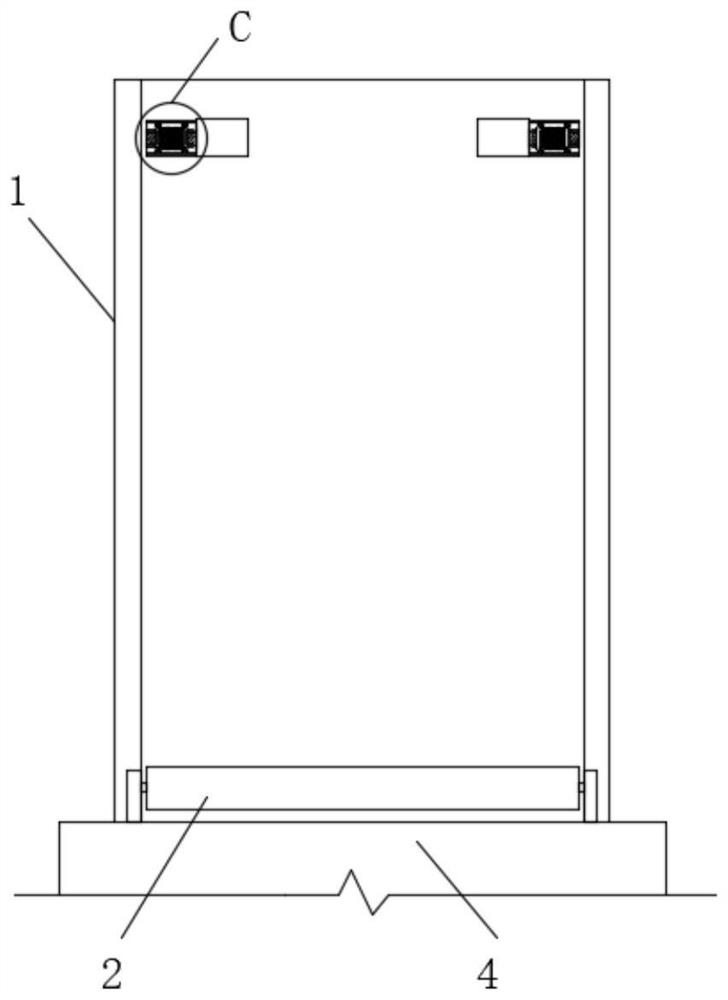

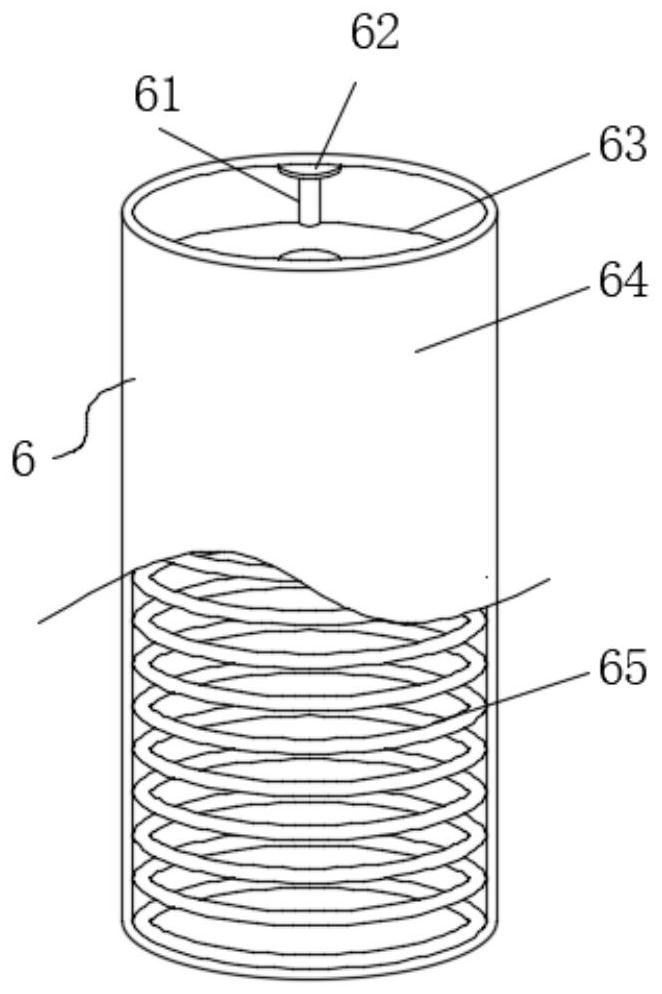

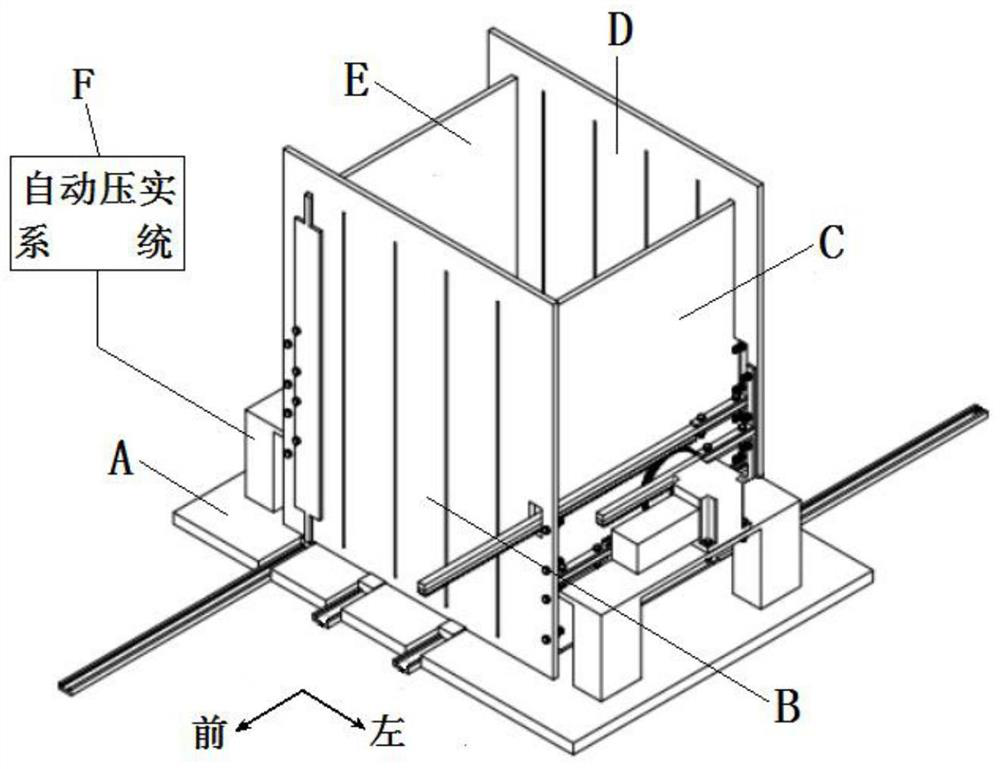

Straw compression mold capable of automatically removing wall surface, for measuring straw springback after compression

The invention belongs to the technical field of agricultural machinery, and relates to a straw compression mold capable of automatically removing a wall surface, for measuring straw springback after compression. The mold consists of a bottom plate assembly, a front plate assembly, a left plate assembly, a rear plate assembly, a right plate assembly and an automatic compaction system, stepping motors in the automatic compaction system can lock a motor rotating shaft without rotating during straw compression; therefore, gears can be locked, racks and four plate surfaces are further locked, and a fixing effect is achieved; and after straw compression is completed, a stepping motor can drive the front, rear, left and right plate surfaces to automatically move out, so that the resilience of pressed straw blocks can be accurately measured, the straw compression process and parameters can be optimized, and the invention aims to improve the straw compression efficiency and density, reduce the energy consumption and realize efficient, high-quality and low-energy straw compression. The straw compression mold has important significance in improvement of a straw briquetting machine and a straw bundling machine.

Owner:JILIN UNIV

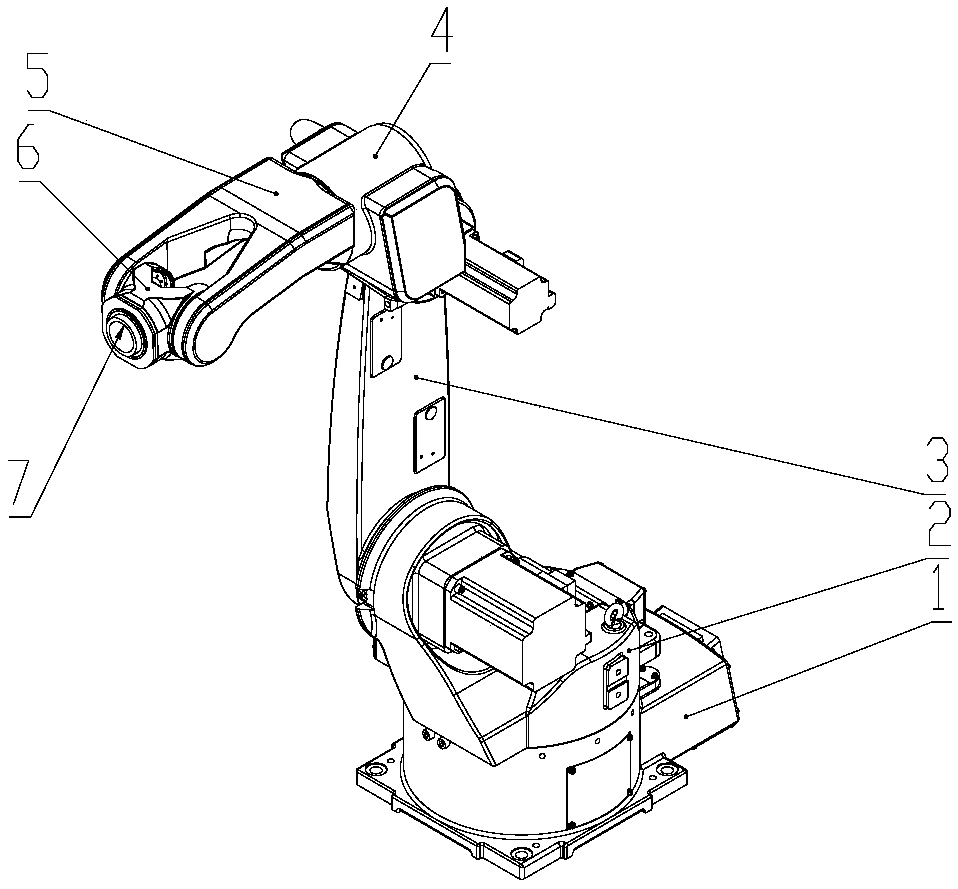

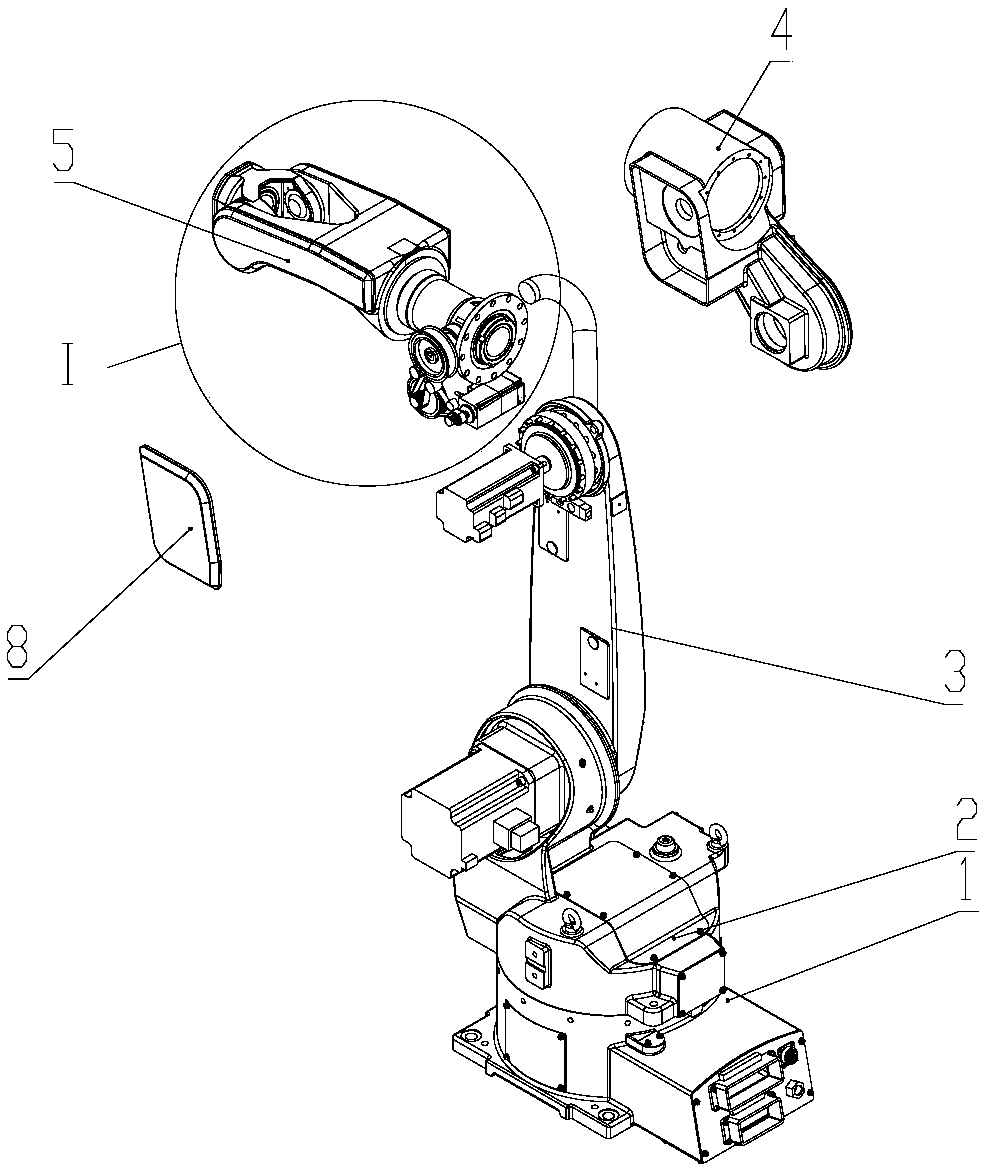

Hollow joint structure of industrial robot

InactiveCN111283722ASmall transmission viscous resistanceHigh energy saving and environmental protection efficiencyJointsElectric machineryEngineering

The invention belongs to the technical field of robots, and particularly relates to a hollow joint structure of an industrial robot. The hollow joint structure comprises a base, a waist seat, a largearm, a three-axis assembly, a small arm, a hollow shaft assembly and a tail end flange which are sequentially and rotationally connected, a four-axis rotation driving mechanism connected with the small arm is arranged in the three-axis assembly, and the four-axis rotation driving mechanism is used for driving the small arm to rotate relative to the three-axis assembly. The four-axis rotation driving mechanism comprises a four-axis motor, a two-stage belt transmission mechanism, a four-axis bevel pinion shaft, a four-axis center cylinder, a bevel pinion and a floating bevel gear wheel, the four-axis center cylinder and the four-axis bevel pinion shaft are rotatably arranged in the three-axis assembly and are perpendicular, the bevel pinion and the floating bevel gear wheel are arranged on the four-axis bevel pinion shaft and the four-axis center cylinder in a sleeved mode respectively and mesh with each other, and the output end of the four-axis motor is in transmission connection withthe four-axis bevel pinion shaft through the two-stage belt transmission mechanism. The hollow joint structure is small in transmission viscous resistance, high in energy-saving and environment-friendly efficiency, large in inertia ratio of the load to the motor rotor and easy to control.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Auxiliary knife grounding drive mechanism of load switch

ActiveCN106710940BSmall transmission resistanceHigh transmission reliabilityAir-break switch detailsEarthing switchesEngineeringHigh pressure

Owner:ZHENJIANG HUAYUAN JINCHANG ELECTRICAL APPLIANCES

Hanging rail elevator

The invention discloses a hanging rail elevator. The hanging rail elevator comprises a rack, a transmission assembly, a conveying rail and a motor for driving the transmission assembly; a low-voltagepower supply wire is arranged along the outer ring of the conveying rail; the conveying rail comprises a climbing rail and a turning rail, the climbing rail is fixed to a top plate of stairs, the turning rail is fixed to a corner of the stairs through an installation bracket and in butt-joint with the climbing rail, and a rack is arranged at the bottom of the conveying rail; a transmission assembly is fixed into the rack, the transmission assembly comprises a traveling gear, the traveling gear is engaged with the rack, a first auxiliary bearing is located on the two sides of a connecting plate, the bottom of the first auxiliary bearing is in contact with the upper end surface of a lower guide rail plate, a second auxiliary bearing is located on the two sides of the connecting plate and horizontally installed, and the end part of the second auxiliary bearing is in contact with the connecting plate; and a folding seat is installed below the rack, and a control button is arranged on the folding seat. According to the hanging rail elevator, an original building structure cannot be damaged, the elevator can directly run from the first floor of the building to the top floor, frequent transfer is not needed, running is stable, and the installation cost is saved.

Owner:NANJING INST OF TECH

Magnetic gear

ActiveCN110112957ASmooth transmissionSmall transmission resistanceGenerators/motorsMagnetic sourcePhase alignment

The invention provides a magnetic gear comprising gear bodies and magnetic sources. The gear bodies comprise a first gear body and a second gear body. A first magnetic source array is uniformly distributed along the circumferential direction of the first gear body, and a second magnetic source array is uniformly distributed along the circumferential direction of the second gear body. The middle parts of the first magnetic source of the first magnetic source array and the second magnetic source of the second magnetic source array cooperate to generate attraction force along the axial directionof the gear bodies. The two ends of the first magnetic source and the second magnetic source cooperate to generate repulsive force respectively. The repulsive force and the attraction force are simultaneously generated between the magnetic sources on the working position. The driving force of the driving gear for driving the driven gear to rotate is improved by generating the repulsive force on both ends of the magnetic sources, and the transmission stability between the gears is improved. The phase alignment in case of engaging between the gears can be realized through the attraction force generated in the middle of the magnetic sources, and the engaging reliability of the gears can be improved.

Owner:ZHUHAI PANSHI ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com