Straw compression mold capable of automatically removing wall surface, for measuring straw springback after compression

An automatic removal and automatic compaction technology, applied in the field of agricultural machinery, can solve problems such as lack of in-depth and systematic research, and achieve the effect of reducing transmission resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

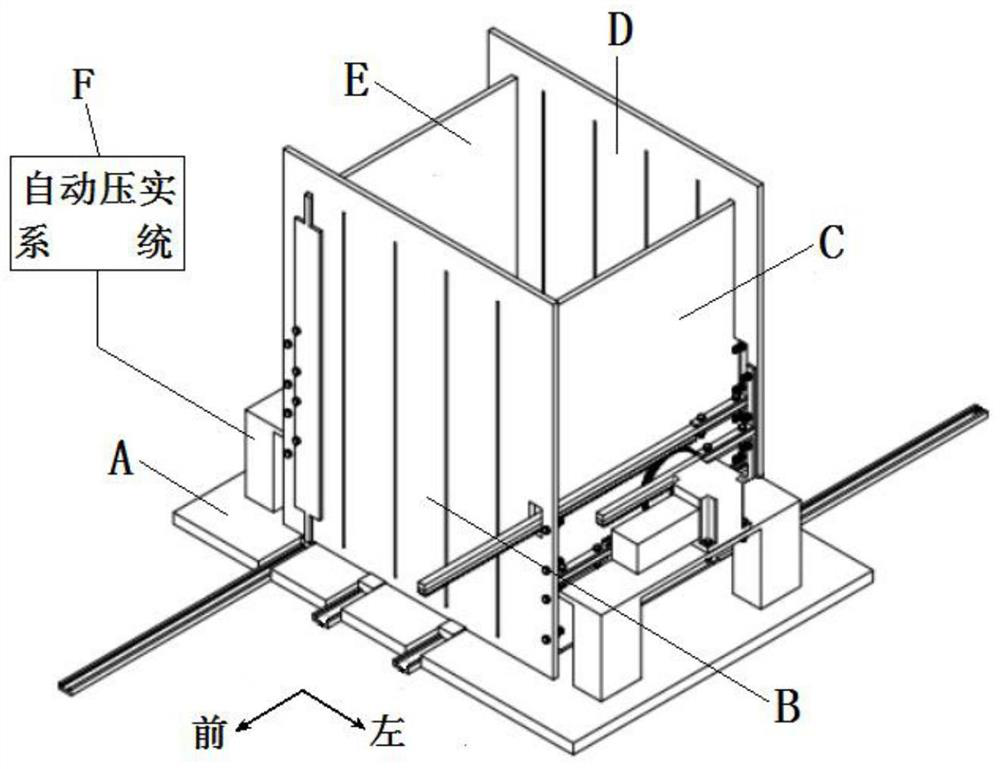

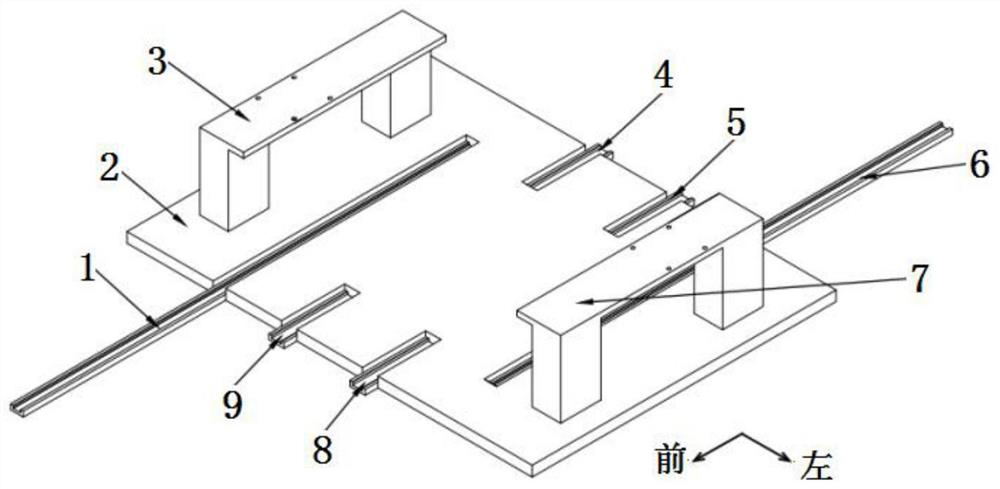

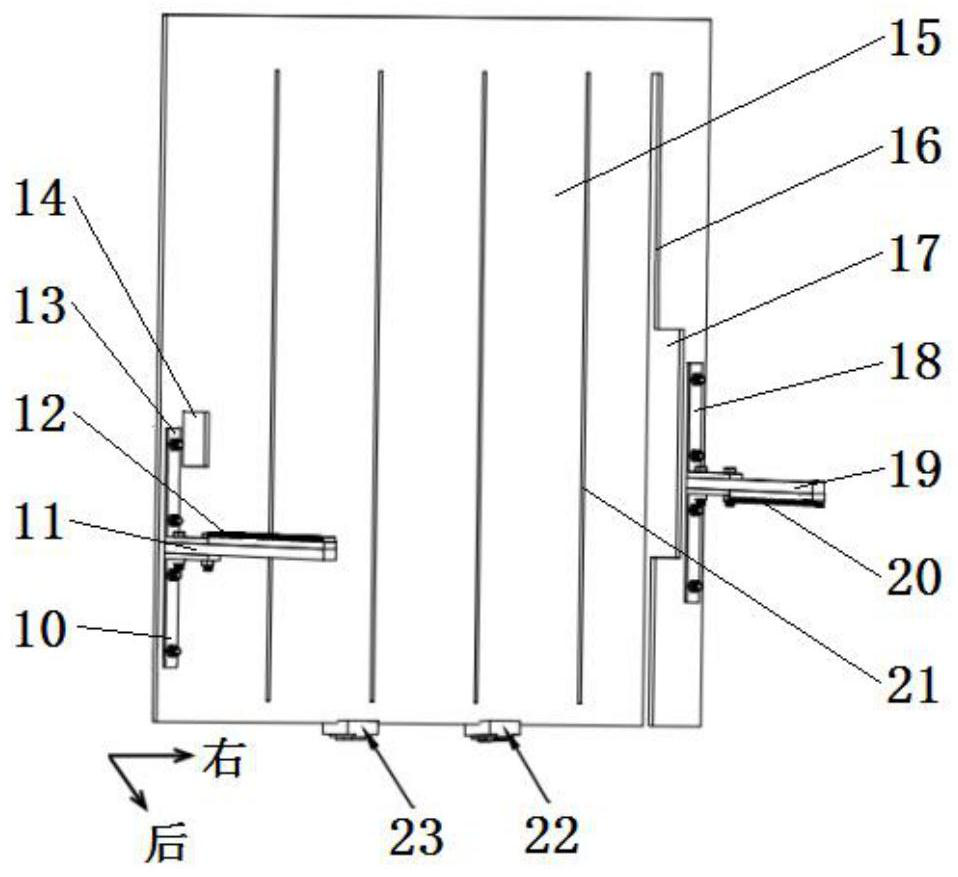

[0040] Such as figure 1 , Figure 11 , Figure 12 with Figure 13 As shown, the present invention is composed of a base plate assembly A, a front plate assembly B, a left plate assembly C, a rear plate assembly D, a right plate assembly E and an automatic compaction system F, wherein the front plate 15 of the front plate assembly B is located on the base plate assembly A The front side of the bottom plate 2, the left plate 26 of the left plate assembly C is located on the left side of the bottom plate 2 of the bottom plate assembly A, the rear plate 37 of the rear plate assembly D is located at the rear side of the bottom plate 2 of the bottom plate assembly A, and the right plate assembly E The right plate 49 is located on the right side of the bottom plate 2 in the bottom plate assembly A; the stepping motor I54 of the automatic compaction system F ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com