Auxiliary knife grounding drive mechanism of load switch

A load switch and drive mechanism technology, applied in the direction of electric switches, grounding switches, air switch components, etc., can solve the problems of large resistance, sticking of moving parts, and affecting the reliable operation of the grounding auxiliary knife, so as to improve the transmission reliability, The effect of small transmission resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

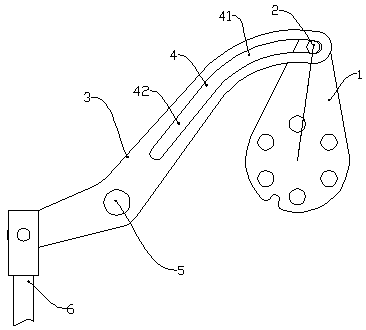

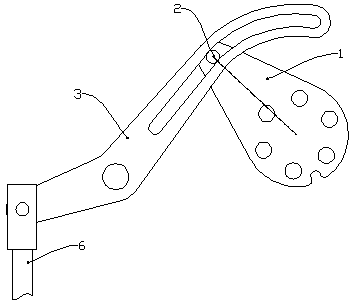

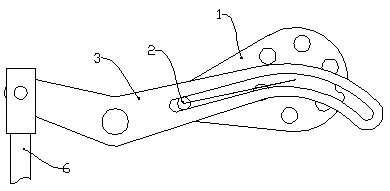

[0011] As shown in the figure, the load switch auxiliary tool grounding drive mechanism includes a linkage crank arm 1 driven by the load switch main shaft. The outer end of the linkage crank arm is provided with a guide pin 2, and the guide pin is located in a guide groove 4 in the front section of a lever 3. And can slide along the guide groove; the middle part of the lever 3 is hinged on the fixed fulcrum shaft 5, the rear end of the lever is hinged on the grounding auxiliary knife pull rod 6, the grounding auxiliary knife pull rod can swing with the lever and drive the grounding auxiliary knife to open and close The front section of the guide groove 4 is an arc segment 41, and the travel track of the guide pin 2 moving from the closing position of the load switch to the opening position with the linkage arm 1 coincides with the arc segment 41; the guide groove The rear segment of 4 is a straight segment 42 extending backward and downward along the tangential direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com