Magnetic unit vertical combination method of permanent magnetic spreader

A combination method and spreader technology, applied in the directions of permanent magnets, load hanging elements, magnets, etc., can solve the problems of difficult drilling, high comprehensive cost, and high manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

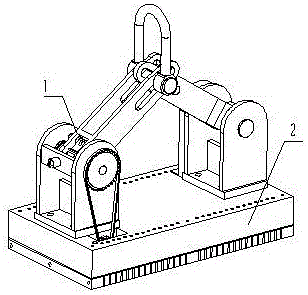

[0025] Examples of the present invention figure 1 As shown, it includes a combination of a lifting system 1 and a magnetic system 2; the magnetic system 2 is arranged at the lower part of the lifting system 1.

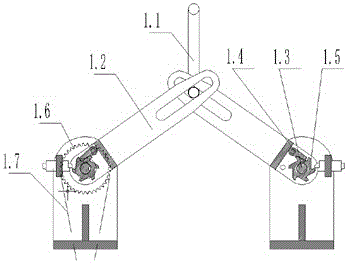

[0026] Hanging system 1 such as figure 2 As shown, a shackle 1.1 is provided; the shackle 1.1 is connected with the left and right booms 1.2; the left and right booms 1.2 are respectively provided with a ratchet shaft 1.3; the ratchet shaft 1.3 is provided with a pawl 1.4, a ratchet wheel 1.5 and a large sprocket 1.6, A chain 1.7 is provided on the large sprocket 1.6. The shackle 1.1 moves up and down, which drives the boom 1.2 to move up and down, and then drives the ratchet shaft 1.3 to rotate, and then drives the ratchet wheel 1.5 and the pawl 1.4 to move, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com