Water-saving mechanical seal device

A mechanical sealing device and top-mounted technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of leakage, large interference, scratches on the water retaining cover, etc., to increase transmission efficiency, excellent compensation performance, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

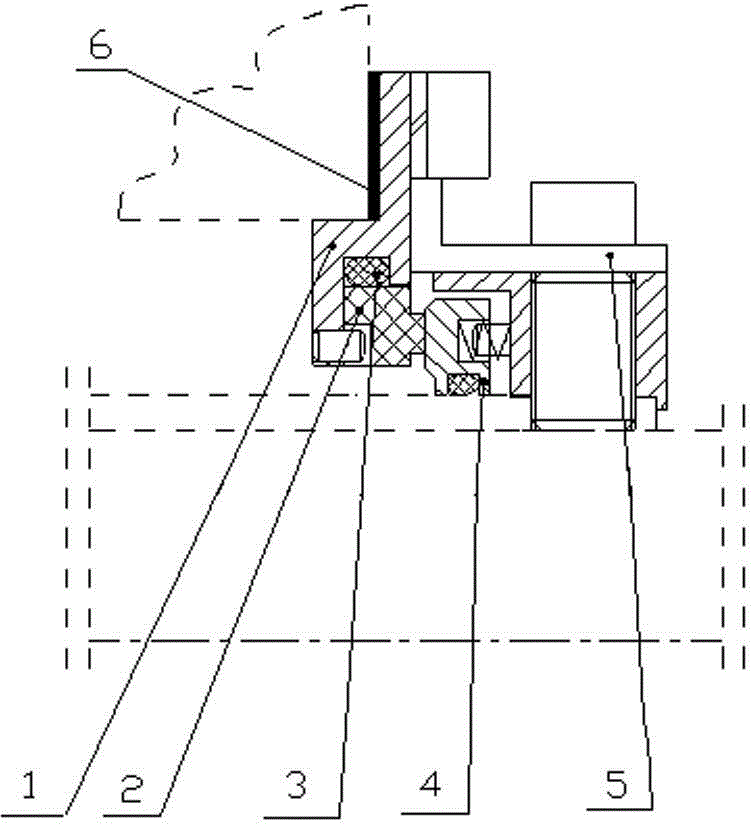

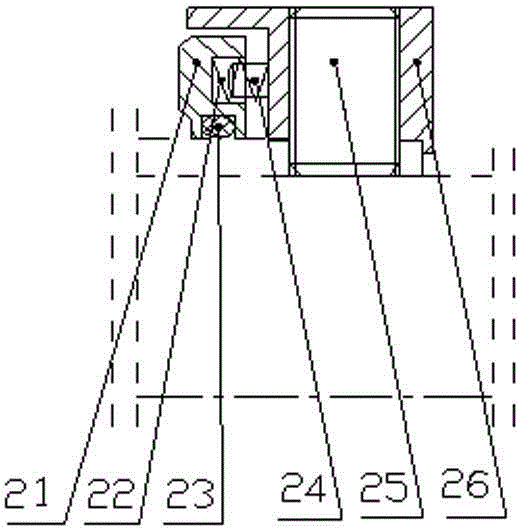

[0010] The structure of the present invention is illustrated in conjunction with the accompanying drawings.

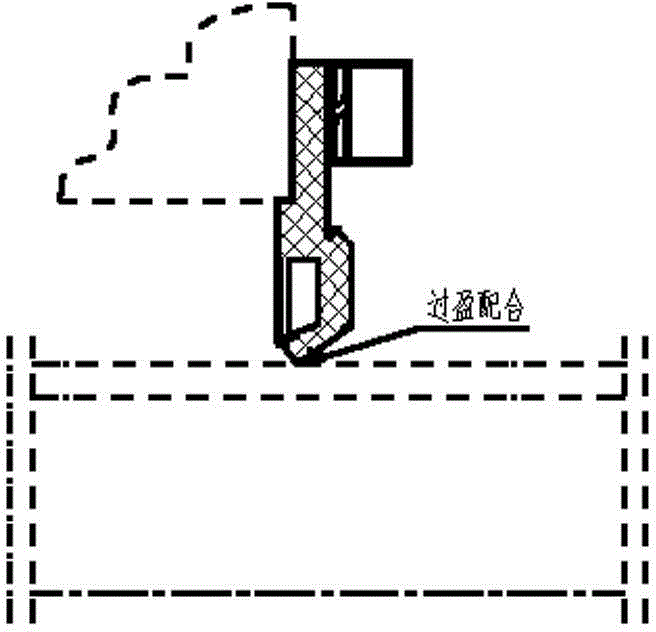

[0011] A water-saving mechanical seal, such as figure 1 with figure 2 As shown, the static ring 2 is installed on the lower part of the static ring seat 1, and the static ring O-ring 3 is installed on the static ring 2. The static ring 2 is made of graphite material, and the static ring seat 1 is sealed by the O-ring interference fit. . The moving ring assembly 4 is installed at the corresponding position inside the static ring 2. The structure of the moving ring assembly is: a spring 22 is installed in the groove of the moving ring 21, the pin 24 on the outside of the spring is connected with the transmission ring 26, and the moving ring 21 is equipped with a moving ring. O-ring 23, transmission screw 25 is housed on the transmission ring. The surface of the friction pair of the moving ring in the moving ring assembly 4 can be selected from surface spraying or su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com