A brush frame structure of a large low-speed DC hoisting motor

A low-speed, large-scale technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of large DC motor capacity and large current, and achieve the effect of firm and reliable structure, less material consumption, and more bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

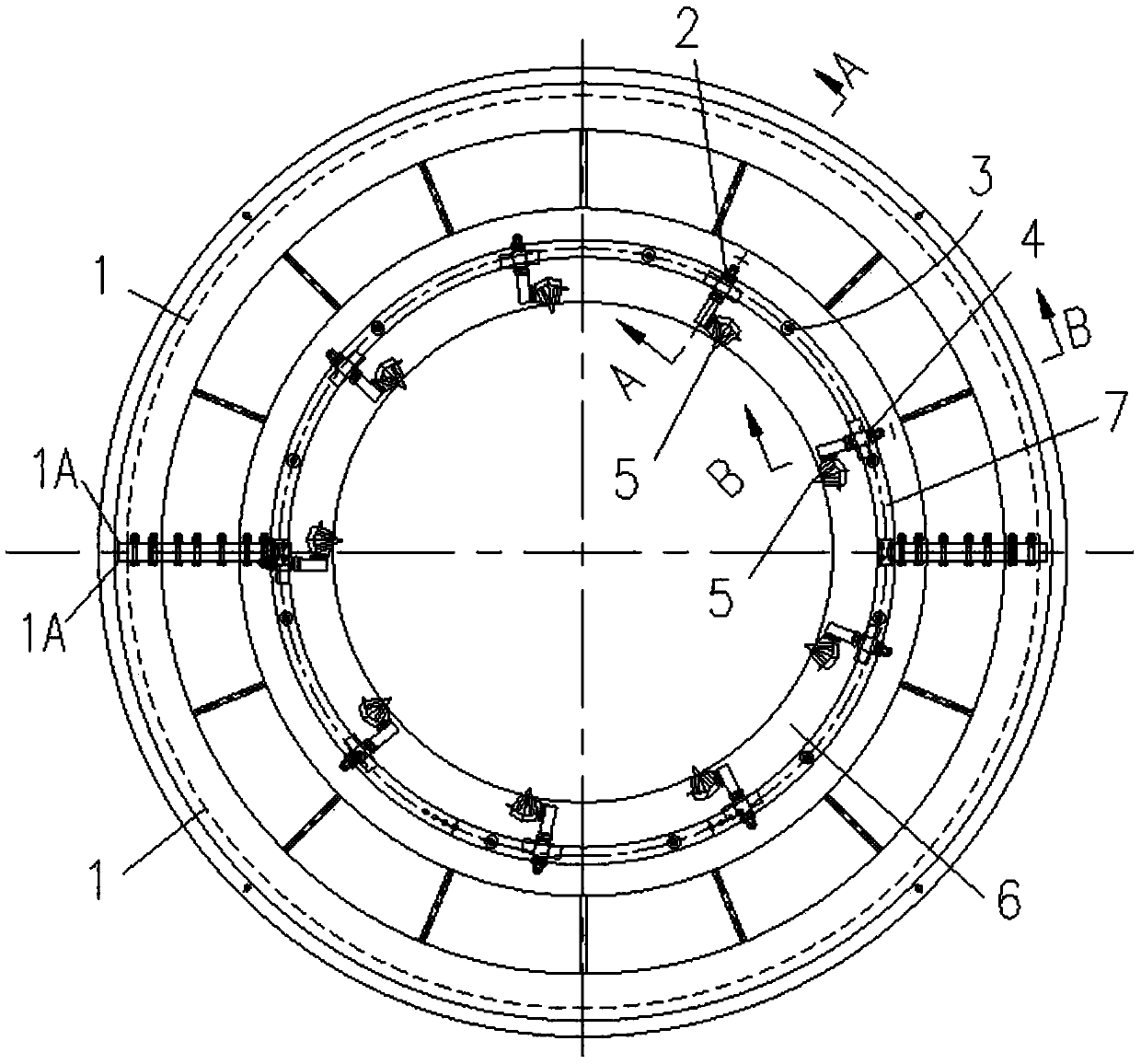

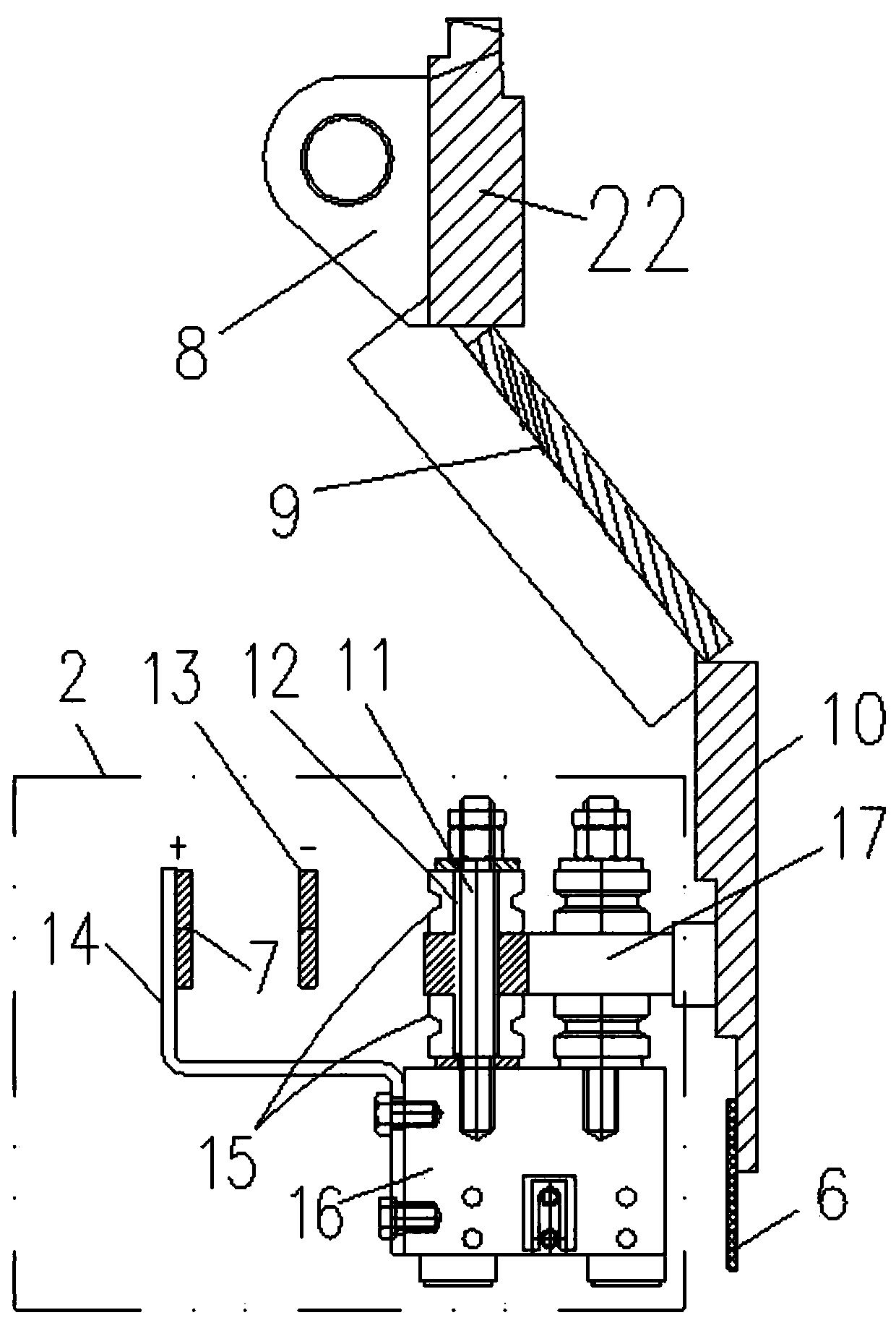

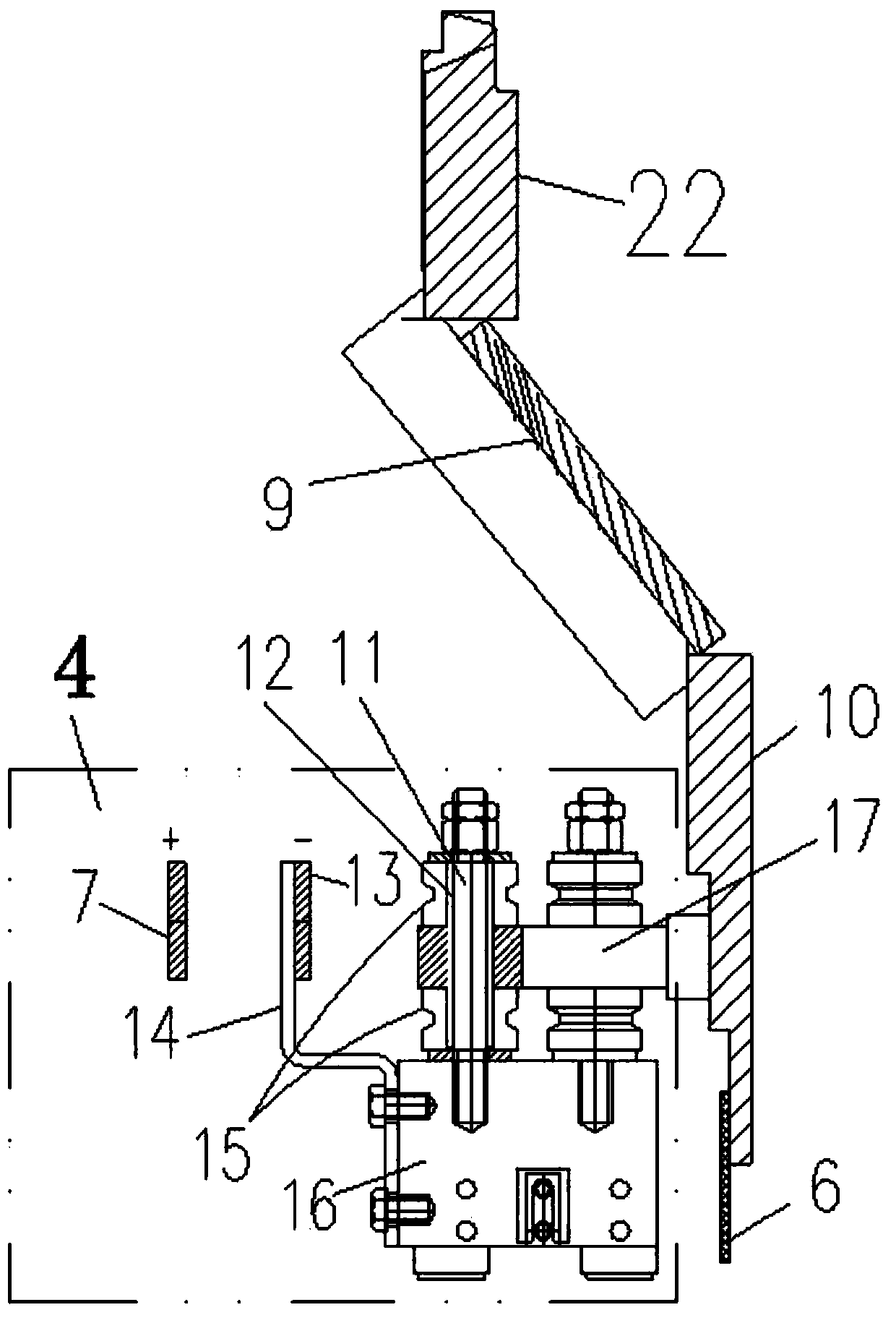

[0034] Depend on Figure 1-Figure 10 The brush holder structure of a large-scale low-speed DC lifting motor shown includes a positive conductive ring 7 , a negative conductive ring 13 and a ring-shaped brush holder seat 1 arranged at intervals along the axial direction from front to back.

[0035] The positive conductive ring 7 is formed by butting two first semi-circular bodies 7A. The positive conductive ring 7 is in the shape of a circular ring, and both ends of one of the first semi-circular bodies 7A are bent to form two first bending parts. 7C, the bent first semi-circular body 7A is composed of two first bending parts 7C and a first circular arc part sandwiched between the two first bending parts 7C, the bent first semi-circular body The two first bending parts 7C of 7A are respectively laminated on the two ends of the other first semi-circular body 7B, and the first bending edge is laminated on the axis of the corresponding end of the other first semi-circular body 7B....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com