Warehouse door driving device regulated by driver

A driving device and driver technology, applied in the direction of transmission, gear transmission, door/window accessories, etc., can solve the problems of easy failure, inconvenient operation, short service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

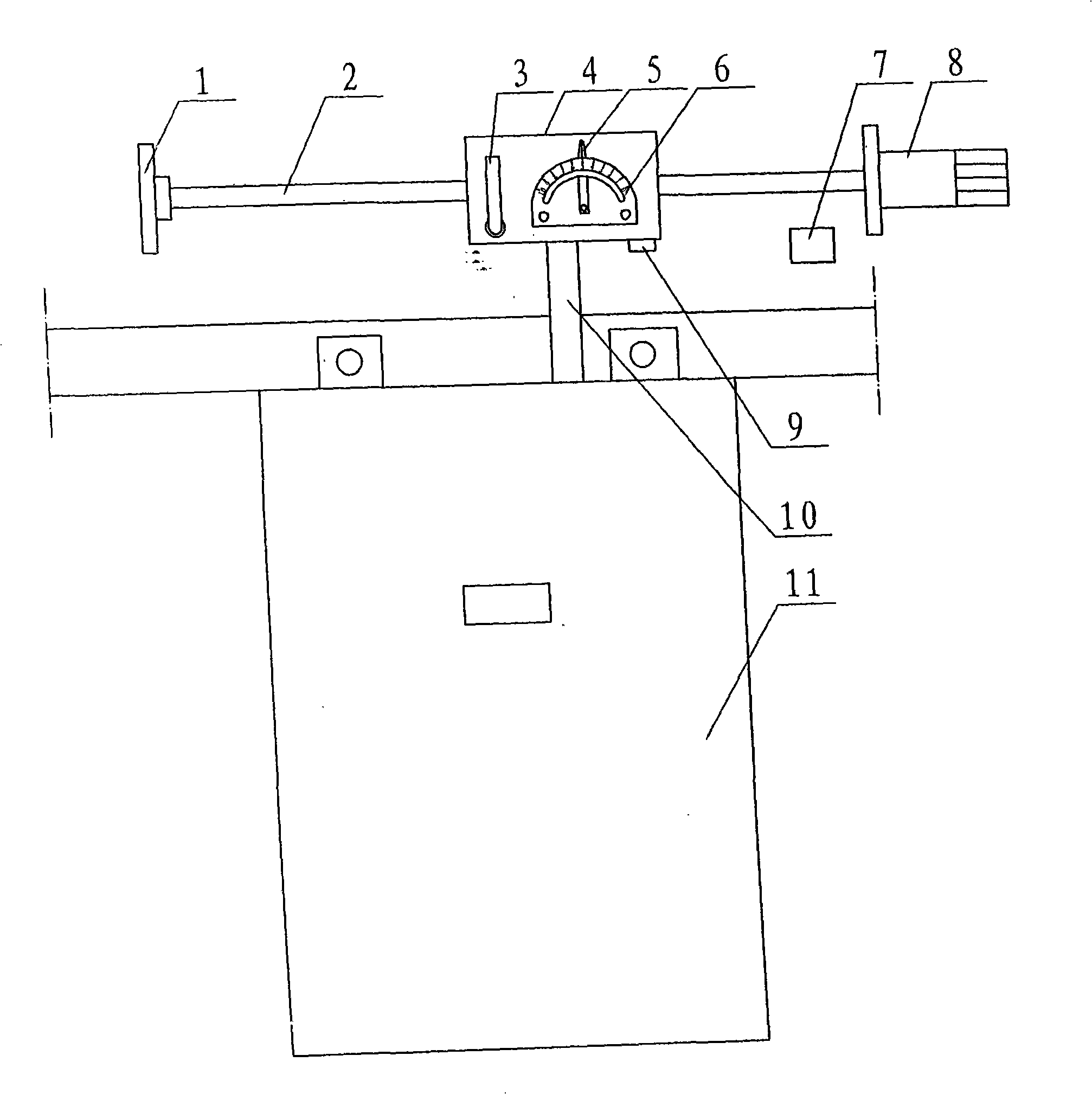

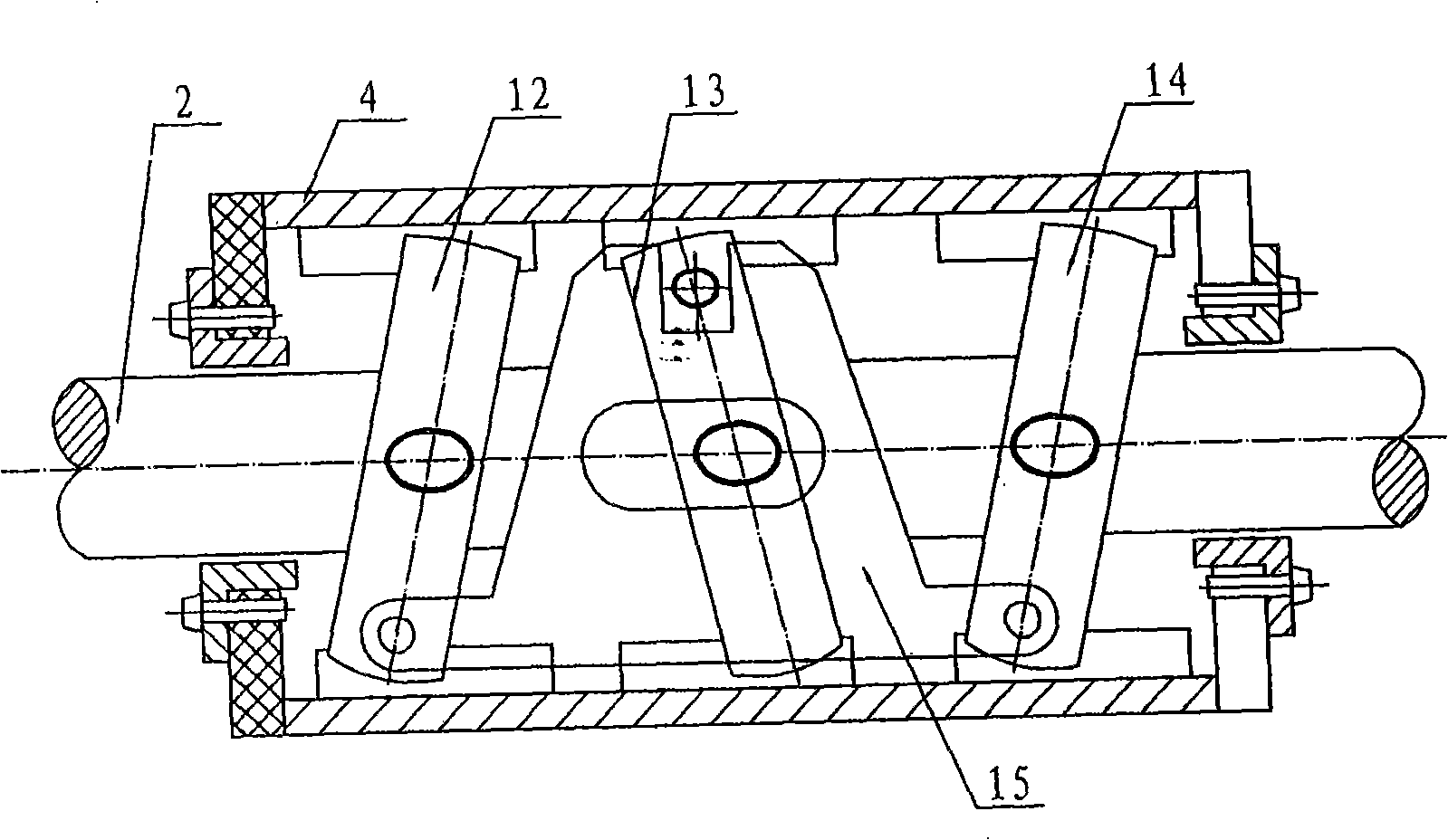

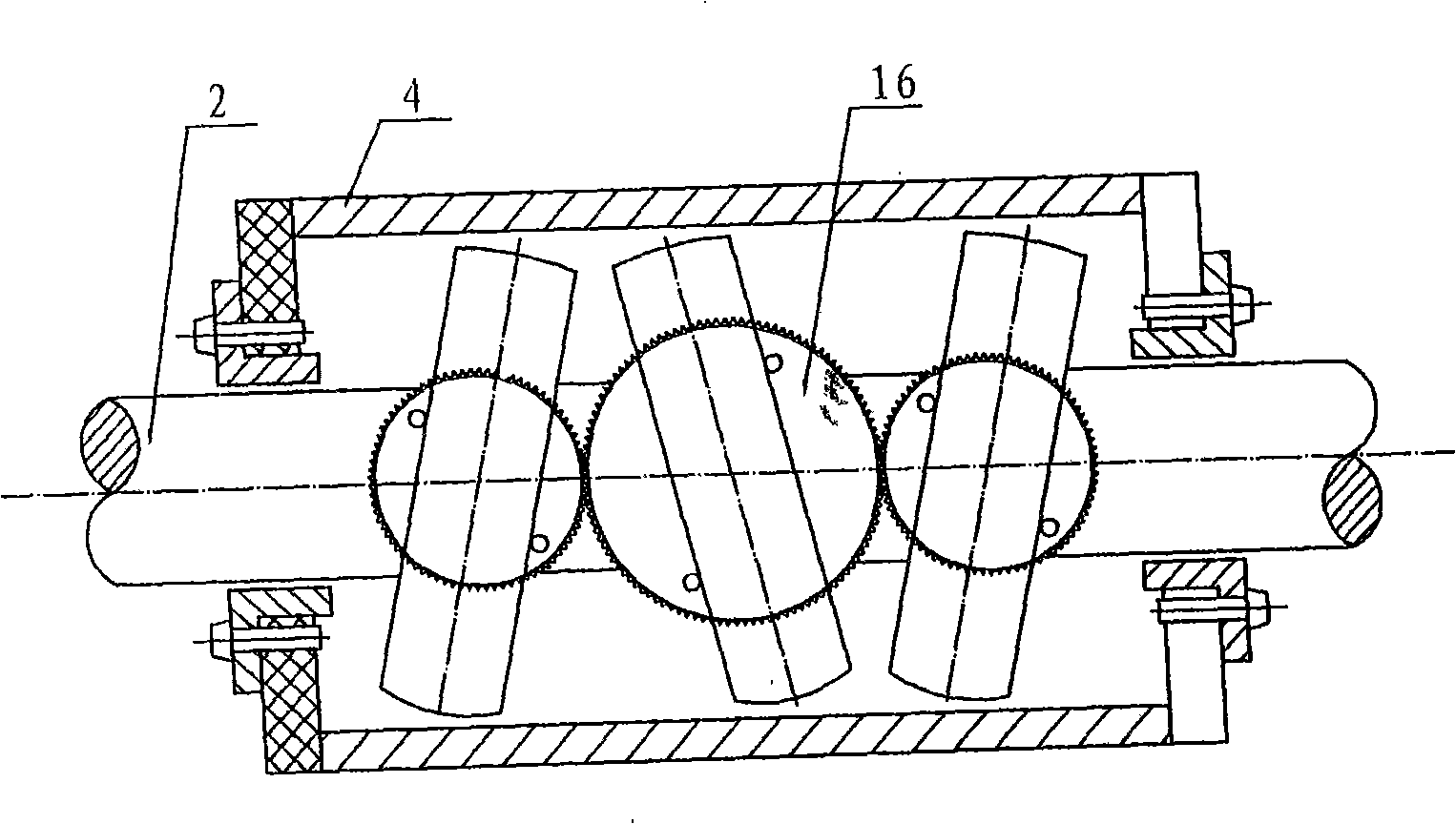

[0005] refer to figure 1 , figure 2 , image 3 , a storage door driving device that adjusts the speed through the driver. The storage door 11 is connected to the driver 4 through the coupling rod 10, the motor 8 is connected to the transmission shaft 2 on the fixing device 1, and the driver 4 is connected to the transmission shaft 2. Its characteristics At least the A bearing 12, the B bearing 13, and the c bearing 14 that are in oblique contact with the transmission shaft are arranged in the driver 4, wherein the A bearing 12 and the c bearing 14 are inclined in the same direction, while the B bearing 13 is inclined in the opposite direction, and the A bearing 12 Contact with the c bearing 14 and the transmission shaft 2 in the same position, such as figure 2 As shown, the contact point is below the transmission shaft, while the B bearing 13 is in reverse contact with the transmission shaft 2, such as figure 2 As shown, the contact point is above the transmission shaft,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com