Circular steel ball worm gear structure and speed reducer provided with same

A technology of worm gear and reducer, applied in mechanical equipment, gear transmission, belt/chain/gear, etc., can solve the problems of complex worm gear structure, high friction and heat generation, low transmission efficiency, etc., to achieve low cost and friction heat. Small, less wear-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

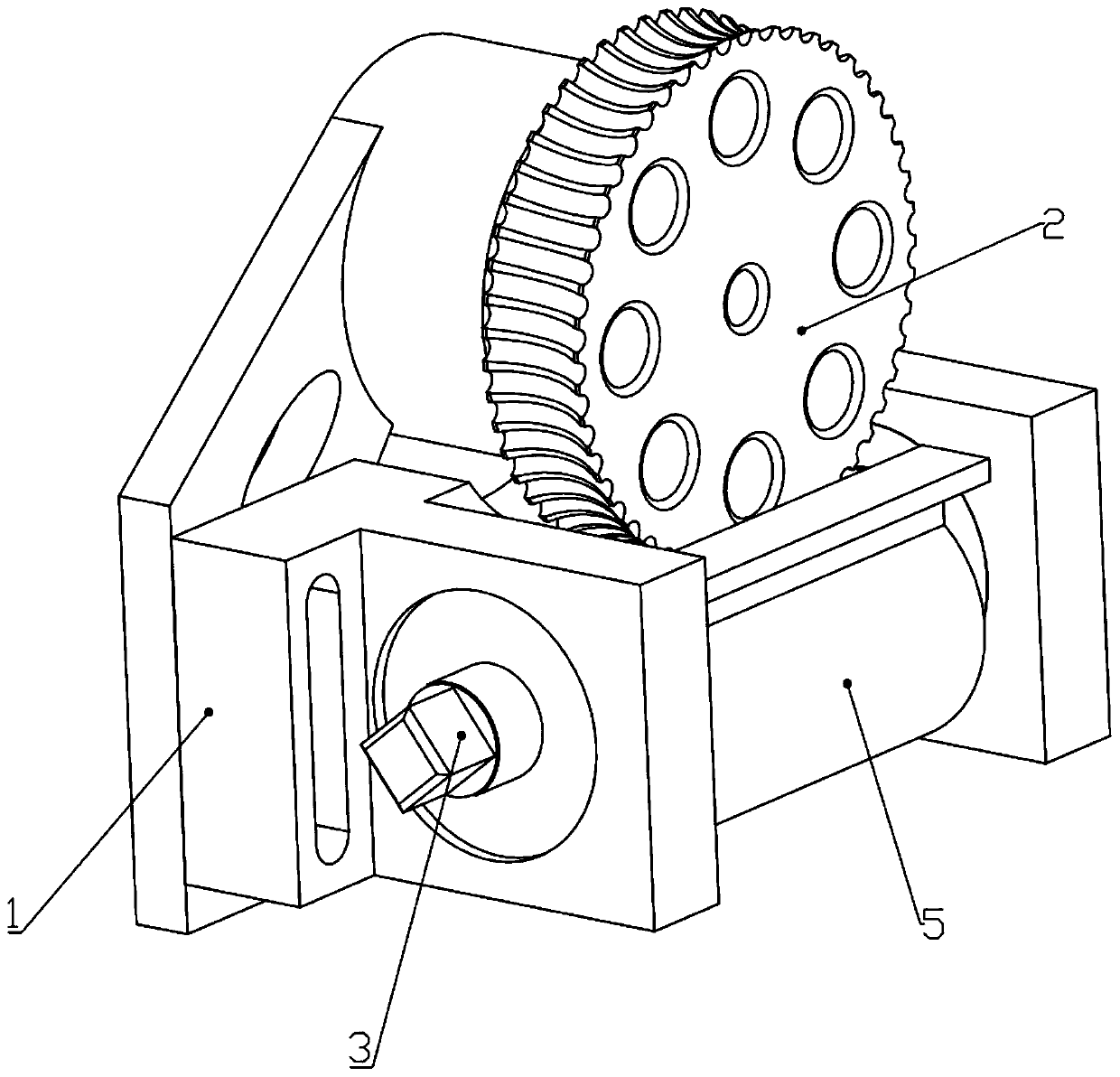

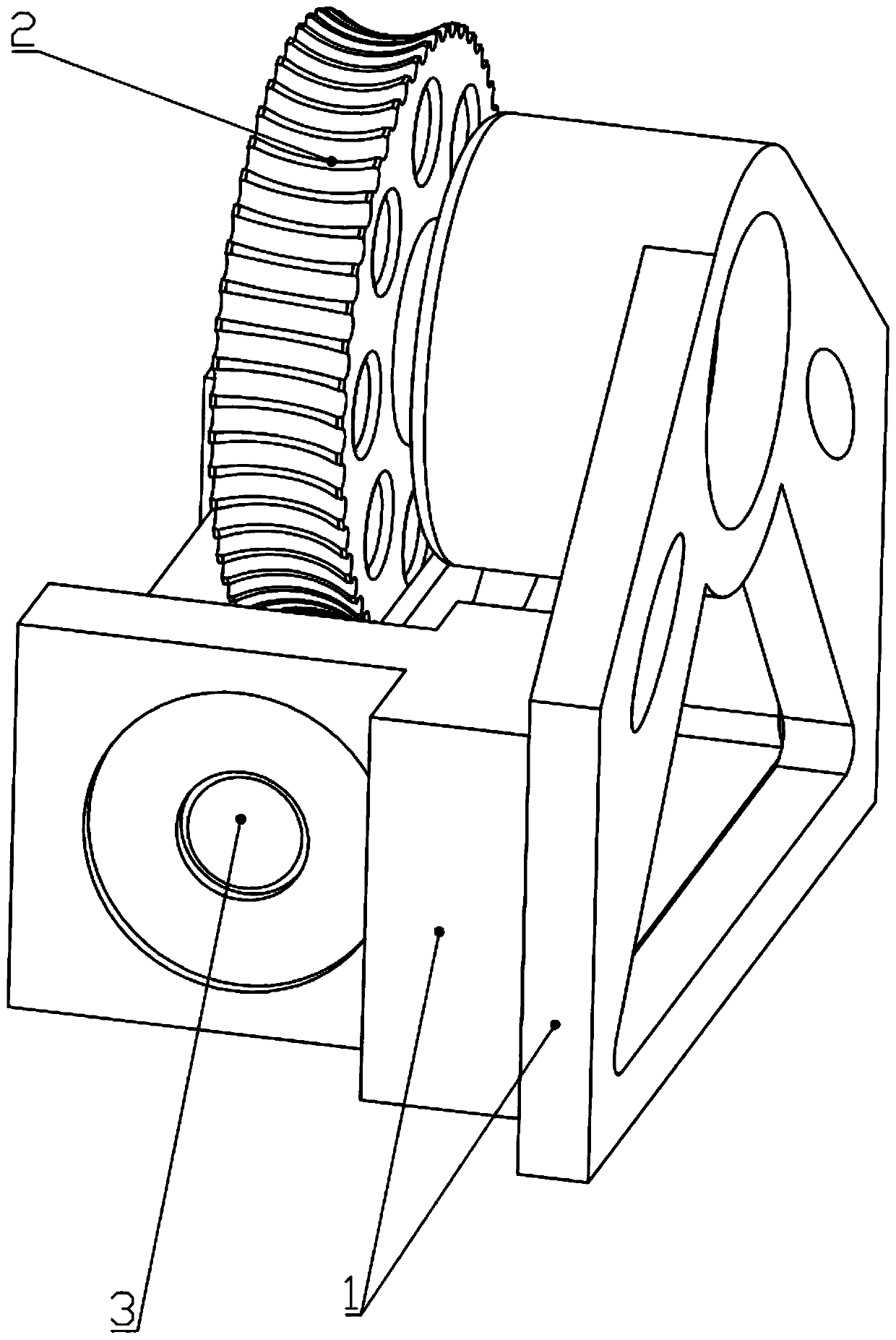

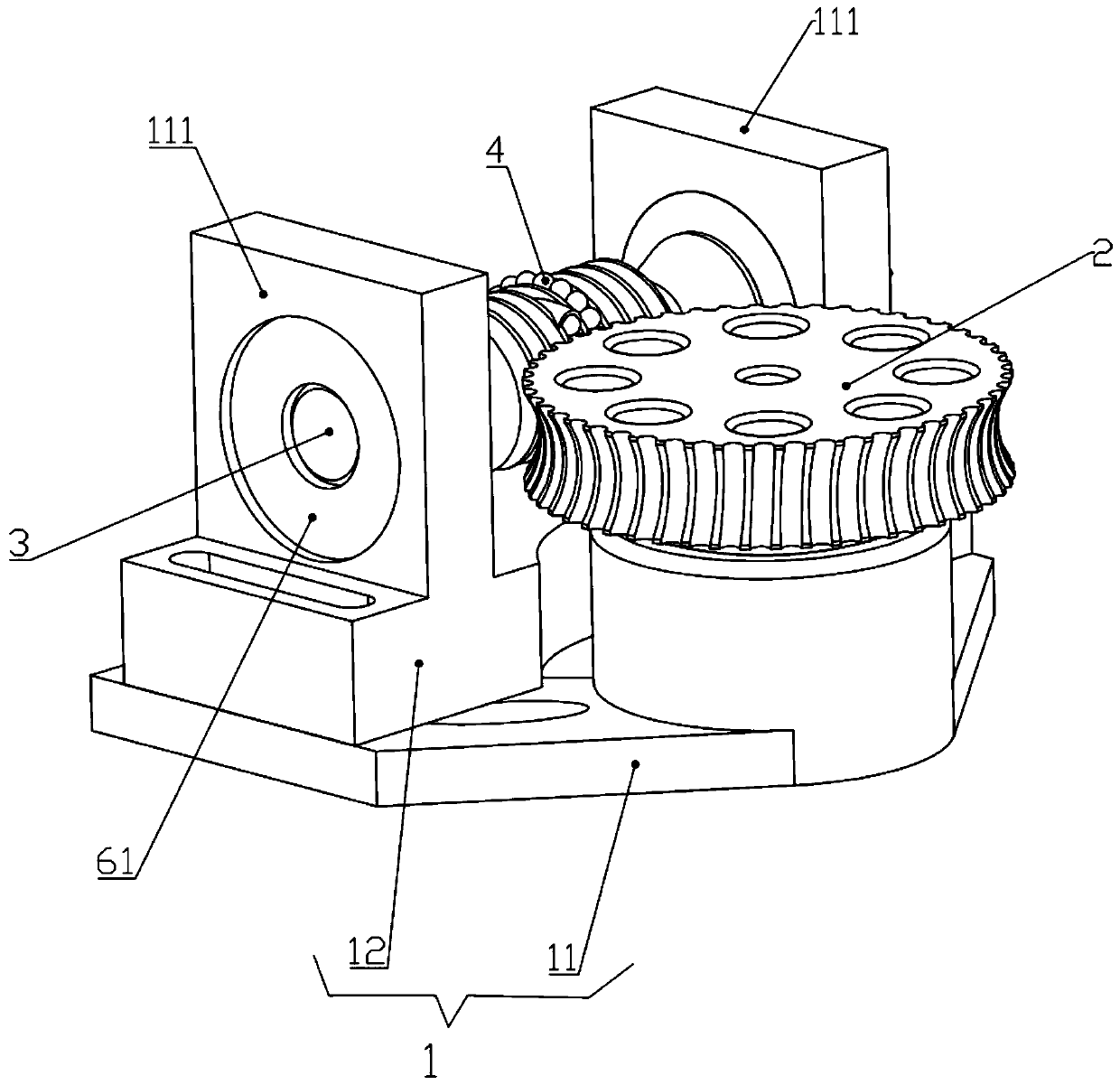

[0034] Such as Figures 1 to 7 As shown, a circulating steel ball worm gear structure includes a base 1, a turbine 2 and a worm 3; the turbine 2 and the worm 3 are both rotatably connected to the base 1;

[0035] The spiral groove 31 of the worm 3 is arc-shaped; the spiral groove 31 is provided with two inlets and outlets 32 for the balls 4 to enter and exit, and the two inlets and outlets 32 are respectively connected to the circulation pipe 33 arranged inside the worm 3 The two ends of the worm screw 3 are connected; the outer side of the extension direction of the worm 3 is provided with a retainer 5; the grooves 22 between the teeth 21 of the worm gear 2 are arc-shaped;

[0036] The balls 4 arranged in sequence are placed in the spiral groove 31 between the two inlets and outlets 32 and in the circulation pipe 33 , and the balls 4 can be moved along the two inlets and outlets 32 . The spiral groove 31 and the circulation pipe 33 circulate; a part of the balls 4 in the spi...

Embodiment 2

[0039] Such as Figures 1 to 7 As shown, a circulating steel ball worm gear structure includes a base 1, a turbine 2 and a worm 3; the turbine 2 and the worm 3 are both rotatably connected to the base 1;

[0040] The base mentioned here is mainly used to fix the position of the turbine 2 and the worm 3, so that the turbine 2 and the worm 3 can be directly or indirectly matched for transmission, and is also used for the installation and fixing of the circulating steel ball turbine and worm structure of the present invention, such as being installed and fixed on in the reducer.

[0041] The spiral groove 31 of the worm 3 is in the shape of an arc; this can form a good contact fit with the ball 4, and keep (limit) the ball 4 in the spiral groove 31, so that the ball 4 can roll or circulate along the spiral groove 31. Displacement. The spiral groove 31 is provided with two inlets and outlets 32 for the balls 4 to go in and out, and the two inlets and outlets 32 communicate with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com