Coulter assembly of disc plow

A disc plough and assembly technology, applied in ploughs, applications, agricultural machinery and implements, etc., can solve the problems of large transmission resistance of the transmission shaft and the influence of service life, and achieve small transmission resistance, improved service life, and balanced force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

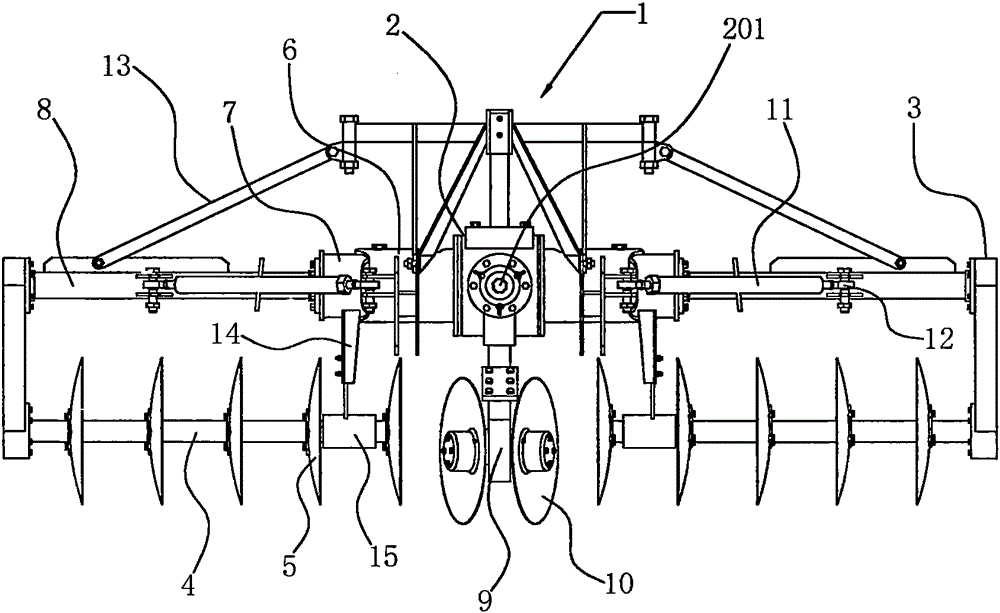

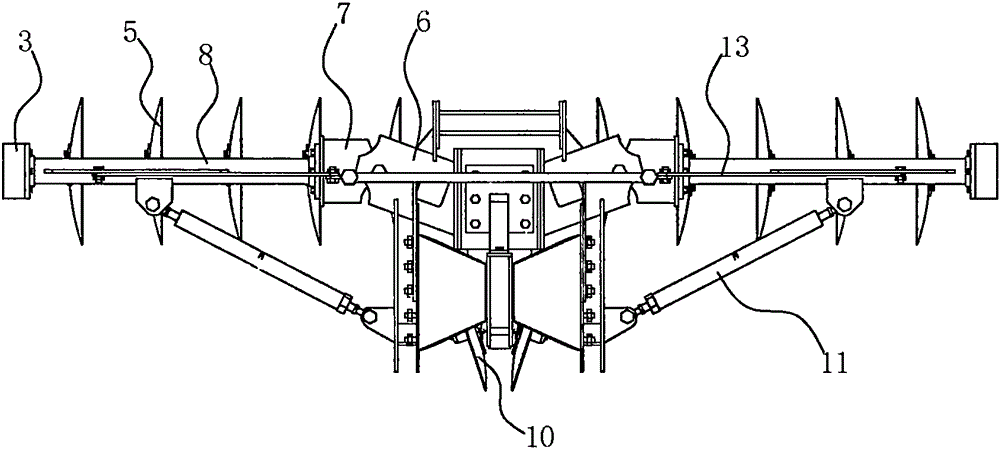

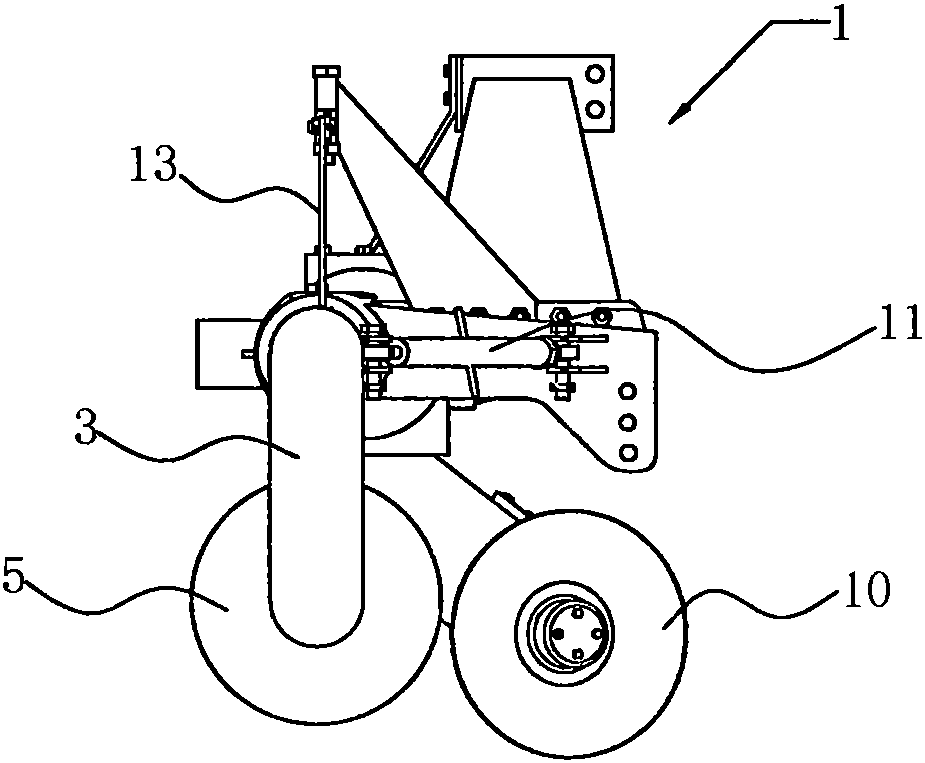

[0016] Such as figure 1 shown, and refer to figure 2 , 3 , 4, the disc plow coulter assembly of the present invention is mounted on the seat frame 1 to form the disc plow as a whole, so this embodiment takes the disc plow coulter assembly installed on the seat frame as an example Be explained.

[0017] The coulter assembly for the disc plow of the present invention comprises two disc coulter shaft assemblies and an intermediate coulter 10, and the two disc coulter shaft assemblies are installed on both sides of the seat frame 1 of the disc plow respectively. The middle coulter 10 is located between the two disk coulter shaft assemblies, and also includes a middle transmission box 2 , a middle coulter assembly gear box 9 and two side transmission boxes 3 .

[0018] The seat frame 1 can be installed on the tractor, the middle transmission box 2 is installed on the seat frame 1, and a side transmission box 3 is respectively provided on both sides of the seat frame 1, and a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com