Gearbox improvement structure for electric vehicle

A technology of gearboxes and electric vehicles, which is applied to vehicle gearboxes, vehicle components, wheeled transmissions, etc., to facilitate human riding or carts and reduce transmission resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

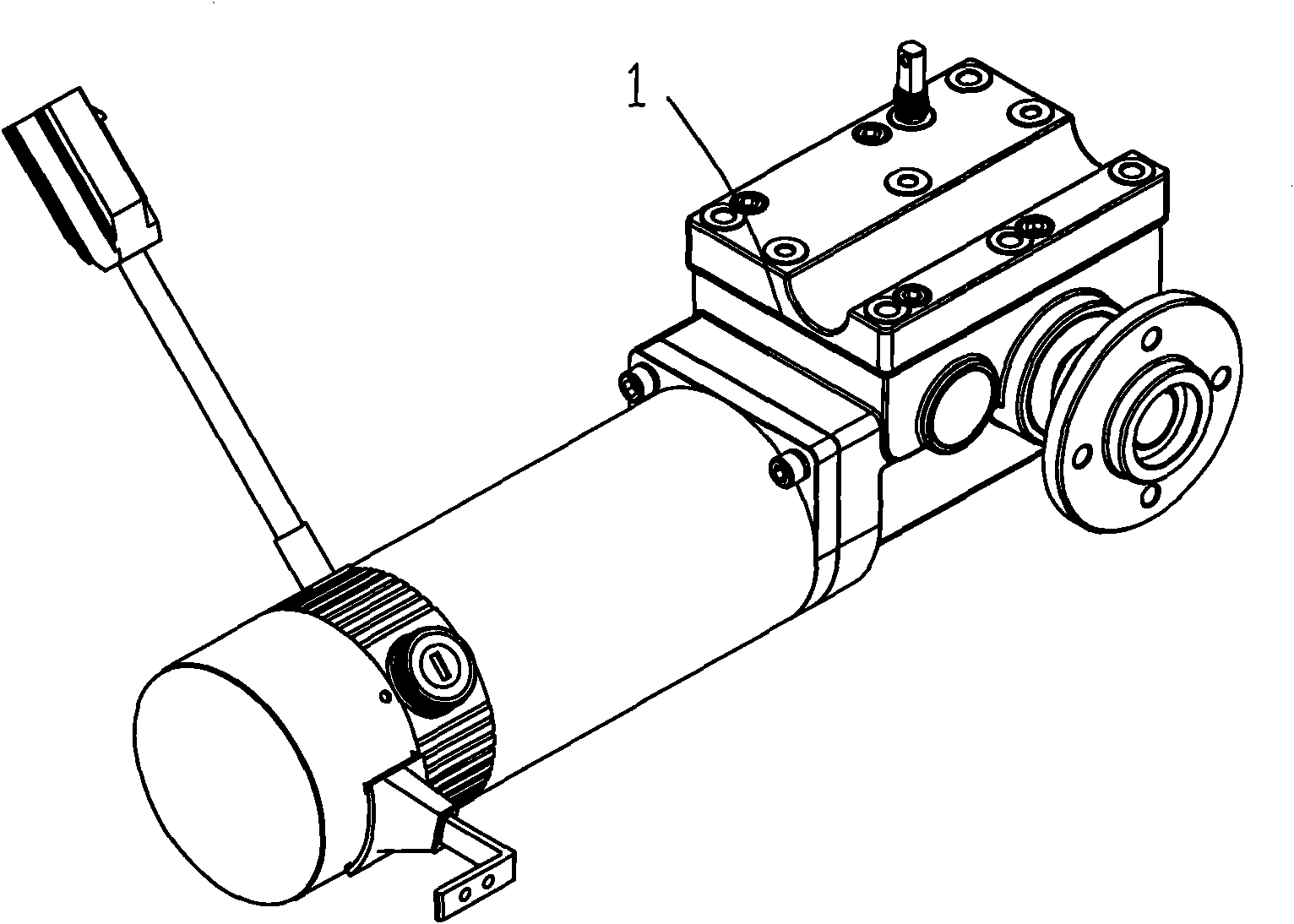

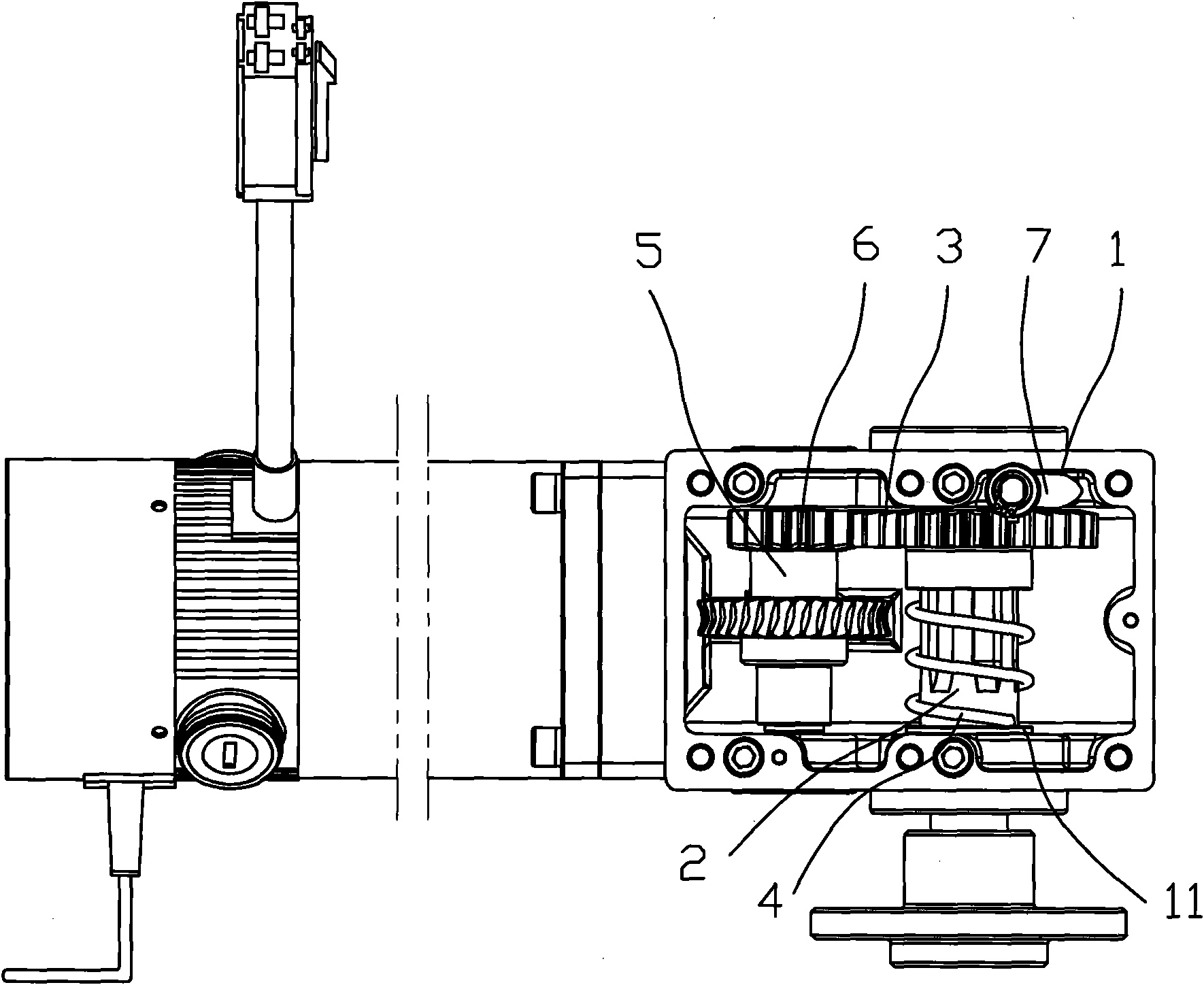

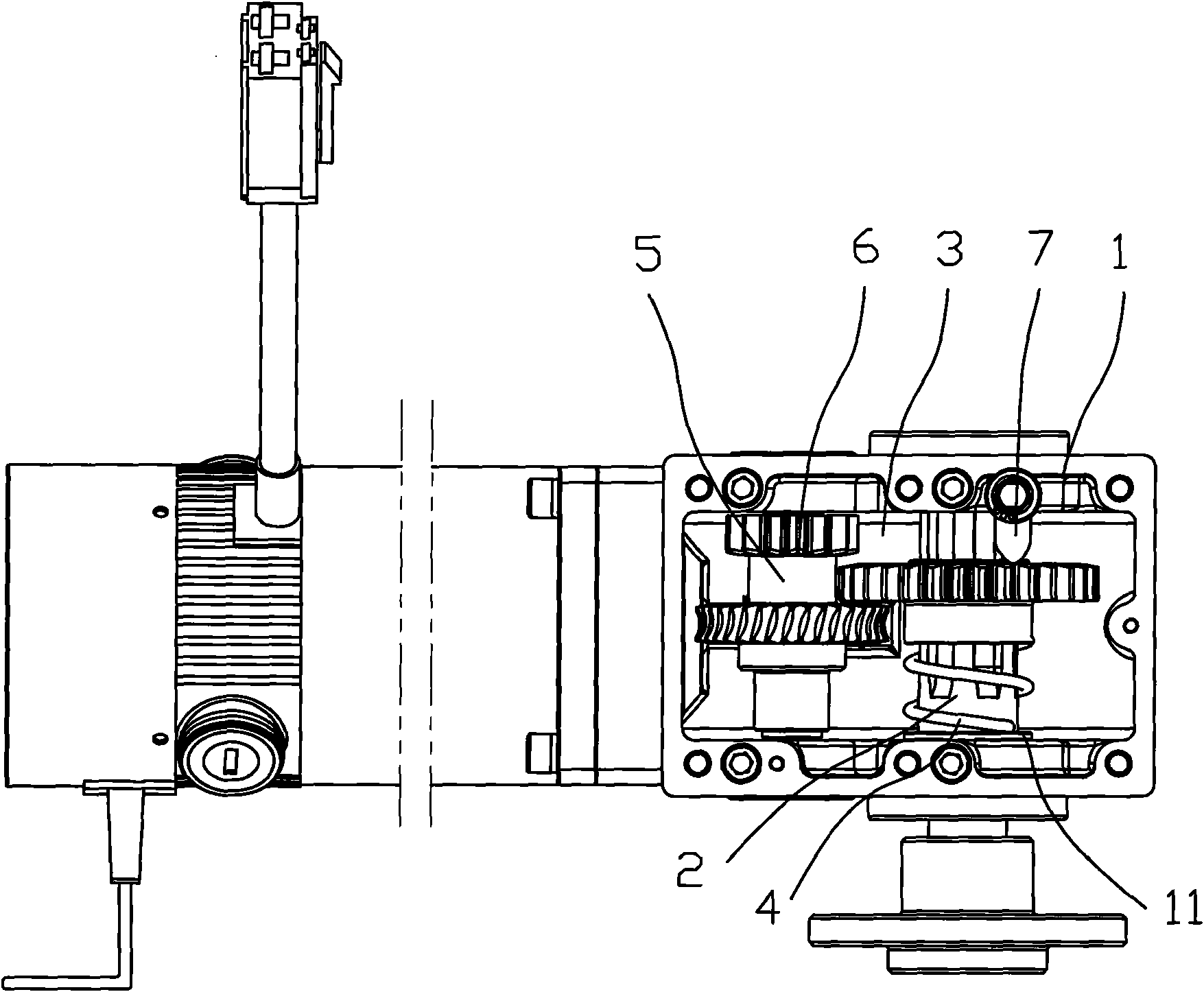

[0017] Such as Figure 1 to Figure 5 Shown here is an embodiment of an improved structure of an electric vehicle gearbox of the present invention, which includes a gearbox 1 and a transmission shaft 5 and an output shaft 2 mounted on the gearbox, and a driving gear 6 is provided on the transmission shaft. The output shaft is provided with a driven gear 3 that meshes with the driving gear 6, the driven gear 3 is slidably connected to the output shaft 2, and the gear box 1 is provided with a control driven gear to disengage from the driving gear and Engaged clutch device. The wheel shaft 2 and the driven gear 3 achieve a sliding connection through spline fitting. The clutch device includes a rotating head 7 arranged on the side wall of the gear box body. The rotating head 7 rotates and pushes the driven gear 3 to slide away from the driving gear 6 on the wheel shaft 2. The rotating head 7 is driven by the gear box. The outer handle 8 controls the rotation. The clutch device fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com