Cone sand making machine and sand making method

A technology of sand making machine and cone, which is applied in the direction of grain processing, etc., can solve the problems of low sand making yield, high equipment cost, high sand making cost, etc., and achieve the effect of high sand making efficiency, long service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

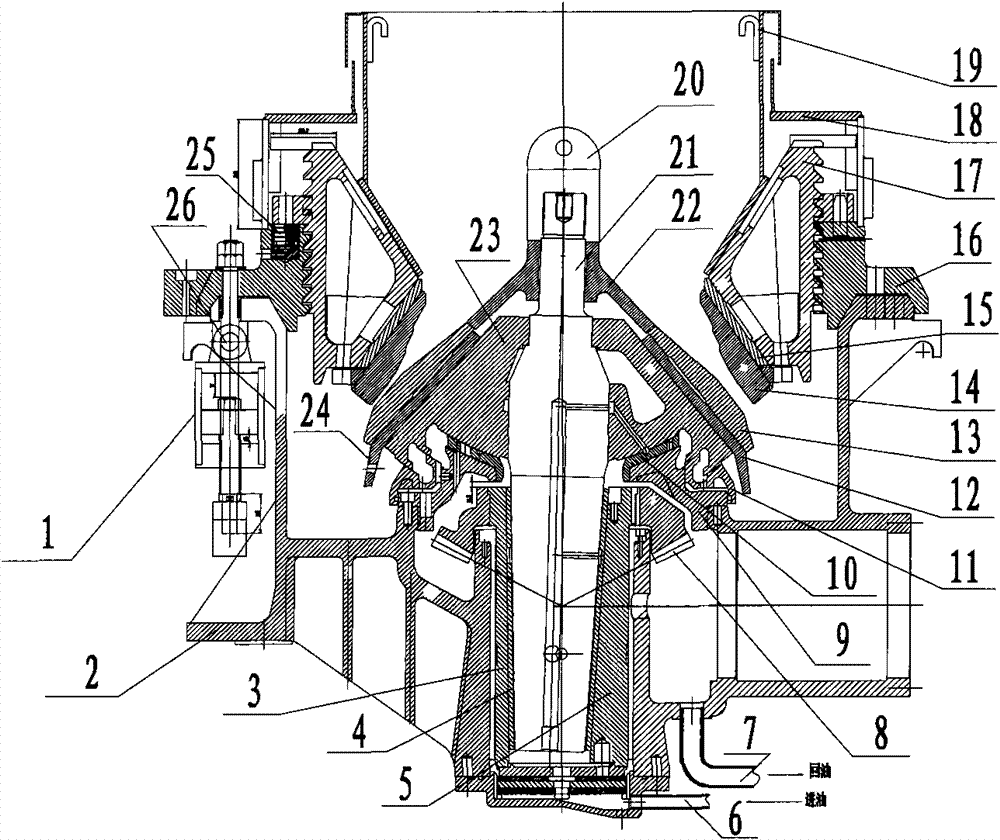

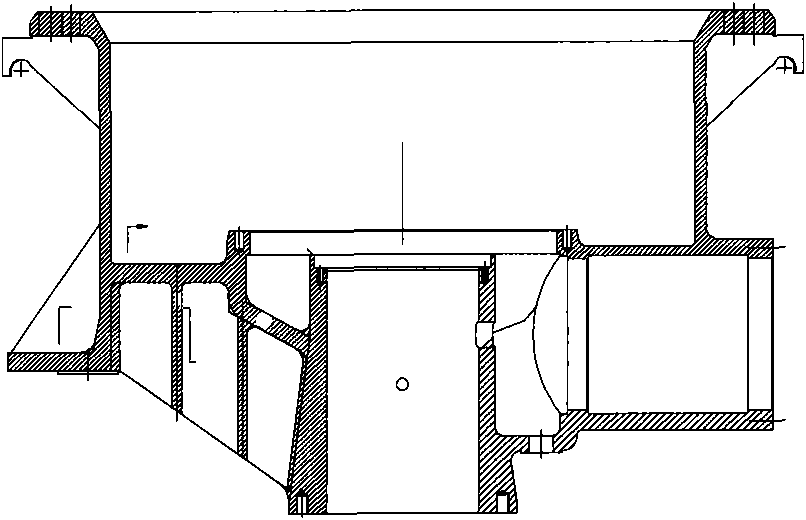

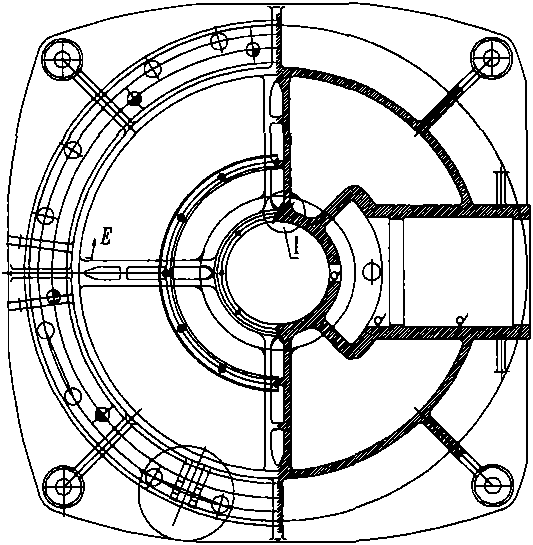

[0023] Embodiment 1: with reference to attached Figure 1-15 . Conical sand making machine, 8 large bevel gears are set on the eccentric shaft sleeve 5, the eccentric shaft sleeve 5 is set in the shaft hole in the center of the lower casing 2 through the copper sleeve 3, and the main shaft 21 is located in the eccentric shaft sleeve 5 through the inner copper sleeve 4 And the main shaft 21 is driven to swing by the eccentric shaft sleeve 5, the spherical seat 9 is located on the shell support ring of the positioning shaft hole in the lower casing 2, the moving cone 23 is set on the main shaft 21 through the spherical copper tile 10 and is driven by the main shaft 21 The cone 23 swings, and an oil film is placed between the contact surfaces of the movable cone 23 and the spherical copper tile 10 . The moving sleeve bushing 12 is set on the conical surface of the moving cone 23, the anti-friction moving sleeve 13 is set on the conical surface of the moving sleeve bushing 12, th...

Embodiment 2

[0032] Embodiment 2: On the basis of Embodiment 1, the sand making method of the conical sand making machine, when making sand, the oil cylinder located outside the upper casing 16 pushes the adjusting screw sleeve 17, so that the lower screw sleeve located in the adjusting screw sleeve 17 The gap formed by the wall surface of the anti-wear fixed sleeve 14 on the horn wall and the wall surface of the anti-wear movable sleeve 13 is just the upper limit of the required sand grain diameter. Start the hydraulic workstation so that the lubricating oil under pressure enters the main shaft 21 through the bottom cover type plane bearing And the horizontal oil outlet in the main shaft injects between the contact surface of the movable cone 23 and the spherical copper tile 10 and between the main shaft 21 and the 4 surfaces of the inner copper sleeve, so that the contact surface of the movable cone 23 and the spherical copper tile 10, the contact surface of the main shaft 21 and the The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com