Machined Metal Dust Collection Devices

A metal dust and mechanical processing technology, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of affecting the processing accuracy of the workpiece, personnel injury, and metal dust easily entering the staff, so as to reduce consumption and Harmful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

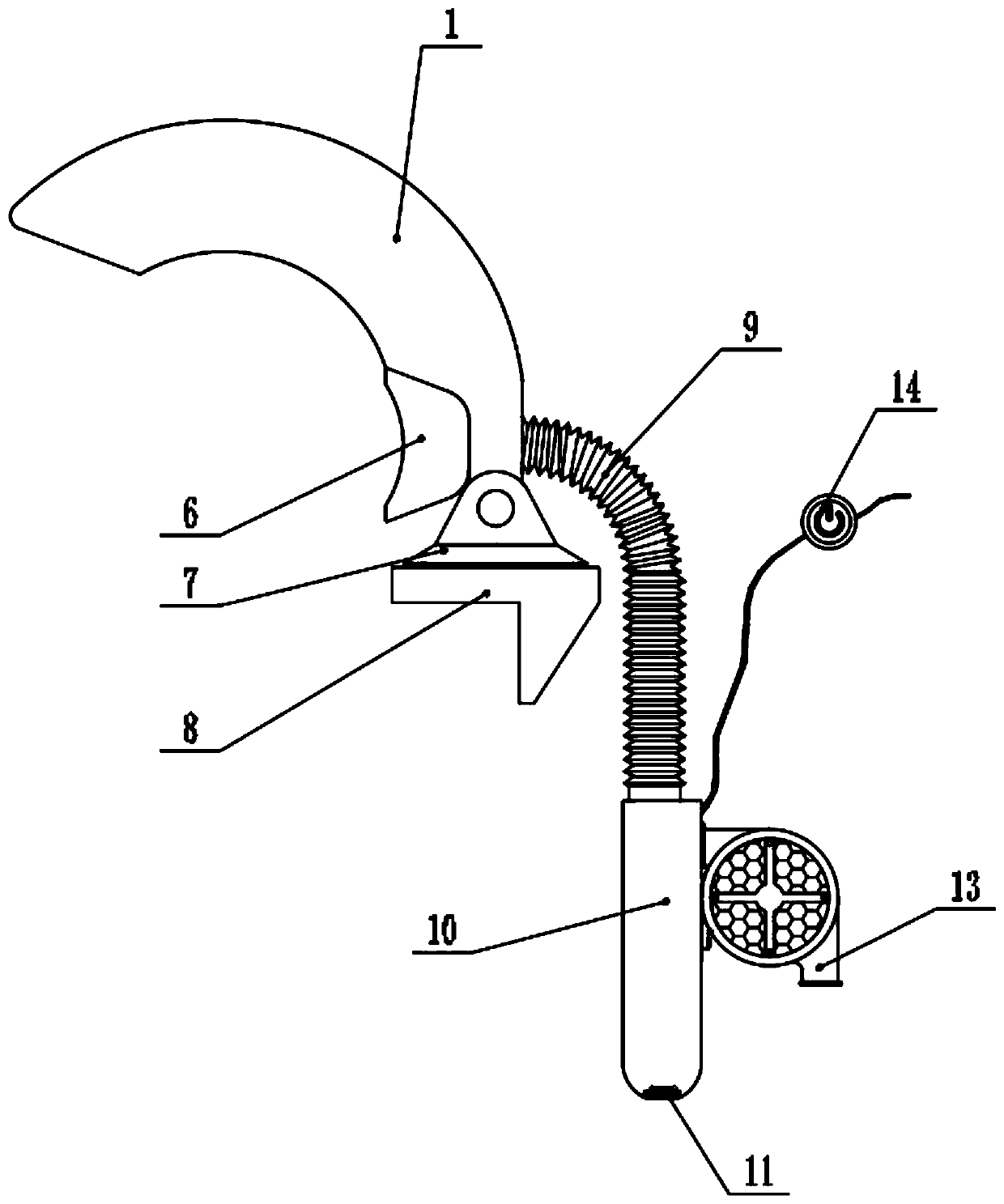

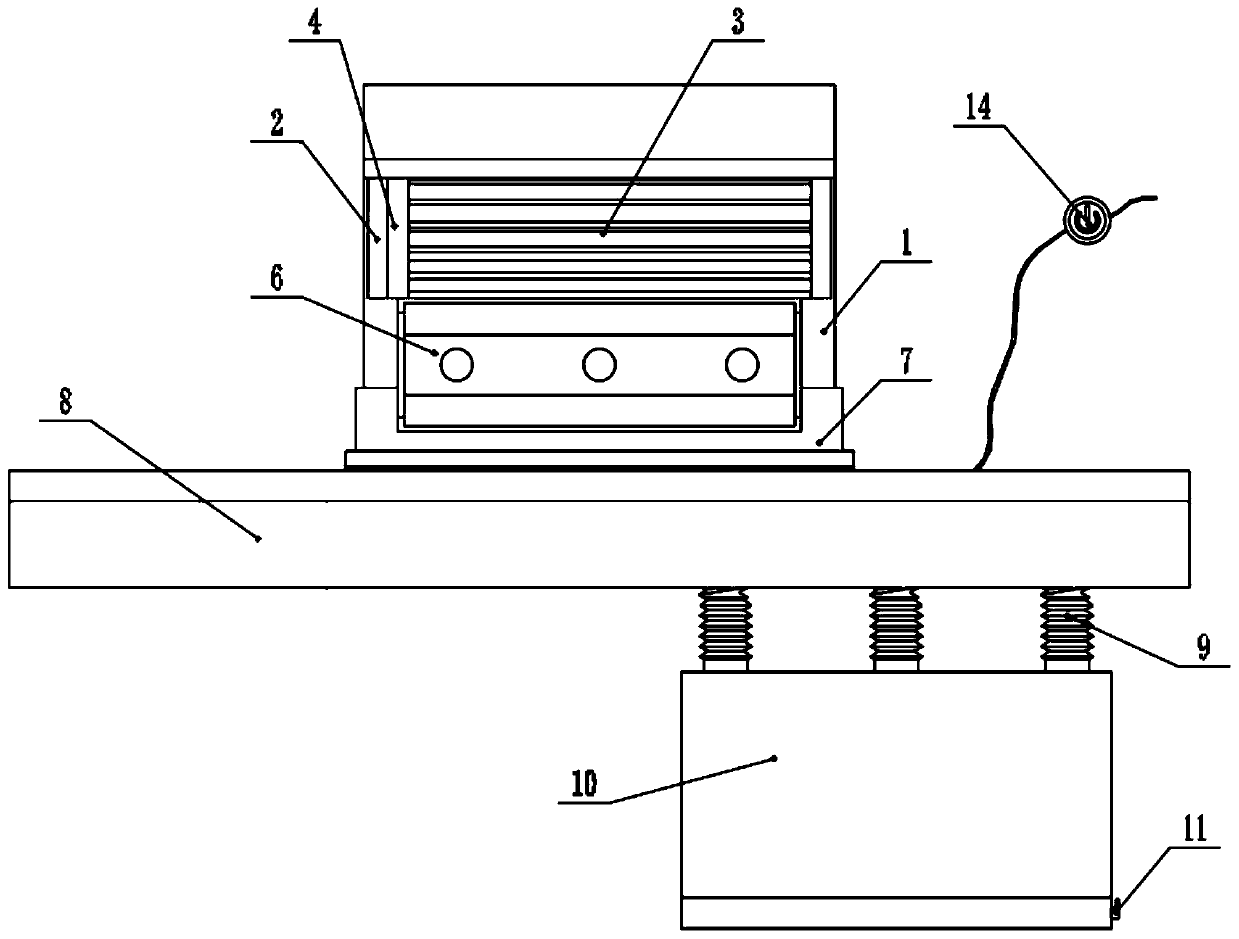

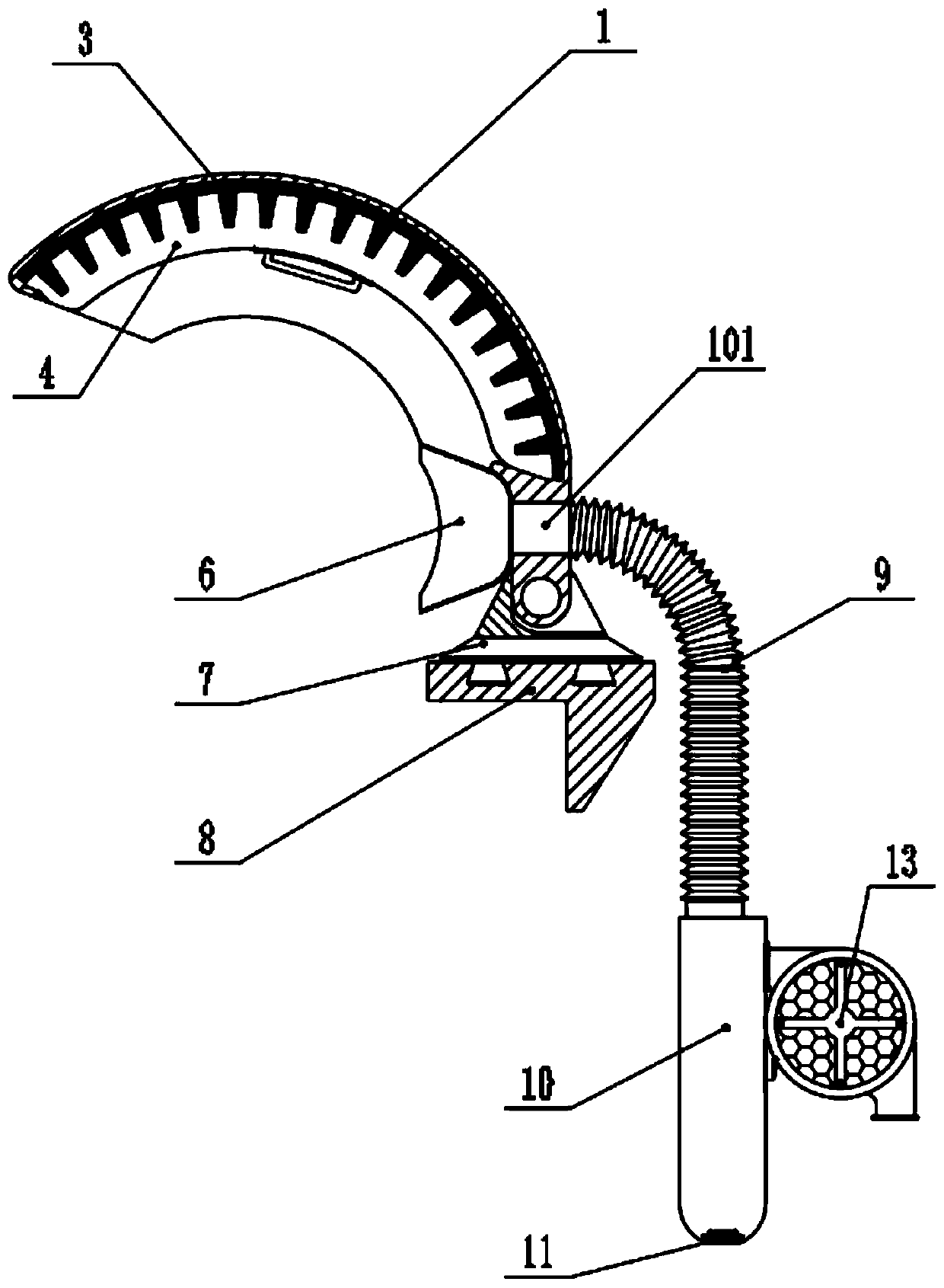

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036]The invention provides a mechanically processed metal dust collection device, which includes a dust collection cover 1, a communication hole 101, a plastic strip 2, a magnet plate 3, a dust scraping block 4, a handle 5, a dust suction port 6, a slider 7, a base 8, a sliding Slot 801, air suction pipe 9, dust collection box 10, slide plate 11, filter screen 12, fan 13 and power switch 14, the dust collection cover 1 is a circular arc-shaped cover structure, and the left and right ends of the dust collection cover 1 are A plastic strip 2 is respectively installed, and three communication holes 101 are opened in the bottom of the dust collection hood 1, and the dust suction port 6 is installed on the front end surface of the bottom of the dust collection hood 1, and a handle is installed at the bottom of the dust removal block 4 5, and the scraping block 4 is an arc-shaped block structure, the slider 7 is a rectangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com