Environmental-friendly separating equipment for granular iron slag processing

A separation equipment and granular technology, applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve problems such as poor adsorption effect of slag iron, influence on slag iron recycling effect, poor slag iron classification effect, etc., and achieve reduction The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

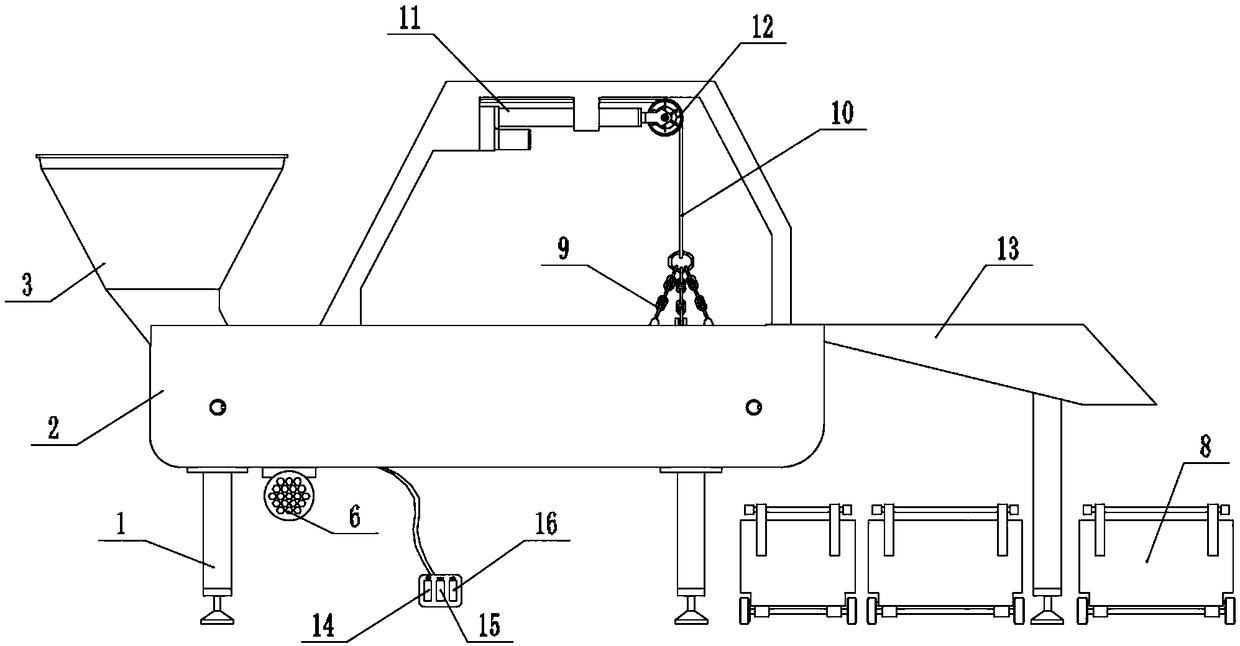

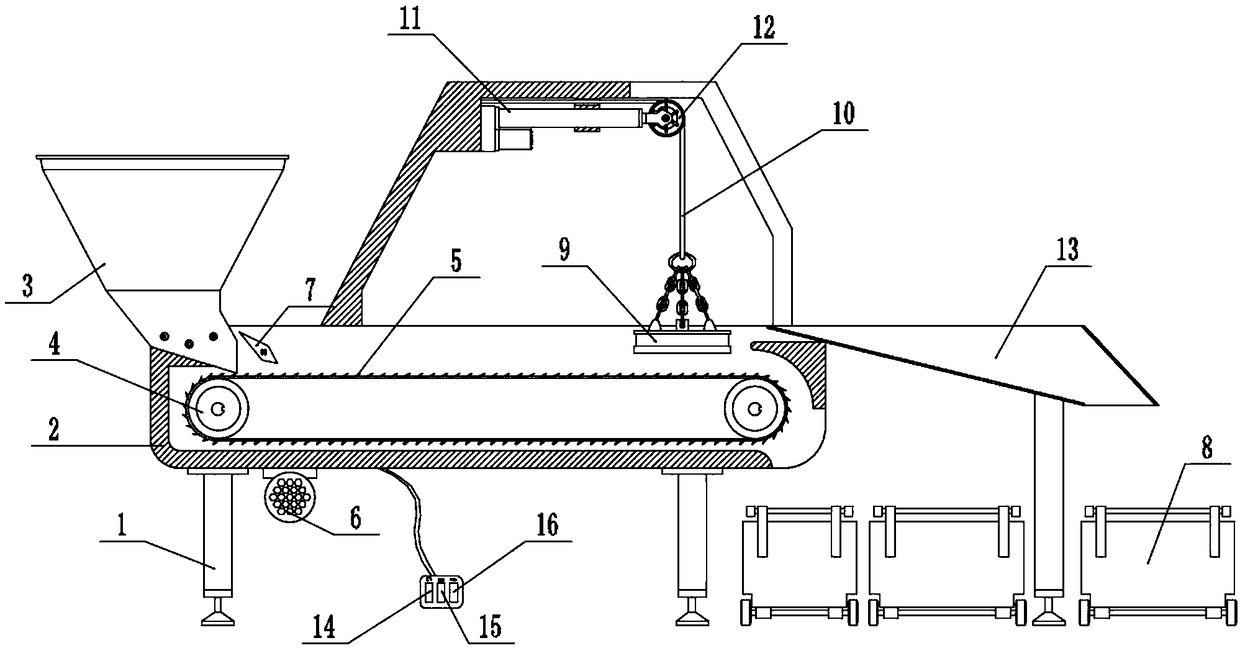

[0036] as attached figure 1 to the attached Figure 9 shown:

[0037]The invention provides an environmentally friendly separation device for granular slag iron treatment, which includes a support frame 1, a main body 2, a storage funnel 3, a transmission wheel 4, a conveyor belt 5, barbs 501, a transmission motor 6, and a slag flattening block 7. Collecting trolley 8, electromagnet 9, traction rope 10, electric telescopic rod 11, pulley 12, slag iron screening tank 13, slag conveying switch 14, magnetic adsorption switch 15 and telescopic control switch 16; the support frame 1 is six , and the six support frames 1 are respectively installed on the bottom end surface of the main body 2 and the slag iron screening tank 13; the bottom of the main body 2 is a groove-shaped structure, and the storage funnel 3 is installed at the top position of the left end of the storage funnel 3 by screws; There are two transmission wheels 4, and the two transmission wheels 4 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com